0317 0054 REV B E-Sea Hooks.indd

0317 0054 REV B E-Sea Hooks.indd

0317 0054 REV B E-Sea Hooks.indd

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

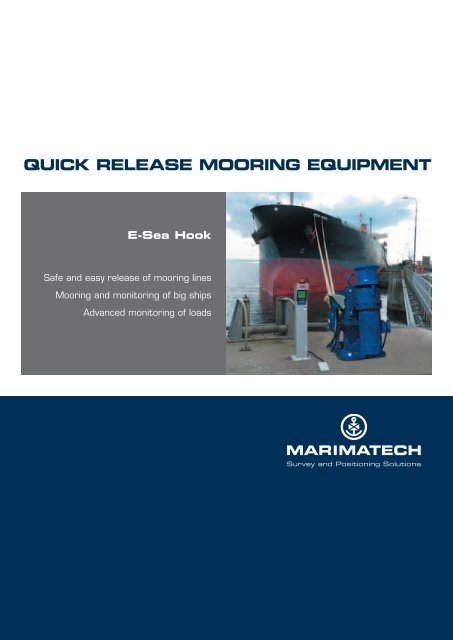

QUICK RELEASE MOORING EQUIPMENT<br />

E-<strong>Sea</strong> Hook<br />

Safe and easy release of mooring lines<br />

Mooring and monitoring of big ships<br />

Advanced monitoring of loads

The E-<strong>Sea</strong> Hook System<br />

MARIMATECH is the world leader in LASER DOCK-<br />

ING SYSTEMS and MOORING LOAD MONITORING<br />

SYSTEMS. A logical consequence of this market<br />

position has been to add Quick Release Mooring<br />

<strong>Hooks</strong> into our range of products, enabling us to<br />

offer complete integrated systems.<br />

16 years of experience with our own Mooring Load<br />

Monitoring Systems and various designs of Quick<br />

Release <strong>Hooks</strong> (QRH) have given us a solid experience,<br />

which has resulted in a QRH design, that<br />

meets the requirements of the latest safety standards<br />

as well as a new dimension of automations.<br />

Typical Applications are:<br />

Oil jetties<br />

LNG/LPG jetties<br />

Single Point Mooring (SPM)<br />

Offshore FSO/FPSO<br />

Ferry terminals<br />

The E-<strong>Sea</strong> hook comes in a large number of variations<br />

covering hook capacity from 10 ton up to<br />

250 ton. They can be delivered with just manual<br />

release as well as electrical and hydraulic remote<br />

operated release systems. The E-<strong>Sea</strong> <strong>Hooks</strong><br />

are often fi tted with load pins, to measure the<br />

dynamic load in the mooring lines. The QRH is<br />

equipped with integrated or freestanding capstans<br />

designed to the required pulling load. In<br />

addition to the basic functions the E-<strong>Sea</strong> Hook<br />

offers a number of new refi nements to improve<br />

safety and automations.<br />

2<br />

E-SEA HOOK<br />

E-<strong>Sea</strong> Hook Features<br />

Individual design<br />

Durable construction<br />

Wide range of applications<br />

Maintenance limited to greasing<br />

High accuracy load pins<br />

“Black-box” integrated into QRH<br />

Local SAFEGUARD system<br />

Integrated remote operation and monitoring<br />

Loop data cabling providing redundancy<br />

Low cable costs<br />

Performance<br />

The E-<strong>Sea</strong> Hook meets the latest requirements of<br />

handling mooring lines with a minimum of labour,<br />

to be able to release mooring lines in an emergency<br />

situation under any load conditions. The<br />

wide range of hooks covers ships of any size and<br />

type. The E-<strong>Sea</strong> Hook is designed for hazardous<br />

areas as well to comply with the international<br />

regulations now also including ATEX.<br />

R E GI E R E D FIR M<br />

“Accredited by INMETRO”<br />

NOTE:<br />

This certifi cate belongs to the hook manufacturer<br />

SAMGONG CO., LTD

The characteristics of the E-<strong>Sea</strong><br />

Hook are:<br />

E-<strong>Sea</strong> Hook<br />

Capacity from 10 to 250 tons<br />

Manual operation possible with force below 10 kg<br />

Hook automatic return under load<br />

Manual return with force below 5 kg<br />

Safety locking device to prevent an accidental<br />

release<br />

Operation of QRH completely spark free<br />

Individual hook release<br />

Electrical or hydraulic remote quick release<br />

Stainless steel foot hybrid switch for capstan<br />

with no moving parts<br />

Remote QRH panel to cover any confi guration<br />

Hook status and load readout at remote QRH<br />

panel<br />

Local and remote alarm management<br />

Mooring Load Monitoring System<br />

Load pins factory calibrated allowing random<br />

installation<br />

Load monitoring accuracy better than ± 1% of<br />

full scale<br />

Load pins made with redundant strain gauges<br />

SAFEGUARD panel to include hook monitoring<br />

and operation<br />

Integrated “Black-box” that will record continuous<br />

12 months operation<br />

Several of the above functions can be deselected<br />

if not needed to be able to meet cost requirements.<br />

Fundamental advantages with<br />

E-<strong>Sea</strong> Hook are:<br />

Excellent value for money<br />

Low profi le and compact design<br />

Each hook can move independently in both<br />

Levels<br />

Each hook is factory tested to 1.5 times nominal<br />

load<br />

<strong>Hooks</strong> are released from safe position<br />

Remote QRH panel in safe and hazardous<br />

design<br />

Multiple connection of QRH panels<br />

Capstans delivered with automatic brake<br />

No maintenance apart from regular greasing<br />

Fabrication under ISO 9001/ATEX regulation<br />

E-SEA HOOK<br />

E-<strong>Sea</strong> Hook with SAFEGUARD panel<br />

System Components<br />

The E-<strong>Sea</strong> Hook system has a modular design<br />

that makes it possible to meet nearly any requirements.<br />

Solutions from cost effective manual types<br />

to remote operated systems that optional can be<br />

equipped with load pins, display/alarm panels and<br />

hook status management. Everything is designed<br />

for extreme conditions. Even the associated electronics<br />

is made of mil classifi ed components to<br />

withstand environmental conditions in the range<br />

of –20°C to +85°C.<br />

The hook itself is designed to be operated without<br />

using force of any kind to avoid damage to<br />

personnel. The capstans are delivered with brake<br />

motors and the operation takes place from a foot<br />

hybrid switch, made of stainless steel. There are<br />

no moving parts and the foot switch controls both<br />

pull-in and payout. The foot hybrid switch is easy<br />

removable to avoid damage.<br />

The hook foot switch is IP68 and no moving parts<br />

3

The Safeguard Panel<br />

The SAFEGUARD panel is the local display and<br />

operating panel from where the user operates<br />

the hook station. This panel with all its options<br />

contains the following:<br />

Remote operation of the Quick Release function<br />

Display that indicates the hook loads<br />

Alarm that will activate sound and fl ash in case<br />

of overload<br />

Connector for removable foot hybrid switch<br />

The advantage of the SAFEGUARD panel is that the<br />

operator has control of the hook release function<br />

from a safe location. Furthermore the display<br />

will indicate the hook station status and provide<br />

alarms in case of malfunction and overload. The<br />

panel is designed for hazardous area and the<br />

construction is made of stainless steel 316.<br />

Mooring Load Monitoring<br />

Quick Release <strong>Hooks</strong> fi tted with load pins have<br />

integrated the LMS-4 amplifi er and input/output<br />

module. This module takes control of all functionality<br />

on the hook station also including the optional<br />

Remote Quick Release operation. The LMS-4 has<br />

internal memory (Black-box function) that automatically<br />

will keep up to one year of history in the<br />

memory. The data and control line is LAN/Ethernet<br />

allowing for both electrical and fi bre optical<br />

connection.<br />

The load cells are EEx certifi ed. They are fi lled<br />

with a special compound to avoid condensation<br />

as well as protecting all components from the<br />

release chock. Cables are protected in hydraulic<br />

hoses made of a material that will withstand salty<br />

marine environment. The load cells are fi tted with<br />

redundant gauging (built-in spare).<br />

4<br />

E-SEA HOOK<br />

SAFEGUARD panel and capstan hybrid foot activator for<br />

capstan (no moving parts)<br />

LMS 4 module<br />

Load Pins

Remote Quick Release Control<br />

The E-<strong>Sea</strong> <strong>Hooks</strong> can be equipped with a Remote<br />

Quick Release option that can be all electric or<br />

hydraulic activated. The hydraulic offers back-up<br />

pressure for release from the power pack should<br />

the main electrical power fail.<br />

The remote quick release panel is designed for<br />

safe and easy operation. It can be located in both<br />

safe and hazardous areas and several panels can<br />

be connected offering control from more than on<br />

location. The panel has built-in display providing<br />

the user with mooring load data as well as status<br />

and alarm functions.<br />

The panel is made of stainless steel and fi ts into a<br />

19” rack consoles as well as ordinary cabinets.<br />

Principles of Operation<br />

The E-<strong>Sea</strong> Hook is designed for both manual and<br />

remote control. It has been a demand in the design<br />

that the hooks are easy to open and close with<br />

extreme low force. This design leads to increased<br />

safety. The electrical system is the LAN/Ethernet<br />

which simplifi es cabling and the latest option is<br />

allowing us to establish a loop network. Should a<br />

cable break in the loop the functionality is not lost.<br />

The below schematic shows a typical network that<br />

also allows connecting other sensors, displays<br />

etc. into the LAN data network.<br />

WIND<br />

SENSOR<br />

&<br />

DIRECTION<br />

CURRENT<br />

LMS 4<br />

LAN / ETHERNET AMPLIFIER & LMS 4<br />

INTERFACE BOX<br />

WAVE<br />

&<br />

TIDE<br />

E-SEA HOOK<br />

Remote quick release panel integrated into a 19” Rack cabinet<br />

HAND CARRIED<br />

ALARM PAGERS<br />

UHF or WLAN<br />

LMS 4 LMS 4 LMS 4 LMS 4 LMS 4 LMS 4<br />

QUAD TRIPLE DUAL DUAL<br />

TRIPLE<br />

QUAD<br />

EXAMPLE OF A LMS 4 MODULE CONNECTION, BASIC SYSTEM<br />

PAGER TRANSMITTER<br />

MONITOR<br />

CONTROL<br />

COMPUTER<br />

PRINTER<br />

5

DockMaster Software<br />

The DockMaster software package provides the<br />

users with easy to use graphical interfaces to<br />

monitor the system. The built in user management<br />

makes the system secure against confi guration<br />

failures. The system can easily be extended<br />

with an unlimited number of DockMaster clients<br />

without any loss of performance.<br />

System features<br />

Multiple users and workstations<br />

Support for different PC platforms<br />

(Linux,Windows, Sun Solaris…)<br />

Redundant data logging<br />

Software features<br />

Monitoring ship movements, the distance to the<br />

jetty, the approaching speed, the tendency and<br />

the approach angle<br />

Monitoring mooring status (mooring lines and<br />

drift)<br />

Monitoring environmental information<br />

Audio and visual indication of alarm and warning<br />

situations<br />

Automatic data logging and replay facilities<br />

Online and offl ine printouts of data and<br />

approaches<br />

Statistic information of approaches and environmental<br />

data<br />

Graphical representation of the whole harbour<br />

area (overview)<br />

Customisable user interfaces<br />

Precalculation of Mooring Loads<br />

A pre-calculation program (OPTIMOOR*) is available.<br />

OPTIMOOR calculates the theoretical loads to<br />

a given mooring pattern and ship from predicted<br />

wind loads and loads from sea current. The OPTI-<br />

MOOR works as an integrated part of the Mooring<br />

Master software.<br />

OPTIMOOR is a very useful tool for precalculating<br />

the loads in the mooring lines<br />

prior to the ships arrival.<br />

* Proberty of TensianTech<br />

6<br />

E-SEA HOOK<br />

Integrated display covering MLMS/BAS and EMS functionality<br />

The BAS docking screen with history<br />

Portable ADP for remote monitoring.<br />

Water-proof and explosion proof are available

The E-<strong>Sea</strong> Hook that meets your specifi c requirements<br />

30 to 250 Ton<br />

Automatic<br />

release<br />

Load pin<br />

The E-<strong>Sea</strong> Hook modular design allows you to design a hook station that will meet your needs<br />

Project management.<br />

In order to secure a successful implementation<br />

of a quick release hook system, MARIMATECH<br />

treats every job as a project rather than a standard<br />

installation.<br />

MARIMATECH has trained experts to take care<br />

of the different tasks within the project such as<br />

documentation, Factory Acceptance test, project<br />

management, training of personal etc<br />

Service.<br />

Hydraulic<br />

power pack<br />

Manual<br />

release<br />

SINGLE<br />

DUAL<br />

TRIPLE<br />

QUAD<br />

Motor starter &<br />

hook controller<br />

After the system is in operation MARIMATECH’s<br />

service and support staff are here to help in case<br />

of any problems. This can be done on an ad hoc<br />

basis or by choosing one of the service products<br />

we offer.<br />

Although the quality of the equipment is fi rst<br />

class, and we have done a good job to bring the<br />

maintenance down to a minimum, we recommend<br />

a preventive maintenance agreement in order to<br />

prolong the lifetime of the system.<br />

E-SEA HOOK<br />

Capstan for<br />

integration<br />

Hybrid foot<br />

switch<br />

Safeguard panel<br />

Local display &<br />

alarm management<br />

Insulation plate<br />

Free standing<br />

capstan<br />

7

SPECIFICATION AND PERFORMANCE DATA<br />

Manual type QRH (dual)<br />

E-<strong>Sea</strong> Hook<br />

SAFE WORKING LOADS (SWL):<br />

10-25-50-60-75<br />

100-125-150-250 ton<br />

(other capacities on request)<br />

Release load = SWL<br />

Test load = 1.5 x SWL<br />

Safety factor: 1.2 x test load<br />

Manual release force < 15 kg@SWL<br />

Capstan<br />

Brake motor type<br />

SWL: 1,0-1,5-2,0-2,5-3,0 ton<br />

Haulling speed: 15,20,25,30 m/min<br />

Supply voltage to be specifi ed<br />

Mounting base methods<br />

Concrete embedment<br />

Bolted to steel deck<br />

Welded onto steel deck<br />

Hook arrangement<br />

Different arrangements available<br />

<strong>Hooks</strong> can be installed on both sides of post<br />

Hook post delivered with or without capstans<br />

Free standing capstans<br />

MARIMATECH AS<br />

Samsøvej 31<br />

DK-8382 Hinnerup<br />

Denmark<br />

Phone +45 86 91 22 55<br />

Fax +45 86 91 22 88<br />

E-mail mail@marimatech.com<br />

Web www.marimatech.com<br />

R E GI E R E D FIR M<br />

Auto type QRH (dual)<br />

Options<br />

Insulation<br />

Load pins<br />

Remote quick release electrical<br />

Remote quick release hydraulic<br />

Hybrid foot activator<br />

Safeguard Panel (SP)<br />

Flash alarm for SP<br />

Audio Alarm for SP<br />

Control system<br />

Mooring Load Monitoring (MLMS), display and data<br />

management<br />

OPTIMOR pre load calculation software (option)<br />

Remote quick release panel for hazardous and safe<br />

area.<br />

LAN/Ethernet loop cable network<br />

Electrical & fi bre optical network<br />

Wireless data network<br />

“Black-Box” for each hook post is standard<br />

Raw data storage of 12 months<br />

Single Hook Double Hook Triple Hook Quadruple Hook<br />

Back to back quadruple<br />

Several other confi guration available<br />

Specifi cations may be changed without notice. 03/2005, <strong>0317</strong> <strong>0054</strong> <strong>REV</strong> B, Check www.marimatech.com for latest update.