Blower Anti-Heeling System - Hoppe Marine

Blower Anti-Heeling System - Hoppe Marine

Blower Anti-Heeling System - Hoppe Marine

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Fluid Management Motion Control<br />

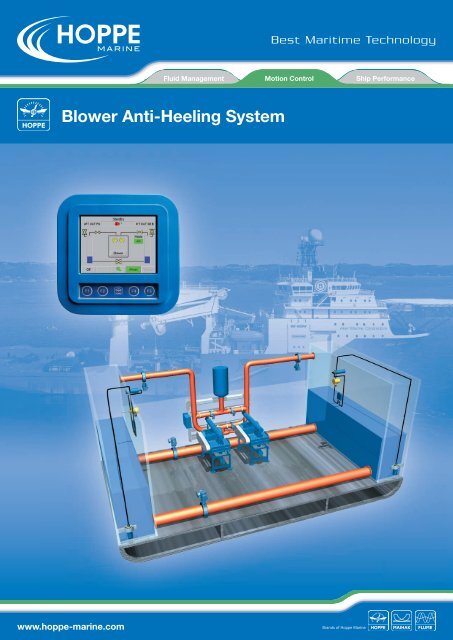

<strong>Blower</strong> <strong>Anti</strong>-<strong>Heeling</strong> <strong>System</strong><br />

www.hoppe-marine.com<br />

Best Maritime Technology<br />

Brands of <strong>Hoppe</strong> <strong>Marine</strong><br />

Ship Performance

<strong>Blower</strong> <strong>Anti</strong>-<strong>Heeling</strong> <strong>System</strong><br />

www.hoppe-marine.com<br />

<strong>System</strong> Overview<br />

The <strong>Blower</strong> <strong>Anti</strong>-<strong>Heeling</strong> <strong>System</strong> is designed for high fl exibility<br />

and short reaction time to support heavy load operations.<br />

Our extensive experience dealing with heel angle correction<br />

is the foundation for these special designs which allow<br />

easy and safe handling in port, as well as during offshore<br />

operations. These systems can be combined with a U-Tank<br />

Stabilization <strong>System</strong> to enable the roll damping tank to be<br />

used for heel compensation and/or ice-heeling purposes.<br />

The closed system consists of one or more side tank pairs<br />

which are connected with air pipes on the top and water<br />

pipes close to the bottom. The compressed air from the<br />

blower unit(s) is used to shift the water between the side<br />

tanks and maintain the water level during operation. The air<br />

fl ow is controlled by a valve group to the tanks and back to<br />

the atmosphere via a silencer. The whole system is constantly<br />

pressurized and levels are monitored by in-house designed<br />

sensor units. All system data is processed in the PLC unit<br />

Valves <strong>Blower</strong><br />

Unit<br />

Control and Operation Panel<br />

Starter Cabinet / Substation<br />

with I/O-Modules<br />

HOMIP with integrated 6“ touch screen and is also<br />

displayed on the larger touch screens of the operation<br />

panels. The control system is designed for either automatic<br />

or manual operation under supervision of a crew member.<br />

Control Unit<br />

HOMIP<br />

Sensors Level<br />

Switch<br />

Key Features<br />

• Short reaction time in combination with high heel<br />

compensation rates<br />

• Variable tank confi guration and performance<br />

• Easy operation by clear, custom designed visualisation<br />

• Automatic or manual operation mode including<br />

pre-heel function<br />

• Can be combined with a U-Tank Stabilizer<br />

• Optional Ice-<strong>Heeling</strong> operation mode<br />

• Suitable for heavy load moment control<br />

• All major electronic components are type approved by<br />

major classifi cation societies<br />

Ship Inertial<br />

Measuring<br />

HOSIM

<strong>Blower</strong> <strong>Anti</strong>-<strong>Heeling</strong> <strong>System</strong><br />

Components<br />

• Touch screen control panels<br />

• <strong>Blower</strong> units; noise reduction covers (optional); silencer<br />

• Motor starter cabinet<br />

• Valve control cabinets<br />

• Valve group consisting of butterfl y valves with<br />

pneumatic actuators<br />

• Butterfl y valves with pneumatic actuators for<br />

pipe systems<br />

• Sensors and level switches for tank content<br />

measurement and pressure monitoring<br />

• Inclinometer for static heel measurement<br />

• Inertial measuring unit (HOSIM) for dynamic heel<br />

measurement (optional)<br />

Performance Overview<br />

The system performance is determined by tank design,<br />

number and performance of blower units.<br />

<strong>System</strong> with<br />

one blower unit<br />

two blower units<br />

three and more<br />

blower units<br />

Compensation<br />

Rates in<br />

tm/min<br />

500 to 1,000<br />

1,000 to 3,500<br />

up to 6,000<br />

and more<br />

<strong>Blower</strong> <strong>System</strong> Control Mimic<br />

Flow Rates<br />

in<br />

m 3 /h<br />

1,500 to 3,000<br />

3,500 to 6,500<br />

up to 10,000<br />

and more<br />

Best Maritime Technology<br />

Valve group with pneumatic actuators<br />

<strong>Blower</strong> unit<br />

Pressure sensors & level switch<br />

Brands of <strong>Hoppe</strong> <strong>Marine</strong>

<strong>Blower</strong> <strong>Anti</strong>-<strong>Heeling</strong> <strong>System</strong><br />

Fluid Management Motion Control Ship Performance<br />

• Valve Remote Control<br />

• Tank Content Measuring<br />

• Bunker Management<br />

• Ballast Management<br />

• Water Ingress Detection<br />

<strong>Hoppe</strong> <strong>Marine</strong> GmbH<br />

Kieler Straße 318<br />

22525 Hamburg<br />

Germany<br />

Tel. +49-40-561949-0<br />

info@hoppe-marine.com<br />

www.hoppe-marine.com<br />

www.hoppe-marine.com<br />

Upgrade Options<br />

Heavy Lift Load Compensation<br />

<strong>Hoppe</strong> also offers an advanced <strong>Anti</strong>-<strong>Heeling</strong> <strong>System</strong> with<br />

a special load moment control. The heeling moments of,<br />

for example, heavy crane operations are recorded and<br />

used to automatically determine the required heel angle<br />

correction moments. The <strong>Blower</strong> <strong>Anti</strong>-<strong>Heeling</strong> <strong>System</strong><br />

ensures immediate fl ow control reaction time.<br />

In the case of offshore heel operation, <strong>Hoppe</strong>’s inertial<br />

measuring unit HOSIM is used to accurately determine the<br />

vessel’s sea motion and eliminate its effect so that the heel<br />

compensation can be executed correctly, even at sea.<br />

• <strong>Anti</strong>-<strong>Heeling</strong><br />

• <strong>Blower</strong> <strong>Anti</strong>-<strong>Heeling</strong><br />

• Flume Stabilization<br />

• U-Tank Stabilization<br />

• Dynamic Floating Monitoring<br />

• Dynamic Trim and<br />

Conning Measuring<br />

• Draught Measuring<br />

• Stabilty Test<br />

<strong>Hoppe</strong> China Co., Ltd.<br />

German Center, Room 708, Tower 1<br />

88 Keyuan Road<br />

201203 Shanghai Pudong<br />

China<br />

Tel. +86-21-50278040<br />

service@hoppe-china.com<br />

www.hoppe-china.com<br />

Best Maritime Technology<br />

Ice-<strong>Heeling</strong><br />

The system can also be used for ice-heeling operations<br />

on ice breakers. It is used to heel the vessel fully from port<br />

to starboard so that the vessel does not get stuck in ice.<br />

Such a system requires fast reaction times and large<br />

heel moments.<br />

Combination with U-Tank Stabilization <strong>System</strong><br />

The <strong>Blower</strong> <strong>Anti</strong>-<strong>Heeling</strong> <strong>System</strong> can be combined with<br />

a U-Tank Stabilization <strong>System</strong> using the same tanks.<br />

During loading operations, the <strong>Blower</strong> <strong>System</strong> provides<br />

heel angle compensation. While at sea or during offshore<br />

operations, the U-Tank Stabilization <strong>System</strong> works as a<br />

controlled passive roll reduction system to minimize the<br />

vessel’s roll.<br />

<strong>Blower</strong> <strong>Anti</strong>-<strong>Heeling</strong> with U-Tank Stabilizer HOMIP with Ice-<strong>Heeling</strong> visualisation<br />

• Maihak Shaft Power Meter<br />

• Torque Power Meter<br />

• Maihak Performance Meter<br />

• Maihak Performance<br />

Monitoring<br />

• Maihak Performance<br />

Optimization<br />

<strong>Hoppe</strong> Korea Co., Ltd.<br />

No 485-3, Gu Pyeong-Dong, Sa Ha-Gu<br />

604-866 Busan<br />

Republic of Korea<br />

Tel. +82-51-4035851<br />

hoppe@korea.com<br />

www.hoppe-korea.com<br />

Brands of <strong>Hoppe</strong> <strong>Marine</strong>