,,,, ,, Heavy Duty Quarry Bucket and GET Options

,,,, ,, Heavy Duty Quarry Bucket and GET Options

,,,, ,, Heavy Duty Quarry Bucket and GET Options

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

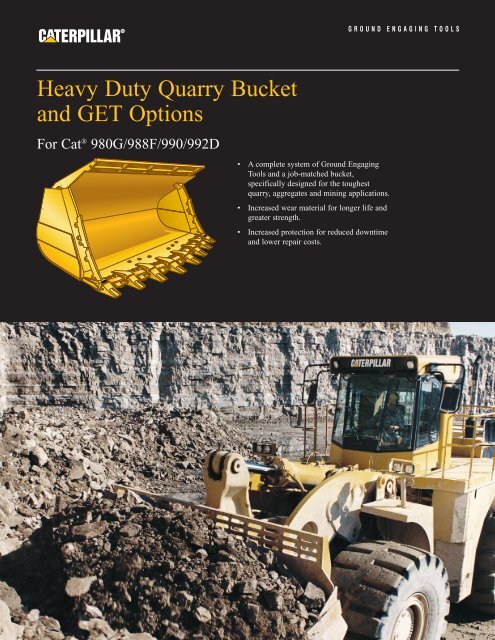

<strong>Heavy</strong> <strong>Duty</strong> <strong>Quarry</strong> <strong>Bucket</strong><br />

<strong>and</strong> <strong>GET</strong> <strong>Options</strong><br />

For Cat ® 980G/988F/990/992D<br />

,<br />

,<br />

,,<br />

,,<br />

R<br />

• A complete system of Ground Engaging<br />

Tools <strong>and</strong> a job-matched bucket,<br />

specifically designed for the toughest<br />

quarry, aggregates <strong>and</strong> mining applications.<br />

• Increased wear material for longer life <strong>and</strong><br />

greater strength.<br />

• Increased protection for reduced downtime<br />

<strong>and</strong> lower repair costs.<br />

GROUND ENGAGING TOOLS

<strong>Heavy</strong> <strong>Duty</strong><br />

Shouldered<br />

Adapters<br />

,,,<br />

,,,<br />

<strong>Heavy</strong> <strong>Duty</strong> Long life<br />

Key Benefits*<br />

• More protection.<br />

• More strength.<br />

• More wear material.<br />

More Protection<br />

• Shoulder protects the rear of the bucket tip<br />

pocket wall, preventing impact which can drive<br />

the bucket tip forward into the pin causing pin<br />

bending or breaking.<br />

More Strength<br />

• Two-strap design with thicker, wider strap<br />

profile to add strength.<br />

• Larger weld groove for easier welding making<br />

stronger <strong>and</strong> better welds.<br />

*See data sheet “Cat <strong>Heavy</strong> <strong>Duty</strong> Rock <strong>Bucket</strong> Adapters” (PEHP5025) for<br />

additional information.<br />

More Wear Material<br />

• Thicker straps add 24-40% more wear material<br />

than st<strong>and</strong>ard adapters for more adapter life <strong>and</strong><br />

increased segment <strong>and</strong> tip protection.<br />

Two Adapter <strong>Options</strong>:<br />

<strong>Heavy</strong> <strong>Duty</strong> (HD)<br />

• Bottom strap thickness is matched to the<br />

thickness of the <strong>Heavy</strong> <strong>Duty</strong> Half-Arrow<br />

Segment for a smoother material flow.<br />

• Available for 980, 988, 990 <strong>and</strong> 992 machines.<br />

<strong>Heavy</strong> <strong>Duty</strong> Long Life (HDLL) with A.R.M.<br />

• Extremely hard Abrasion Resistant Material<br />

(A.R.M.) retards wear.<br />

• A.R.M. is placed in special grooves to protect it<br />

from impact <strong>and</strong> allows use in more applications.<br />

• Should not be used in extremely high<br />

impact applications.<br />

• Available for 980, 988, 990 <strong>and</strong> 992 machines.<br />

,,, ,,, ,,,<br />

,,, ,,, ,,,<br />

<strong>Heavy</strong> <strong>Duty</strong> Long Life Adapter<br />

,,,<br />

,,,<br />

St<strong>and</strong>ard Adapter

G R O U N D E N G A G I N G T O O L S<br />

Cat Operating Tip:<br />

Install HDLL Tips<br />

“Upside Down.”<br />

When putting HDLL<br />

tips on adapters, it’s<br />

important to place the<br />

self-sharpening cavity<br />

(the side with the<br />

most A.R.M.) down.<br />

This is opposite of<br />

how bucket tips are<br />

normally positioned.<br />

<strong>Heavy</strong> <strong>Duty</strong><br />

Tips<br />

<strong>Heavy</strong> <strong>Duty</strong> Long<br />

<strong>Heavy</strong> <strong>Duty</strong> Abrasion<br />

<strong>Heavy</strong> <strong>Duty</strong> Long Life<br />

(with A.R.M.)<br />

Key Benefits*<br />

Three heavy-duty tip options offer different<br />

combinations of strength, wear life <strong>and</strong> penetration<br />

to best fit your job needs. Available for 980, 988,<br />

990 <strong>and</strong> 992 machines.<br />

<strong>Heavy</strong> <strong>Duty</strong> Long (HDL)<br />

• For use in general loading <strong>and</strong> excavation work.<br />

<strong>Heavy</strong> <strong>Duty</strong> Abrasion (HDA)<br />

• Has added wear material for extended life in<br />

abrasive materials such as s<strong>and</strong> <strong>and</strong> gravel.<br />

Strength<br />

Penetration<br />

Wear Material<br />

*See data sheet “Caterpillar <strong>Bucket</strong> Tips <strong>and</strong> Adapters” (PEHP9011-05)<br />

for additional information <strong>and</strong> options.<br />

<strong>Heavy</strong> <strong>Duty</strong> Long Life (HDLL)<br />

with A.R.M.**<br />

• Provides up to five times more wear life<br />

than HDL tips.<br />

• Bottom A.R.M. increases life of the tip front<br />

<strong>and</strong> back pocket areas.<br />

• Thin strip of A.R.M. on top creates a wear pattern<br />

that provides better penetration as it wears.<br />

• Should not be used in extremely high<br />

impact applications.<br />

HDL vs HDA vs HDLL <strong>Bucket</strong> Tips<br />

Cost Per Hour Comparison 1<br />

Price Wear Life Cost/Hour<br />

Index Index Index<br />

HDL 100 100 100<br />

HDA 120 to 139 150 80 to 93<br />

HDLL 180 300 to 500 60 to 36<br />

1 Example uses index numbers based upon actual price relationships <strong>and</strong><br />

customer usage results. (In applications where tips are completely worn).<br />

**See data sheet “Caterpillar <strong>Heavy</strong> <strong>Duty</strong> Long Life <strong>Bucket</strong> Tips” (PEDP3075)<br />

for additional information.

<strong>Heavy</strong> <strong>Duty</strong> Tip Retention<br />

System<br />

Key Benefits*<br />

<strong>Heavy</strong> <strong>Duty</strong> Tip Retention System has<br />

eliminated pin walking in customer applications.<br />

Available for 980, 988, 990 <strong>and</strong> 992 machines.<br />

Two-Coil Retainer<br />

• Two-coil retainer grips the pin much tighter<br />

than st<strong>and</strong>ard retainers.<br />

• Stops retainer rotation <strong>and</strong> keeps abrasives<br />

from causing pin/retainer wear.<br />

• Will not spread when subjected to side loads.<br />

Designed for Easy Installation<br />

• Ivory-colored plastic holder helps align the<br />

pin <strong>and</strong> retainer during installation to assure<br />

maximum clamping force <strong>and</strong> prevent possible<br />

retainer damage.<br />

• Ivory-colored holder cues installer to<br />

use <strong>Heavy</strong> <strong>Duty</strong> Pins only with <strong>Heavy</strong><br />

<strong>Duty</strong> Retainers.<br />

• <strong>Heavy</strong> <strong>Duty</strong> Pins are chamfered on both ends<br />

to allow installation from either side, so they<br />

can be installed easily...even on machines<br />

where space between bucket tips is tight.<br />

*See data sheet “Caterpillar Tip Retention System” (PEHP4035-01) for<br />

additional information.

G R O U N D E N G A G I N G T O O L S<br />

St<strong>and</strong>ard Flat Segments<br />

<strong>Heavy</strong> <strong>Duty</strong> Flat Segment<br />

<strong>Heavy</strong> <strong>Duty</strong> Half-Arrow Segments<br />

<strong>Heavy</strong> <strong>Duty</strong> Edge<br />

Segments<br />

Key Benefits<br />

Designed to allow choices between more wear<br />

material, protection, strength <strong>and</strong> penetration.<br />

<strong>Heavy</strong> <strong>Duty</strong> Flat Segments<br />

• <strong>Heavy</strong> <strong>Duty</strong> Flat Segments are thicker than<br />

st<strong>and</strong>ard segments for longer wear life.<br />

• Made of tough, through-hardened DH-2 steel.<br />

• Lowest cost per hour when both wear surfaces<br />

can be used.<br />

<strong>Heavy</strong> <strong>Duty</strong> Half-Arrow Segments*<br />

• Half-Arrow profile with self-sharpening cavities<br />

on the outer forward areas improves penetration.<br />

*See data sheet “Rock <strong>Bucket</strong> <strong>Options</strong> – Half-Arrow Segments”<br />

(PEHP5036) for additional information.<br />

• Provides bevel <strong>and</strong> leading edge protection for<br />

extended base edge life.<br />

• Forward protrusion <strong>and</strong> thicker center<br />

cross-section combats<br />

scalloping <strong>and</strong> increases<br />

segment life.<br />

• Segments match the strap thickness of Cat<br />

<strong>Heavy</strong> <strong>Duty</strong> Adapters producing a smooth floor<br />

capability which helps prevent tire damage.<br />

• Lowest cost per hour when only one flat<br />

segment wear surface can be used.<br />

• Available for 980G, 988B, 988F, 990, <strong>and</strong><br />

992D machines.

<strong>Heavy</strong> <strong>Duty</strong> <strong>Quarry</strong> <strong>Bucket</strong><br />

System*<br />

Key Benefits<br />

Cat <strong>Heavy</strong> <strong>Duty</strong> <strong>Quarry</strong> <strong>Bucket</strong>s offer superior protection,<br />

durability <strong>and</strong> performance. Specifically designed<br />

for quarry, aggregates <strong>and</strong> mining operations, these<br />

buckets are factory-modified with additional protection.<br />

<strong>Heavy</strong>-duty Cat <strong>GET</strong> components are designed to reduce<br />

down time <strong>and</strong> bucket-related operating cost to help you<br />

get the most from your machines. Each protection item<br />

<strong>and</strong> component was carefully chosen in response to<br />

customer requests for a bucket that delivers maximum<br />

strength, durability <strong>and</strong> wear life in high impact/high<br />

abrasion conditions.<br />

The <strong>Heavy</strong> <strong>Duty</strong> <strong>Quarry</strong> <strong>Bucket</strong> should only be used in<br />

material densities of 2700 pounds per cubic yard or less<br />

due to increased bucket weight.<br />

Upsized Base Edge <strong>and</strong> Adapters 1<br />

St<strong>and</strong>ard HD <strong>Quarry</strong><br />

Base Edge Adapter Base Edge Adapter<br />

Machine Thickness Size Thickness Size<br />

980G 45 mm (1.75") J400 50 mm (2.00") J460<br />

988F 50 mm (2.00") J460 63 mm (2.50") J550<br />

990 63 mm (2.50") J550 63 mm (2.50") J550<br />

992D 63 mm (2.50") J550 70 mm (2.75") J600<br />

1 Base Edge <strong>and</strong> Adapters: Except for 990 buckets the base edge <strong>and</strong><br />

adapters are upsized for greater strength.<br />

Inner Side Wear Plate<br />

One piece inner side wear plate matches thickness of<br />

outer upper side wear plate. Provides protection to<br />

lower half of inner side plate.<br />

<strong>Heavy</strong> <strong>Duty</strong> Adapters<br />

Interior adapters feature new shouldered design which<br />

provides greater strength, protection <strong>and</strong> wear life.<br />

Bottom strap thickness is matched to the thickness<br />

of the <strong>Heavy</strong> <strong>Duty</strong> Half-Arrow Segment for smoother<br />

material flow.<br />

*See “The Best Tools in the Trade” (PEDP4015-02) for other bucket <strong>and</strong><br />

<strong>GET</strong> options.<br />

Liner<br />

Adds strength <strong>and</strong> extends overall<br />

bucket life. The base edge is raised<br />

to match the liner’s height <strong>and</strong><br />

provide a smooth working surface.<br />

<strong>Heavy</strong> <strong>Duty</strong><br />

Long Tip<br />

or<br />

<strong>Heavy</strong> <strong>Duty</strong><br />

Abrasion Tip<br />

or<br />

<strong>Heavy</strong> <strong>Duty</strong><br />

Long Life Tip<br />

,<br />

,<br />

<strong>Heavy</strong> <strong>Duty</strong> Half-<br />

Arrow Segment<br />

or<br />

<strong>Heavy</strong> <strong>Duty</strong><br />

Flat Segment<br />

or<br />

St<strong>and</strong>ard Flat<br />

Segment

G R O U N D E N G A G I N G T O O L S<br />

,,<br />

,,<br />

<strong>Heavy</strong> <strong>Duty</strong> Long Life<br />

(A.R.M.) Corner Adapters<br />

Shouldered corner adapters use Abrasion Resistant<br />

Material (A.R.M.) to increase wear resistance.<br />

Because corner adapters are subjected to higher wear<br />

rates, A.R.M. is used to extend corner adapter life.<br />

Base Edge Wear Plates<br />

Wear plates offer enhanced protection to the<br />

base edge. Bolt holes accept bolt-on wear<br />

plates for complete edge protection <strong>and</strong><br />

extended base edge life. Base edge wear<br />

plates cover the bottom area of the base<br />

edge not protected by segments.<br />

<strong>Heavy</strong> <strong>Duty</strong> Rear Wear Plates<br />

Bolt-on thicker rear wear plates to<br />

extend life.<br />

Hinge Bracket Wear Plates<br />

Weld-on wear plates protect the lower<br />

heel of the hinge bracket assembly during<br />

bucket loading for longer bracket life.<br />

Dual Sidebar Protectors<br />

Sidebars are drilled to accept dual<br />

sidebar protectors. Cat Modulok<br />

Sidebar Protectors can be stacked<br />

to cover wear patterns that extend<br />

above a single protector. Single<br />

or dual sidebar protectors can be<br />

used to match the wear conditions<br />

of the application.<br />

Outer Upper Side Wear Plate<br />

Upper side wear plates combat the wear<br />

that occurs on bucket side plates in high<br />

impact/abrasion conditions. Because<br />

wear on the upper areas of the bucket is<br />

less severe, these plates are thinner than<br />

the lower side wear plates to save weight.<br />

Outer Lower Side Wear Plate<br />

Lower side wear plates are thicker than<br />

the upper side wear plates. These thicker<br />

plates h<strong>and</strong>le the greater wear which<br />

occurs on the lower quarter of the bucket<br />

sides in tough quarry, aggregates <strong>and</strong><br />

mining operations.<br />

Outer Skid Plates<br />

Skid plates on the outer bottom areas<br />

of the bucket shield high wear areas at<br />

<strong>and</strong> just behind the bucket’s corners.<br />

They also add corner strength. Skid<br />

plates protrude past the outside of the<br />

bucket side plates to protect the side<br />

plate welds.

PEHP5041<br />

<strong>GET</strong> Specialists<br />

Your Cat Dealer is an expert<br />

on Ground Engaging Tools.<br />

He has in-depth information <strong>and</strong><br />

knowledge that you can draw on<br />

to choose the appropriate <strong>GET</strong><br />

for your applications. He can<br />

also show you how to use <strong>and</strong><br />

maintain all your <strong>GET</strong> for<br />

maximum productivity <strong>and</strong><br />

lowest operating costs.<br />

Caterpillar <strong>GET</strong> Warranty<br />

Caterpillar warrants<br />

most Ground Engaging<br />

Tools against breakage<br />

during normal operation. If a Cat<br />

Ground Engaging Tool breaks,<br />

Caterpillar will replace it at no<br />

charge. See your Cat Dealer for<br />

complete warranty details.<br />

R<br />

Printed in U.S.A.<br />

© 1995 Caterpillar