Shift harvesting into high gear. - Massey Ferguson

Shift harvesting into high gear. - Massey Ferguson

Shift harvesting into high gear. - Massey Ferguson

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

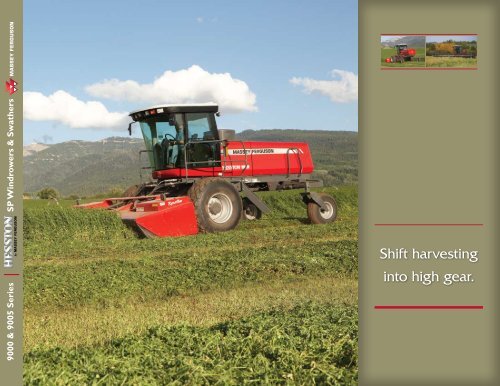

SP Windrowers & Swathers<br />

9000 & 9005 Series |<br />

<strong>Shift</strong> <strong>harvesting</strong><br />

<strong>into</strong> <strong>high</strong> <strong>gear</strong>.

First in the field …<br />

more than once<br />

People tend to trust a leader… which<br />

may explain why Hesston ® -designed<br />

windrowers have been a market leader<br />

for more than 50 years. Fact is, it was<br />

Hesston that built the first commercially<br />

available self-propelled swather<br />

back in 1955.<br />

Today the Hesston 9000 and 9005<br />

Series self-propelled windrowers by<br />

<strong>Massey</strong> <strong>Ferguson</strong> ® carry on the tradition<br />

with proven design, coupled with new<br />

technology that’s still occasionally found<br />

in non-traditional places. The cutterbed<br />

<strong>gear</strong>s in the new Model 9190 and 9192<br />

RazorBar disc headers, are just one<br />

example. They’re actually forged and<br />

ground by AGCO SISU POWER , the<br />

corporate-owned engine manufacturer<br />

that builds the majority of engines for<br />

<strong>Massey</strong> <strong>Ferguson</strong> machines. As a result,<br />

they’re the strongest cutterbed <strong>gear</strong>s<br />

you’ll find anywhere in any header.<br />

We realize that there are a lot more<br />

windrower choices on the market now<br />

than there were in the 1950s. But we<br />

believe ours are still the best selfpropelled<br />

windrowers and swathers in<br />

the industry.<br />

I am the frontier. And the dust bowl. And abundant waves of grain.<br />

The Spirit of the Brand<br />

I am six generations of farmers, looking forward to sunrise.<br />

And six generations, working <strong>into</strong> the night.<br />

I am the sun on your back. And the swagger in your step.<br />

I am your independence. I am hard work. And bountiful rewards.<br />

A steadier hand. And a comfortable companion.<br />

I am an easier ride on that rough row to hoe.

I am resolute. Resourceful. Inventive. And honest.<br />

I understand your dreams. And your realities.<br />

I am the next chore. The next crop. The next harvest. The next opportunity.<br />

I am your tractor. Your tool. Your edge.<br />

I am <strong>Massey</strong> <strong>Ferguson</strong>.<br />

I am your strong right hand.<br />

The heart of the farm. And the joy in the work.<br />

PAGE 3

Once a pioneer,<br />

always a pioneer.<br />

Over 160 years ago, Daniel <strong>Massey</strong><br />

started it all. He was a family man,<br />

working man, businessman, inventor,<br />

tradesman, manager, entrepreneur and<br />

genius. In other words, he was a farmer.<br />

For more than 50 years, we’ve shown<br />

that same commitment in the hay and<br />

forage business, too. Since 1955,<br />

Hesston has been the undisputed<br />

leader, with innovations like the first<br />

self-propelled windrower, the first<br />

hydrostatic windrower and the first big<br />

rectangular baler.<br />

Today, more than ever, we’re determined<br />

to prove that the heart of the<br />

original <strong>Massey</strong> <strong>Ferguson</strong> and Hesston<br />

brands still beats under the shiny new<br />

exteriors of every model we make.<br />

“Beauty in engineering is that which is<br />

simple, has no superfluous parts and<br />

which answers exactly its purpose.”<br />

–Harry <strong>Ferguson</strong><br />

1847<br />

It was 1847 when Daniel <strong>Massey</strong> began<br />

what would become <strong>Massey</strong> <strong>Ferguson</strong> –<br />

the same year Thomas Edison, Joseph<br />

Pulitzer and Jesse James were born.<br />

1891<br />

Canada’s top two farm equipment<br />

companies merged in 1891 to form<br />

1926<br />

<strong>Massey</strong>-Harris Limited.<br />

In 1926, Harry <strong>Ferguson</strong> patented the 3-point hitch. In various forms,<br />

it is still used on virtually all of our competitors’ tractors today.<br />

Henry Ford and Harry <strong>Ferguson</strong> entered<br />

<strong>into</strong> partnership in 1938 and <strong>Massey</strong> Harris<br />

introduced the first commercially available<br />

1938<br />

self-propelled combine.<br />

Now part of the <strong>Massey</strong> <strong>Ferguson</strong><br />

family, the Hesston Manufacturing<br />

Company was<br />

1947<br />

founded in 1947.

The Hesston Model 100 was<br />

introduced, making it the industry’s<br />

first commercially available selfpropelled<br />

windrower.<br />

2006<br />

1955<br />

Hesston introduced the Hydro-Static 600,<br />

the first hydrostatic drive windrower in<br />

the<br />

1967<br />

industry.<br />

<strong>Massey</strong> <strong>Ferguson</strong> and<br />

Hesston joined forces to<br />

produce the new Hesston<br />

complete line of hay<br />

equipment.<br />

<strong>Massey</strong> <strong>Ferguson</strong> became the world’s<br />

best-selling tractor brand in 1962.<br />

1962<br />

Hesston by <strong>Massey</strong> <strong>Ferguson</strong> introduced a<br />

16-foot RazorBar cutterbed featuring the<br />

lowest profile in the industry.<br />

2009<br />

TABLE OF OPPORTUNITIES<br />

Introduction p. 6<br />

Cab Control & Comfort p. 8<br />

Power & Productivity p. 10<br />

RazorBar Disc Header p. 12<br />

Sickle Headers p. 14<br />

Draper Headers p. 16<br />

Service & Support p. 18<br />

Specifications p. 20<br />

PAGE 5

Your choices abound with <strong>Massey</strong> <strong>Ferguson</strong>.<br />

Only <strong>Massey</strong> <strong>Ferguson</strong> has you covered with more windrower and swather models<br />

than anyone in the industry… not to mention a wide choice of headers for hay, grain,<br />

oilseed crops or a combination of crops. Your selections begin with two different<br />

tractor lines – the Hesston 9005 Series, which feature a deluxe cab and the option of a<br />

disc header with the Hesston 9635, or the 9000 Series with a smaller cab and an economical<br />

price that appeals to farmers who only use a swather once a year during small<br />

grain harvest. Then, add your choice of disc, sickle or draper headers – depending on<br />

the tractor model and header compatibility – to match your crop and harvest program.<br />

With optional quick couplers standard on some models, no other headers on the<br />

market can be interchanged or attached as quickly. Our “smart” hydraulic system<br />

allows the operator to change headers by simply attaching the unit and connecting the<br />

electrical wiring harness. The tractor “senses” which header is attached and automatically<br />

adjusts hydraulic flow to match the header type (i.e. a draper header runs slower<br />

than a disc header). Quick couplers on the hydraulic system and 3-point hitch style ball<br />

and socket header linkage (or the appropriate adapter kit) also help speed hook-up and<br />

improve performance… no matter which header you ultimately choose.<br />

Variable conditions call for an adaptable machine<br />

Travel the U.S. and Canada and you’ll find a lot of diversity in the way a windrower<br />

or swather is used. That’s why Hesston 9000 and 9005 Series windrowers by <strong>Massey</strong><br />

<strong>Ferguson</strong> are designed to be easily customized to your operation. Start with a choice<br />

of turf or bar tread tire options on all models.<br />

Your ground-engaging options on the 9435, 9430 and 9220 also include your choice of<br />

an adjustable walking beam axle or a fixed rear axle with formed casters. The latter is<br />

particularly valuable in grain swathing applications where mud buildup can be a problem.<br />

For larger hay windrows that match the capacity of big balers and <strong>high</strong>-capacity<br />

forage harvesters, add the double windrow attachment to the 9435 or 9635 or the<br />

windrow tripler kit on the 9635. There’s even an offset tailwheel kit available to<br />

reposition the right tailwheel behind the axle when building double windrows.

SERIES MODEL CAB ENgINE RATED HP COMPATIBLE<br />

HEADERS<br />

Hesston<br />

9000 Series<br />

Swathers<br />

by <strong>Massey</strong><br />

<strong>Ferguson</strong><br />

Hesston<br />

9005 Series<br />

Windrowers<br />

by <strong>Massey</strong><br />

<strong>Ferguson</strong><br />

9220 Narrow 3.3L Cummins 85 (63 kW) 9125, 5200<br />

9430 Narrow<br />

9435 Deluxe<br />

9635 Deluxe<br />

4.4L AGCO<br />

SISU POWER<br />

4.4L AGCO<br />

SISU POWER<br />

6.6L AGCO<br />

SISU POWER<br />

120 (89 kW)<br />

120 (89 kW)<br />

190 (138 kW)<br />

9125, 9145,<br />

5200<br />

9125, 9145,<br />

5200<br />

9190, 9192,<br />

9125, 9145,<br />

5200<br />

THE PERFECT FIT<br />

Designed for Northern Plains<br />

grain producers, the 9220 provides<br />

the power and performance<br />

to handle annual swathing needs,<br />

as well as occasional hay <strong>harvesting</strong>,<br />

without the frills that add<br />

unnecessary costs.<br />

Like its 9220 counterpart, the<br />

9430 is primarily used with the<br />

5200 draper header as a swather.<br />

However, its larger engine permits<br />

the use of either sickle header,<br />

while providing the power to<br />

handle larger draper headers in<br />

heavy crops and rolling terrain.<br />

The variety of tractor combinations<br />

and the ability to handle any<br />

Hesston sickle or draper header<br />

allows the 9435 to meet the<br />

productivity needs of custom hay<br />

operators, large grain and hay<br />

growers, and commercial hay<br />

operations.<br />

Designed and powered to handle<br />

the 9190 and 9192 disc headers, as<br />

well as any other header in the<br />

line-up, the 9635 is ideal for the<br />

custom operator, large rancher or<br />

dairy/livestock operator who has<br />

to put up large volumes of hay on<br />

a timely basis.<br />

See complete specs on page 20.<br />

9220<br />

9430<br />

9435<br />

9635<br />

Introduction<br />

PAGE 7

Wrap yourself in total comfort.<br />

Whether you choose the 9005 Series<br />

with its deluxe cab or the 9000 Series<br />

with the standard cab, Hesston 9000/<br />

9005 windrowers by <strong>Massey</strong> <strong>Ferguson</strong><br />

wrap you in the kind of comfort and<br />

quietness that keeps you productive,<br />

no matter how long your day may last.<br />

The smooth ride actually starts with<br />

the long wheelbase that helps level the<br />

contours on rough fields. Of course, any<br />

bumps that get past the large-diameter<br />

tires, extended frame and optional isolation-mounted<br />

cab are quickly absorbed<br />

by a fully adjustable air-ride seat.<br />

Standard on the 9635 and optional on<br />

the 9435, 9430 and 9220, a performance<br />

monitor mounted on the steering<br />

column provides ground speed, header<br />

speed, engine rpm, acres per hour, field<br />

acres cut and total acres cut.<br />

A seat-mounted console, which<br />

adjusts vertically and horizontally with<br />

the seat to fit the operator, puts all<br />

regularly used controls at your fingertips.<br />

An instrument gauge cluster,<br />

incorporated <strong>into</strong> the control console,<br />

where it’s at eye level while viewing<br />

the header, includes a full bank of<br />

gauges and monitors, as well as engine<br />

indicator lights to alert the operator<br />

of any problem.<br />

Naturally, the cab is fitted with both a<br />

heater and <strong>high</strong>-capacity air conditioner<br />

to keep the operator environment<br />

In addition to speed and direction, the<br />

travel control lever is used to control<br />

header lift, header tilt, swathboard<br />

actuation, reel raise and lower, reel<br />

speed and monitor selection (some<br />

functions require optional kits).<br />

comfortable, no matter the temperature<br />

outside.<br />

Optional cab suspension<br />

An optional cab suspension system,<br />

which incorporates dual air bags, an<br />

air reservoir and dual shock absorbers,<br />

is available on the Hesston 9635<br />

tractor to help reduce operator<br />

fatigue and improve productivity.<br />

The system is especially valuable<br />

when <strong>harvesting</strong> rough and uneven<br />

fields with the <strong>high</strong>-speed 9190 or<br />

9192 RazorBar disc header.<br />

There’s no reason to stop when it gets<br />

dark, thanks to a full bank of rectangular<br />

halogen lights that includes five at the<br />

front of the cab, two at the rear of the<br />

cab and one at the rear of the tractor.<br />

Although they share the same<br />

control features, the deluxe cab<br />

on the 9005 Series includes an<br />

instructor’s seat with seat belt,<br />

73 square feet of tinted glass<br />

and a larger, curved windshield.

Cab Control & Comfort<br />

PAGE 9

Productivity is built in.<br />

Whether it comes via quicker service and maintenance in the<br />

yard or <strong>high</strong>er capacity in the field, Hesston 9000 and 9005 Series<br />

windrowers and swathers by <strong>Massey</strong> <strong>Ferguson</strong> are at the top of their<br />

class in total productivity.<br />

Positive ground drive<br />

In all models, a pair of hydrostatic pumps power wheel motors that<br />

are attached directly to the planetary drives, eliminating the need<br />

for chain drives. Superior torque and radial load characteristics from<br />

the planetary drives further contributes to the pulling power when<br />

climbing hills or crossing ditches.<br />

Fingertip hydraulic control<br />

A pioneer in the use of hydraulic header drive, Hesston built headers<br />

are electronically engaged with a single toggle switch on the operator’s<br />

console.<br />

Hydraulic header flotation, which is standard on all Hesston Series<br />

windrowers, is just as easily adjusted via a gauge and switch on the<br />

console – allowing on-the-go adjustment to changing field and crop<br />

conditions.<br />

It all starts with the power to<br />

handle extreme conditions, which<br />

comes in the form of a durable<br />

and reliable Cummins ® or AgCO<br />

SISU POWER diesel engine.<br />

Power & Productivity<br />

PAGE 11

Solid, <strong>high</strong>-speed performance in any crop.<br />

When it comes to acres per hour, there’s nothing that lays a crop on the ground<br />

faster than a Hesston 9190 or 9192 RazorBar disc header.<br />

Its modular heavy-duty design spells an end to costly downtime. Not only do the<br />

wide-profile teeth offer increased <strong>gear</strong>-to-<strong>gear</strong> contact, but the entire drivetrain<br />

is designed to handle maximum load. An industry exclusive, the RazorBar’s sealed<br />

bearings also do not need constant lubrication, no matter the slope of the terrain.<br />

Should the worst happen, however, the <strong>gear</strong> spindle is designed to shear off<br />

outside the cutterbed, keeping contamination away from the <strong>gear</strong>s. The stronger<br />

<strong>gear</strong> bed allows the RazorBar header to operate without the use of a weakened<br />

sheer hub.<br />

For even greater time savings, each <strong>gear</strong> assembly and adjacent idler <strong>gear</strong> can<br />

be individually removed through the top of the module, without disassembly of<br />

the cutterbar.<br />

Other new features of the RazorBar include:<br />

• Radura ® <strong>high</strong>-carbon steel knives in a choice of degrees and bevels.<br />

• Counter-rotating discs with increased overlap.<br />

• Sloping disc hub mounts for reduced debris buildup.<br />

• Ductile cast-iron module housings that are machined for perfect alignment<br />

and maximum durability.<br />

• Disc speed is infinitely variable from 1,600 to 2,600 rpm to match crop<br />

conditions.<br />

Standard or double conditioning<br />

While the 9190 RazorBar header features the standard steel-on-steel conditioner, the<br />

9192 uses the Hesston Advanced Conditioning System, which includes two sets of<br />

steel-on-steel rolls. All rolls feature a herringbone tread pattern that cracks stems<br />

without stripping leaves and each set of rolls, whether single or double, feature<br />

hydraulic roll tension that provides constant roll pressure, yet is easy to adjust.<br />

The RazorBar cutterbed features a new low-profile, spur <strong>gear</strong> cutterbed that’s thinner in<br />

design for closer cutting; it slices a 16-foot swath through lush alfalfa, tangled grass and tall<br />

sudan with equal ease.<br />

A turbulence reduction roll, or helper<br />

roll, located between the conditioner<br />

rolls and the cutterbed allows the<br />

conditioner rolls to be positioned<br />

farther back, improving performance<br />

in light crops.<br />

Dual hydraulic motors, which drive<br />

the cutterbed from each end, provide<br />

even torque load across the entire<br />

width of the cutterbar for increased<br />

reliability.

RazorBar Disc Header<br />

PAGE 13

The gold-standard in sickle bar headers.<br />

Leave it to the brand that invented the auger header to provide the smooth, clean cutting you demand<br />

from a sickle/auger header. Available in 14-, 16- and 18-foot cutting widths the Hesston 9125 features the<br />

Hesston trademark dual augers along with a double sickle and a single pair of rubber-on-steel or steel-onsteel<br />

conditioner rolls.<br />

Meanwhile, the Hesston 9145, which boasts the exclusive Advanced Conditioning System in addition to the<br />

9100 Series’ standard features, is available in 14- and 16-foot cutting widths. All models feature hydraulic<br />

drive, hydraulic header flotation and hydraulic roll tension for easy adjustment and time-tested reliability.<br />

Time-tested features<br />

• A standard five-bat (a sixth bat is optional) reel that takes smaller “bites” provides smooth feeding<br />

to the augers and conditioner.<br />

• A half-swaybar dual sickle drive system that uses a counter-balanced flywheel to reduce peak<br />

starting, stopping and cutting loads. The system also reduces vibration and side-to-side movement while<br />

driving the sickle at 1,840 strokes per minute.<br />

• Dual, counter-rotating augers, which provide two separate “live” feeding elements, ensure smooth,<br />

even feeding across the full width of the conditioner rolls.<br />

• A standard header reverser on the Hesston 9125 allows the operator to back large objects or slugs<br />

out of the header without leaving the seat.<br />

• Tine tubes are segmented between bulkhead spiders for quicker and easier tine replacement. Reel<br />

tine tubes also rotate on sealed ball bearings for longer life and less downtime.<br />

• Sickle sections are bolted to the sickle bar, rather than riveted, for quicker, easier field replacement.

The Hesston dual auger system features<br />

a slip clutch on each auger for maximum<br />

protection, as well as center supports<br />

on the bottom augers for less vibration<br />

and reduced risk of damage. Meanwhile,<br />

the top auger floats up to 1.4 inches<br />

(36 mm) for more efficient feeding in a<br />

wider range of crop conditions.<br />

Unlike traditional conditioners, the<br />

Advanced Conditioning System on the<br />

Hesston 9145 sickle header utilizes two<br />

pairs of independently controlled herringbone<br />

conditioner rolls positioned in<br />

line for double conditioning. A pair of<br />

steel-on-steel rolls start the conditioning<br />

process, while a pair of shallow-lug,<br />

machined rubber rolls provide the extra<br />

crushing action that speeds crop drying.<br />

Sickle Headers<br />

PAGE 15

Adjust the windrow opening from<br />

54 to 70 inches (1.37 -1.78 m) to<br />

accommodate a wide variety of<br />

grain and oilseed crops. Narrowopening<br />

inserts are available for<br />

light or short crops.<br />

Turn amber waves of grain <strong>into</strong> uniform swaths.<br />

Turn any 9000 or 9005 Series model <strong>into</strong> a <strong>high</strong>-capacity swather by simply adding a Hesston 5200 Series draper<br />

header. Choose from five center-delivery header widths – 18-, 22-, 25-, 30- and 36-foot (5.5, 6.7, 7.6, 9.1 and<br />

10.9 m) – that build the perfect swath for today’s <strong>high</strong>-capacity combines and harvesters. Or select one of three<br />

double swath models in 22-, 25- and 30-foot (6.7, 7.6 and 9.1 m) cutting widths.<br />

These shiftable draper models let you position the swath at the center or to the left and right side of the header<br />

for double swaths.<br />

Say ‘good-bye’ to sickle vibration<br />

Whether you’re cutting close to the ground or leaving 10 inches of stubble, you can count on the 5200 header<br />

for smooth, clean performance. A hydraulically driven sickle drive features a planetary <strong>gear</strong> system that eliminates<br />

starting and stopping loads. The lack of shafts, belts and sheaves translates <strong>into</strong> reduced maintenance.<br />

The planetary drive, which runs at 1,400 strokes per minute, also produces a linear knife movement that ensures<br />

against up-and-down and side-to-side movement during its stroke for less wear and better cutting performance.<br />

Finally, a skid plate along the bottom of the cutterbar protects the entire unit when cutting close to the ground.<br />

Heavy-duty, nylon reinforced belts are<br />

driven by a hydraulic motor and are<br />

adjustable from the cab to any speed<br />

from 0 to 600 feet (0 - 183 m) per minute.<br />

A<br />

B<br />

The hydraulic reel drive is infinitely<br />

variable from 0 to 60 rpm to precisely<br />

match reel speed to ground speed and<br />

crop conditions.<br />

A - Reel Speed Fast<br />

B - Reel Speed Slow<br />

Draper Headers<br />

PAGE 17

Quicker service means greater productivity.<br />

Like any <strong>harvesting</strong> unit, a windrower or swather<br />

needs to be ready to go when the crop is ready to cut.<br />

Fortunately, that’s been the case with Hesston-built<br />

machines for more than 50 years.<br />

With every redesign, Hesston windrowers have not<br />

only improved in efficiency, strength and productivity,<br />

but reliability and serviceability. The one-piece engine<br />

hood, for example, offers two positions for quicker,<br />

easier access. Tilt it back to a partially open position<br />

for daily service, or fully open for periodic service and<br />

maintenance.<br />

The rotary screen air intake, which is standard on the 9435<br />

and 9635, sits forward of the engine and <strong>high</strong> on the tractor,<br />

where it provides cleaner air to the engine without the<br />

worry of chaff and debris buildup.<br />

Top-hinged radiator compartment doors, along with<br />

hydraulic oil cooler and air conditioner condenser units<br />

that slide out, further add to the service convenience.<br />

Our engineers even thought of the little things, like<br />

adding a walkway with non-slip friction strips to the top<br />

of the headers for safer, easier access when cleaning the<br />

cab windows.<br />

Like you, we realize that easier often means faster… and<br />

faster means getting in the field earlier.<br />

A folding access ladder and service platform permit quick<br />

refueling, even if it only comes once a day, thanks to a<br />

100-gallon (377.4 l) fuel tank on the Model 9635 and an<br />

80-gallon tank (303 l) on all other models.<br />

LOW-RATE,<br />

FLEXIBLE FINANCINg<br />

Your dealer and AgCO Finance offer<br />

attractive financing to ensure the<br />

Hesston self-propelled windrower or<br />

swather of your choice will fit in your<br />

operating budget. Extremely competitive<br />

rates as low as 0% APR and terms<br />

make it easy to buy, lease or rent.<br />

Not only is the cab air filter located externally, where it can<br />

be changed without dropping contents <strong>into</strong> the cab, but the<br />

system is designed to purge dust from the filter each time the<br />

cab door is closed, extending the filter life.

A great deal includes a great dealer.<br />

If you’re like most farmers, when you find the perfect piece of equipment, it<br />

becomes almost like part of your family. And when you buy a Hesston ® 9000<br />

or 9005 Series windrower by <strong>Massey</strong> <strong>Ferguson</strong>, you instantly become part of<br />

ours. Our network of dealers understands what owning a commercial-grade<br />

swather or windrower really means. They’ll advise and support you through<br />

the selection process, the buying process, through operation, maintenance and<br />

beyond. Because our dealers share your passion for farming, they’re happy to<br />

share their knowledge to keep you working happy. After all, you’re family. And<br />

there’s nothing we wouldn’t do for family.<br />

All-inclusive warranty<br />

Even our warranty is <strong>high</strong> performance, covering 2 years/2,000 hours on<br />

the engine and 1-year/unlimited hours all-inclusive coverage on all parts and<br />

labor. From header to tailwheel, it’s one of the best in the business, backed by<br />

dealers who understand how to help you make the most of it.<br />

Quality parts<br />

Genuine <strong>Massey</strong> <strong>Ferguson</strong> replacement parts are manufactured to the same<br />

<strong>high</strong> standards of quality and dependability as the original part used on the<br />

assembly line. Using original equipment parts will help keep your Hesston<br />

9000 or 9005 Series windrower or swather running like new.<br />

Visit www.AgCOParts.com to find genuine <strong>Massey</strong><br />

<strong>Ferguson</strong> replacement parts and accessories. Then click<br />

the link to AgCOPartsBooks.com to conveniently<br />

identify the specific part number for your model,<br />

create a shopping cart and notify your dealer for<br />

ordering. Day or night, 365 days a year.<br />

At <strong>Massey</strong> <strong>Ferguson</strong>, you’re family. And there’s nothing<br />

we wouldn’t do for family.<br />

Questions? Go to<br />

masseyferguson.com<br />

Our website opens the door to<br />

all sorts of technical information<br />

and product specifications. If you<br />

can’t find what you’re looking for,<br />

click on “contact us” and we’ll<br />

provide you with access to folks<br />

who can get you all the answers.<br />

AGCO Answers<br />

(877) 525-4384<br />

agcoanswers@agcocorp.com<br />

At AGCO, customer care isn’t just<br />

a department. It’s a commitment.<br />

Contact us with your questions.<br />

We’ll do our best to answer them<br />

promptly, or put you in touch with<br />

someone who can.<br />

&<br />

The doors are open<br />

at Shop<strong>Massey</strong>.com<br />

You’ll find all sorts of ways to live<br />

<strong>Massey</strong> <strong>Ferguson</strong> from the latest<br />

in wearables to gifts for the entire<br />

family. And some good old-<br />

fashioned bargains, too.<br />

The <strong>Massey</strong> <strong>Ferguson</strong> Farm Life<br />

magazine is our exclusive publication<br />

that offers news, interviews and<br />

insights <strong>into</strong> all the joys – and<br />

challenges – of farming.<br />

Join the clubs.<br />

<strong>Ferguson</strong> Enthusiasts of North<br />

America has grown from just 59<br />

members in 2001 to almost 600<br />

members today. They publish a<br />

newsletter five times a year and hold<br />

annual get-togethers at well-known<br />

tractor shows. Join today, visit<br />

fergusonenthusiasts.com.<br />

The <strong>Ferguson</strong> Club is an international,<br />

independent member’s club<br />

established in 1986 to promote and<br />

disseminate information and interest<br />

in the work of the late Harry<br />

<strong>Ferguson</strong>, <strong>Ferguson</strong> products and<br />

in particular, the “<strong>Ferguson</strong> System.”<br />

fergusonclub.com<br />

The Friends of <strong>Ferguson</strong> Heritage<br />

Ltd. exists to encourage and assist<br />

enthusiasts in their interest in the<br />

engineering achievements of the late<br />

Harry <strong>Ferguson</strong>. fofh.co.uk<br />

Service & Support<br />

PAGE 19

SP WINDROWER MODEL<br />

Dimensions and Weight<br />

9220 9430 9435 9635<br />

Cab size Standard cab Standard cab Deluxe cab Deluxe cab<br />

Length overall with header in. (mm) 257.6 (6,543) 257.6 (6,543) 257.6 (6,543) 266.3 (6,764)<br />

Wheelbase in. (mm)<br />

Height<br />

140.0 (3,556) 140 (3,556) 140 (3,556) 140.0 (3,556)<br />

Top of cab in. (mm)<br />

Width<br />

132.2 (3,358) 132.2 (3,358) 132.2 (3,358) 133.4 (3,388)<br />

Outside of largest tires in. (mm)<br />

Tread Width<br />

146.5 (3,722) 146.5 (3,722) 146.5 (3,722) 156 (3,949)<br />

Drive tires in. (mm)<br />

127.6 (3,241)<br />

126 (3,202)<br />

126 (3,202)<br />

131.9 (3,348)<br />

Tail wheels - min. in. (mm)<br />

84.4 (2,144)<br />

84.4 (2,144)<br />

84.4 (2,144)<br />

84.4 (2,144)<br />

Tail wheels - max. in. (mm)<br />

Weight (approximate) without<br />

120 (3,048)<br />

120 (3,048)<br />

120 (3,048)<br />

120 (3,048)<br />

header lb. (kg)<br />

Speed (approximate)<br />

7,950 (3,606) 8,600 (3,900) 8,650 (3,924) 11,180 (5,070)<br />

Field range mph (km/h) 0 to 11 (0 to 17.7) 0 to 8.6 (0 to 13.7) 0 to 8.6 (0 to 13.7) 0 to 11 (0 to 18)<br />

Road range mph (km/h)<br />

Engine<br />

0 to 15 (0 to 24) 0 to 15 (0 to 24) 0 to 15 (0 to 24)<br />

Model<br />

Cummins<br />

turbocharged diesel<br />

B3.3T<br />

AGCO SISU POWER<br />

4.4 CTA turbocharged<br />

AGCO SISU POWER<br />

4.4 CTA turbocharged<br />

AGCO SISU POWER<br />

6.6 CTA turbocharged<br />

Horsepower 85 120 120 190<br />

Displacement cu in. (L) 201 (3.3) 269 (4.4) 269 (4.4) 403 (6.6)<br />

Fuel tank capacity US Gal (L)<br />

ground Drive System<br />

80 (303) 80 (303) 80 (303) 100 (377.4)<br />

Type Direct drive planetary Direct drive planetary Direct drive planetary Direct drive planetary<br />

Transmission<br />

Hydrostatic -<br />

single speed<br />

Hydrostatic - 2 speed Hydrostatic - 2 speed Hydrostatic - 2 speed<br />

Tandem pump<br />

Tires<br />

Sauer-Danfoss,<br />

Series M44<br />

Sauer-Danfoss,<br />

Series M44<br />

Sauer-Danfoss,<br />

Series M44<br />

Sauer-Danfoss,<br />

Series M44<br />

Drive wheels<br />

18.4 x 26 turf tread<br />

16.9 x 28R4 bar tread<br />

18.4R x 26R1 bar tread<br />

18.4 x 26 turf tread<br />

16.9 x 28R4 bar tread<br />

18.4R x 26R1 bar tread<br />

18.4 x 26 turf tread<br />

16.9 x 28R4 bar tread<br />

18.4R x 26R1 bar tread<br />

23.1 x 26 turf tread<br />

18.4 x 28R4 bar tread<br />

Tail wheels<br />

14L x 16.1 or<br />

12.5L x 15<br />

14L x 16.1 or<br />

12.5L x 15<br />

14L x 16.1 or<br />

12.5L x 15<br />

14L x 16.1<br />

DRAPER HEADER MODEL<br />

Dimensions and Weights<br />

Overall width<br />

Center delivery and double swath model<br />

5200<br />

18 ft. (5.5 m) in. (m)<br />

230 (5.84)<br />

22 ft. (6.7 m) in. (m)<br />

278 (7.06)<br />

25 ft. (7.6 m) in. (m)<br />

314 (7.98)<br />

30 ft. (9.1 m) in. (m)<br />

374 (9.50)<br />

36 ft. (10.92 m) in. (m)<br />

Width of Cut<br />

Center delivery and double swath model<br />

446 (11.33)<br />

18 ft. (5.5 m) in. (m)<br />

219 (5.56)<br />

22 ft. (6.7 m) in. (m)<br />

267 (6.78)<br />

25 ft. (7.6 m) in. (m)<br />

303 (7.70)<br />

30 ft. (9.1 m) in. (m)<br />

363 (9.22)<br />

36 ft. (11.0 m) in. (m)<br />

Weight with Reel lb (kg) approximate<br />

433 (11.0)<br />

18 ft. (5.5 m) center delivery<br />

2,300 (1,043)<br />

22 ft. (6.7 m) center delivery<br />

2,750 (1,247)<br />

25 ft. (7.6 m) center delivery<br />

3,100 (1,406)<br />

30 ft. (9.1 m) center delivery<br />

3,700 (1,678)<br />

36 ft. (10.92 m) center delivery<br />

4,700 (2,131)<br />

22 ft. (6.7 m) shiftable draper<br />

2,850 (1,293)<br />

25 ft. (7.6 m) shiftable draper<br />

3,200 (1,451)<br />

30 ft. (9.1 m) shiftable draper<br />

Header<br />

3,800 (1,724)<br />

Drive - draper and reel Hydraulic<br />

Guard angle (4 cylinder tractors, adjustable) 9° to 19°<br />

Guard angle (6 cylinder tractors, adjustable) 4° to 18°<br />

Flotation<br />

Size of opening<br />

Without draper inserts<br />

Hydraulic<br />

Max. in. (mm)<br />

70 (1,778)<br />

Min. in. (mm)<br />

Cutterbar<br />

54 (1,372)<br />

Speed spm (cpm) 1,300 (650)<br />

Stroke in. (mm) 3.125 (79.38)<br />

Drive Inline <strong>gear</strong>box<br />

Guard spacing in. (mm) 3 (76)<br />

Number of sickles<br />

Draper<br />

One<br />

Drive Hydraulic<br />

Speed (adjustable from cab) ft/min (m/min) 0 to 600 (0 to 183)<br />

Width in. (mm) 41 (1,041)<br />

Type<br />

Rubberized draper<br />

w/ reinforced slats

RAzORBAR<br />

DISC HEADER MODEL<br />

Dimensions and Weights<br />

Width (overall) in. (mm)<br />

9175<br />

12'<br />

150 (3,810)<br />

9190<br />

16'<br />

195 (4,963)<br />

9192<br />

16'<br />

195 (4,963)<br />

SICKLE HEADER MODEL<br />

Dimensions and Weights<br />

14' Header<br />

Width of cut in. (mm)<br />

9145<br />

168 (4,276)<br />

9125 A<br />

168 (4,276)<br />

Weight (with forming shields)<br />

lb. (kg)<br />

3,490 (1,583) 4,200 (2,168) 4,200 (2,168)<br />

Width (overall) in. (mm)<br />

Weight (less forming shields) lb. (kg)<br />

188.4 (4,786)<br />

4,630 (2,100)<br />

188.4 (4,786)<br />

3,850 (1,746)<br />

Header<br />

16' (4.9m) Header<br />

Header drive<br />

Input shaft speed (max.) rpm<br />

Header lift range<br />

in. (mm) to in. (mm)<br />

Dual hydraulic<br />

motors<br />

2,600<br />

-3.3 (-84) to +25.1<br />

(+638)<br />

Dual hydraulic<br />

motors<br />

2,600<br />

-3.3 (-84) to +25.1<br />

(+638)<br />

Dual hydraulic<br />

motors<br />

2,600<br />

-3.3 (-84) to +25.1<br />

(+638)<br />

Width of cut in. (mm)<br />

Width (overall) in. (mm)<br />

Weight (less forming shields) lb. (kg)<br />

18' (5.5 m) Header<br />

Width of cut in. (mm)<br />

Width (overall) in. (mm)<br />

192 (4,877)<br />

212.4 (5,396)<br />

4,900 (2,223)<br />

N/A<br />

192 (4,877)<br />

212.4 (5,396)<br />

4,100 (1,860)<br />

216 (5,486)<br />

236.4 (60,05)<br />

Radial and vertical Radial and vertical Radial and vertical Weight (less forming shields) lb. (kg)<br />

4,400 (1,996)<br />

Header flotation<br />

Header tilt<br />

Header angle<br />

hydraulic,<br />

adjustable from cab<br />

Hydraulic, adjustable<br />

from cab<br />

0° to 10°<br />

hydraulic,<br />

adjustable from cab<br />

Hydraulic, adjustable<br />

from cab<br />

0° to 10°<br />

hydraulic,<br />

adjustable from cab<br />

Hydraulic, adjustable<br />

from cab<br />

0° to 10°<br />

Header<br />

Header drive<br />

Header flotation<br />

Reel<br />

Hydraulic<br />

Hydraulic adjustable from<br />

the control console<br />

Hydraulic<br />

Hydraulic adjustable from<br />

the control console<br />

Cutterbed<br />

Bats 5 5<br />

Cutting Width - 12' Header<br />

in. (mm)<br />

Cutting height (mm)<br />

Number of discs - 12' Header<br />

Number of knives - 12' Header<br />

Disc speed (max.) rpm<br />

Tip speed (max.) mph (km/h)<br />

Cutterbed design<br />

Hay Conditioner<br />

144 (3,658)<br />

0.75 to 3 (19 to 76)<br />

8<br />

16 (2 per disc)<br />

2,600<br />

184 (296)<br />

Spur <strong>gear</strong>s<br />

192 (4,895)<br />

0.75 to 3 (19 to 76)<br />

10<br />

20 (2 per disc)<br />

2,600<br />

189 (304)<br />

Spur <strong>gear</strong>s<br />

192 (4,895)<br />

0.75 to 3 (19 to 76)<br />

10<br />

20 (2 per disc)<br />

2,600<br />

189 (304)<br />

Spur <strong>gear</strong>s<br />

Diameter in. (mm)<br />

Drive<br />

Speed rpm<br />

Sickle<br />

Speed spm (cpm)<br />

Stroke in (mm)<br />

Guard angle (adjustable)<br />

Drive<br />

42 (1,067)<br />

Belt & chain<br />

72 to 83<br />

1,840 (920)<br />

3 (76.2)<br />

5° to 12°<br />

Timed <strong>gear</strong>boxes with<br />

half swaybar<br />

42 (1,067)<br />

Belt & chain<br />

72 to 83<br />

1,840 (920)<br />

3 (76.2)<br />

5° to 12°<br />

Timed <strong>gear</strong>boxes with<br />

half swaybar<br />

Type Roll conditioner Roll conditioner Roll conditioner Number of sickles 2 2<br />

Front<br />

Rear (9192 only)<br />

Length in. (mm)<br />

Herringbone,<br />

steel-on-steel<br />

N/A<br />

110 (2,794)<br />

Herringbone,<br />

steel-on-steel<br />

N/A<br />

110 (2,794)<br />

Herringbone,<br />

steel-on-steel<br />

Herringbone,<br />

steel-on-steel<br />

110 (2,794)<br />

Augers<br />

Type<br />

Diameter<br />

Upper auger in. (mm)<br />

Lower auger in. (mm)<br />

Dual, opposed rotation<br />

9 (229)<br />

10 (254)<br />

Dual, opposed rotation<br />

9 (229)<br />

10 (254)<br />

Diameter in. (mm) 7.75 (197) 7.75 (197) 7.75 (197) Speed<br />

Speed rpm (maximum) 1,280 1,264 1,264<br />

Upper auger rpm<br />

Lower auger rpm<br />

368<br />

585<br />

368<br />

585<br />

Windrow width<br />

Min. in. (mm)<br />

Max. in. (mm)<br />

Adjustable<br />

40 (1,016)<br />

96 (2,438)<br />

Adjustable<br />

40 (1,016)<br />

96 (2,438)<br />

Adjustable<br />

40 (1,016)<br />

96 (2,438)<br />

Hay Conditioners<br />

Type<br />

Front<br />

Herringbone, steel-on-steel Herringbone, steel-on-steel<br />

Type Spoke conditioner N/A N/A<br />

or spiral rubber-on-steel<br />

Number of spokes<br />

Length in. (mm)<br />

74 v-tines<br />

110 (2,794)<br />

N/A<br />

N/A<br />

N/A<br />

N/A<br />

Rear (9145 only)<br />

Length in. (mm)<br />

Diameter in. (mm)<br />

Herringbone, rubber-on-rubber<br />

110 (2,794)<br />

N/A<br />

110 (2,794)<br />

Diameter in. (mm)<br />

Speed rpm (maximum)<br />

21.6 (550)<br />

1,030<br />

N/A<br />

N/A<br />

N/A<br />

N/A<br />

Steel<br />

Rubber<br />

Speed (maximum) rpm<br />

7.75 (197)<br />

8 (203)<br />

1,026<br />

7.75 (197)<br />

8 (203)<br />

1,026<br />

Windrow width<br />

Min in. (mm)<br />

Max in. (mm)<br />

36 (914)<br />

96 (2,438)<br />

N/A N/A<br />

Windrow width<br />

Min. in. (mm)<br />

Max. in. (mm)<br />

Adjustable<br />

40 (1,016)<br />

96 (2,438)<br />

Adjustable<br />

40 (1,016)<br />

96 (2,438)<br />

Specifications<br />

PAGE 21

The name says it all.<br />

“Hesston by <strong>Massey</strong> <strong>Ferguson</strong>” may seem a little long for a name, but it’s our way of honoring the top<br />

names in the business. After all, there’s not a company in North America – past or present – with more hay<br />

equipment patents than Hesston.<br />

Of course, Daniel <strong>Massey</strong> and Harry <strong>Ferguson</strong> have their own legacy in the farm equipment business with<br />

innovations that span over 160 years. It’s a history we’re proud to display, even if it does take a bigger decal.

Welcome<br />

to the family.

Hesston 9000 & 9005 Series SP Windrowers & Swathers<br />

masseyferguson.com<br />

MASSEY FERgUSON and HESSTON are registered trademarks of AGCO. (877) 525-4384 • MF009455RP (2) 8 PD<br />

AGCO, Your Agriculture Company, is a premier manufacturer of agricultural equipment, providing <strong>high</strong>-tech solutions for professional farmers feeding the world.<br />

The company is dedicated to delivering superior customer service, innovation and quality. AGCO products are distributed in more than 140 countries worldwide.<br />

©2010 AGCO Corporation. All rights reserved. This document and all<br />

of its contents are owned exclusively by AGCO and are protected by<br />

copyright law. AGCO has a corporate policy of continuous product<br />

improvement and development; therefore, specifications are subject<br />

to change without any advance notice. AGCO is not responsible for<br />

differences between the specifications or illustrations contained in<br />

this publication and the actual equipment. Equipment produced by<br />

other manufacturers is shown in photographs in this brochure for the<br />

purpose of illustration only and is not intended as an endorsement of<br />

that particular equipment or its suitability. All rights reserved. AGCO,<br />

4205 River Green Parkway, Duluth, GA 30096.<br />

We proudly support: