Energy floater water power plant - Technologiekompetenz Fluss-Strom

Energy floater water power plant - Technologiekompetenz Fluss-Strom

Energy floater water power plant - Technologiekompetenz Fluss-Strom

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Energy</strong> <strong>floater</strong> <strong>water</strong><br />

<strong>power</strong> <strong>plant</strong><br />

Water<strong>power</strong> without dams<br />

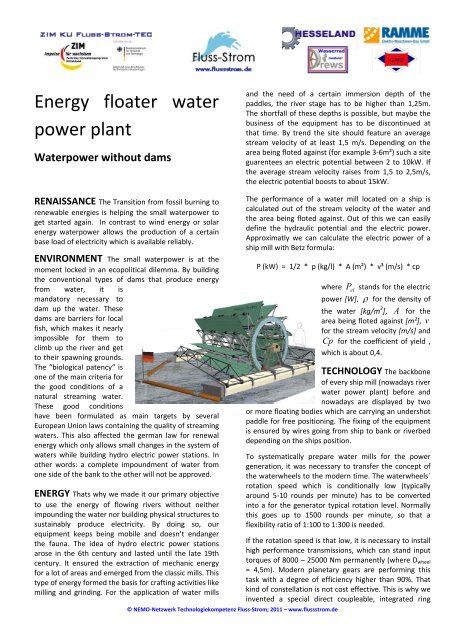

RENAISSANCE The Transition from fossil burning to<br />

renewable energies is helping the small <strong>water</strong><strong>power</strong> to<br />

get started again. In contrast to wind energy or solar<br />

energy <strong>water</strong><strong>power</strong> allows the production of a certain<br />

base load of electricity which is available reliably.<br />

ENVIRONMENT The small <strong>water</strong><strong>power</strong> is at the<br />

moment locked in an ecopolitical dilemma. By building<br />

the conventional types of dams that produce energy<br />

from <strong>water</strong>, it is<br />

mandatory necessary to<br />

dam up the <strong>water</strong>. These<br />

dams are barriers for local<br />

fish, which makes it nearly<br />

impossible for them to<br />

climb up the river and get<br />

to their spawning grounds.<br />

The “biological patency“ is<br />

one of the main criteria for<br />

the good conditions of a<br />

natural streaming <strong>water</strong>.<br />

These good conditions<br />

have been formulated as main targets by several<br />

European Union laws containing the quality of streaming<br />

<strong>water</strong>s. This also affected the german law for renewal<br />

energy which only allows small changes in the system of<br />

<strong>water</strong>s while building hydro electric <strong>power</strong> stations. In<br />

other words: a complete impoundment of <strong>water</strong> from<br />

one side of the bank to the other will not be approved.<br />

ENERGY Thats why we made it our primary objective<br />

to use the energy of flowing rivers without neither<br />

impounding the <strong>water</strong> nor building physical structures to<br />

sustainably produce electricity. By doing so, our<br />

equipment keeps being mobile and doesn’t endanger<br />

the fauna. The idea of hydro electric <strong>power</strong> stations<br />

arose in the 6th century and lasted until the late 19th<br />

century. It ensured the extraction of mechanic energy<br />

for a lot of areas and emerged from the classic mills. This<br />

type of energy formed the basis for crafting activities like<br />

milling and grinding. For the application of <strong>water</strong> mills<br />

and the need of a certain immersion depth of the<br />

paddles, the river stage has to be higher than 1,25m.<br />

The shortfall of these depths is possible, but maybe the<br />

business of the equipment has to be discontinued at<br />

that time. By trend the site should feature an average<br />

stream velocity of at least 1,5 m/s. Depending on the<br />

area being floted against (for example 3‐6m²) such a site<br />

guarentees an electric potential between 2 to 10kW. If<br />

the average stream velocity raises from 1,5 to 2,5m/s,<br />

the electric potential boosts to about 15kW.<br />

The performance of a <strong>water</strong> mill located on a ship is<br />

calculated out of the stream velocity of the <strong>water</strong> and<br />

the area being floted against. Out of this we can easily<br />

define the hydraulic potential and the electric <strong>power</strong>.<br />

Approximatly we can calculate the electric <strong>power</strong> of a<br />

ship mill with Betz formula:<br />

P (kW) = 1/2 * p (kg/l) * A (m²) * v³ (m/s) * cp<br />

© NEMO‐Netzwerk <strong>Technologiekompetenz</strong> <strong>Fluss</strong>‐<strong>Strom</strong>; 2011 – www.flussstrom.de<br />

where P el stands for the electric<br />

<strong>power</strong> [W], ρ for the density of<br />

the <strong>water</strong> [kg/m 3 ], A for the<br />

area being floted against [m²], v<br />

for the stream velocity [m/s] and<br />

Cp for the coefficient of yield ,<br />

which is about 0,4.<br />

TECHNOLOGY The backbone<br />

of every ship mill (nowadays river<br />

<strong>water</strong> <strong>power</strong> <strong>plant</strong>) before and<br />

nowadays are displayed by two<br />

or more floating bodies which are carrying an undershot<br />

paddle for free positioning. The fixing of the equipment<br />

is ensured by wires going from ship to bank or riverbed<br />

depending on the ships position.<br />

To systematically prepare <strong>water</strong> mills for the <strong>power</strong><br />

generation, it was necessary to transfer the concept of<br />

the <strong>water</strong>wheels to the modern time. The <strong>water</strong>wheels´<br />

rotation speed which is conditionally low (typically<br />

around 5‐10 rounds per minute) has to be converted<br />

into a for the generator typical rotation level. Normally<br />

this goes up to 1500 rounds per minute, so that a<br />

flexibility ratio of 1:100 to 1:300 is needed.<br />

If the rotation speed is that low, it is necessary to install<br />

high performance transmissions, which can stand input<br />

torques of 8000 – 25000 Nm permanently (where Dwheel<br />

= 4,5m). Modern planetary gears are performing this<br />

task with a degree of efficiency higher than 90%. That<br />

kind of constellation is not cost effective. This is why we<br />

invented a special direct coupleable, integrated ring

segment generator for the project “<strong>Energy</strong> <strong>floater</strong>” to<br />

convert energy without gear!<br />

CONSTRCTION Also the production‐ and material<br />

technology have made a large step forwards. High‐<br />

quality steel, aluminium, FBE/CFL and CNC‐based/<br />

controlled manufacturing processes are replacing the<br />

carpenters work. Very expensive special editions to<br />

adapt to geographical circumstances of a specific<br />

location are not necessary anymore. In the sense of<br />

customized clothing our modular system, based on<br />

standardized elements (pontoons, <strong>Fluss</strong>‐<strong>Strom</strong>‐TEC‐<br />

Teflon‐Polyamide‐plain‐bearing; generator, stator<br />

segments etc.) allows the individual batch production of<br />

modern and cheap ship mills to produce electric current<br />

economically.<br />

BUSINESS This includes the unmanned operation<br />

with remote monitoring and ‐control. State enquiries<br />

and changes of operational sequences like stopping the<br />

wheel can be performed easily from home via mobile<br />

phone, PC, or internet.<br />

In hydrological institutes you can find for virtually all<br />

streaming <strong>water</strong>s in Germany and Europe a certain list,<br />

in which the flow rates are shown. The feeding of<br />

electric current into the open electric grid and its<br />

compensation is guaranteed by law for 20 years. With its<br />

last amendment, the compensation for electricity fed<br />

into the grid coming from small hydro electric <strong>power</strong><br />

stations (under 500kW) has been raised to 12,67<br />

Cent/kWh. Based on these numbers it is possible to<br />

make investment decisions.<br />

PROFITABLENESS Assuming a rate of availability of<br />

85%, which corresponds to an annual operating time of<br />

44 weeks or 7400 hours, you should take a look on the<br />

following example:<br />

Clamshell‐<strong>water</strong>wheel: Example I<br />

Width = 5m; depth of immersion = 1m; area to be floted<br />

against = 5m²; continuous output at a stream velocity of<br />

1.8 m/s (1,17kW/m²):<br />

5m² * 1,17kW/m² = 5,85kW, generator <strong>power</strong> * 7400h/a<br />

= 43.290kWh/year; annual income guaranteed from the<br />

law for renewable energy: 43.290kWh/year * 0.1267<br />

Euro/kWh = ~ 5485,‐€/year<br />

Investment (bases on batch production of all<br />

components): ~6500,‐€/kW (generator <strong>power</strong>), 5,85kW<br />

(generator <strong>power</strong>) * 6500€/kW = 38.000,‐Euro total<br />

investment leading to an amortization time of 6,9<br />

years.<br />

Clamshell‐<strong>water</strong>wheel: Example II<br />

Same overall size, but faster stream velocity: Width =<br />

5m; depth of immersion = 1m; area to be floted against<br />

= 5m²; continuous output at a stream velocity of 2.2 m/s<br />

(2.13 kW/m²):<br />

5m² * 2.13 kW/m² = 10.65kW, generator <strong>power</strong> *<br />

7400h/a = 78.810 kWh/year; annual income guaranteed<br />

from the law for renewable energy: 78.810kWh/year *<br />

0.1267 Euro/kWh = ~9985,‐€/year<br />

Investment (bases on batch production of all<br />

components): same kit as in Example I, but 2 pieces of<br />

stator segments for a bigger energy extraction = 38.000,‐<br />

EURO + 2 * 4.000,‐ EURO = 46.000,‐ EURO total<br />

investment leading to an amortization time of 4,6<br />

years.<br />

500‐1000€ have to be used for Maintenance and<br />

business.<br />

Fleet of <strong>water</strong> mills for about 100 kW at 2.5 m/s<br />

© NEMO‐Netzwerk <strong>Technologiekompetenz</strong> <strong>Fluss</strong>‐<strong>Strom</strong>; 2011 – www.flussstrom.de