You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

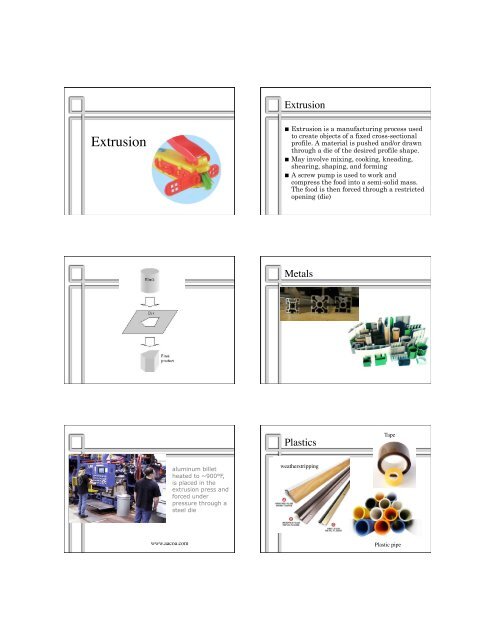

Extrusion<br />

www.aacoa.com<br />

aluminum billet<br />

heated to ~900°F,<br />

is placed in the<br />

extrusion press and<br />

forced under<br />

pressure through a<br />

steel die<br />

Extrusion<br />

Extrusion is a manufacturing process used<br />

to create objects of a fixed cross-sectional<br />

profile. A material is pushed and/or drawn<br />

through a die of the desired profile shape.<br />

May involve mixing, cooking, kneading,<br />

shearing, shaping, and forming<br />

A screw pump is used to work and<br />

compress the food into a semi-solid mass.<br />

The food is then forced through a restricted<br />

opening (die)<br />

Metals<br />

Plastics<br />

weatherstripping<br />

Tape<br />

Plastic pipe

plastic pellets which are dried in a hopper before going to<br />

the feed screw. The polymer resin is heated to molten<br />

state as it is fed to the extrusion tooling. The die molds<br />

the heated mass into the desired shape. The extrudate is<br />

cooled and solidified as it is pulled through the die or<br />

water tank.<br />

Food Products<br />

Stuffings, croutons<br />

Crispbread<br />

Cornflakes, cheerios, Crispix<br />

Texturized soy proteins<br />

Confections: liquorice, fruit gums<br />

Dry expanded pet foods<br />

Prefab cookie dough<br />

Snack foods; puffed snack products<br />

www.math.utwente.nl<br />

Plastics<br />

Extruded cereal

Fig Newtons<br />

Sevai<br />

Advantages<br />

Dry cat food<br />

Reduced costs: labor, energy, and processing costs<br />

lower than other cooking and forming methods<br />

High production rates: snacks continuously<br />

produced at 700 lbs/hr; cereals at 2800 lbs/hr.<br />

Versatility: one unit can produce a wide range of<br />

different products by changing a few components<br />

Improved functional characteristics:<br />

solubility and textural characteristic can be<br />

adjusted, e.g. soluble breakfast powders to<br />

chew breakfast cereals.<br />

No process effluents<br />

Textured soy chunks<br />

www.americankuhne.com<br />

= blender + mixer + kneader +<br />

heater/cooking + shaping + portion control<br />

Videos<br />

• Ice Cream Bars<br />

http://www.youtube.com/watch?v=7hXfFfGMT_M<br />

• De-germed maize or corn http://video.google.com/<br />

videoplay?docid=2448334957785560450<br />

• Plastic<br />

http://www.youtube.com/watch?v=j1FcCH8tzNU<br />

http://www.youtube.com/watch?v=KboGBwJQIuw<br />

• Home pasta<br />

http://www.youtube.com/watch?v=SCofPv2Heqs<br />

• Tootsie roll<br />

http://www.youtube.com/watch?v=n263fXBYXi0<br />

• Fish food<br />

http://www.youtube.com/watch?v=LIrsV5CqrM0

Hot or Cold<br />

<strong>Extruder</strong> Types<br />

Extrusion cookers: food is heated by steam jacket<br />

(or electric heater). High pressure, small dies<br />

used to form expanded products as moisture<br />

evaporates outside of die. Low pressure, large<br />

dies for high density products.<br />

High shear products: Snackfoods, croutons,<br />

cereals, meat analogs.<br />

Low shear products: chewing gum, dense<br />

snackfoods<br />

Cold Extrusion: product extruded into strips<br />

without cooking or expansion. Deep<br />

flighted screws at low speed in a smooth<br />

barrel.<br />

– Pasta, hot dogs, pastry doughs, some candies,<br />

ice cream novelties.<br />

– Special die may inject filling into an outer shell<br />

(coextrusion).<br />

Puffed snacks<br />

http://foodprotein.tamu.edu/extrusion<br />

Cherry mash bars<br />

Ram versus Screw<br />

Textured vegetable protein

Ice cream bars<br />

Twin Screw <strong>Extruder</strong>: Two screws rotate in a<br />

figure 8 shaped bore. Advantages:<br />

– throughput independent of feedrate, fluctuations in<br />

production accommodated<br />

– can handle oily, sticky, or wet materials that slip in a<br />

single screw<br />

– Forward and reverse conveying allow greater pressure<br />

control<br />

– Short discharge section, less wear on machine<br />

– Larger variety of feed particle sizes possible<br />

<strong>Extruder</strong> Screw<br />

Extrusion Screw<br />

δ<br />

w<br />

B<br />

θ<br />

Channel<br />

r<br />

Central<br />

shaft<br />

Helical flights<br />

Single and Twin Screw <strong>Extruder</strong>s<br />

Single Screw <strong>Extruder</strong>s: a single screw<br />

with feed, kneading, and cooking/metering<br />

sections.<br />

– Lower capital and operating costs<br />

– Require less skill to operate and maintain<br />

Factors Effecting Nature of Extruded Product<br />

Operating conditions<br />

– Temperature<br />

– Pressure<br />

– Diameter (and shape) of the die<br />

– Shear rate<br />

Rheological properties of the food<br />

apvbaker

Archimedian screw rotates in a tightly<br />

fitting barrel<br />

Relatively shallow flights and mechanism<br />

for compressing food as it moves from<br />

hopper to discharge die.<br />

Screw flights completely filled with food<br />

Rotation causes high shear conditions<br />

– decreasing pitch, constant root diameter<br />

– constant diameter screw, decreasing barrel<br />

The careful control of the screw properties<br />

along the barrel control the degree of mixing,<br />

compression, and even temperature rise<br />

www.technicalwelding.co.uk<br />

Compression accomplished with one of<br />

several designs<br />

– increasing root diameter<br />

– decreasing pitch, decreasing barrel<br />

– restrictions in barrel

Screw Sections<br />

Feed section: has deeper flights or with<br />

greater pitch. Feed falls easily into screw<br />

and begins to be conveyed.<br />

Transition or compression region: granular<br />

or sticky mass converted to a uniform<br />

plasticized dough. Product compacted,<br />

mixed, and worked.<br />

Metering section: shallow flights, reduced q<br />

used to thoroughly mix and/or increase T<br />

Other Components<br />

Extrusion stand: base that supports the<br />

drive, bearings, and extrusion barrel and<br />

screw<br />

Drive mechanism: usually an electric motor<br />

operating through gear reduction to obtain<br />

proper speed. Drive attached to screw via<br />

flexible coupling.<br />

Barrel: Usually bolted together sections<br />

containing cylinder within which screw<br />

rotates. Usually hardened surface to limit<br />

abrasion caused by high shear conditions.<br />

Common diameters: 2.54 - 20.32 cm. Long<br />

barrels give more surface for heating/<br />

cooling, longer residence time => more<br />

control. L/D range from 3:1 to 25:1.<br />

Normal operating pressures: 15 - 70 atm.<br />

Hopper<br />

Feeder<br />

FEED<br />

SECTION<br />

COMPRESSION<br />

SECTION<br />

Steam Jacket<br />

METERING<br />

SECTION<br />

Thrust bearing: extrusion screw supported<br />

by bearing at driven end. Rearward thrust<br />

must be absorbed to compensate for force<br />

imparted to extruded food as it moves<br />

forward.<br />

Feed hopper: opening through which feed<br />

materials enter screw. Often with agitators,<br />

offset, and with cooling jackets to enhance<br />

feed. May be dry grits, flours, sticky<br />

doughs, etc.<br />

Barrel temperature control: heat is added/<br />

removed from sections of barrel surface.<br />

Hollow jackets around barrel can accept<br />

steam or cooling water. Temperature of last<br />

barrel most commonly varied to achieve<br />

desired product temperature. Steam<br />

injection sometimes used.<br />

Die

Temperature sensing: T of product sensed<br />

just behind die (melt temperature).<br />

Temperatures along barrel also often<br />

monitored with thermocouple probes.<br />

Pressure sensing: pressures just behind die<br />

are useful.<br />

Breaker plate: perforated metal discs<br />

between end of screw and die. Stops hard<br />

uncooked pieces from entering die and<br />

plugging. Also enhances back-mixing.<br />

Estimated moisture loss<br />

mC p(T 1 − T 2) = m(M 1 − M 2 )ΔH v<br />

M 2 = M 1 ΔH v − C p (T 1 − T 2 )<br />

ΔH v<br />

m =mass flow rate of food, Cp=ht capacity, M=moisture<br />

content, ∆Hv=latent heat of vaporization (at ambient pressure),<br />

1 = before die 2 = after die.<br />

Food Properties During Extrusion<br />

200<br />

Temp<br />

(°C)<br />

0<br />

Flour H 2O<br />

Feed Zone<br />

Venting<br />

Plasticizing<br />

Zone<br />

Pressure<br />

Build-up Zone<br />

Die: shaped holes through which exudate<br />

emerges. May form rods, spheres, donuts,<br />

tubes, strips, etc. Expansion occurs as<br />

product leaves because of rapid release of<br />

pressure from the end of the extruder to<br />

ambient conditions. Flashing of moisture<br />

occurs (H 2 O was above normal TB).<br />

High P,<br />

High T<br />

Product<br />

50<br />

Moisture<br />

(%)<br />

0<br />

Flour H 2O<br />

Feed Zone<br />

Atmospheric Pressure<br />

T > T b<br />

Venting<br />

Steam<br />

Steam leaves product and<br />

expands matrix. As moisture<br />

content decreases, structure<br />

solidifies.<br />

Plasticizing<br />

Zone<br />

Pressure<br />

Build-up Zone

1<br />

Density<br />

(g/cm 3 )<br />

0<br />

Flour H 2 O<br />

Feed Zone<br />

Venting<br />

Plasticizing<br />

Zone<br />

Pressure<br />

Build-up Zone<br />

50<br />

Pressure<br />

(bar)<br />

0<br />

Flour H 2 O<br />

Feed Zone<br />

Venting<br />

Plasticizing<br />

Zone<br />

Pressure<br />

Build-up Zone