FUCHS Product Data Sheets - Food - Lubri-Expert

FUCHS Product Data Sheets - Food - Lubri-Expert

FUCHS Product Data Sheets - Food - Lubri-Expert

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

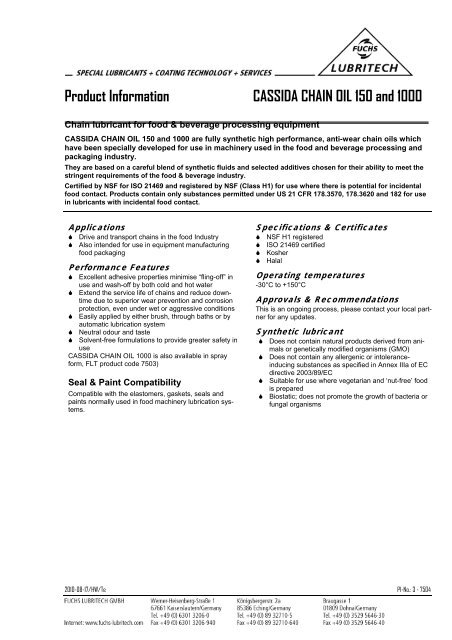

<strong>Product</strong> Information CASSIDA CHAIN OIL 150 and 1000<br />

Chain lubricant for food & beverage processing equipment<br />

CASSIDA CHAIN OIL 150 and 1000 are fully synthetic high performance, anti-wear chain oils which<br />

have been specially developed for use in machinery used in the food and beverage processing and<br />

packaging industry.<br />

They are based on a careful blend of synthetic fluids and selected additives chosen for their ability to meet the<br />

stringent requirements of the food & beverage industry.<br />

Certified by NSF for ISO 21469 and registered by NSF (Class H1) for use where there is potential for incidental<br />

food contact. <strong>Product</strong>s contain only substances permitted under US 21 CFR 178.3570, 178.3620 and 182 for use<br />

in lubricants with incidental food contact.<br />

Applications<br />

Drive and transport chains in the food Industry<br />

Also intended for use in equipment manufacturing<br />

food packaging<br />

Performance Features<br />

Excellent adhesive properties minimise “fling-off” in<br />

use and wash-off by both cold and hot water<br />

Extend the service life of chains and reduce downtime<br />

due to superior wear prevention and corrosion<br />

protection, even under wet or aggressive conditions<br />

Easily applied by either brush, through baths or by<br />

automatic lubrication system<br />

Neutral odour and taste<br />

Solvent-free formulations to provide greater safety in<br />

use<br />

CASSIDA CHAIN OIL 1000 is also available in spray<br />

form, FLT product code 7503)<br />

Seal & Paint Compatibility<br />

Compatible with the elastomers, gaskets, seals and<br />

paints normally used in food machinery lubrication systems.<br />

Specifications & Certificates<br />

NSF H1 registered<br />

ISO 21469 certified<br />

Kosher<br />

Halal<br />

Operating temperatures<br />

-30°C to +150°C<br />

Approvals & Recommendations<br />

This is an ongoing process, please contact your local partner<br />

for any updates.<br />

Synthetic lubricant<br />

Does not contain natural products derived from animals<br />

or genetically modified organisms (GMO)<br />

Does not contain any allergenic or intoleranceinducing<br />

substances as specified in Annex IIIa of EC<br />

directive 2003/89/EC<br />

Suitable for use where vegetarian and ‘nut-free’ food<br />

is prepared<br />

Biostatic; does not promote the growth of bacteria or<br />

fungal organisms<br />

2010-08-17/HW/Te PI-No.: 3 - 7504

<strong>Product</strong> Information CASSIDA CHAIN OIL 150 and 1000<br />

“Incidental <strong>Food</strong> contact”<br />

Registered by NSF (Class H1) and meets the USDA H1<br />

guidelines (1998) for lubricants for use where there is a<br />

potential for incidental food contact.<br />

Certified by NSF for ISO 21469, Safety of machinery,<br />

<strong>Lubri</strong>cants with incidental product contact, Hygiene requirements.<br />

Made only from substances permitted under the US FDA<br />

Title 21 CFR 178.3570, 178.3620 and/or those generally<br />

regarded as safe (US 21 CFR 182) for use in food grade<br />

lubricants.<br />

To comply with the requirements of US 21 CFR<br />

178.3570, contact with food should be avoided where<br />

possible. In the case of incidental food contact, the concentration<br />

of this product in the food must not exceed 10<br />

parts per million (10mg/kg of foodstuff).<br />

In locations and/or applications where local legislation<br />

does not specify maximum concentration limits, it is<br />

recommended that this same 10 ppm limit be observed,<br />

as up to this concentration CASSIDA CHAIN OIL will not<br />

impart undesirable taste, odour or colour to food, nor will<br />

cause adverse health effects.<br />

Consistent with good manufacturing practice, use only<br />

the amount necessary to achieve correct lubrication and<br />

take appropriate corrective action should excessive<br />

incidental contact with food be detected.<br />

Protect the environment<br />

Take used lubricants and empty packs to an authorised<br />

collection point. Do not discharge into drains, soil or<br />

water.<br />

Health & Safety<br />

Based on information available, CASSIDA CHAIN OILs<br />

are unlikely to present any significant health or safety<br />

hazard when properly used in the recommended application<br />

and good standards of industrial and personal hygiene<br />

are maintained. As for all oils, prolonged or repeated<br />

contact with the skin should be avoided.<br />

For further information refer to the appropriate Material<br />

Safety <strong>Data</strong> Sheet.<br />

Handling & storage<br />

All food grade lubricants should be stored separately from<br />

other lubricants, chemical substances and foodstuffs and<br />

out of direct sunlight or other heat sources. Store between<br />

0°C and 40°C. Provided that the product has been stored<br />

under these conditions we recommend that the product<br />

be used within 5 years from the date of manufacture.<br />

Accept for use new CASSIDA CHAIN OIL only if the<br />

manufacturer's seal is intact.<br />

Before opening the pack ensure the area around the closure<br />

is clean. It is recommended that it be cleaned with<br />

potable water and then dried with a clean cloth before<br />

opening.<br />

Record the date the seal was broken. To prevent product<br />

contamination, always close the package after use. Upon<br />

opening a pack, the product must be used within 2 years<br />

(or within 5 years of date of manufacture, whichever is the<br />

sooner).<br />

Typical characteristics<br />

CASSIDA CHAIN OIL 150 1000<br />

Property Test method<br />

NSF Registration No. 92533 92532<br />

Colour Colourless to pale yellow<br />

Density at 15°C kg/m 3<br />

ISO 12185 846 852<br />

Flashpoint °C ISO 2592 260 268<br />

Pourpoint °C ISO 3016 -54 -36<br />

Kin. Visc. at 40°C mm 2 /s ISO 3104 150 1000<br />

Kin. Visc. at 100°C mm 2 /s ISO 3104 19 80.6<br />

These characteristics are typical for current production. Variations in these characteristics may occur.<br />

As far as we know these information reflect the current state of knowledge and our research. They cannot, however, be taken as an assurance about the properties nor as a<br />

guarantee of the suitability of the product for the individual case in point. Before using our products the purchaser must, therefore, check their suitability and be satisfied that the<br />

output will be satisfactory. Our products are continually being up-dated. We reserve the right, therefore, to alter the information of this product information at any time and<br />

without prior announcement.<br />

2010-08-17/HW/Te<br />

We are specialized in developing products for extreme tribological problems in cooperation with end users.<br />

<strong>FUCHS</strong> LUBRITECH provides service and individual advice. Please contact us!<br />

E-Mail: cassida.lubricants@fuchs-lubritech.de<br />

PI-No.: 3 - 7504

<strong>Product</strong> Information CASSIDA CHAIN OIL 150 and 1000<br />

“Incidental <strong>Food</strong> contact”<br />

Registered by NSF (Class H1) and meets the USDA H1<br />

guidelines (1998) for lubricants for use where there is a<br />

potential for incidental food contact.<br />

Certified by NSF for ISO 21469, Safety of machinery,<br />

<strong>Lubri</strong>cants with incidental product contact, Hygiene requirements.<br />

Made only from substances permitted under the US FDA<br />

Title 21 CFR 178.3570, 178.3620 and/or those generally<br />

regarded as safe (US 21 CFR 182) for use in food grade<br />

lubricants.<br />

To comply with the requirements of US 21 CFR<br />

178.3570, contact with food should be avoided where<br />

possible. In the case of incidental food contact, the concentration<br />

of this product in the food must not exceed 10<br />

parts per million (10mg/kg of foodstuff).<br />

In locations and/or applications where local legislation<br />

does not specify maximum concentration limits, it is<br />

recommended that this same 10 ppm limit be observed,<br />

as up to this concentration CASSIDA CHAIN OIL will not<br />

impart undesirable taste, odour or colour to food, nor will<br />

cause adverse health effects.<br />

Consistent with good manufacturing practice, use only<br />

the amount necessary to achieve correct lubrication and<br />

take appropriate corrective action should excessive<br />

incidental contact with food be detected.<br />

Protect the environment<br />

Take used lubricants and empty packs to an authorised<br />

collection point. Do not discharge into drains, soil or<br />

water.<br />

Health & Safety<br />

Based on information available, CASSIDA CHAIN OILs<br />

are unlikely to present any significant health or safety<br />

hazard when properly used in the recommended application<br />

and good standards of industrial and personal hygiene<br />

are maintained. As for all oils, prolonged or repeated<br />

contact with the skin should be avoided.<br />

For further information refer to the appropriate Material<br />

Safety <strong>Data</strong> Sheet.<br />

Handling & storage<br />

All food grade lubricants should be stored separately from<br />

other lubricants, chemical substances and foodstuffs and<br />

out of direct sunlight or other heat sources. Store between<br />

0°C and 40°C. Provided that the product has been stored<br />

under these conditions we recommend that the product<br />

be used within 5 years from the date of manufacture.<br />

Accept for use new CASSIDA CHAIN OIL only if the<br />

manufacturer's seal is intact.<br />

Before opening the pack ensure the area around the closure<br />

is clean. It is recommended that it be cleaned with<br />

potable water and then dried with a clean cloth before<br />

opening.<br />

Record the date the seal was broken. To prevent product<br />

contamination, always close the package after use. Upon<br />

opening a pack, the product must be used within 2 years<br />

(or within 5 years of date of manufacture, whichever is the<br />

sooner).<br />

Typical characteristics<br />

CASSIDA CHAIN OIL 150 1000<br />

Property Test method<br />

NSF Registration No. 92533 92532<br />

Colour Colourless to pale yellow<br />

Density at 15°C kg/m 3<br />

ISO 12185 846 852<br />

Flashpoint °C ISO 2592 260 268<br />

Pourpoint °C ISO 3016 -54 -36<br />

Kin. Visc. at 40°C mm 2 /s ISO 3104 150 1000<br />

Kin. Visc. at 100°C mm 2 /s ISO 3104 19 80.6<br />

These characteristics are typical for current production. Variations in these characteristics may occur.<br />

As far as we know these information reflect the current state of knowledge and our research. They cannot, however, be taken as an assurance about the properties nor as a<br />

guarantee of the suitability of the product for the individual case in point. Before using our products the purchaser must, therefore, check their suitability and be satisfied that the<br />

output will be satisfactory. Our products are continually being up-dated. We reserve the right, therefore, to alter the information of this product information at any time and<br />

without prior announcement.<br />

2010-08-17/HW/Te<br />

We are specialized in developing products for extreme tribological problems in cooperation with end users.<br />

<strong>FUCHS</strong> LUBRITECH provides service and individual advice. Please contact us!<br />

E-Mail: cassida.lubricants@fuchs-lubritech.de<br />

PI-No.: 3 - 7505

<strong>Product</strong> Information CASSIDA CHAIN OIL 150 and 1000<br />

Chain lubricant for food & beverage processing equipment<br />

CASSIDA CHAIN OIL 150 and 1000 are fully synthetic high performance, anti-wear chain oils which<br />

have been specially developed for use in machinery used in the food and beverage processing and<br />

packaging industry.<br />

They are based on a careful blend of synthetic fluids and selected additives chosen for their ability to meet the<br />

stringent requirements of the food & beverage industry.<br />

Certified by NSF for ISO 21469 and registered by NSF (Class H1) for use where there is potential for incidental<br />

food contact. <strong>Product</strong>s contain only substances permitted under US 21 CFR 178.3570, 178.3620 and 182 for use<br />

in lubricants with incidental food contact.<br />

Applications<br />

Drive and transport chains in the food Industry<br />

Also intended for use in equipment manufacturing<br />

food packaging<br />

Performance Features<br />

Excellent adhesive properties minimise “fling-off” in<br />

use and wash-off by both cold and hot water<br />

Extend the service life of chains and reduce downtime<br />

due to superior wear prevention and corrosion<br />

protection, even under wet or aggressive conditions<br />

Easily applied by either brush, through baths or by<br />

automatic lubrication system<br />

Neutral odour and taste<br />

Solvent-free formulations to provide greater safety in<br />

use<br />

CASSIDA CHAIN OIL 1000 is also available in spray<br />

form, FLT product code 7503)<br />

Seal & Paint Compatibility<br />

Compatible with the elastomers, gaskets, seals and<br />

paints normally used in food machinery lubrication systems.<br />

Specifications & Certificates<br />

NSF H1 registered<br />

ISO 21469 certified<br />

Kosher<br />

Halal<br />

Operating temperatures<br />

-30°C to +150°C<br />

Approvals & Recommendations<br />

This is an ongoing process, please contact your local partner<br />

for any updates.<br />

Synthetic lubricant<br />

Does not contain natural products derived from animals<br />

or genetically modified organisms (GMO)<br />

Does not contain any allergenic or intoleranceinducing<br />

substances as specified in Annex IIIa of EC<br />

directive 2003/89/EC<br />

Suitable for use where vegetarian and ‘nut-free’ food<br />

is prepared<br />

Biostatic; does not promote the growth of bacteria or<br />

fungal organisms<br />

2010-08-17/HW/Te PI-No.: 3 - 7505

2010-08-17/HW/Te PI-No.: 3 - 7509

<strong>Product</strong> Information CASSIDA FLUID CR series<br />

In locations and/or applications where local legislation<br />

does not specify maximum concentration limits, it is<br />

recommended that this same 10 ppm limit be observed,<br />

as up to this concentration CASSIDA FLUID CR will not<br />

impart undesirable taste, odour or colour to food, nor will<br />

cause adverse health effects.<br />

Consistent with good manufacturing practice, use only<br />

the amount necessary to achieve correct lubrication and<br />

take appropriate corrective action should excessive<br />

incidental contact with food be detected.<br />

Health & Safety<br />

Based on information available, CASSIDA FLUID CR is<br />

unlikely to present any significant health or safety hazard<br />

when properly used in the recommended application<br />

and good standards of industrial and personal hygiene<br />

are maintained. As for all oils, prolonged or repeated<br />

contact with the skin should be avoided. For further<br />

information refer to the appropriate Material Safety <strong>Data</strong><br />

Sheet.<br />

Oil condition during use<br />

It is recommended that the condition of the oil and the<br />

equipment be regularly checked to ensure safe operation.<br />

Protect the environment<br />

Take used oil to an authorised collection point. Do not<br />

discharge into drains, soil or water<br />

Handling and storage<br />

All food grade lubricants, such as CASSIDA FLUID CR,<br />

should be stored separately, out of direct sunlight or<br />

other heat sources, from other lubricants, chemical substances<br />

and foodstuffs. Provided that the product has<br />

been stored under these conditions we recommend that<br />

the product be used within 5 years from the date of<br />

manufacture.<br />

Accept for use new CASSIDA FLUID CR only if the<br />

manufacturer's seal is intact.<br />

Before opening the pack ensure the area around the closure<br />

is clean. It is recommended that it be cleaned with<br />

CASSIDA FLUID PL and/or potable water and then dried<br />

with a clean cloth before opening.<br />

Record the date the seal was broken. To prevent product<br />

contamination, always close the package after use. Upon<br />

opening a pack, the product must be used within 2 years<br />

(or within 5 years of date of manufacture, whichever is<br />

the sooner).<br />

Typical characteristics<br />

CASSIDA FLUID CR 46 100<br />

Property Test method<br />

NSF Registration No. 115022 141040<br />

Colour Pale yellow<br />

Density at 15°C kg/m 3 ISO 12185 838 846<br />

Flashpoint °C ISO 2592 252 258<br />

Pourpoint °C ISO 3016 -57 -54<br />

Kin. Visc. at 40°C mm 2 /s ISO 3104 46 100<br />

Kin. Visc. at 100°C mm 2 /s ISO 3104 7.88 14.6<br />

Viscosity index ISO 2909 142 151<br />

Demulsibility at 54°C min. ISO 6614 15 20 (82°C)<br />

These characteristics are typical for current production. Variations in these characteristics may occur.<br />

As far as we know these information reflect the current state of knowledge and our research. They cannot, however, be taken as an assurance about<br />

the properties nor as a guarantee of the suitability of the product for the individual case in point. Before using our products the purchaser must, therefore,<br />

check their suitability and be satisfied that the output will be satisfactory. Our products are continually being up-dated. We reserve the right,<br />

therefore, to alter the information of this product information at any time and without prior announcement.<br />

We are specialized in developing products for extreme tribological problems in cooperation with end users.<br />

<strong>FUCHS</strong> LUBRITECH provides service and individual advice. Please contact us!<br />

E-Mail: cassida.lubricants@fuchs-lubritech.de<br />

2010-08-17/HW/Te PI-No.: 3 - 7509

<strong>Product</strong> Information CASSIDA FLUID CR series<br />

Compressor lubricants for food manufacturing machinery<br />

CASSIDA FLUID CR 46 and 100 are high performance fluids specially developed for use in rotary<br />

screw and vane air compressors used in the food and beverage processing and packaging industry.<br />

They are based on a careful blend of synthetic fluids and selected additives chosen for their ability to meet the<br />

stringent requirements of the food industry.<br />

Certified by NSF for ISO 21469 and registered by NSF (Class H1) for use where there is potential for incidental<br />

food contact. These products meet the guidelines (1998) of, and were previously authorized by, the US Department<br />

of Agriculture <strong>Food</strong> Safety and Inspection Service (USDA FSIS) for H1 use (lubricant with incidental food<br />

contact) and listed in Miscellaneous Publication No 1419 “List of Proprietary Substances and Nonfood Compounds”.<br />

<strong>Product</strong>s contain only substances permitted under US 21 CFR 178.3570, 178.3620 and 182 for use in<br />

lubricants with incidental food contact.<br />

Applications<br />

Screw and vane compressors<br />

Plain and anti-friction bearings<br />

General purpose lubrication including light duty<br />

gearboxes<br />

Performance Features<br />

Base fluids have an ability to provide superior lubrication<br />

under the majority of operating conditions<br />

Very good anti-wear performance resulting in greater<br />

plant utilisation.<br />

CASSIDA FLUID CR has inherently good water<br />

shedding properties and resistance to foaming<br />

Excellent high temperature performance resists the<br />

formation of harmful products of oxidation at elevated<br />

temperatures, resulting in long oil life<br />

Neutral odour and taste<br />

High viscosity index<br />

Good protection against corrosion of all metal working<br />

surfaces<br />

Good low temperature properties down to -40°C<br />

These products have demonstrated similar performance<br />

to conventional compressor lubricants in rotary air compressors<br />

(Hydrovane type) operating at normal temperatures,<br />

e.g. up to 100°C. It is strongly recommended that<br />

a used oil and/or equipment condition monitoring service<br />

be employed for extended periods of operation in excess<br />

of the pump manufacturers’ recommended oil<br />

change intervals.<br />

Seal and Paint Compatibility<br />

Compatible with the elastomers, gaskets, seals and<br />

paints normally used in food machinery lubrication systems.<br />

Specifications and Certificates<br />

NSF H1<br />

NSF ISO 21469<br />

Kosher<br />

Halal<br />

DIN 51506 VBL, VCL, VDL<br />

Approvals & Recommendations<br />

This is an ongoing process, please contact your local<br />

partner for any updates.<br />

Extensive field experience with CASSIDA FLUID CR<br />

for:<br />

- Atlas Copco<br />

- Grassair<br />

- Compair<br />

- Ingersoll Rand<br />

- Kaeser/HPC<br />

FAG recommendation<br />

Synthetic lubricants<br />

Do not contain natural products derived from animals<br />

or genetically modified organisms (GMO).<br />

May contain derivatives of coconut oil<br />

Do not contain any allergenic or intolerance-inducing<br />

substances as specified in Annex IIIa of EC directive<br />

203/98/EC<br />

Suitable for use where vegetarian and ‘nut-free’ food<br />

is prepared.<br />

Biostatic; do not promote the growth of bacteria or<br />

fungal organisms.<br />

“Incidental <strong>Food</strong> contact”<br />

Registered by NSF (Class H1) and meets the USDA H1<br />

guidelines (1998) for lubricants for use where there is a<br />

potential for incidental food contact.<br />

Certified by NSF for ISO 21469, Safety of machinery, <strong>Lubri</strong>cants<br />

with incidental product contact, Hygiene requirements.<br />

Made only from substances permitted under the US FDA<br />

Title 21 CFR 178.3570, 178.3620 and/or those generally<br />

regarded as safe (US 21 CFR 182) for use in food grade<br />

lubricants.<br />

To comply with the requirements of US 21 CFR 178.3570,<br />

contact with food should be avoided where possible. In<br />

the case of incidental food contact, the concentration of<br />

these products in the food must not exceed 10 parts per<br />

million (10mg/kg of foodstuff).<br />

2010-08-17/HW/Te PI-No.: 3 - 7509

2010-08-17/HW/Te PI-No.: 3 - 7517

<strong>Product</strong> Information CASSIDA FLUID GL series<br />

Consistent with good manufacturing practice, use only<br />

the amount necessary to achieve correct lubrication and<br />

take appropriate corrective action should excessive<br />

incidental contact with food be detected.<br />

Health & Safety<br />

Based on information available, CASSIDA FLUID GL is<br />

unlikely to present any significant health or safety hazard<br />

when properly used in the recommended application<br />

and good standards of industrial and personal hygiene<br />

are maintained. As for all oils, prolonged or repeated<br />

contact with the skin should be avoided.<br />

For further information refer to the appropriate Material<br />

Safety <strong>Data</strong> Sheet.<br />

Oil condition during use<br />

It is recommended that the condition of the oil and the<br />

equipment be regularly checked to ensure safe operation.<br />

Protect the environment<br />

Take used lubricants and empty packs to an authorised<br />

collection point. Do not discharge into drains, soil<br />

or water.<br />

Handling and storage<br />

All food grade lubricants, such as CASSIDA FLUID GL,<br />

should be stored separately, out of direct sunlight or<br />

other heat sources, from other lubricants, chemical substances<br />

and foodstuffs.<br />

Store between 0°C and 40°C. Provided that the product<br />

has been stored under these conditions we recommend<br />

that the product be used within 5 years from the date of<br />

manufacture.<br />

Accept for use new CASSIDA FLUID GL only if the<br />

manufacturer's seal is intact.<br />

Before opening the pack ensure the area around the closure<br />

is clean. It is recommended that it be cleaned with<br />

CASSIDA FLUID PL and/or potable water and then dried<br />

with a clean cloth before opening.<br />

Record the date the seal was broken. To prevent product<br />

contamination, always close the package after use. Upon<br />

opening a pack, the product must be used within 2 years<br />

(or within 5 years of date of manufacture, whichever is<br />

the sooner).<br />

Typical characteristics<br />

CASSIDA FLUID GL 150 220 320 460 680<br />

Property Test Method<br />

NSF Registration Number 92534 92535 92536 92537 92538<br />

Colour Colourless, pale yellow<br />

Density at 15°C kg/m3 ISO 12185 845 847 852 855 858<br />

Flashpoint °C ISO 2592 268 276 278 270 286<br />

Pourpoint °C ISO 3016 -54 -48 -45 -45 -39<br />

Kin. Visc. at 40°C mm2/s ISO 3104 150 220 320 460 680<br />

Kin. Visc. at 100°C mm2/s ISO 3104 18.9 25.0 33.4 43.8 58.6<br />

Viscosity index ISO 2909 143 143 147 148 152<br />

FZG-Test A/8.3/90<br />

Failure Load Stage<br />

DIN 51599<br />

These characteristics are typical for current production. Variations in these characteristics may occur.<br />

As far as we know these information reflect the current state of knowledge and our research. They cannot, however, be taken as an assurance about<br />

the properties nor as a guarantee of the suitability of the product for the individual case in point. Before using our products the purchaser must, therefore,<br />

check their suitability and be satisfied that the output will be satisfactory. Our products are continually being up-dated. We reserve the right,<br />

therefore, to alter the information of this product information at any time and without prior announcement. We are specialized in developing products for<br />

extreme tribological problems in cooperation with end users. <strong>FUCHS</strong> LUBRITECH provides service and individual advice. Please contact us!<br />

E-Mail: cassida.lubricants@fuchs-lubritech.de<br />

2010-08-17/HW/Te PI-No.: 3 - 7517<br />

>12

<strong>Product</strong> Information CASSIDA FLUID GL series<br />

Gear lubricants for use in food manufacturing equipment<br />

CASSIDA FLUID GL 150, 220, 320, 460 and 680 are high performance, anti-wear gear oils specially<br />

developed for the lubrication of enclosed gears in food and beverage processing machinery.<br />

They are based on a careful blend of synthetic fluids and selected additives chosen for their ability to meet the<br />

stringent requirements of the food industry.<br />

Registered by NSF (Class H1) for use where there is potential for incidental food contact. These products meet<br />

the guidelines (1998) of, and were previously authorized by, the US Department of Agriculture <strong>Food</strong> Safety and<br />

Inspection Service (USDA FSIS) for H1 use (lubricant with incidental food contact) and listed in Miscellaneous<br />

Publication No 1419 “List of Proprietary Substances and Nonfood Compounds”. <strong>Product</strong> contain only substances<br />

permitted under US 21 CFR 178.3570, 178.3620 and 182 for use in lubricants with incidental food contact.<br />

Applications<br />

<strong>Lubri</strong>cation of enclosed gearboxes used in the food<br />

industry.<br />

Also intended for use in equipment manufacturing<br />

food packaging.<br />

Performance Features<br />

Resists the formation of harmful products of oxidation<br />

even at elevated temperatures.<br />

Base oil has an ability to provide superior lubrication<br />

under all operating conditions.<br />

Excellent EP properties make CASSIDA FLUID GL<br />

suitable for steel-on-steel and worm and phosphorbronze<br />

wheel applications.<br />

Neutral odour and taste<br />

High viscosity index resulting in minimum variation of<br />

viscosity with change in temperature.<br />

Seal and Paint Compatibility<br />

Compatible with the elastomers, gaskets, seals and<br />

paints normally used in food machinery lubrication systems.<br />

Specifications and Certificates<br />

NSF H1<br />

Kosher<br />

Halal<br />

DIN 51506 VBL (GL 150, 220), VCL (GL 150)<br />

ISO/DP 6743/6 L-CKD<br />

DIN 51517 CLP<br />

Approvals & Recommendations<br />

This is an ongoing process, please contact your local<br />

partner for any updates.<br />

David Brown: CASSIDA FLUIDGL 460 for worm<br />

gears<br />

Lenze<br />

Getriebebau Nord: CASSIDA FLUID GL 220 & 680<br />

Krones<br />

SEW (GL 220 for helical units & GL 460 for worm<br />

gear units)<br />

Bonfiglioli (for parallel shaft and helical in-line reducers;<br />

CASSIDA FLUID GL 460 for worm or worm/screw<br />

gears)<br />

FMC can seamers (viscosity for different models according<br />

to OEM specification).<br />

FAG<br />

Buehler<br />

Westfalia <strong>Food</strong> Tec (CASSIDA FLUID GL 220)<br />

Toyo Can Seamer type 43M (CASSIDA FLUID GL<br />

150)<br />

Stork <strong>Food</strong> and Dairy Systems (GL 150-680)<br />

Synthetic lubricants<br />

Does not contain natural products derived from animals<br />

or genetically modified organisms (GMO).<br />

Does not contain any allergenic or intoleranceinducing<br />

substances as specified in Annex IIIa of EC directive<br />

203/98/EC<br />

Suitable for use where vegetarian and ‘nut-free’ food<br />

is prepared.<br />

Biostatic; does not promote the growth of bacteria or<br />

fungal organisms.<br />

“Incidental <strong>Food</strong> contact”<br />

Registered by NSF (Class H1) and meets the USDA H1<br />

guidelines (1998) for lubricants for use where there is a<br />

potential for incidental food contact.<br />

Made only from substances permitted under the US FDA<br />

Title 21 CFR 178.3570, 178.3620 and/or those generally<br />

regarded as safe (US 21 CFR 182) for use in food grade<br />

lubricants.<br />

To comply with the requirements of US 21 CFR 178.3570,<br />

contact with food should be avoided where possible. In<br />

the case of incidental food contact, the concentration of<br />

this product in the food must not exceed 10 parts per million<br />

(10mg/kg of foodstuff).<br />

In locations and/or applications where local legislation<br />

does not specify maximum concentration limits, it is recommended<br />

that this same 10 ppm limit be observed, as<br />

up to this concentration CASSIDA FLUID GL will not impart<br />

undesirable taste, odour or colour to food, nor will<br />

cause adverse health effects.<br />

2010-08-17/HW/Te PI-No.: 3 - 7517

<strong>Product</strong> Information CASSIDA FLUID GL series<br />

Consistent with good manufacturing practice, use only<br />

the amount necessary to achieve correct lubrication and<br />

take appropriate corrective action should excessive<br />

incidental contact with food be detected.<br />

Health & Safety<br />

Based on information available, CASSIDA FLUID GL is<br />

unlikely to present any significant health or safety hazard<br />

when properly used in the recommended application and<br />

good standards of industrial and personal hygiene are<br />

maintained. As for all oils, prolonged or repeated contact<br />

with the skin should be avoided.<br />

For further information refer to the appropriate Material<br />

Safety <strong>Data</strong> Sheet.<br />

Oil condition during use<br />

It is recommended that the condition of the oil and the<br />

equipment be regularly checked to ensure safe operation.<br />

Protect the environment<br />

Take used lubricants and empty packs to an authorised<br />

collection point. Do not discharge into drains, soil<br />

or water.<br />

Handling and storage<br />

All food grade lubricants, such as CASSIDA FLUID GL,<br />

should be stored separately, out of direct sunlight or other<br />

heat sources, from other lubricants, chemical substances<br />

and foodstuffs.<br />

Store between 0°C and 40°C. Provided that the product<br />

has been stored under these conditions we recommend<br />

that the product be used within 5 years from the date of<br />

manufacture.<br />

Accept for use new CASSIDA FLUID GL only if the manufacturer's<br />

seal is intact.<br />

Before opening the pack ensure the area around the closure<br />

is clean. It is recommended that it be cleaned with<br />

CASSIDA FLUID PL and/or potable water and then dried<br />

with a clean cloth before opening.<br />

Record the date the seal was broken. To prevent product<br />

contamination, always close the package after use. Upon<br />

opening a pack, the product must be used within 2 years<br />

(or within 5 years of date of manufacture, whichever is the<br />

sooner).<br />

Typical characteristics<br />

CASSIDA FLUID GL 150 220 320 460 680<br />

Property Test Method<br />

NSF Registration Number 92534 92535 92536 92537 92538<br />

Colour Colourless, pale yellow<br />

Density at 15°C kg/m3 ISO 12185 845 847 852 855 858<br />

Flashpoint °C ISO 2592 268 276 278 270 286<br />

Pourpoint °C ISO 3016 -54 -48 -45 -45 -39<br />

Kin. Visc. at 40°C mm2/s ISO 3104 150 220 320 460 680<br />

Kin. Visc. at 100°C mm2/s ISO 3104 18.9 25.0 33.4 43.8 58.6<br />

Viscosity index<br />

FZG-Test A/8.3/90<br />

ISO 2909 143 143 147 148 152<br />

Failure Load Stage<br />

DIN 51599<br />

>12<br />

These characteristics are typical for current production. Variations in these characteristics may occur.<br />

As far as we know these information reflect the current state of knowledge and our research. They cannot, however, be taken as an assurance about the properties nor as a<br />

guarantee of the suitability of the product for the individual case in point. Before using our products the purchaser must, therefore, check their suitability and be satisfied that the<br />

output will be satisfactory. Our products are continually being up-dated. We reserve the right, therefore, to alter the information of this product information at any time and<br />

without prior announcement.<br />

We are specialized in developing products for extreme tribological problems in cooperation with end users.<br />

<strong>FUCHS</strong> LUBRITECH provides service and individual advice. Please contact us!<br />

2010-08-17/HW/Te E-Mail: cassida.lubricants@fuchs-lubritech.de<br />

PI-No.: 3 - 7519

<strong>Product</strong> Information CASSIDA FLUID GL series<br />

Gear lubricants for use in food manufacturing equipment<br />

CASSIDA FLUID GL 150, 220, 320, 460 and 680 are high performance, anti-wear gear oils specially<br />

developed for the lubrication of enclosed gears in food and beverage processing machinery.<br />

They are based on a careful blend of synthetic fluids and selected additives chosen for their ability to meet the<br />

stringent requirements of the food industry.<br />

Registered by NSF (Class H1) for use where there is potential for incidental food contact. These products meet<br />

the guidelines (1998) of, and were previously authorized by, the US Department of Agriculture <strong>Food</strong> Safety and<br />

Inspection Service (USDA FSIS) for H1 use (lubricant with incidental food contact) and listed in Miscellaneous<br />

Publication No 1419 “List of Proprietary Substances and Nonfood Compounds”. <strong>Product</strong> contain only substances<br />

permitted under US 21 CFR 178.3570, 178.3620 and 182 for use in lubricants with incidental food contact.<br />

Applications<br />

<strong>Lubri</strong>cation of enclosed gearboxes used in the food<br />

industry.<br />

Also intended for use in equipment manufacturing<br />

food packaging.<br />

Performance Features<br />

Resists the formation of harmful products of oxidation<br />

even at elevated temperatures.<br />

Base oil has an ability to provide superior lubrication<br />

under all operating conditions.<br />

Excellent EP properties make CASSIDA FLUID GL<br />

suitable for steel-on-steel and worm and phosphorbronze<br />

wheel applications.<br />

Neutral odour and taste<br />

High viscosity index resulting in minimum variation of<br />

viscosity with change in temperature.<br />

Seal and Paint Compatibility<br />

Compatible with the elastomers, gaskets, seals and<br />

paints normally used in food machinery lubrication systems.<br />

Specifications and Certificates<br />

NSF H1<br />

Kosher<br />

Halal<br />

DIN 51506 VBL (GL 150, 220), VCL (GL 150)<br />

ISO/DP 6743/6 L-CKD<br />

DIN 51517 CLP<br />

Approvals & Recommendations<br />

This is an ongoing process, please contact your local<br />

partner for any updates.<br />

David Brown: CASSIDA FLUIDGL 460 for worm<br />

gears<br />

Lenze<br />

Getriebebau Nord: CASSIDA FLUID GL 220 & 680<br />

Krones<br />

SEW (GL 220 for helical units & GL 460 for worm<br />

gear units)<br />

Bonfiglioli (for parallel shaft and helical in-line reducers;<br />

CASSIDA FLUID GL 460 for worm or worm/screw<br />

gears)<br />

FMC can seamers (viscosity for different models according<br />

to OEM specification).<br />

FAG<br />

Buehler<br />

Westfalia <strong>Food</strong> Tec (CASSIDA FLUID GL 220)<br />

Toyo Can Seamer type 43M (CASSIDA FLUID GL<br />

150)<br />

Stork <strong>Food</strong> and Dairy Systems (GL 150-680)<br />

Synthetic lubricants<br />

Does not contain natural products derived from animals<br />

or genetically modified organisms (GMO).<br />

Does not contain any allergenic or intoleranceinducing<br />

substances as specified in Annex IIIa of EC directive<br />

203/98/EC<br />

Suitable for use where vegetarian and ‘nut-free’ food is<br />

prepared.<br />

Biostatic; does not promote the growth of bacteria or<br />

fungal organisms.<br />

“Incidental <strong>Food</strong> contact”<br />

Registered by NSF (Class H1) and meets the USDA H1<br />

guidelines (1998) for lubricants for use where there is a<br />

potential for incidental food contact.<br />

Made only from substances permitted under the US FDA<br />

Title 21 CFR 178.3570, 178.3620 and/or those generally<br />

regarded as safe (US 21 CFR 182) for use in food grade<br />

lubricants.<br />

To comply with the requirements of US 21 CFR 178.3570,<br />

contact with food should be avoided where possible. In the<br />

case of incidental food contact, the concentration of this<br />

product in the food must not exceed 10 parts per million<br />

(10mg/kg of foodstuff).<br />

In locations and/or applications where local legislation<br />

does not specify maximum concentration limits, it is recommended<br />

that this same 10 ppm limit be observed, as up<br />

to this concentration CASSIDA FLUID GL will not impart<br />

undesirable taste, odour or colour to food, nor will cause<br />

adverse health effects.<br />

2010-08-17/HW/Te PI-No.: 3 - 7519

As far as we know these information reflect the current state of knowledge and our research. They cannot, however, be taken as an assurance about<br />

the properties nor as a guarantee of the suitability of the product for the individual case in point. Before using our products the purchaser must, therefore,<br />

check their suitability and be satisfied that the output will be satisfactory. Our products are continually being up-dated. We reserve the right,<br />

therefore, to alter the information of this product information at any time and without prior announcement.<br />

We are specialized in developing products for extreme tribological problems in cooperation with end users.<br />

<strong>FUCHS</strong> LUBRITECH provides service and individual advice. Please contact us!<br />

E-Mail: cassida.lubricants@fuchs-lubritech.de<br />

2010-08-17/HW/Te PI-No.: 3 - 7521

<strong>Product</strong> Information CASSIDA FLUID GLE series<br />

“Incidental <strong>Food</strong> contact”<br />

Registered by NSF (Class H1) and meets the USDA H1<br />

guidelines (1998) for lubricants for use where there is a<br />

potential for incidental food contact.<br />

Certified by NSF for ISO 21469, Safety of machinery,<br />

<strong>Lubri</strong>cants with incidental product contact, Hygiene<br />

requirements.<br />

Made only from substances permitted under the US<br />

FDA Title 21 CFR 178.3570, 178.3620 and/or those<br />

generally regarded as safe (US 21 CFR 182) for use in<br />

food grade lubricants.<br />

To comply with the requirements of US 21 CFR<br />

178.3570, contact with food should be avoided where<br />

possible. In the case of incidental food contact, the concentration<br />

of this product in the food must not exceed 10<br />

parts per million (10mg/kg of foodstuff).<br />

In locations and/or applications where local legislation<br />

does not specify maximum concentration limits, it is<br />

recommended that this same 10 ppm limit be observed,<br />

as up to this concentration CASSIDA FLUID GLE will not<br />

impart undesirable taste, odour or colour to food, nor will<br />

cause adverse health effects.<br />

Consistent with good manufacturing practice, use only<br />

the amount necessary to achieve correct lubrication and<br />

take appropriate corrective action should excessive<br />

incidental contact with food be detected.<br />

Protect the environment<br />

Take used lubricants and empty packs to an authorised<br />

collection point.<br />

Typical characteristics<br />

CASSIDA FLUID GLE 150 220<br />

Property Test Method<br />

NSF Registration Number 119921 119104<br />

Colour Colourless / slight pale<br />

Density at 15°C kg/m 3 ISO 12185 849 852<br />

Flashpoint °C ISO 2592 258 270<br />

Pourpoint °C ISO 3016 -54 -48<br />

Kin. Visc. at 40°C mm 2 /s ISO 3104 150 220<br />

Kin. Visc. at 100°C mm 2 /s ISO 3104 19 25<br />

Viscosity Index ISO 2909 140 143<br />

Demulsibility at 82°C after 60 min. ISO 6614 No separation<br />

FZG-Test A/8.3/90<br />

ISO 14635-1<br />

Failure Load Stage<br />

>12<br />

Health & Safety<br />

Based on information available, CASSIDA FLUID GLE is<br />

unlikely to present any significant health or safety hazard<br />

when properly used in the recommended application and<br />

good standards of industrial and personal hygiene are<br />

maintained. As for all oils, prolonged or repeated contact<br />

with the skin should be avoided. For further information<br />

refer to the appropriate Material Safety <strong>Data</strong> Sheet.<br />

Handling & storage<br />

All food grade lubricants should be stored separately<br />

from other lubricants, chemical substances and foodstuffs<br />

and out of direct sunlight or other heat sources.<br />

Store between 0°C and 40°C. Provided that the product<br />

has been stored under these conditions we recommend<br />

that the product be used within 5 years from the date of<br />

manufacture.<br />

Accept for use new CASSIDA FLUID GLE only if the<br />

manufacturer's seal is intact.<br />

Before opening the pack ensure the area around the closure<br />

is clean. It is recommended that it be cleaned with<br />

potable water and then dried with a clean cloth before<br />

opening.<br />

Record the date the seal was broken. To prevent product<br />

contamination, always close the package after use. Upon<br />

opening a pack, the product must be used within 2 years<br />

(or within 5 years of date of manufacture, whichever is<br />

the sooner).<br />

These characteristics are typical for current production. Variations in these characteristics may occur.<br />

2010-08-17/HW/Te PI-No.: 3 - 7521

<strong>Product</strong> Information CASSIDA FLUID GLE series<br />

Enhanced performance gear lubricant for food & beverage processing Equipment<br />

CASSIDA FLUID GLE 150 and 220 are fully synthetic, high performance, antiwear gear lubricants,<br />

specifically designed for use in the food and beverage canning industry.<br />

They are based on a careful blend of synthetic fluids and selected additives chosen for their ability to meet the<br />

stringent requirements of the food & beverage industry.<br />

Certified by NSF for ISO 21469 and registered by NSF (Class H1) for use where there is potential for incidental<br />

food contact. <strong>Product</strong>s contain only substances permitted under US 21 CFR 178.3570, 178.3620 and 182 for use<br />

in lubricants with incidental food contact.<br />

Applications<br />

<strong>Lubri</strong>cation of rotary can seaming machines<br />

equipped with either enclosed (recirculating) or total<br />

loss systems<br />

Circulating and bearing oil systems where contamination<br />

with water or food juice can occur, such as citrus<br />

juice extraction machines<br />

Performance Features<br />

The fully synthetic base fluid has been selected for<br />

its ability to provide superior lubrication under variety<br />

of applications<br />

CASSIDA FLUID GLE is specially formulated to<br />

provide excellent lubrication even when operating in<br />

locations where it is subject to contamination with<br />

water, juice and food, which is held in suspension,<br />

thus protecting metal surfaces from wear and corrosion<br />

Excellent separation properties, from water, in oil<br />

recirculating and filtration systems<br />

Neutral odour and taste<br />

Good anti-oxidant properties. Resists the formation<br />

of deposits and sludge even at elevated temperatures<br />

resulting in long oil and equipment life<br />

Seal & Paint Compatibility<br />

Compatible with the elastomers, gaskets, seals and<br />

paints, such as poly-urethane and two part epoxy resin<br />

paints, frequently used on machinery and in lubrication<br />

systems employed in the food processing industry.<br />

Specifications & Certificates<br />

NSF H1 registered<br />

ISO 21469 certified<br />

Kosher<br />

Halal<br />

DIN 51517 CLP<br />

Approvals & Recommendations<br />

This is an ongoing process, please contact your local<br />

partner for any updates.<br />

Synthetic lubricant<br />

Does not contain natural products derived from animals<br />

or genetically modified organisms (GMO)<br />

Does not contain any allergenic or intoleranceinducing<br />

substances as specified in Annex IIIa of EC<br />

directive 2003/89/EC<br />

Suitable for use where vegetarian and ‘nutfree’ food is<br />

prepared<br />

Biostatic; does not promote the growth of bacteria or<br />

fungal organisms<br />

2010-08-17/HW/Te PI-No.: 3 - 7521

<strong>Product</strong> Information CASSIDA FLUID HF series<br />

“Incidental <strong>Food</strong> contact”<br />

Registered by NSF (Class H1) and meets the USDA H1<br />

guidelines (1998) for lubricants for use where there is a<br />

potential for incidental food contact.<br />

Made only from substances permitted under the US FDA<br />

Title 21 CFR 178.3570, 178.3620 and/or those generally<br />

regarded as safe (US 21 CFR 182) for use in food grade<br />

lubricants.<br />

To comply with the requirements of US 21 CFR 178.3570,<br />

contact with food should be avoided where possible. In the<br />

case of incidental food contact, the concentration of this<br />

product in the food must not exceed 10 parts per million<br />

(10mg/kg of foodstuff).<br />

In locations and/or applications where local legislation does<br />

not specify maximum concentration limits, it is recommended<br />

that this same 10 ppm limit be observed, as up to<br />

this concentration CASSIDA FLUID HF will not impart undesirable<br />

taste, odour or colour to food, nor will cause adverse<br />

health effects.<br />

Consistent with good manufacturing practice, use only the<br />

amount necessary to achieve correct lubrication and take<br />

appropriate corrective action should excessive incidental<br />

contact with food be detected.<br />

Health & Safety<br />

Based on information available, CASSIDA FLUID HF is<br />

unlikely to present any significant health or safety hazard<br />

when properly used in the recommended application and<br />

good standards of industrial and personal hygiene are maintained.<br />

As for all oils, prolonged or repeated contact with the<br />

skin should be avoided. For further information refer to the<br />

appropriate Material Safety <strong>Data</strong> Sheet.<br />

Oil condition during use<br />

It is recommended that the condition of the oil and the<br />

equipment be regularly checked to ensure safe operation.<br />

Protect the environment<br />

Take used lubricants and empty packs to an authorised collection<br />

point. Do not discharge into drains, soil or water<br />

Handling and storage<br />

All food grade lubricants, such as CASSIDA FLUID HF,<br />

should be stored separately, out of direct sunlight or other<br />

heat sources, from other lubricants, chemical substances<br />

and foodstuffs. Store between 0°C and 40°C. Provided that<br />

the product has been stored under these conditions we recommend<br />

that the product be used within 5 years from the<br />

date of manufacture.<br />

Accept for use new CASSIDA FLUID HF only if the manufacturer's<br />

seal is intact.<br />

Before opening the pack ensure the area around the closure<br />

is clean. It is recommended that it be cleaned with CASSIDA<br />

FLUID PL and/or potable water and then dried with a clean<br />

cloth before opening.<br />

Record the date the seal was broken. To prevent product<br />

contamination, always close the package after use. Upon<br />

opening a pack, the product must be used within 2 years (or<br />

within 5 years of date of manufacture, whichever is the<br />

sooner).<br />

Typical characteristics<br />

CASSIDA FLUID HF 15 32 46 68 100<br />

Property Test Method<br />

NSF Registration Number 925400 92542 92543 92544 92539<br />

Colour Colourless<br />

Density at 15°C kg/m3 ISO 12185 819 832 836 840 841<br />

Flashpoint °C ISO 2592 200 222 248 258 268<br />

Pourpoint °C ISO 3016 < -60 -60 -57<br />

Kin. Visc. at 40°C mm2/s ISO 3104 15 32 46 68 100<br />

Kin. Visc. at 100°C mm2/s ISO 3104 3,6 6,1 7,9 10,6 14,1<br />

Viscosity index<br />

FZG-Test A/8.3/90<br />

ISO 2909 125 140 142 143 143<br />

Failure Load Stage<br />

DIN 51599<br />

---<br />

12<br />

> 12<br />

These characteristics are typical for current production. Variations in these characteristics may occur.<br />

As far as we know these information reflect the current state of knowledge and our research. They cannot, however, be taken as an assurance about the properties nor as a<br />

guarantee of the suitability of the product for the individual case in point. Before u sing our products the purchaser must, therefore, check their suitability and be satisfied that the<br />

output will be satisfactory. Our products are continually being up -dated. We reserve the right, therefore, to alter the information of this product information at any time and<br />

without prior announcement.<br />

We are specialized in developing products for extreme tribological problems in cooperation with end users.<br />

<strong>FUCHS</strong> LUBRITECH provides service and individual advice. Please contact us!<br />

E-Mail: cassida.lubricants@fuchs-lubritech.de<br />

2010-08-17/HW/Te PI-No.: 3 - 7527

<strong>Product</strong> Information CASSIDA FLUID HF series<br />

Hydraulic fluids for food manufacturing machinery<br />

CASSIDA FLUID HF 15, 32, 46, 68 and 100 are high performance, anti-wear multipurpose lubricants, specially<br />

developed for use in machinery used in the food and beverage processing and packaging industry.<br />

They are based on a careful blend of synthetic fluids and selected additives chosen for their ability to meet the stringent<br />

requirements of the food industry.<br />

Registered by NSF (Class H1) for use where there is potential for incidental food contact. These products meet the<br />

guidelines (1998) of, and were previously authorized by, the US Department of Agriculture <strong>Food</strong> Safety and Inspection<br />

Service (USDA FSIS) for H1 use (lubricant with incidental food contact) and listed in Miscellaneous Publication No 1419<br />

“List of Proprietary Substances and Nonfood Compounds”. <strong>Product</strong> contain only substances permitted under US 21<br />

CFR 178.3570, 178.3620 and 182 for use in lubricants with incidental food contact.<br />

Applications<br />

Hydraulic systems<br />

Hydrostatic gears<br />

Plain and anti-friction bearings<br />

General purpose lubrication including light duty gearboxes<br />

Circulating oil systems<br />

Performance Features<br />

The base fluid has an ability to provide superior lubrication<br />

under the majority of operating conditions.<br />

Good anti-wear performance offers long and reliable<br />

component life, resulting in greater plant utilisation and<br />

therefore lower maintenance costs.<br />

Prevent component damage trough excellent water<br />

separation properties, which resist formation of potentially<br />

harmful emulsions.<br />

Excellent air release and antifoam characteristics minimise<br />

cavitation.<br />

Resist the formation of harmful products of oxidation,<br />

even at elevated temperatures, resulting in long oil life.<br />

Neutral odour and taste.<br />

High viscosity index results in minimum variation of<br />

viscosity with change in temperature.<br />

Effective protection against corrosion of metal surfaces.<br />

Seal and Paint Compatibility<br />

Compatible with the elastomers, gaskets, seals and paints<br />

normally used in food machinery lubrication systems.<br />

Specifications and Certificates<br />

NSF H1<br />

Kosher<br />

Halal<br />

DIN 51524 HLP<br />

DIN 51524 HVLP (except HF 15)<br />

DIN 51517 CLP (HF 68, HF 100)<br />

ISO 6743-4 L-HM (HF 15), L-HV<br />

Approvals & Recommendations<br />

This is an ongoing process, please contact your local Fuchs<br />

partner for any updates.<br />

Krones<br />

David Brown<br />

Buehler Utzwil<br />

Mannesmann Rexroth (for axial piston pumps)<br />

FAG<br />

Ferrum (can seamer CASSIDA FLUID HF 100)<br />

FMC (can seamer, viscosity see to OEM specification)<br />

Westfalia <strong>Food</strong> Tec<br />

Hawe Hydraulic pumps<br />

Hoegger Alpina hydraulic pumps<br />

Piller Industrieventilatoren GmbH (CASSIDA FLUID HF<br />

46)<br />

Poclain-Hydraulics (CASSIDA FLUID HF 46)<br />

Grégoire (A Kverneland Group Company) for their harvesting<br />

machinery<br />

GEA Niro atomisors (CASSIDA FLUID HF 32-68)<br />

Stork <strong>Food</strong> and Dairy Systems (CASSIDA FLUID HF 15 -<br />

100)<br />

Mitsubishi Caterpillar Forklift Europe<br />

Synthetic lubricants<br />

Do not contain natural products derived from animals or<br />

genetically modified organisms (GMO).<br />

Do not contain any allergenic or intolerance-inducing substances<br />

as specified in Annex IIIa of EC directive<br />

203/98/EC<br />

Suitable for use where vegetarian and ‘nut-free’ food is<br />

prepared.<br />

Biostatic; does not promote the growth of bacteria or fungal<br />

organisms.<br />

2010-08-17/HW/Te PI-No.: 3 - 7527

As far as we know these information reflect the current state of knowledge and our research. They cannot, however, be taken as an assurance about<br />

the properties nor as a guarantee of the suitability of the product for the individual case in point. Before using our products the purchaser must, therefore,<br />

check their suitability and be satisfied that the output will be satisfactory. Our products are continually being up-dated. We reserve the right,<br />

therefore, to alter the information of this product information at any time and without prior announcement.<br />

We are specialized in developing products for extreme tribological problems in cooperation with end users.<br />

<strong>FUCHS</strong> LUBRITECH provides service and individual advice. Please contact us!<br />

E-Mail: cassida.lubricants@fuchs-lubritech.de<br />

2010-08-17/HW/Te PI-No.: 3 - 7528

<strong>Product</strong> Information CASSIDA FLUID HF series<br />

“Incidental <strong>Food</strong> contact”<br />

Registered by NSF (Class H1) and meets the USDA H1<br />

guidelines (1998) for lubricants for use where there is a<br />

potential for incidental food contact.<br />

Made only from substances permitted under the US<br />

FDA Title 21 CFR 178.3570, 178.3620 and/or those<br />

generally regarded as safe (US 21 CFR 182) for use in<br />

food grade lubricants.<br />

To comply with the requirements of US 21 CFR<br />

178.3570, contact with food should be avoided where<br />

possible. In the case of incidental food contact, the concentration<br />

of this product in the food must not exceed 10<br />

parts per million (10mg/kg of foodstuff).<br />

In locations and/or applications where local legislation<br />

does not specify maximum concentration limits, it is<br />

recommended that this same 10 ppm limit be observed,<br />

as up to this concentration CASSIDA FLUID HF will not<br />

impart undesirable taste, odour or colour to food, nor will<br />

cause adverse health effects.<br />

Consistent with good manufacturing practice, use only<br />

the amount necessary to achieve correct lubrication and<br />

take appropriate corrective action should excessive<br />

incidental contact with food be detected.<br />

Health & Safety<br />

Based on information available, CASSIDA FLUID HF is<br />

unlikely to present any significant health or safety hazard<br />

when properly used in the recommended application<br />

and good standards of industrial and personal hygiene<br />

are maintained. As for all oils, prolonged or repeated<br />

contact with the skin should be avoided. For further<br />

information refer to the appropriate Material Safety <strong>Data</strong><br />

Sheet.<br />

Oil condition during use<br />

It is recommended that the condition of the oil and the<br />

equipment be regularly checked to ensure safe operation.<br />

Protect the environment<br />

Take used lubricants and empty packs to an authorised<br />

collection point. Do not discharge into drains, soil or water<br />

Handling and storage<br />

All food grade lubricants, such as CASSIDA FLUID HF,<br />

should be stored separately, out of direct sunlight or<br />

other heat sources, from other lubricants, chemical substances<br />

and foodstuffs. Store between 0°C and 40°C.<br />

Provided that the product has been stored under these<br />

conditions we recommend that the product be used<br />

within 5 years from the date of manufacture.<br />

Accept for use new CASSIDA FLUID HF only if the<br />

manufacturer's seal is intact.<br />

Before opening the pack ensure the area around the closure<br />

is clean. It is recommended that it be cleaned with<br />

CASSIDA FLUID PL and/or potable water and then dried<br />

with a clean cloth before opening.<br />

Record the date the seal was broken. To prevent product<br />

contamination, always close the package after use. Upon<br />

opening a pack, the product must be used within 2 years<br />

(or within 5 years of date of manufacture, whichever is<br />

the sooner).<br />

Typical characteristics<br />

CASSIDA FLUID HF 15 32 46 68 100<br />

Property Test Method<br />

NSF Registration Number 925400 92542 92543 92544 92539<br />

Colour Colourless<br />

Density at 15°C kg/m3 ISO 12185 819 832 836 840 841<br />

Flashpoint °C ISO 2592 200 222 248 258 268<br />

Pourpoint °C ISO 3016 < -60 -60 -57<br />

Kin. Visc. at 40°C mm2/s ISO 3104 15 32 46 68 100<br />

Kin. Visc. at 100°C mm2/s ISO 3104 3,6 6,1 7,9 10,6 14,1<br />

Viscosity index ISO 2909 125 140 142 143 143<br />

FZG-Test A/8.3/90<br />

Failure Load Stage<br />

DIN 51599<br />

These characteristics are typical for current production. Variations in these characteristics may occur.<br />

2010-08-17/HW/Te PI-No.: 3 - 7528<br />

---<br />

12<br />

> 12

<strong>Product</strong> Information CASSIDA FLUID HF series<br />

Hydraulic fluids for food manufacturing machinery<br />

CASSIDA FLUID HF 15, 32, 46, 68 and 100 are high performance, anti-wear multipurpose lubricants,<br />

specially developed for use in machinery used in the food and beverage processing and packaging<br />

industry.<br />

They are based on a careful blend of synthetic fluids and selected additives chosen for their ability to meet the<br />

stringent requirements of the food industry.<br />

Registered by NSF (Class H1) for use where there is potential for incidental food contact. These products meet<br />

the guidelines (1998) of, and were previously authorized by, the US Department of Agriculture <strong>Food</strong> Safety and<br />

Inspection Service (USDA FSIS) for H1 use (lubricant with incidental food contact) and listed in Miscellaneous<br />

Publication No 1419 “List of Proprietary Substances and Nonfood Compounds”. <strong>Product</strong> contain only substances<br />

permitted under US 21 CFR 178.3570, 178.3620 and 182 for use in lubricants with incidental food contact.<br />

Applications<br />

Hydraulic systems<br />

Hydrostatic gears<br />

Plain and anti-friction bearings<br />

General purpose lubrication including light duty<br />

gearboxes<br />

Circulating oil systems<br />

Performance Features<br />

The base fluid has an ability to provide superior<br />

lubrication under the majority of operating conditions.<br />

Good anti-wear performance offers long and reliable<br />

component life, resulting in greater plant utilisation<br />

and therefore lower maintenance costs.<br />

Prevent component damage trough excellent water<br />

separation properties, which resist formation of potentially<br />

harmful emulsions.<br />

Excellent air release and antifoam characteristics<br />

minimise cavitation.<br />

Resist the formation of harmful products of oxidation,<br />

even at elevated temperatures, resulting in long oil<br />

life.<br />

Neutral odour and taste.<br />

High viscosity index results in minimum variation of<br />

viscosity with change in temperature.<br />

Effective protection against corrosion of metal surfaces.<br />

Seal and Paint Compatibility<br />

Compatible with the elastomers, gaskets, seals and<br />

paints normally used in food machinery lubrication systems.<br />

Specifications and Certificates<br />

NSF H1<br />

Kosher<br />

Halal<br />

DIN 51524 HLP<br />

DIN 51524 HVLP (except HF 15)<br />

DIN 51517 CLP (HF 68, HF 100)<br />

ISO 6743-4 L-HM (HF 15), L-HV<br />

Approvals & Recommendations<br />

This is an ongoing process, please contact your local<br />

Fuchs company for any updates.<br />

Krones<br />

David Brown<br />

Buehler Utzwil<br />

Mannesmann Rexroth (for axial piston pumps)<br />

FAG<br />

Ferrum (can seamer CASSIDA FLUID HF 100)<br />

FMC (can seamer, viscosity see to OEM specification)<br />

Westfalia <strong>Food</strong> Tec<br />

Hawe Hydraulic pumps<br />

Hoegger Alpina hydraulic pumps<br />

Piller Industrieventilatoren GmbH (CASSIDA FLUID<br />

HF 46)<br />

Poclain-Hydraulics (CASSIDA FLUID HF 46)<br />

Grégoire (A Kverneland Group Company) for their<br />

harvesting machinery<br />

GEA Niro atomisors (CASSIDA FLUID HF 32-68)<br />

Stork <strong>Food</strong> and Dairy Systems (CASSIDA FLUID HF<br />

15 - 100)<br />

Mitsubishi Caterpillar Forklift Europe<br />

Synthetic lubricants<br />

Do not contain natural products derived from animals<br />

or genetically modified organisms (GMO).<br />

Do not contain any allergenic or intolerance-inducing<br />

substances as specified in Annex IIIa of EC directive<br />

203/98/EC<br />

Suitable for use where vegetarian and ‘nut-free’ food is<br />

prepared.<br />

Biostatic; does not promote the growth of bacteria or<br />

fungal organisms.<br />

2010-08-17/HW/Te PI-No.: 3 - 7528

As far as we know these information reflect the current state of knowledge and our research. They cannot, however, be taken as an assurance about<br />

the properties nor as a guarantee of the suitability of the product for the individual case in point. Before using our products the purchaser must, therefore,<br />

check their suitability and be satisfied that the output will be satisfactory. Our products are continually being up-dated. We reserve the right,<br />

therefore, to alter the information of this product information at any time and without prior announcement.<br />

We are specialized in developing products for extreme tribological problems in cooperation with end users.<br />

<strong>FUCHS</strong> LUBRITECH provides service and individual advice. Please contact us!<br />

E-Mail: cassida.lubricants@fuchs-lubritech.de<br />

2010-08-17/HW/Te PI-No.: 3 - 7529

<strong>Product</strong> Information CASSIDA FLUID HF series<br />

“Incidental <strong>Food</strong> contact”<br />

Registered by NSF (Class H1) and meets the USDA H1<br />

guidelines (1998) for lubricants for use where there is a<br />

potential for incidental food contact.<br />

Made only from substances permitted under the US<br />

FDA Title 21 CFR 178.3570, 178.3620 and/or those<br />

generally regarded as safe (US 21 CFR 182) for use in<br />

food grade lubricants.<br />

To comply with the requirements of US 21 CFR<br />

178.3570, contact with food should be avoided where<br />

possible. In the case of incidental food contact, the concentration<br />

of this product in the food must not exceed 10<br />

parts per million (10mg/kg of foodstuff).<br />

In locations and/or applications where local legislation<br />

does not specify maximum concentration limits, it is<br />

recommended that this same 10 ppm limit be observed,<br />

as up to this concentration CASSIDA FLUID HF will not<br />

impart undesirable taste, odour or colour to food, nor will<br />

cause adverse health effects.<br />

Consistent with good manufacturing practice, use only<br />

the amount necessary to achieve correct lubrication and<br />

take appropriate corrective action should excessive<br />

incidental contact with food be detected.<br />

Health & Safety<br />

Based on information available, CASSIDA FLUID HF is<br />

unlikely to present any significant health or safety hazard<br />

when properly used in the recommended application<br />

and good standards of industrial and personal hygiene<br />

are maintained. As for all oils, prolonged or repeated<br />

contact with the skin should be avoided. For further<br />

information refer to the appropriate Material Safety <strong>Data</strong><br />

Sheet.<br />

Oil condition during use<br />

It is recommended that the condition of the oil and the<br />

equipment be regularly checked to ensure safe operation.<br />

Protect the environment<br />

Take used lubricants and empty packs to an authorised<br />

collection point. Do not discharge into drains, soil or water<br />

Handling and storage<br />

All food grade lubricants, such as CASSIDA FLUID HF,<br />

should be stored separately, out of direct sunlight or<br />

other heat sources, from other lubricants, chemical substances<br />

and foodstuffs. Store between 0°C and 40°C.<br />

Provided that the product has been stored under these<br />

conditions we recommend that the product be used<br />

within 5 years from the date of manufacture.<br />

Accept for use new CASSIDA FLUID HF only if the<br />

manufacturer's seal is intact.<br />

Before opening the pack ensure the area around the closure<br />

is clean. It is recommended that it be cleaned with<br />

CASSIDA FLUID PL and/or potable water and then dried<br />

with a clean cloth before opening.<br />

Record the date the seal was broken. To prevent product<br />

contamination, always close the package after use. Upon<br />

opening a pack, the product must be used within 2 years<br />

(or within 5 years of date of manufacture, whichever is<br />

the sooner).<br />

Typical characteristics<br />

CASSIDA FLUID HF 15 32 46 68 100<br />

Property Test Method<br />

NSF Registration Number 925400 92542 92543 92544 92539<br />

Colour Colourless<br />

Density at 15°C kg/m3 ISO 12185 819 832 836 840 841<br />

Flashpoint °C ISO 2592 200 222 248 258 268<br />

Pourpoint °C ISO 3016 < -60 -60 -57<br />

Kin. Visc. at 40°C mm2/s ISO 3104 15 32 46 68 100<br />

Kin. Visc. at 100°C mm2/s ISO 3104 3,6 6,1 7,9 10,6 14,1<br />

Viscosity index ISO 2909 125 140 142 143 143<br />

FZG-Test A/8.3/90<br />

Failure Load Stage<br />

DIN 51599<br />

These characteristics are typical for current production. Variations in these characteristics may occur.<br />

2010-08-17/HW/Te PI-No.: 3 - 7529<br />

---<br />

12<br />

> 12

<strong>Product</strong> Information CASSIDA FLUID HF series<br />

Hydraulic fluids for food manufacturing machinery<br />

CASSIDA FLUID HF 15, 32, 46, 68 and 100 are high performance, anti-wear multipurpose lubricants,<br />

specially developed for use in machinery used in the food and beverage processing and packaging<br />

industry.<br />

They are based on a careful blend of synthetic fluids and selected additives chosen for their ability to meet the<br />

stringent requirements of the food industry.<br />

Registered by NSF (Class H1) for use where there is potential for incidental food contact. These products meet<br />

the guidelines (1998) of, and were previously authorized by, the US Department of Agriculture <strong>Food</strong> Safety and<br />

Inspection Service (USDA FSIS) for H1 use (lubricant with incidental food contact) and listed in Miscellaneous<br />

Publication No 1419 “List of Proprietary Substances and Nonfood Compounds”. <strong>Product</strong> contain only substances<br />

permitted under US 21 CFR 178.3570, 178.3620 and 182 for use in lubricants with incidental food contact.<br />

Applications<br />

Hydraulic systems<br />

Hydrostatic gears<br />

Plain and anti-friction bearings<br />

General purpose lubrication including light duty<br />

gearboxes<br />

Circulating oil systems<br />

Performance Features<br />

The base fluid has an ability to provide superior<br />

lubrication under the majority of operating conditions.<br />

Good anti-wear performance offers long and reliable<br />

component life, resulting in greater plant utilisation<br />

and therefore lower maintenance costs.<br />

Prevent component damage trough excellent water<br />

separation properties, which resist formation of potentially<br />

harmful emulsions.<br />

Excellent air release and antifoam characteristics<br />

minimise cavitation.<br />

Resist the formation of harmful products of oxidation,<br />

even at elevated temperatures, resulting in long oil<br />

life.<br />

Neutral odour and taste.<br />

High viscosity index results in minimum variation of<br />

viscosity with change in temperature.<br />

Effective protection against corrosion of metal surfaces.<br />

Seal and Paint Compatibility<br />

Compatible with the elastomers, gaskets, seals and<br />

paints normally used in food machinery lubrication systems.<br />

Specifications and Certificates<br />

NSF H1<br />

Kosher<br />

Halal<br />

DIN 51524 HLP<br />

DIN 51524 HVLP (except HF 15)<br />

DIN 51517 CLP (HF 68, HF 100)<br />

ISO 6743-4 L-HM (HF 15), L-HV<br />

Approvals & Recommendations<br />

This is an ongoing process, please contact your local<br />

Shell company for any updates.<br />

Krones<br />

David Brown<br />

Buehler Utzwil<br />

Mannesmann Rexroth (for axial piston pumps)<br />

FAG<br />

Ferrum (can seamer CASSIDA FLUID HF 100)<br />

FMC (can seamer, viscosity see to OEM specification)<br />

Westfalia <strong>Food</strong> Tec<br />

Hawe Hydraulic pumps<br />

Hoegger Alpina hydraulic pumps<br />

Piller Industrieventilatoren GmbH (CASSIDA FLUID<br />

HF 46)<br />

Poclain-Hydraulics (CASSIDA FLUID HF 46)<br />

Grégoire (A Kverneland Group Company) for their<br />

harvesting machinery<br />

GEA Niro atomisors (CASSIDA FLUID HF 32-68)<br />

Stork <strong>Food</strong> and Dairy Systems (CASSIDA FLUID HF<br />

15 - 100)<br />

Mitsubishi Caterpillar Forklift Europe<br />

Synthetic lubricants<br />