Download the PDF file - Weber

Download the PDF file - Weber

Download the PDF file - Weber

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Our o<strong>the</strong>r activities are:<br />

Decorative Renders<br />

& Finishes<br />

External Wall Insulation<br />

(EWI) Systems<br />

Construction Mortars<br />

Tile Fixing<br />

Saint-Gobain <strong>Weber</strong> Ltd<br />

GB Head Office<br />

Dickens House<br />

Enterprise Way<br />

Maulden Road<br />

Flitwick, Beds<br />

MK45 5BY<br />

Tel: 08703 330070<br />

Fax: 01525 718988<br />

Ireland<br />

The Old Paper Mill<br />

Ballyclare<br />

Co. Antrim<br />

Nor<strong>the</strong>rn Ireland<br />

BT39 9EB<br />

Tel: 028 9335 2999<br />

Fax: 028 9332 3232<br />

Email: mail@netweber.co.uk<br />

Web: www.netweber.co.uk<br />

Flooring Systems

2 3<br />

<strong>Weber</strong> is a leading player in <strong>the</strong> construction products<br />

industry and is a recognised manufacturer and<br />

innovator of easy to apply products in <strong>the</strong> flooring,<br />

facades, tile fixing and construction mortars markets.<br />

<strong>Weber</strong> does not sell only products but <strong>the</strong> complete<br />

solutions which includes <strong>the</strong> services that go with <strong>the</strong><br />

products; technical support and training. Based on<br />

its strong knowledge and experience of <strong>the</strong> market,<br />

<strong>the</strong> <strong>Weber</strong> training programmes meet <strong>the</strong> needs of<br />

its customers. <strong>Weber</strong> provides specifiers, developers<br />

and contractors across <strong>the</strong> board with substantial<br />

technical support, both before, during and after<br />

contract periods.<br />

<strong>Weber</strong> currently employs over 180 people across<br />

Great Britain and Ireland and is a subsidiary of Saint-<br />

Gobain. Established in France in 1665, Saint-Gobain<br />

is one of <strong>the</strong> world’s largest industrial groups, with<br />

an annual turnover of €43.8 billion and 209,000<br />

employees. The Group has been operating in <strong>the</strong> UK<br />

and Ireland since 1985 across five sectors; Building<br />

Distribution, Packaging, Construction Products, Flat<br />

Glass & High Performance Materials.<br />

Welcome to <strong>Weber</strong><br />

Above: <strong>Weber</strong> has manufacturing facilities in Flitwick (Bedfordshire), Telford (Shropshire) and Ballyclare (Nor<strong>the</strong>rn Ireland).<br />

MAXIT GROUP ACQUISITION<br />

The Saint-Gobain Group acquired <strong>the</strong> Maxit Group<br />

from Heidelberg Cement in June 2008. The<br />

international Maxit Group has been integrated into<br />

Saint-Gobain’s <strong>Weber</strong> organisation which operates<br />

in 35 countries.<br />

This immediately expanded <strong>Weber</strong>’s product<br />

range by adding specialist levelling and smoothing<br />

screeds and lightweight expanded clay aggregate.<br />

It also streng<strong>the</strong>ned <strong>Weber</strong>’s position in external<br />

render, wall insulation systems, construction mortars<br />

and tile fixing products.<br />

Log on to www.netweber.co.uk today to access<br />

<strong>the</strong> very latest news from <strong>Weber</strong> and all <strong>the</strong><br />

essential technical information on our flooring<br />

systems product range, including:<br />

• Detailed product/system data sheets<br />

• Project case studies<br />

• Solutions to specific problems<br />

• The latest press releases<br />

IT’S THE ENERGY-SAVING WAY TO CREATE<br />

FOUNDATIONS FOR RENOVATION AND NEW BUILD<br />

Leca Insulation Fill is lightweight insulation that cuts<br />

foundation time by hours. It is available in 50 litre<br />

bags, making insulated foundations which comply<br />

with Part L of <strong>the</strong> Building Regulations a simple, one<br />

man process. What is really clever about Leca<br />

Insulation Fill in bags is that it is stored in <strong>the</strong> bag,<br />

collected and transported in <strong>the</strong> bag, laid in <strong>the</strong> site<br />

in <strong>the</strong> bag and covered in concrete – still in <strong>the</strong> bag.<br />

It will save hours of time, hard labour and cost when<br />

creating foundations for extensions, conservatories,<br />

garages, driveways and patios. The 50 litre bags<br />

weigh just 15kg and are easily portable. There’s no<br />

mess, no need for heavy machinery, no heavy lifting<br />

and no waste.<br />

Step 1<br />

Lay loose material to<br />

level base and lay <strong>the</strong><br />

bags on top<br />

Step 2<br />

Lay <strong>the</strong> bags side by<br />

side to cover <strong>the</strong> floor<br />

area<br />

Step 3<br />

Once at <strong>the</strong> required<br />

depth, use loose<br />

material to fill <strong>the</strong> holes<br />

between bags and<br />

level off.<br />

Step 4<br />

Cover with 1200 gauge<br />

poly<strong>the</strong>ne and <strong>the</strong>n lay<br />

<strong>the</strong> concrete or <strong>Weber</strong><br />

levelling compound.<br />

LECA INSULATION FILL ENABLES YOU TO:<br />

• save time and money preparing floors<br />

• eliminate <strong>the</strong> cost of machinery hire<br />

• eliminate <strong>the</strong> need for secondary polystyrene<br />

insulation in ground floor construction<br />

• meet <strong>the</strong> Building Regulations<br />

• simply carry into restricted access sites<br />

MEET THE BUILDING REGULATIONS<br />

FOR THERMAL INSULATION<br />

The table is for guidance only. Where U-value is<br />

critical, please refer to <strong>Weber</strong>’s technical<br />

department on 01525 722110. The U-value has<br />

been calculated in accordance with BS EN ISO<br />

13370:1998 ‘Thermal Performance of Buildings. Heat<br />

Transfer via <strong>the</strong> ground. Calculation methods’ or can<br />

be calculated using CIBSE Guide: Part A3:1999<br />

‘Thermal Properties of Building Structures’.<br />

U-value (W/m2k) Nominal Depth (mm) Quantity (no. of bags)<br />

0.22 300 6 bags per m2 0.45 150 3 bags per m2 ELIMINATE HEALTH AND SAFETY PROBLEMS<br />

Leca Insulation Fill bags weigh a nominal 15kg, well<br />

within <strong>the</strong> H&SE recommendations for a single-man<br />

lift. Leca Insulation Fill is chemically neutral and<br />

does not contain any environmentally harmful<br />

constituents. It is safe to handle and does not need<br />

any special protective clothing or special<br />

requirements for disposal.

4 5<br />

Commercial Screeds In <strong>the</strong> fast moving commercial and retail<br />

environment, time is money. Floors have to be<br />

laid quickly and be available to o<strong>the</strong>r trades in <strong>the</strong><br />

shortest time possible. <strong>Weber</strong>’s commercial screeds<br />

have been designed with this in mind.<br />

Developed for optimum speed, <strong>the</strong>se high<br />

performance products give a smooth surface that is<br />

ready for foot traffic after only a few hours and that<br />

can be covered with a soft floor covering in 24 hours.<br />

The range consists of products for use as floating,<br />

un-bonded and bonded screeds including insulated,<br />

acoustic or heated floors.<br />

For a full listing of all products in <strong>Weber</strong>’s flooring<br />

range go to <strong>the</strong> selection table on pages 14-15.

6 7<br />

Industrial Screeds<br />

In <strong>the</strong> industrial environment, speed, strength and<br />

durability are <strong>the</strong> keys for a successful floor installation.<br />

<strong>Weber</strong>’s comprehensive range of floor products, which<br />

are specifically designed for industrial applications, offer<br />

exactly this creating stronger, smoo<strong>the</strong>r, longer lasting<br />

floors with minimal down time.<br />

Ideal for factory or warehouse situations, <strong>Weber</strong>’s<br />

industrial screed range has products for every situation.<br />

Designed to cope with <strong>the</strong> high levels of wear and<br />

abrasion associated with <strong>the</strong>se demanding situations,<br />

<strong>the</strong>se high performance products are truly class<br />

leading. The speed of application is up to ten times<br />

faster than traditional screeds and <strong>the</strong> fast drying/<br />

curing properties allow forklift traffic or resin finishes to be<br />

applied within 24 hours.<br />

The range consists of standard and high strength<br />

base screeds, and hard-wearing and heavy duty top<br />

screeds which can be applied as <strong>the</strong> final finish or<br />

painted.<br />

For a full listing of all products in <strong>Weber</strong>’s flooring range<br />

go to <strong>the</strong> selection table on pages 14-15.

8 9<br />

weber.floor 4650 duro colour<br />

White code G05 Off White code G10<br />

Light Yellow code F10<br />

Design Floor Screeds <strong>Weber</strong>’s design floor concept opens up new horizons<br />

for architects, designers and specifiers seeking an<br />

added dimension in striking, long-lasting and low<br />

maintenance floor finishes.<br />

Beige code F20<br />

Light Grey code G20<br />

Blue code F30<br />

Warm Grey code G40<br />

Dark Grey code G60<br />

Terracotta code F40 Black code G80<br />

Design floor products are <strong>the</strong> key to creating<br />

hard-wearing, seamless super-smooth floors to<br />

complement any environment, whe<strong>the</strong>r in <strong>the</strong> retail<br />

sector, commercial developments or domestic<br />

settings. Design floor products enable you to create<br />

practical floors with eye-pleasing aes<strong>the</strong>tics, toge<strong>the</strong>r<br />

weber.floor 4635 duro stone<br />

Light code G10 Dark code G60<br />

Colours are representative only and limited<br />

by photographic and printing processes.<br />

For exact colour matching, please request<br />

samples from your <strong>Weber</strong> representative.<br />

with <strong>the</strong> advantages of self-levelling screeds that are<br />

quick, simple and cost-effective to install.<br />

weber.floor 4650 duro colour is available in ten<br />

natural colours and weber.floor 4635 duro stone is<br />

available in two.<br />

For a full listing of all products in <strong>Weber</strong>’s flooring<br />

range go to <strong>the</strong> selection table on pages 14-15.

10 11<br />

Calcium Sulphate Screeds <strong>Weber</strong>’s Alpha range of levelling screeds are some<br />

of <strong>the</strong> most technologically advanced screeds<br />

available. Alpha’s advanced formulation means<br />

it reacts with water quickly, providing consistent,<br />

reliable drying characteristics and considerably faster<br />

drying times, enabling following trades to proceed<br />

without delay.<br />

Fast drying, laitance free and resistant to wetting,<br />

Alpha offers many benefits to a traditional anhydrite<br />

screed. It can be applied as a levelling screed<br />

directly onto concrete, an unbonded screed, a<br />

floating floor over <strong>the</strong>rmal or acoustic insulation or<br />

heated floors.<br />

The range consists of preparation products, screeds<br />

and smoothing compounds which can be installed<br />

at over 1000m² per day.<br />

For a full listing of all products in <strong>Weber</strong>’s flooring<br />

range go to <strong>the</strong> selection table on pages 14-15.

12 13<br />

Marine Screeds<br />

<strong>Weber</strong>’s marine screeds have been specifically<br />

designed to offer superior strength and durability<br />

whilst keeping down time to a minimum.<br />

Specifically designed for pump application onto<br />

steel decking, <strong>the</strong>se products can be installed at<br />

over 1000m² per day. Suitable for foot traffic after<br />

only 1-2 hours and soft floor coverings after<br />

24 hours, disruption is kept to a minimum allowing<br />

<strong>the</strong> installation to be back in service very quickly.<br />

For a full listing of all products in <strong>Weber</strong>’s flooring<br />

range go to <strong>the</strong> selection table on pages 14-15.

14 15<br />

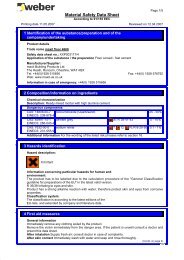

CHOOSING THE RIGHT SYSTEM – A STEP BY STEP GUIDE<br />

Category Product Name Size Description Application Application Strength (EN13813) Curing Times<br />

Thickness Comp. Flex. Foot Traffic Final Covering<br />

Commercial Screeds weber.floor 4150 fine flow 25kg A standard drying screed for levelling and smoothing concrete substrates Bonded 4-30mm C25 F6 2-4 hours 1-3 weeks<br />

Hand Applied<br />

Screeds<br />

weber.floor 4160 fine flow rapid 25kg A rapid drying screed for levelling and smoothing concrete substrates Bonded 2-30mm C30 F7 1-3 hours 24 hours<br />

weber.floor 4310 fibre flow 25kg A standard drying, fibre modified screed for bonded, unbonded and floating applications Bonded & Floating 5-50mm C20 F5 2-4 hours 1-3 weeks<br />

weber.floor 4320 fibre flow rapid 25kg A rapid drying, fibre modified screed for bonded, unbonded and floating applications Bonded & Floating 4-50mm C30 F7 2-4 hours 3 days<br />

weber.floor 4360 base flow rapid 25kg A rapid drying, fibre modified base screed for most applications Bonded & Floating 20-80mm C30 F5 2-3 hours 3 days<br />

weber.floor 4031 super flow 25kg A standard drying screed for levelling and smoothing concrete substrates Bonded 0-5mm C20 F5 2-3 hours 24 hours<br />

weber.floor 4040 combi rapid 25kg An ultra rapid drying screed for repairs and building falls Bonded 0.5-50mm C30 F8 0.5-1 hour 2 hours<br />

weber.floor 4050 medium finish 25kg A rapid drying, fibre modified screed for general use Bonded & Floating 15-100mm C30 F6 2-3 hours 1-3 days<br />

weber.floor 4060 rapid drying screed 25kg A rapid drying, thick section screed for renovation Bonded & Floating 10-250mm C20 F5 1-3 hours 15 hours<br />

Industrial Screeds weber.floor 4600 duro base 25kg A rapid hardening base screed for industrial use Bonded 5-30mm C20 F6 2-4 hours 8-12 hours<br />

weber.floor 4610 duro top 25kg A standard drying, hard wearing screed for industrial use Bonded 4-15mm C35 F10 2-4 hours 1 week<br />

weber.floor 4655 duro flow rapid 25kg A rapid drying screed and resin base for industrial use Bonded 4-15mm C25 F7 1-2 hours 24 hours<br />

Design Floor Screeds weber.floor 4635 duro stone 25kg A standard drying coloured screed that can be ground/polished to a decorative finish Bonded 10-12mm C30 F7 2-4 hours 24 hours<br />

Calcium Sulphate<br />

Screeds<br />

weber.floor 4650 duro colour 25kg A standard drying, through coloured screed available in many natural colours Bonded 4-15mm C25 F7 3-5 hours 24 hours<br />

weber.floor 4095 alpha smoothing 25kg A calcium sulphate, polymer modified smoothing screed Bonded 2-10mm C25 F7 3-4 hours 24 hours<br />

weber.floor 4490 alpha screed 25kg A pumpable, calcium sulphate levelling screed Bonded & Floating 20-50mm C20 F4 16 hours 2-6 weeks<br />

weber.floor alpha 700 pipe liner 25kg A calcium sulphate pipe lining material N/A N/A N/A N/A N/A N/A<br />

Marine Screeds weber.floor 4660 marine elastic 25kg A fibre modified, rapid drying, self-smoothing screed for steel decks Bonded & Floating 2-30mm C25 F8 1-3 hours 1-3 days<br />

weber.floor 4665 marine fire 25kg A pumpable base screed that conforms as an A-60 non-combustible deck covering Bonded & Floating 25-50mm C25 F5 6-12 hours 1-3 weeks<br />

weber.floor 4670 marine base 25kg A fibre modified, levelling base screed for steel decks Bonded & Floating 20-100mm C20 F4 2-3 hours 24 hours<br />

weber.floor 4680 marine light 13kg A lightweight, fine smoothing screed for steel decks Bonded 0-20mm C20 F4 2-4 hours 1-3 days<br />

Auxiliary weber.floor 4716 primer 25L A styrene acrylate dispersion primer for most substrates Most substrates 1-2 coats 3-5 hours<br />

weber.floor 4716 primer 10L A styrene acrylate dispersion primer for most substrates Most substrates 1-2 coats 3-5 hours<br />

weber.floor 4716 primer 5L A styrene acrylate dispersion primer for most substrates Most substrates 1-2 coats 3-5 hours<br />

weber.floor duroprime F DPM 10kg A two part epoxy damp proof membrane Most substrates 2 coats 18-24 hours 18-24 hours<br />

weber.floor 4912 600mm serrated spatula A spatula for use with screeds<br />

weber.floor 4912 600mm straight spatula A spatula for use with screeds<br />

weber.floor 4914 300mm serrated spatula A spatula for use with screeds<br />

weber.floor 4914 300mm straight spatula A spatula for use with screeds<br />

weber.floor 4931 flow ring & plate 127cm³ A flow ring and plate for testing <strong>the</strong> flow of screeds<br />

weber.floor 4945 fibre mesh 100m x 1m A glass fibre reinforcing mesh for use in screeds<br />

weber.floor 4965 (15mm) barrier foam 25 x 2m A self adhesive barrier foam for creating day work joints<br />

weber.floor 4965 (30mm) barrier foam 25 x 2m A self adhesive barrier foam for creating day work joints<br />

weber.floor spatula joint Adaptor to attach spatula to handle<br />

NOTE: Minimum application thickness is dependant on <strong>the</strong> type of application. Foot traffic and floor covering times stated are<br />

based on minimum thicknesses in good drying conditions. Refer to <strong>the</strong> relevant product datasheet for full details.<br />

Visit www.netweber.co.uk<br />

for more information and<br />

<strong>the</strong> full list of datasheets<br />

for all flooring products.