Firetube Boilers and Accessories

Firetube Boilers and Accessories

Firetube Boilers and Accessories

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

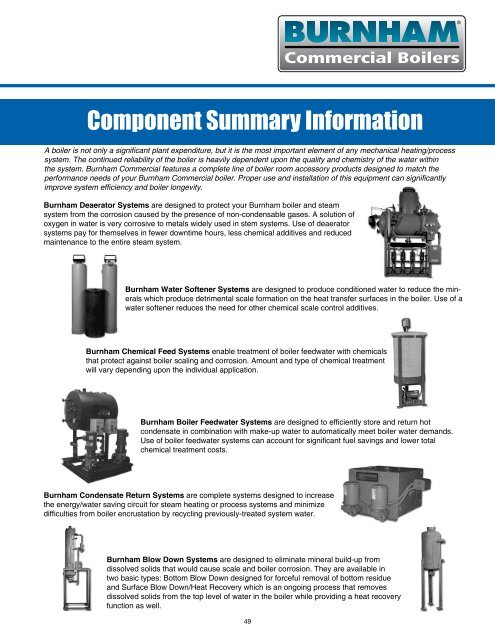

Component Summary Information<br />

A boiler is not only a significant plant expenditure, but it is the most important element of any mechanical heating/process<br />

system. The continued reliability of the boiler is heavily dependent upon the quality <strong>and</strong> chemistry of the water within<br />

the system. Burnham Commercial features a complete line of boiler room accessory products designed to match the<br />

performance needs of your Burnham Commercial boiler. Proper use <strong>and</strong> installation of this equipment can significantly<br />

improve system efficiency <strong>and</strong> boiler longevity.<br />

Burnham Deaerator Systems are designed to protect your Burnham boiler <strong>and</strong> steam<br />

system from the corrosion caused by the presence of non-condensable gases. A solution of<br />

oxygen in water is very corrosive to metals widely used in stem systems. Use of deaerator<br />

systems pay for themselves in fewer downtime hours, less chemical additives <strong>and</strong> reduced<br />

maintenance to the entire steam system.<br />

Burnham Water Softener Systems are designed to produce conditioned water to reduce the minerals<br />

which produce detrimental scale formation on the heat transfer surfaces in the boiler. Use of a<br />

water softener reduces the need for other chemical scale control additives.<br />

Burnham Chemical Feed Systems enable treatment of boiler feedwater with chemicals<br />

that protect against boiler scaling <strong>and</strong> corrosion. Amount <strong>and</strong> type of chemical treatment<br />

will vary depending upon the individual application.<br />

Burnham Boiler Feedwater Systems are designed to efficiently store <strong>and</strong> return hot<br />

condensate in combination with make-up water to automatically meet boiler water dem<strong>and</strong>s.<br />

Use of boiler feedwater systems can account for significant fuel savings <strong>and</strong> lower total<br />

chemical treatment costs.<br />

Burnham Condensate Return Systems are complete systems designed to increase<br />

the energy/water saving circuit for steam heating or process systems <strong>and</strong> minimize<br />

difficulties from boiler encrustation by recycling previously-treated system water.<br />

Burnham Blow Down Systems are designed to eliminate mineral build-up from<br />

dissolved solids that would cause scale <strong>and</strong> boiler corrosion. They are available in<br />

two basic types: Bottom Blow Down designed for forceful removal of bottom residue<br />

<strong>and</strong> Surface Blow Down/Heat Recovery which is an ongoing process that removes<br />

dissolved solids from the top level of water in the boiler while providing a heat recovery<br />

function as well.<br />

9