You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

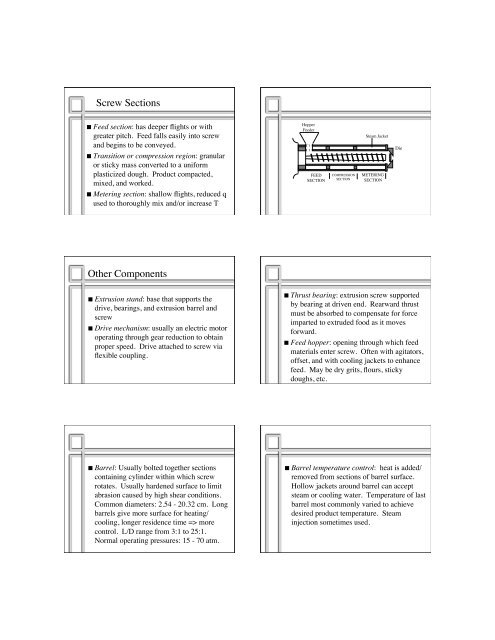

Screw Sections<br />

Feed section: has deeper flights or with<br />

greater pitch. Feed falls easily into screw<br />

and begins to be conveyed.<br />

Transition or compression region: granular<br />

or sticky mass converted to a uniform<br />

plasticized dough. Product compacted,<br />

mixed, and worked.<br />

Metering section: shallow flights, reduced q<br />

used to thoroughly mix and/or increase T<br />

Other Components<br />

Extrusion stand: base that supports the<br />

drive, bearings, and extrusion barrel and<br />

screw<br />

Drive mechanism: usually an electric motor<br />

operating through gear reduction to obtain<br />

proper speed. Drive attached to screw via<br />

flexible coupling.<br />

Barrel: Usually bolted together sections<br />

containing cylinder within which screw<br />

rotates. Usually hardened surface to limit<br />

abrasion caused by high shear conditions.<br />

Common diameters: 2.54 - 20.32 cm. Long<br />

barrels give more surface for heating/<br />

cooling, longer residence time => more<br />

control. L/D range from 3:1 to 25:1.<br />

Normal operating pressures: 15 - 70 atm.<br />

Hopper<br />

Feeder<br />

FEED<br />

SECTION<br />

COMPRESSION<br />

SECTION<br />

Steam Jacket<br />

METERING<br />

SECTION<br />

Thrust bearing: extrusion screw supported<br />

by bearing at driven end. Rearward thrust<br />

must be absorbed to compensate for force<br />

imparted to extruded food as it moves<br />

forward.<br />

Feed hopper: opening through which feed<br />

materials enter screw. Often with agitators,<br />

offset, and with cooling jackets to enhance<br />

feed. May be dry grits, flours, sticky<br />

doughs, etc.<br />

Barrel temperature control: heat is added/<br />

removed from sections of barrel surface.<br />

Hollow jackets around barrel can accept<br />

steam or cooling water. Temperature of last<br />

barrel most commonly varied to achieve<br />

desired product temperature. Steam<br />

injection sometimes used.<br />

Die