Semper Tan Brochure.indd

Semper Tan Brochure.indd

Semper Tan Brochure.indd

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Operation<br />

<strong>Semper</strong> <strong>Tan</strong><br />

The Complete “Desert <strong>Tan</strong>” Solution<br />

United States United Kingdom Germany France Nordic Italy Spain Japan<br />

April 2011

Glenair: The Only Interconnect System<br />

Supplier to Offer Our Military Customer a<br />

Complete “Desert <strong>Tan</strong>” Solution<br />

Glenair now off ers a complete range of interconnect component materials suitable for use in military applications<br />

that require (or would prefer) FED-STD-33446 Desert <strong>Tan</strong> colored and conductive parts over other available colors<br />

such as CAD green or black. Materials and components successfully developed by Glenair now include cable jacketing,<br />

shrink boots, composite connectors and accessories, junction boxes, fabric cable braid, convoluted tubing, and more.<br />

The materials are intended for use on military vehicles, equipment trailers, soldier systems and other ground-based or<br />

ground-deployed applications.<br />

2<br />

Operation <strong>Semper</strong> <strong>Tan</strong><br />

OPERATION SEMPER TAN (XD) PRODUCTS<br />

Harsh Environment Cable Jacketing and Overmolding<br />

High-Temperature Heat Shrink Boots and Transitions<br />

Composite Thermoplastic Connectors and Accessories<br />

Rugged Fabric Cable Overbraid<br />

Annular Convoluted Tubing<br />

Corrosion-Proof Composite Junction Boxes<br />

Injection-Molded Cable Assemblies

<strong>Semper</strong> <strong>Tan</strong> Tubular Braid<br />

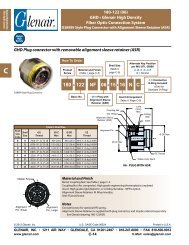

103 - 013 - 008 TN<br />

Tubular<br />

Braid<br />

Dash<br />

No.<br />

004<br />

008<br />

012<br />

016<br />

024<br />

040<br />

Nomex<br />

Dash<br />

Number<br />

(Size, Table I)<br />

Nominal<br />

I.D.<br />

.125 (3.2)<br />

.250 (6.4)<br />

.375 (9.5)<br />

.500 (12.7)<br />

.750 (19.1)<br />

1.250 (31.8)<br />

Desert<br />

<strong>Tan</strong><br />

TABLE I<br />

Wire Bundle<br />

Accomodation Range Ref.<br />

Min.<br />

.090 (2.3)<br />

.125 (3.2)<br />

.312 (7.9)<br />

.250 (6.4)<br />

.500 (12.7)<br />

.750 (19.1)<br />

770 - 001 A 1 00 W1 - TAN<br />

Full Nelson<br />

Heat-Shrink<br />

Boots<br />

Max.<br />

.250 (6.4)<br />

.375 (9.5)<br />

.500 (12.7)<br />

.750 (19.1)<br />

1.250 (31.8)<br />

1.500 (38.1)<br />

Series 77 Full Nelson Desert <strong>Tan</strong> Shrink Boots<br />

4<br />

Standard<br />

Lipped<br />

Boot with<br />

Eyelet Eyelet<br />

Angle and<br />

Profi le<br />

A = 90°<br />

Boot<br />

Material<br />

1 = High<br />

Performance<br />

Elastomer<br />

Boot Size Desert<br />

<strong>Tan</strong><br />

Adhesive<br />

Type<br />

W1 =<br />

Standard Hot<br />

Melt<br />

Table 1: Boot Size Selection Guide<br />

Adapter Diameter Min. Cable<br />

Boot Inches Millimeters Diameter<br />

Size Min Max Min Max In. mm.<br />

02 .350 .625 8.89 15.88 .175 4.45<br />

03 .450 .850 11.43 21.59 .225 5.72<br />

04 .575 1.000 14.61 25.40 .250 6.35<br />

05 .750 1.200 19.05 30.48 .300 7.62<br />

06 .950 1.350 24.13 34.29 .375 9.53<br />

07 1.150 1.600 29.21 40.64 .425 10.80<br />

08 1.600 2.000 40.60 50.80 .650 16.50<br />

09 1.780 2.550 45.20 64.80 .700 17.80

<strong>Semper</strong> <strong>Tan</strong> Composite Junction Boxes<br />

TABLE II: MATERIAL COLOR & FINISH OPTIONS<br />

Sym Material & Color Finish Options<br />

B Thermoplastic / Black XO and XMS<br />

D Thermoplastic / Desert <strong>Tan</strong> XO and XMS<br />

G Thermoplastic / Grey XO and XMS<br />

– Thermoplastic / NA XM, XW and XZN<br />

<strong>Semper</strong> <strong>Tan</strong> D38999 Series III<br />

Composite Protective Covers<br />

Basic Part Number<br />

660-049 - Plug<br />

660-050 - Receptacle<br />

Finish Symbol<br />

(See Table II)<br />

Connector<br />

Shell Size<br />

(See Table I)<br />

660-049 XD 21 R 6 - 04<br />

Attachment Type<br />

See Table III<br />

on Page B-2<br />

Attachment Length<br />

(In Inches)<br />

Ring Style Dash Number<br />

See Tables IV, V, VI and VII<br />

on Page B-2<br />

TABLE I: CONNECTOR SHELL SIZE ORDER NUMBER<br />

SHELL A B DIA C DIA<br />

SIZE THREAD MAX MAX<br />

09 .6250 -0.1P-0.3L-TS .906 (23.0) .906 (23.0)<br />

11 .7500 -0.1P-0.3L-TS 1.024 (26.0) 1.102 (28.0)<br />

13 .8750 -0.1P-0.3L-TS 1.220 (31.0) 1.220 (31.0)<br />

15 1.0000 -0.1P-0.3L-TS 1.300 (33.0) 1.260 (32.0)<br />

17 1.1875 -0.1P-0.3L-TS 1.457 (37.0) 1.457 (37.0)<br />

19 1.2500 -0.1P-0.3L-TS 1.575 (40.0) 1.535 (39.0)<br />

21 1.3750 -0.1P-0.3L-TS 1.732 (44.0) 1.654 (42.0)<br />

23 1.5000 -0.1P-0.3L-TS 1.811 (46.0) 1.772 (45.0)<br />

25 1.6250 -0.1P-0.3L-TS 1.969 (50.0) 1.929 (49.0)<br />

Product Series<br />

140 - Composite Boxes<br />

Basic Part<br />

Number<br />

140 D 106 XMS - 0000<br />

Material Color<br />

Symbol<br />

(See Table II)<br />

Finish Symbol<br />

(See Table I)<br />

TABLE I: FINISHES<br />

Symbol Finish Description<br />

XO No Plating (Non-Conductive Finish)<br />

Dash Number<br />

XMS<br />

Internal Surfaces - Electroless Nickel<br />

External Surfaces - See Table II<br />

XM All Surfaces – Electroless Nickel<br />

XW All Surfaces – Cadmium Olive Drab over Electroless Nickel<br />

XZN All Surfaces – Zinc Nickel/Black<br />

XMT<br />

2000 Hour Corrosion Resistant Ni-PTFE, Nickel-<br />

Fluorocarbon Polymer. 1000 Hour Grey TM<br />

TABLE II<br />

Symbol Finish Description<br />

XB<br />

XD<br />

XMD<br />

XM<br />

XMT<br />

XW<br />

Black Color - No Plating<br />

(Non-Conductive Finish)<br />

Desert <strong>Tan</strong> Color - No Plating<br />

(Non-Conductive Finish)<br />

Desert <strong>Tan</strong> Color - External Surfaces<br />

Electroless Nickel - Internal Surfaces<br />

2000 Hour Corrosion Resistant<br />

Electroless Nickel<br />

2000 Hour Corrosion Resistant<br />

Ni-PTFE, Nickel-Fluorocarbon<br />

Polymer. 1000 Hour Grey TM<br />

2000 Hour Corrosion Resistant<br />

Cadmium/Olive Drab over<br />

Electroless Nickel<br />

5

<strong>Semper</strong> <strong>Tan</strong> Composite Connectors<br />

Shell<br />

Size<br />

Code<br />

Shell<br />

Size<br />

TABLE III: SHELL SIZE<br />

CC<br />

Max<br />

Dia<br />

DD<br />

Max<br />

Dia<br />

EE<br />

Thread<br />

A 09 .811 (20.6) .858 (21.8) M12 x 1.0-6g 0.100R<br />

B 11 .929 (23.6) .984 (25.0) M15 x 1.0-6g 0.100R<br />

C 13 1.110 (28.2) 1.157 (29.4) M18 x 1.0-6g 0.100R<br />

D 15 1.232 (31.3) 1.280 (32.5) M22 x 1.0-6g 0.100R<br />

E 17 1.358 (34.5) 1.406 (35.7) M25 x 1.0-6g 0.100R<br />

F 19 1.469 (37.3) 1.516 (38.5) M28 x 1.0-6g 0.100R<br />

G 21 1.594 (40.5) 1.642 (41.7) M31 x 1.0-6g 0.100R<br />

H 23 1.720 (43.7) 1.768 (44.9) M34 x 1.0-6g 0.100R<br />

J 25 1.843 (46.8) 1.890 (48.0) M37 x 1.0-6g 0.100R<br />

<strong>Semper</strong> <strong>Tan</strong> Composite<br />

Shrink Boot Adapters<br />

6<br />

Product Series<br />

310 - Shrink Boot<br />

Adapter<br />

Angle and Profi le<br />

S - Straight<br />

Connector Designator<br />

A, F or H<br />

Basic Part<br />

Number<br />

Desert <strong>Tan</strong><br />

No Plating,<br />

Non-Conductive<br />

310 F S 045 XD 16 D T<br />

Connector Shell Size<br />

(See Table II)<br />

Basic Part Number<br />

233-105 - D38999 Series III Type<br />

Power and Signal Connector<br />

Finish Material<br />

(See Table II)<br />

TABLE II: FINISH<br />

SYM MATERIAL CONDUCTIVE ELEMENTS<br />

XMD<br />

XMTD<br />

XWD<br />

Desert <strong>Tan</strong><br />

Composite<br />

Desert <strong>Tan</strong><br />

Composite<br />

Desert <strong>Tan</strong><br />

Composite<br />

Electroless Nickel<br />

Contact Type<br />

(See Table I)<br />

Ni-PTFE 1000 Hour Grey TM<br />

Cadmium O.D. Over<br />

Electroless Nickel<br />

*Consult Factory for Additional Plating Options<br />

Alternate Key<br />

Position<br />

A, B, C, D, or E<br />

(N for Normal)<br />

233-105 - G6 XMD 21 - 11 S N<br />

Drain Holes<br />

(Omit for None)<br />

Shrink Boot<br />

(Omit for None)<br />

Shell Style<br />

G6 - Plug<br />

Shell<br />

Size<br />

Shell Size<br />

09<br />

11<br />

13<br />

13L<br />

15<br />

15L<br />

17<br />

17L<br />

19<br />

19L<br />

21<br />

21L<br />

23<br />

23L<br />

25<br />

25C<br />

25L<br />

25Q<br />

TABLE II: SHELL SIZE<br />

E<br />

Max<br />

Insert Arrangement<br />

per MIL-STD-1560<br />

and JSFD08<br />

F<br />

Max<br />

Cable Entry<br />

Min.<br />

A, F H<br />

08 09 .533 (13.5) .940 (23.9) .250 (6.4)<br />

10 11 .605 (15.4) .940 (23.9) .355 (9.0)<br />

12 13 .774 (19.7) .940 (23.9) .491 (12.5)<br />

14 15 .838 (21.3) .940 (23.9) .565 (14.4)<br />

16 17 .963 (24.5) .940 (23.9) .690 (17.5)<br />

18 19 1.042 (26.5) .940 (23.9) .769 (19.5)<br />

20 21 1.217 (30.9) .940 (23.9) .894 (22.7)<br />

22 23 1.355 (34.4) .940 (23.9) 1.019 (25.9)<br />

24 25 1.443 (36.7) .940 (23.9) 1.134 (28.8)

<strong>Semper</strong> <strong>Tan</strong> Overmolded Cables<br />

Glenair now off ers high-performance cable jacketing and overmolding materials that provide<br />

outstanding, damper-proof environmental protection for cables and conduit used in harsh<br />

application environments. The materials are ideally suited for high-heat environments (up to 200° C<br />

continuous) and withstand all common forms of caustic chemicals and fuels per MIL STD 810F, Method<br />

4. The material conforms to additional military performance requirements such as accelerated UV<br />

weathering per IEC 60068-2-5 and is halogen free and fl ame resistant per IEC 60614-1.<br />

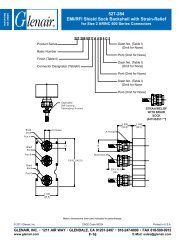

<strong>Semper</strong> <strong>Tan</strong> EMI-RFI Shielded and Jacketed<br />

Metal-Core Conduit Assemly<br />

750 - 172 - 16 TN<br />

Product<br />

Series<br />

Basic<br />

Number<br />

Dash<br />

No<br />

Dash<br />

Number<br />

(Table I)<br />

Table I<br />

A Dia +.015 (0.4)<br />

-.000 (0.0)<br />

TN = Desert <strong>Tan</strong> Jacket<br />

B Dia<br />

±.03 (.8)<br />

06 .187 (4.7) .44 (11.2)<br />

08 .250 (6.3) .52 (13.2)<br />

09 .281 (7.1) .56 (14.2)<br />

12 .375 (9.5) .64 (16.3)<br />

16 .500 (12.7) .77 (19.6)<br />

20 .625 (15.9) .89 (22.6)<br />

24 .750 (19.1) 1.03 (26.2)<br />

32 1.000 (25.4) 1.28 (32.5)<br />

40 1.250 (31.8) 1.65 (41.9)<br />

48 1.500 (38.1) 1.88 (47.8)<br />

64 2.000 (50.8) 2.40 (61.0)<br />

80 2.500 (63.5) 2.86 (72.6)<br />

7

<strong>Semper</strong> <strong>Tan</strong> EMI/RFI Helical Tubing Assembly<br />

8<br />

Product<br />

Series<br />

Basic<br />

Number<br />

Convolution<br />

1 = Standard<br />

2 = Close<br />

121 - 184 - 1 - 1 - 16 B E T TN<br />

Class<br />

1 = Standard Wall<br />

2 = Thin Wall<br />

Table II<br />

Sym Tubing Material<br />

E ETFE, Tefzel<br />

F FEP, Tefl on<br />

K PEEK<br />

P PFA, Tefl on<br />

Dash<br />

No<br />

Fractional<br />

Size Ref<br />

Dash<br />

Number<br />

(Table I)<br />

Conduit Color<br />

B = Black<br />

C = Clear<br />

Table I<br />

A Inside Dia<br />

Min Max<br />

Tubing<br />

Material<br />

(Table II)<br />

Braided<br />

Shield<br />

Option<br />

(Table III)<br />

Table IIi<br />

Sym Braided Shield<br />

B Bronze<br />

C Stainless Steel<br />

N Nickel Copper<br />

S SnCuFe<br />

T Tin Copper<br />

TN = Desert <strong>Tan</strong> Jacket<br />

(Omit for Standard Black)<br />

B Dia Max<br />

06 3/16 0.181 (4.6) 0.188 (4.8) 0.490 (0.5)<br />

09 9/32 0.273 (6.9) 0.281 (7.1) 0.584 (0.6)<br />

10 5/16 0.306 (7.8) 0.312 (7.9) 0.620 (0.6)<br />

12 3/8 0.359 (9.1) 0.375 (9.5) 0.680 (0.7)<br />

14 7/16 0.427 (10.8) 0.437 (11.1) 0.741 (0.7)<br />

16 1/2 0.480 (12.2) 0.500 (12.7) 0.820 (0.8)<br />

20 5/8 0.603 (15.3) 0.625 (15.9) 0.940 (0.9)<br />

24 3/4 0.725 (18.4) 0.750 (19.1) 1.000 (1.0)<br />

28 7/8 0.860 (21.8) 0.875 (22.2) 1.243 (1.2)<br />

32 1 0.970 (24.6) 1.000 (25.4) 1.396 (1.4)<br />

40 1 1/4 1.205 (30.6) 1.250 (31.8) 1.709 (1.7)<br />

48 1 1/2 1.437 (36.5) 1.500 (38.1) 2.002 (2.0)<br />

56 1 3/4 1.688 (42.9) 1.750 (44.5) 2.252 (2.3)<br />

64 2 1.937 (49.2) 2.000 (50.8) 2.502 (2.5)

Master Seal Self-Vulcanizing Sealing Tape<br />

Glenair Duralectric weatherproof jacketing is halogen free, fl ame resistant, and functional to 260˚C. Duralectric<br />

far surpasses the accelerated solar weathering standards under IEC 60068-2-5, and is tested to 56 accelerated<br />

days, equivalent to 53 years of solar exposure. Glenair can supply the material in a variety of formats, including<br />

blown jacketing, as an extrusion over wire and cable, as an overmolding compound and as a self-vulcanizing<br />

“stretch-to-activate” repair tape.<br />

Originally qualifi ed to the US navy Mil-PRF-24758A specifi cation, Duralectric is available in standard US Navy<br />

haze gray in accordance with Fed Std 595B #26270. Other colors are also standard including black, and Fed<br />

Std #3446 Desert <strong>Tan</strong>. Additional Made-to-Order colors are available. The material has the following performance<br />

characteristics:<br />

GLENAIR Duralectric MATERIAL SPECIFICATIONS<br />

Temperature rating: -70°C to +200°C (with excursions to 260°C)<br />

Halogen free per iec 60614-1. Less than 5mg of hcl per 1 gm of product tested.<br />

Accelerated Weathering (Solar) per IEC 60068-2-5; 56 days exposure<br />

Flame Resistant per IEC 60614-1; Material does not sustain combustion when the source of fl ame is removed.<br />

Low Smoke Index per NES 711 (11.75); Minimum standard is 25. The Glenair tested level is 11.75. This makes<br />

the material acceptable for interior applications as well as topside.<br />

Smoke Density Class F1 Per NF F 16-101 IAW DIN EN 60695-2-11:2001<br />

Toxicity Index per NES 713 (1.9); Minimum standard is 5. The Glenair tested level is 1.9. This makes the<br />

material acceptable for interior applications as well as topside.<br />

Colorable to Fed Std 595B<br />

Markable IAW MIL-PRF-24758A<br />

Oxygen Limiting Index = 45.1 Per EN ISO 4589-2:1999; Minimum is 28.<br />

12 Sec Vertical Burn: (Pass) Per 14CFR Part 25.853(a) amdt 25-116 App F Part 1 (a)(1)(ii)<br />

Fluids Per MIL STD 810F, Method 504<br />

Fuel (MIL-T-83133): JPG<br />

Hydraulic Fluid (MIL H 5606): ROYCO 756<br />

Lube Oil (MIL-L-23699): ROYCO-500<br />

Cleaner (MIL-C-85570): CALLA-855<br />

Solvent (Isopropyl Alcohol): TT-I-735<br />

De Icer (AMS-1432): E36 Runway Deicer<br />

Coolant (MIL-C-87252): Coolanol 25R<br />

Fire Extinguishant Foam: AMEREX AFFF<br />

MASTER<br />

SEAL Self-Vulcanizing<br />

Sealing Tape<br />

GLENAIR PART NO.<br />

687-758 T<br />

Duralectric material sealing<br />

tape designed for temporary<br />

repair of cable and conduit.<br />

Glenair Master Seal effectively<br />

stops water incursion until a<br />

permanent repair can be made.<br />

9

SEMPER TAN<br />

The Permanent FED-STD-33446<br />

Desert <strong>Tan</strong> Solution<br />

Maintenance-Free Desert <strong>Tan</strong> Cables,<br />

Conduits, Junction Boxes and More<br />

The parts shown on these pages are just examples of the unlimited range of Desert <strong>Tan</strong> interconnect solutions<br />

supplied by Glenair. Please don’t hesitate to ask the factory for guidance on converting virtually any interconnect<br />

component or system to <strong>Semper</strong> <strong>Tan</strong>—the permanent FED-STD-33446 Desert <strong>Tan</strong> solution that eliminates the costly<br />

labor of manually painting and maintaining standard cables, conduit assemblies, and junction boxes used in military<br />

applications. Recently, one of our customers requested a <strong>Semper</strong> <strong>Tan</strong> version of our popular high-temperature annular<br />

tubing (hylar or trade name Kynar). Glenair was able to produce the product shown below in just a few short weeks<br />

and it is now being used in a military vehicle application. Please consult the factory for this and other innovative<br />

<strong>Semper</strong> <strong>Tan</strong> solutions.<br />

10<br />

Hylar (trade name<br />

Kynar) <strong>Semper</strong> <strong>Tan</strong><br />

annular tubing