CORELUBE 950 SER. WIRE ROPE OIL APPLICATOR

CORELUBE 950 SER. WIRE ROPE OIL APPLICATOR

CORELUBE 950 SER. WIRE ROPE OIL APPLICATOR

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

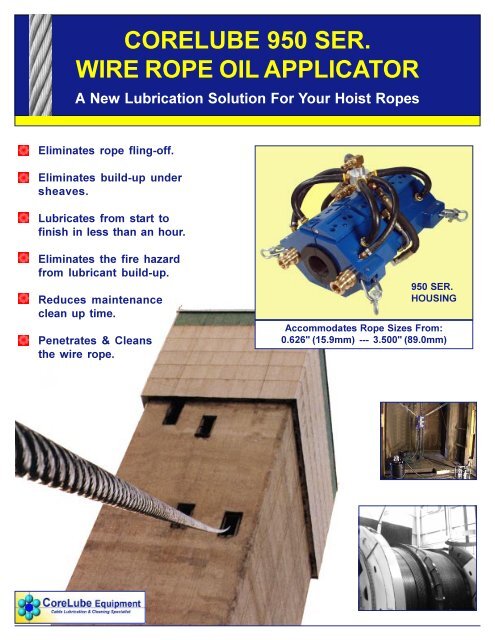

<strong>CORELUBE</strong> <strong>950</strong> <strong>SER</strong>.<br />

<strong>WIRE</strong> <strong>ROPE</strong> <strong>OIL</strong> <strong>APPLICATOR</strong><br />

A New Lubrication Solution For Your Hoist Ropes<br />

Eliminates rope fling-off.<br />

Eliminates build-up under<br />

sheaves.<br />

Lubricates from start to<br />

finish in less than an hour.<br />

Eliminates the fire hazard<br />

from lubricant build-up.<br />

Reduces maintenance<br />

clean up time.<br />

Penetrates & Cleans<br />

the wire rope.<br />

<strong>950</strong> <strong>SER</strong>.<br />

HOUSING<br />

Accommodates Rope Sizes From:<br />

0.626" (15.9mm) --- 3.500" (89.0mm)

<strong>950</strong> <strong>SER</strong>.<br />

HOUSING<br />

CoreLube solves the problem of hoist rope fling-off and the<br />

labour associated with the clean up.<br />

STRAINER<br />

BASKET<br />

SUCTION<br />

STRAINER<br />

HARD CENTRALIZING<br />

BUSHING SET<br />

The Problem Solving<br />

Solution of the year.<br />

MANIFOLD<br />

BREATHER LID<br />

LINER SET<br />

PUMP<br />

The <strong>950</strong> Ser. CoreLube System comes complete<br />

as shown with 1 Liner Set & 1 Bushing Set.<br />

The miners shown in the photo won $16,000.00<br />

when they submitted the CoreLube System in a<br />

contest put on by their company, for the best<br />

overall problem solving solution of the year.<br />

They had used two other grease lubricators<br />

prior to the CoreLube System.<br />

HOSES WITH QUICK<br />

COUPLERS<br />

15' RATCHET<br />

TIE-DOWNS<br />

The Kinetic Energy behind the patented<br />

Air Seals sets the <strong>CORELUBE</strong> SYSTEM<br />

apart from all other lubricating devices.<br />

AIR<br />

SEALS<br />

LINER<br />

Comments from the miners after switching<br />

to the CoreLube System<br />

> The rope fling-off and mess has virtually been eliminated.<br />

> Our previous wire rope grease system was subject to a lot of wastage, with the<br />

CoreLube System there is no wastage.<br />

> Switching over to the CoreLube System has removed the fire hazard caused by<br />

excess grease building up under the sheave and on our wood timbers.<br />

> The maintenance crew found the CoreLube System to be a neater, faster and safer<br />

than the grease type system.<br />

> The old wire rope grease applicator we used, piled up grease like mud under the<br />

tread wheels. We cleaned the mess up when we switched to the CoreLube System<br />

and from that time on there has been no added mess anywhere. There was a lot of<br />

labour spent cleaning up after the old system and money spent to dispose of the<br />

barrels of grease. The CoreLube System has completely solved this problem for us.<br />

Distributed By:<br />

TOTAL OF ( 4 )<br />

LUBRICANT INJECTION PORTS<br />

RETURN<br />

EXHAUST PORTS<br />

SCRAPER GUIDE<br />

BUSHING<br />

AIR<br />

SEALS<br />

Phone: 403-529-9645 Fax: 403-527-1369<br />

E-mail: sales@corelube.com<br />

www.corelube.com