Download Complete Acco Wire Rope Hoist Catalogue (PDF

Download Complete Acco Wire Rope Hoist Catalogue (PDF

Download Complete Acco Wire Rope Hoist Catalogue (PDF

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Table of Contenls<br />

Wotk-Rated <strong>Hoist</strong>s . ......2<br />

ParallelMounted ...........3<br />

Cross Mounted . . . . . . . . . . . . .3<br />

Work-Rated Cut-away. . ....4,5<br />

Twin Hook<strong>Hoist</strong>s . .........6<br />

ElectricWinches . . . . . . . . . . . . . . . . . . .6<br />

Deck Mounted <strong>Hoist</strong>s . .... . .7<br />

Top Running Trolley <strong>Hoist</strong>s ..........7<br />

WrightAmerican<strong>Hoist</strong>s ...........8<br />

Lug Mounted ......9<br />

4WheelTrolley. ............9<br />

owheelTrolley. ............9<br />

Wright Ametican Cut-away . . . . . . . 10,11<br />

Wright-Way <strong>Hoist</strong>s.. .....12<br />

StandardHeadroom .......13<br />

Close Headroom ..... .....13<br />

Wright-Way Cul-away . . . . . . . . . . . . 14,15<br />

<strong>Hoist</strong> Features .......16,17<br />

Features/OptionsTable ........18,19<br />

Reeving . . . . .20,21<br />

TrolleySuspensions.. .......-...22<br />

<strong>Hoist</strong> Duty Glassif ications ........23<br />

How to Select and Order the Right <strong>Hoist</strong> . . . .24<br />

Quality Assurance . . . . ...........25<br />

Glossaryof Terms ....26,27

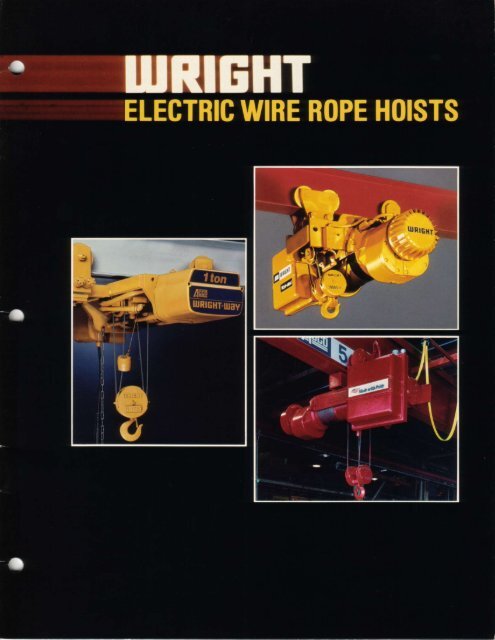

Electric <strong>Wire</strong> Ro e <strong>Hoist</strong>s IIIRIEHT'<br />

Work-Rated <strong>Wire</strong> <strong>Rope</strong> <strong>Hoist</strong>s<br />

The Work-Rated hoists are custom<br />

engineered to meet your specifications and<br />

exacting material handling needs.<br />

Wright American <strong>Wire</strong> <strong>Rope</strong> <strong>Hoist</strong>s<br />

Wright American hoists combine the<br />

engineered durability of custom specified<br />

hoists with the price and delivery of off-theshelf<br />

products.<br />

Wright-Way <strong>Wire</strong> <strong>Rope</strong> <strong>Hoist</strong>s<br />

The pre-packaged solution to many<br />

material handling problems.<br />

WARNING:<br />

Equipment described herein is not designed for, and should not<br />

be used for, lifting, supporting, or transporting humans.<br />

Modifications to upgrade, rerale, or olherwise allsr the hoist or<br />

crane equipment shall be authorized onty by the origlnal<br />

manufacturer or qualified professional engineer. Failure to<br />

comply wlth any one of the limitalions noted herein may result in<br />

serious bodily injury. Specifications subject to change without<br />

noltce.

Work-rated@ <strong>Hoist</strong>s<br />

Capacities-l to 25 fons*<br />

These hoists are engineered to meet your<br />

particular material handling needs. Severe,<br />

heavy and normal duly Work-Rafed models<br />

are offered in each capacity. You buy exactly<br />

the hoist you need, no more, no less.<br />

The basic conf iguration of the one ton hoist<br />

is the same as the twenty-five ton capacity<br />

unit, providing a unif ied design approach<br />

that makes Ihe Work-Rated line the most<br />

complete family of hoists available. This<br />

design unity also simplifies maintenance.<br />

The most current design and safety<br />

features are built in, not added on. These<br />

reliable, field tested design features combine<br />

with a wide range of mechanical and<br />

electrical options to satisfy the most exacting<br />

user demands. <strong>Hoist</strong>s for special<br />

operating environments, for example explosion<br />

proof hoists, are also available.<br />

Both oarallel or close headroom cross<br />

mounted conf igurations are available in a<br />

variety of reeving arrangements to meet<br />

hook travel and headroom constraints.<br />

<strong>Hoist</strong> suspens ions available are:<br />

. Lug mounted<br />

. Plain trolley<br />

. Geared trolley<br />

. Motorized trolley<br />

. Deck mounted<br />

. Base mounted<br />

. Top running trolley<br />

-<br />

<strong>Hoist</strong>s with capacities greater than 25 tons are<br />

available uoon reo uest.

!<br />

v<br />

t;l<br />

t:t<br />

v<br />

bl<br />

o<br />

v<br />

1#-<br />

IIIRIEHT'<br />

PARALLEL MOUNTED HOISTS<br />

When lateral hook travel, headroom and<br />

end approach are not concerns, a parallel<br />

mounted Work-Rated hoist provides a good<br />

hoist value. The hoist travels in a<br />

lengthwise position to the beam or track<br />

and requires no counter balancing. Single<br />

reeving is the most economic choice, but<br />

when lateral hook travel presents a problem,<br />

double reeving, with true vertical lift,<br />

is also available on oarallel mounted<br />

hoists.<br />

CROSS MOUNTED HOISTS<br />

For situations where headroom and end aoproach<br />

dimensions are critical, cross<br />

mounted Work-Bated hoists, that travel<br />

perpendicular to the track or beam, offer<br />

the closest minimum operating profile of<br />

underhung hoists.

Work-ratediu' <strong>Hoist</strong>s<br />

CONTROLS<br />

LIMIT SWITCH<br />

WIRE ROPE<br />

BOTTOM BLOCK<br />

OVERLOAD CUTOFF<br />

T^,)<br />

*<br />

a<br />

I<br />

a<br />

GEAR TRAIN

!<br />

BEARINGS MECHANTCAL LOAD BRAKE<br />

MOTOR BRAKE<br />

IIIRIGHT'

Work-rated@ <strong>Hoist</strong>s<br />

Capacities-l12 to 3 Tons<br />

Capacities-l/2 to 5 Tons<br />

TWIN HOOK HOISTS<br />

Work-Rated twin hook hoists are designed<br />

for lifting long or bulky loads. The twin<br />

hooks provide support at two<br />

points...minimizing load sway, tipping or<br />

rotation. The compact close headroom profile<br />

is ideally suited for severe duty applications<br />

in patented track, bridge cranes and<br />

lifting sections. The strong steel frame,<br />

when attached to either a plain, geared or<br />

motorized trolley, makes lifting and<br />

transporting bulky loads easy. The balanced<br />

hoist design centers the load hook<br />

directly under the track and elim inates tippino<br />

as the load varies.<br />

ELECTRIC WINCHES<br />

Work-Rated winches meet specif ic lifting or<br />

pulling needs where conventional hoist<br />

reeving is not required. Base or wall<br />

mounted models are available with single<br />

and double line reeving and have the same<br />

proven Wright constructron features as<br />

Work-Rated hoists, except for the gravity<br />

limit switch and the Wright overload cutoff.

DECK/BASE MOUNTED HOISTS<br />

Deck or base mounted hoists are designed<br />

for lifting applications where hoist movement<br />

is not required, or where the crane<br />

builder will fabricate his own trollev.<br />

TOP RUNNING TROLLEY HOISTS<br />

Our largest capacity Work-Rated hoist that<br />

are designed to run on top of the double<br />

girder crane bridge. A Work-Rated hoist is<br />

mounted on a frame of welded ductile<br />

structural shapes for maximum strength<br />

and wheel/bearing alignment, with an independent<br />

trolley drive motor that drives<br />

the trolley through the wheel axles.<br />

IURIGHT<br />

Capacities-l to 20 Tons<br />

Capacities-l to 30 Tons

Wright American <strong>Hoist</strong>s<br />

fhe Wright American hoist line combines<br />

the engineered durability of custom<br />

specified hoists with the price and delivery<br />

of "off-the-shelf" products. Using high<br />

volume Wright pafts, parts with years of iob<br />

proven dependability, creates cost saving<br />

production efficiencies. Offering a limited<br />

Standard Features<br />

8<br />

. 2,3, 5,7-112 and 10 capacities<br />

. H-4 Duty Class<br />

. Low Headroom<br />

. Minimum End Approach<br />

. Lug mounted, Plain, geared and<br />

motorized trolley susPensions<br />

. True Vertical Lift-2 part double<br />

reeving on 2 through 5 ton, and 4<br />

part double reeving on the 7'112<br />

and 10 ton capacities.<br />

. Helical gearing on high speed<br />

shaft<br />

. Spur gearing on the drum shaft<br />

. D.C. disc brake<br />

. Single speed or two speed motor<br />

. NEMA 3R Enclosure<br />

. Complies with ANSI 830.16 and<br />

ANSI/ASM E-4M specif ications<br />

choice models (available only in cross<br />

mounted, under hung suspensions), with<br />

the most f requently requested Wright<br />

features, results in a high quality, very competitively<br />

priced hoist delivered in two to<br />

f our weeks.<br />

Optional Features<br />

. UPPer and lower geared limit<br />

switc hes<br />

. Trolley motor brake<br />

. Mainline contactor<br />

o Trolley with ACM or ballast<br />

resistors<br />

. Thermal overload relays<br />

. NEMA type 4 or 12 enclosures<br />

. Optional trolley speeds-32 FPM on<br />

all models and 125 FPM on 2 and<br />

3 ton models.<br />

. Operation on Patented track<br />

o Extra oush button stations<br />

. Optional Paint colors<br />

v<br />

v<br />

v

w<br />

ty<br />

\,<br />

IIIRIEHT"<br />

Wright Ametican hoists are available in lug<br />

mounted, plain, geared and motorized<br />

trolley suspensions. The 3 and 5 ton capacity<br />

models are available in both 4 and 6<br />

wheel trolley arrangements. The 6 wheel<br />

trolleys have lower per pair wheel loads,<br />

making them ideal for operation on smaller<br />

structural beams and palented track.<br />

LUG MOUNTED<br />

Capacities-2 to 10 Tons<br />

4 WHEEL MOTORIZED TROLLEY<br />

Capacities-2 to 5 Tons<br />

6 WHEEL MOTORIZED TROLLEY<br />

Gapacities-3 to 10 Tons

Wright American <strong>Hoist</strong>s<br />

10<br />

MOTOR<br />

WIRE ROPE<br />

CONTROLS<br />

BOTTOM BLOCK

\-<br />

LIMIT SWITCH<br />

GEAR TRAIN<br />

BEARINGS<br />

MOTOR BRAKE<br />

MECHANICAL LOAD<br />

BRAKE<br />

IIIRIGHT'<br />

'11

Wright-Wayt <strong>Hoist</strong>s<br />

Capacities-l14 to 2 Tons<br />

Wright-Way hoists are built with many of<br />

the same construction features as the<br />

Work-Rated and Wright American hoists;<br />

construction fealures unioue to hoists of<br />

their size and orice.<br />

The exclusive patented Wright overload<br />

cutoff is standard equipment on all Wright-<br />

Way hoists. The device protects the<br />

operator, the load and the hoist by sensing<br />

an excessive overload and interrupting the<br />

lifting circuit, preventing lifting but allowing<br />

the overload to be safely lowered and<br />

removed. The device then automatically<br />

resets and the hoist is ready for the next lift.<br />

Othet Wright-Way lealures include; dual<br />

braking using an electric motor brake and a<br />

12<br />

mechanical load brake, automatic reset<br />

thermostats in the motor windings, a combination<br />

of helical and spur gearing encased<br />

in an oil-tight aluminum housing, easily<br />

accessible controls in a tough NEMA 3R<br />

enclosure, ductile iron lifting frame and<br />

preformed aircraft grade steel wire rope on<br />

a steel drum with machined grooves and<br />

large f langes.<br />

Wright-Way hoists are available in lug,<br />

plain, geared and motorized trolley suspensions.<br />

In addition to operating on structural<br />

beams, standard Wright-Way trolleys can<br />

operate on 3.25 and 3.33 inch patented<br />

track.<br />

\t<br />

\,<br />

v

IIIRIGHT<br />

Capacities-1/4 to 2 Tons<br />

STANDARD HEADROOM<br />

Parallel mounted Wright-Way hoists with<br />

single part reeving are designed for applications<br />

where headroom and lateral hook<br />

movement are not critical.<br />

CLOSE HEADROOM<br />

Capacities-l/4 to 1 Ton<br />

When headroom and lateral hook travel are<br />

concerns, cross mounted double reeved<br />

Wright-Way hoist, with true vertical lift, provide<br />

the answer.

Wright-Wayt <strong>Hoist</strong>s<br />

't4<br />

CONTROLS<br />

MOTOR<br />

PUSH BUTTON STATION<br />

OVERLOAD CUTOFF

v<br />

v MECHANICAL LOAD BRAKE<br />

GEAR TRAIN<br />

MOTOR BRAKE<br />

EARED LIMIT<br />

SWITCH<br />

IIIRIEHT.<br />

15

<strong>Hoist</strong> Gonstruction Features<br />

16<br />

GEAR TRAIN<br />

Quiet, compact helical gearing and external spur drum gear are<br />

enclosed in the same oil-tight housing. All gearing is machine cut,<br />

heat-treated alloy steel with shock-resistant ductile cores. Gearing is<br />

designed to AGMA standards for maximum life, and operates in an oil<br />

bath. Rugged aluminum alloy housing provides rapid heat dissipation.<br />

EEARINGS<br />

Precision heavy-duty ball bearings support allshatts. All bearings are<br />

either solash lubricated. or lifetime Dre-lubricated and sealed.<br />

HOOK<br />

Drop forged heat-treated steel hook swivels 3600 on a shielded roller<br />

thrust bearing. Spring latch is standard.<br />

WIRE ROPE<br />

Either improved plow steel (lPS), or extra improved plow steel (XPS) is<br />

supplied on Work-Rated and W ght American hoists. Prelormed aircratt<br />

quality steel wire rope is supplied on Wflghl-Way hoists.<br />

CONTROLS<br />

Choose lrom single., 2.speed or s.step variable speed on wo*-Rated<br />

hoisls. On Wright Ametican and Wright-way hoists single and two<br />

speed motors are available. Controls are magnetic reversing type,<br />

mechanically and eleclrically interlocked with 115.V control circuit.<br />

All wiring conforms to applicable NEC and CSA requirements. Included<br />

are time delay fuses tor branch circuit overcurrent protection and<br />

motor running overcurrent protection. NEMA type 3R enclosures are<br />

standald. Cover is lightweighl, tough, ABS material, deep.drawn lor<br />

maximum control accessibility.<br />

LIMIT SWITCH<br />

A gravity-type upper hook travel limit switch is provided. The unit is<br />

equipped with an automatic momentary lowering circuit. An optional<br />

geared limit switch which can be lield mounted is also available.

v<br />

\,<br />

\,<br />

MOTOR ERAKE<br />

Wright rcclilied D-C magnet-actuated disc brake has been proven in<br />

millions ot hours of in-service operation. lt delivers rapid stops with<br />

minimum to zero hook dritt. The motor brake assembly is seperated<br />

from the gear housing for rapid cooling. This multiple coil brake is<br />

rated a minimum ot 150% ot lull load motor torque.<br />

Exclusive brake-sensing microswitch, standard on Work-Rated and<br />

Wtight Ametican hoists, prevents molor from operating against the<br />

engaged brake. lt also prevents the motor from operating when brake<br />

requires adjustment.<br />

OVERLOAD CUTOFF<br />

Exclusive palented Wright unit is standard on all Work-Rated and<br />

Wtight-Way hoists except single line models. Protects load, hoist and<br />

operator by interrupting raising circuit when hoist is overloaded. The<br />

electro-mechanical device is designed to interrupt the hoist lifting cir<br />

cuit if the load it senses exceeds the preset capacity of the cutoff<br />

device. When the lifting circuit is interrupted, the lowering circuit remains<br />

intact to allow the load to be lowered and removed. When the<br />

overload is removed, the lifting circuit is automatically restored.<br />

MECHANICAL LOAD BRAKE<br />

Automatic Weston-type multiple disc brake can hold a tull capacity<br />

load independent of motor brake. This brake assures that load does<br />

not accelerate while being lowered. No wear compensation adjustment<br />

is reouired.<br />

MOTOR<br />

Standard NEMA flange, Class F Insulation, 3o-minute duty motor is<br />

provided for standard commercial power supplies. The motor has a<br />

standard NElt A shaft extension.<br />

DRUM<br />

The large diameter steel drum has deep machined grooves and large<br />

flanges. At least two full turns of rope remain on the drum at the<br />

lowest hook position of rated lift.<br />

TROLLEY WHEELS<br />

On the Wotk-Rated and Wright American hoists trolley wheels are<br />

forged steel with machined and hardened treads. On lhe Wright-Way<br />

hoists wheels are cast iron with hardened treads. They come complete<br />

with pre-lubricated, sealed, heavy duty ball bearings.<br />

IIIRIEHT"<br />

17

<strong>Hoist</strong> Features/Options<br />

Table<br />

The table below shows at a glance what is available on Wright hoists as a standard, optional<br />

or on-application accessory or modification.<br />

IUoRK-RaTEO"<br />

,€<br />

IURIEHT" IIIRIGHT-UAY"<br />

AMERICAN<br />

Susponsiong<br />

Trolleys<br />

Lug Mounted<br />

Base Mounted<br />

Straioht Track Trollev-Plain<br />

Straight Track Trolley-Geared<br />

Curved Track<br />

Patented Track<br />

Bronze Wheels<br />

Soecial DroD of Chain<br />

Aluminum Hand Chain<br />

Grev lron Wheels<br />

Standard<br />

Standard<br />

Standard<br />

Standard<br />

On ADolication<br />

Optional<br />

On ADolication<br />

Optional<br />

On ADolication<br />

N/A<br />

Standard<br />

N/A<br />

Standard<br />

Standard<br />

N/A<br />

Ootional<br />

NiA<br />

Optional<br />

On Aoolication<br />

N/A<br />

Standard<br />

Optional<br />

Standard<br />

Standard<br />

On Aoolication<br />

Optional<br />

Optional<br />

Optional<br />

On Aoolication<br />

Standard<br />

Trollov Drlve<br />

Forged Steel Wheels<br />

DroD down luos & trollev bumoers<br />

Rail sweeps<br />

65 FPM Sinols SDeed<br />

32 FPM Sinole SDeed<br />

65122 FPM Two Soeed<br />

'125<br />

FPM 5 SteD Variable SDeed<br />

ACM (Acceleration Control Module)<br />

AC Disc Brake<br />

Trolley Travel Limit Switch<br />

Nose Piece for Patented Track<br />

Standard<br />

On ADolication<br />

On ADolication<br />

Standard<br />

Optional<br />

ODtional<br />

Standard<br />

Optional<br />

Optional<br />

Optional<br />

Optional<br />

Standard<br />

NiA<br />

N/A<br />

Standard<br />

ODtional<br />

ODtional<br />

N/A<br />

Optional<br />

Optional<br />

N/A<br />

On ADDlication<br />

On Application<br />

On ApDlication<br />

On Application<br />

Standard<br />

Optional<br />

Optional<br />

On Aoolication<br />

ODtional<br />

ODtional<br />

ODtional<br />

On ADDlication<br />

Ballast Resistors Optional ODtional On Aoolication<br />

Electrillcatlon<br />

Special Speeds<br />

Collector Mountino Arm<br />

Collectors<br />

Taqline Tow Arm<br />

On ADDlication<br />

Ootional<br />

Optional<br />

Optional<br />

N/A<br />

Ootional<br />

Ootional<br />

Optional<br />

On Application<br />

ODtional<br />

Ootional<br />

Ootional<br />

Power Supply Cable<br />

Cable Reel, Loose<br />

Cable Reel Base. 3600<br />

Ootional<br />

On ADDlication<br />

On Application<br />

On AoDlication<br />

On ADolication<br />

On Aoolication<br />

Standard<br />

Ootional<br />

Optional<br />

Cable Reel Base. 3300 On Aoolication On Application ODtional<br />

Cable Trolleys<br />

Festooned Taoline<br />

Power Plugs-Sinqle Phase<br />

On Application<br />

Optional<br />

N/A<br />

On Aoolicalion<br />

Optional<br />

N/A<br />

ODtional<br />

Ootional<br />

On Aoolication<br />

Motors<br />

Power Pluos-Three Phase<br />

'115-1-60<br />

Power (sinole sDeed onlv)<br />

230- l-60 Power<br />

200.3-60 Power<br />

230.3-60 Power<br />

On ADDlication<br />

N/A<br />

N/A<br />

Standard<br />

Standard<br />

On ADDlication<br />

N/A<br />

N/A<br />

On Aoolication<br />

Standard<br />

On Aoolication<br />

Standard<br />

Standard<br />

Standard<br />

Standard<br />

460-360 Power Standard Standard Standard<br />

575-3€0 Power<br />

Special Voltaoe<br />

'1800<br />

RPM<br />

Standard<br />

ODtional<br />

Standard<br />

N/A<br />

NiA<br />

7-112 & 10 ton onlv<br />

Standard<br />

On Aoolication<br />

Standard<br />

Slow Spesd<br />

Hioh Temoerature lnsulation<br />

ODtional<br />

ODtional<br />

N/A<br />

N/A<br />

On ADDlication<br />

On Application<br />

Special Environment Insulation<br />

Motor Thermostat<br />

ODtional<br />

Optional<br />

N/A<br />

N/A<br />

N/A<br />

Standard<br />

Motor SDace Heater Ootional N/A N/A<br />

Hazardous Environments On Aoolication N/A N/A<br />

18

\,<br />

\,<br />

\,<br />

l||oRK-RaTEO'<br />

€<br />

ITIRIGHT.<br />

AMERICAN<br />

IURIEHT.<br />

IIIRIGHT-UAY'<br />

Conlrollers NEMA tyoe 3R Standard Standard Standard<br />

NEMA type 4<br />

NEMA tvDe 4X<br />

Ootional<br />

On Application<br />

Ootional<br />

N/A<br />

ODtional<br />

N/A<br />

NEMA type 7D On Aoolication N/A N/A<br />

NEMA tyDe 9<br />

NEMA tvoe 12<br />

Motor Branch Circuit Fuse<br />

On ADDlication<br />

Ootional<br />

Standard<br />

N/A<br />

Ootional<br />

Standard<br />

N/A<br />

On Application<br />

On ADolication<br />

Control Circuit Fuse Standard Standard On AoDlication<br />

Thermal Overload Relavs optional Optional Ootiona<br />

Mainline Contactor Optional Optional Ootiona<br />

Control Space Heater ODtional N/A On Aoolication<br />

Inchino Control Ootional N/A On Aoolication<br />

Timed Delav Relav Ootional N/A On ADDlication<br />

Oversized Transf ormers Ootional N/A On ADolication<br />

Extra Controllers Optional N/A On Application<br />

Less Conlrollers Optional Ootional Optional<br />

Limil SrYltches<br />

115V Control Circuit<br />

24VControl Circuit<br />

Overload Cutoft Device<br />

Slandard<br />

Standard<br />

Standard<br />

Standard<br />

On AoDlication<br />

N/A<br />

Standard<br />

Optional<br />

Standard<br />

Gravity Operated Limit Switch Standard Standard Standard<br />

Geared Limit Switch<br />

Power Circuit Limit Switch<br />

ODtional<br />

ODtional<br />

Optional<br />

N/A<br />

Optional<br />

N/A<br />

Slack Cable Limit Switch On ADDlication N/A N/A<br />

Push Builon<br />

Overlao Limit Switch<br />

Brake Wear Limit Switch<br />

NEMA tvDe 3R<br />

On Applicalion<br />

Standard<br />

Standard<br />

N/A<br />

tandard<br />

itandard<br />

N/A<br />

N/A<br />

Standard<br />

NEMA tvoe 4 Standard Standard Standard<br />

NEMA tvoe 4X On ADolication N/A N/A<br />

NEMA tyoe 7 Optional N/A NiA<br />

NEMA tvDe 9 On Application N/A N/A<br />

NEMA tvpe 12<br />

Extra Push Buttons<br />

Push Button Deductions<br />

Standard<br />

Optional<br />

Optional<br />

Standard<br />

Optional<br />

Optional<br />

Standard<br />

Optional<br />

Ootiona<br />

Extra Cord ODtional Ootional Optional<br />

SDecial Name Plate Markinos<br />

Push Button Balancer<br />

On Application<br />

On Aoolication<br />

N/A<br />

N/A<br />

On Aoolication<br />

N/A<br />

Outriooer Arm On AoDlication N/A On Aoolication<br />

Surtace Mounted Station On Aoolication N/A On ADDlication<br />

Load Blocks<br />

Pilot Lioht<br />

Sprino type latch hooks<br />

On Aoolication<br />

Standard<br />

N/A<br />

Standard<br />

On ADD|ication<br />

Standard<br />

Special Hooks and Fittinos On Aoolication N/A On Aoolication<br />

Sheaves and Load Blocks On ADDlication N/A On Application<br />

Special Lengths of <strong>Wire</strong> Fope On Application N/A On Aoolication<br />

Special Environments On ADolication N/A N/A<br />

Less <strong>Wire</strong> Rooe Assembly ODtional N/A ODtional<br />

Less Bottom Block Ootional N/A Ootional<br />

G6n6ral Pollcv Orawinqs On Aoolication On ADD|ication On Aoolication<br />

Testino Standard Standard Standard<br />

Service Manual Standard Standard Standard<br />

Special Paintino On Aoolication On ADolication On Aoolication<br />

Export Packaqinq On ADolication On Aoolication On ADDlication<br />

Special Taqqino On Application On Applicalion On Application<br />

19

Reeving<br />

20<br />

2 Part Single<br />

4 Part Single<br />

Producl Series 32 throuoh 35<br />

(a)4 PD Reeving shown does<br />

nol apply to lhe WRIGHT<br />

AMERICAN hoist.<br />

Common Applications ol HOIST Reevings<br />

Reeving refers to the configuration of the wire rope, blocks<br />

and drum of the hoist. Beeving elfects headroom, lifting<br />

speed and capacity by increasing the hoist's mechanical<br />

advantage. Reeving also determines if the hoist has lateral<br />

hook movement or true vertical lift.<br />

The three terms used in reeving ate; single, double and<br />

part. Single or double refers to the number of ropes coming<br />

from the drum. Part deals with the mechanical advantaoe<br />

gained by multiple reeving. For example. with two ptrt<br />

single reeving (2PS) the load is distributed over the two<br />

parts, and the mechanical advantage doubles the capacity<br />

of one part reeving but reduces by one half the lifting or<br />

lowering speed of the hook.<br />

Some applications require that the load not move right or<br />

left of the hoist centerline while being lifted. This is called<br />

true vertical lift and requires that the hoist be double reeved.<br />

Double reeving also requires less headroom than<br />

single reeving.<br />

FEQUEST MASTEFI CATALOG SECTION NO 30.2 FOA DETAILED INFOFMATION<br />

Reeving changes hoist arrangement to the beam or track,<br />

minimum headroom distance, and lateral hook travel.<br />

HEADROOM: Some applications require that the distance<br />

from the bottom ot beam to saddle of the hook be held to a<br />

minimum. This dimension will determine whether a standard<br />

or close headroom is required.<br />

LATERAL HOOK TRAVEL:<br />

ffi<br />

7,4<br />

Lateral n<br />

Hook Travel \\,<br />

Standard Headroom<br />

Parallgl Mounigd<br />

Clos€ HeadroomCloss<br />

H€adroom<br />

Pafallel Mount€d Cross Mount€d<br />

R€evin9: 2PSor4PS 2PD 2 PDor4PD<br />

Minimum<br />

Hgadroom:<br />

Lat€ral<br />

Hook Travel:<br />

Fair Good Best<br />

Hook travels None NOne<br />

Cost: High<br />

True<br />

Vertical Litl<br />

Some applications require that the load, when being lifted,<br />

not move right or left trom hoist centerline. lf this requirement<br />

is known, a true vertical lift hoist must be used.<br />

These are described as two part double (2PD) or four part<br />

double (4PD) and are available in both parallel or cross<br />

mou nted hoists.

\,<br />

Common Types of WINCH Reevings<br />

Work-rated winches can be reeved in various ways to gain<br />

designed mechanical advantages. The illustrations on this<br />

page demonstrate some of those advantages.<br />

Winch reeving effects capacity, lifting distance, litting<br />

speed and cable size. Winches are available in sinole and<br />

double line arrangements.<br />

The lead off angle is a critical specification in winch applications.<br />

Standard lead off angles are shown below. For<br />

the optional lead off angles indicated by the shaded areas,<br />

the exact degree of the ang le or range of ang les is required<br />

when ordering.<br />

Standard Work-rated winches are supplied without wire<br />

rope. When wire rope is supplied, it is 6 x 37 preformed, except<br />

on applications that require non rotating, 18 x 7 construction<br />

cable.<br />

The swaged on drum end fittings of the wire rope are provided.<br />

A vareity of "dead-end" fittings, such as swivel<br />

hooks and load blocks, and idler sheaves, are available to<br />

meet your specific application.<br />

WINCH DRUM REEVING ARRANGEMENTS<br />

SINGLE LINE REEVING ARRANGEI\4ENTS<br />

Standard Arrangement AA Arrangement<br />

DOUBLE LINE REEVING ARRANGEMENTS<br />

BB Arrangement<br />

CC Arrangement<br />

DD Arrangement EE Arrangement<br />

Arrangemenls AA, CC, DD & EE are non.standard.<br />

REOUEST MASTER CATALOG SECIION NO. 33I03 FO8 DETAILED INFOBMATION<br />

LINE LEADOFF ANGLES<br />

Work-rcted winches are designed with a standard range or<br />

ranges of leadoft angles. See the illustration tor location<br />

of the standard range.<br />

AEOUEST MASTER CATALOG SECIION NO 33.102 FOR DEIAILED INFOBMATION<br />

PRODUCT SERIES 32.35 WINCHES PRODUCT SERIES 36 WINCHSS<br />

1PS<br />

1 Part Single Feeving<br />

1PD<br />

1 Part Double<br />

Double Hook (a)<br />

1PD<br />

1 Part Double<br />

Single Hook<br />

IIIRIEHT"<br />

2-2PS<br />

2 - 2 Pa't Single (a)<br />

2PD<br />

2 Part Double

Trolley Suspensions<br />

Motor driven<br />

Wright wlre rope hoists are available lug<br />

mounted or in a variety of trolley suspensrons.<br />

Wrightway, Wright Ametican and Work-rated<br />

hoists are available in plain trolley, hand chain<br />

driven geared trolley and motorized trolley<br />

underhung suspensions. Work-rated hoists are<br />

also available with top running trolleys.<br />

Trolleys are available to fit standard'S'beams,<br />

wide flanged<br />

'W' beams and patented track.<br />

(see Figure l on facing page) Articulated<br />

trolleys for curved track are also available.<br />

Beam flange width and thickness and the<br />

minimum radius curve must always be supplied<br />

when ordering hoist suspensions.<br />

Pla in<br />

Geared (hand chain)<br />

22<br />

@<br />

Straight irack<br />

Curved track

\,<br />

Sr.nd.rd w{d. Ft.na. (WF) p.r.m.dTmr<br />

'l &!m or'll &rm<br />

FIGURE 1<br />

<strong>Hoist</strong> Duty Service Classification<br />

IIIRIEHT"<br />

To help in hoist selection the <strong>Hoist</strong> Manufacturers Institute has grouped these typical areas<br />

of application into five classifications shown in the chart below. These are only guidelines<br />

and do not consider overall equipment life or routine maintenance.<br />

Duty Class Typical Areas of Application<br />

H1<br />

H2<br />

H3<br />

H4<br />

H5<br />

Powerhouse and utilities, infrequent handling. <strong>Hoist</strong>s are primarily to<br />

install and service heavy equipment, where loads frequently approach<br />

rated load, and where the hoist is idle for 1 to 6 month periods between<br />

periods of operation.<br />

Light machine shop, fabricating service, and maintenance. Loads and<br />

utilization randomly distributed. Rated loads infrequently handled.<br />

Total running time not over 12.5o/o of the work period.<br />

General machine shop, fabricating, assembly, storage, and warehous.<br />

ing. Loads and utilization randomly distributed. Total running time not<br />

over 25o/o of the work oeriod.<br />

High volume handling of heavy loads, frequently near rated load in<br />

steel warehousing, machine and fabricating shops, mills, and foundries,<br />

with total running time not over 50% of the work period.<br />

Manual or automatic cycling operations of lighter loads with rated<br />

loads infrequently handled such as in heat treating and plating operations,<br />

with total running time frequently 50% of the work period.<br />

Bulk handling of material in combination with buckets, magnets, or<br />

other heavy attachments. Equipment often cab operated. Duty cycles<br />

approaching continuous operation are frequently necessary. User<br />

must specify exact delails of operation, including weight of<br />

attachments.<br />

23

How to order check list IIIRIEHT'<br />

How will the hoist be used? (CAPAC|TY)<br />

! Avg. load will be 65% of hoist capacity or less. Occasional litts made at full hoist capacity.<br />

! Avg. load will be greater than 65% of hoist capacity. More frequenl lifts at or near full<br />

capacrry.<br />

How far must loads normally be lifted or lowered? (LIFT)<br />

n 1.3ft. D 8-11 tt.<br />

! 4.7 fr. n 12. 15 ft.<br />

n 16- t9 ft.<br />

! 20-30 fr.<br />

3. How many limes will the hoist be used in a typical hour? (LtFTS/HR.)<br />

(lt the hoist is used exlenslvely fot two hours ot a shift, report the times tot one of those nours;<br />

clo not average those lilts over the entire shitt)<br />

n 1-4times<br />

! 8- 11times n 20 - 24 times<br />

! 5-9times<br />

I 15 - 19 times<br />

! 25 - 29 times<br />

4 . what kind of suspension is required? (susPENSloN) 6ee ittustrction on pases 7 and 22)<br />

n lug mounted n deck mounted D geared trolley<br />

n base mounted D plain trolley ! motorized trolley<br />

a) Specify the type of beam or lrack on which the trolley will operate. gee Figute 1 on page 23)<br />

! SShape ! Wshape ! patented Track<br />

b) Specify beam tlange width<br />

tn.<br />

c) Must the trolley operate on curved lrack?<br />

lf so, specify curve radii<br />

5.<br />

What is the minimum beam to high hook distance? (HEADROOM)<br />

6. What kind of hoist motor is required? (MOTOB TypE)<br />

n<br />

-<br />

single speed n two speed<br />

other<br />

! 5 step variable speed<br />

a) What catalog lifting speedis<br />

required? (LIFTING SPEED)<br />

b) Specify hoist power source(MOTOB<br />

VOLTAGE/PHASE)<br />

FPM<br />

ls lateral hook travel a problem? (REEVING)<br />

! single reeving n double reeving<br />

8. What options or accessories are required?<br />

9. Are there any special operating environment requirements?<br />

When ordering any tvtight hoist, the first place to start is its proper <strong>Acco</strong> product number. The product<br />

number is specific for the tollowing information: capacity, headroom, reeving, suspension, lift, lifting<br />

speed, hoist control and motor horse power. For Wright-Way hoist it also specifies motor voltage (foi<br />

work'Rated a d Wtight Ametican hoists the motor voltage must be supplied along with the hoiat pro.<br />

duct number).<br />

Product numbers lo( Wrightway hoists are found in "Wright <strong>Hoist</strong>s" Bulletin No. PD-2000. l,y/grl<br />

American product numbers are found in "Wright American Electric <strong>Wire</strong> <strong>Rope</strong> <strong>Hoist</strong>s" Bulletin No.<br />

PD-2010. Product numbers tor work-Rated hoists are found in the "Wright Products" engineering<br />

catalog sections 30 through 35.<br />

For more information regarding identifying beams and track, the "Wright Structural Beam Guide" is a<br />

helpful publication available by ordering Bulletin No. PD-2020.<br />

In.

Qualit Assurance IURIEHT'<br />

fhe Wright Dealer Nelwork<br />

Your f irst contact with Wright is your local Wright hoist dealer. Ex.<br />

perienced, knowledgeable dealers are qualified to answer questions<br />

that you might have regarding l/V/lght equipment. The dealer organization<br />

is strongly supported by Iactory representatives, strategically<br />

located warehouses and parls and service cenlers. Product aoolication<br />

data is yours for the asking. Yo|;r Wright dealer can provide lactory<br />

trained service personnel quickly to help you with your specific<br />

prootems.<br />

/<br />

Wright Engineering and Manuf acturing<br />

Wright aclively participates in the <strong>Hoist</strong><br />

lVanufacturers Institute, the Crane Manufacturers<br />

Associalion of America. the Monorail<br />

Manufacturers Association, the N4aterial<br />

Handling In stit ute and the Industrial<br />

Distributors Association, lo establish and to<br />

meet the most currenl industry standards.<br />

Our extensive engineering staff, experienced in<br />

analyzing and meeting your material handling<br />

needs, is supported by state-of-the-art computer<br />

aided design equipmenl (CAD) in their on<br />

going prod uct development programs.<br />

They assure lhal Wright hoists meet or exceed<br />

all national safety codes and specifications, including<br />

<strong>Hoist</strong> Manufacturing Institule<br />

specifications lor electric wire rope hoists HMI<br />

100-74, "Safety<br />

Standards for Overhead <strong>Hoist</strong>s"<br />

ANSI 830.16.1973 and the Nationat Etectrical<br />

Code.<br />

A sixty year heritage of quality hoist manufacturing<br />

continues in a modern 400,000 square<br />

foot facility. Your hoist's progress through<br />

each step of manufacluring is monitored with<br />

the latest process control and documentation<br />

procedures. Parts machined on digitally controlled<br />

equipment are assembled by a highly<br />

skilled worklorce.<br />

Inspection and quality control procedures for<br />

evety Wright hoist range from basic capacity<br />

tesls to sophisticated dimensional checking.<br />

Constant inspection assures you a reliable proouct.<br />

25

Glossary of Terms<br />

26<br />

ACM (Acceleration Control Module) A solid state electronic control that provides<br />

gentle acceleration and deceleration of a hoist trolley or crane throughout the en.<br />

tire operation cycle. ACM minimizes load pendulum swing more efficiently than<br />

ballast resistors or f luid coupling by controlling acceleration up to 5 seconds after<br />

start while providing full motor voltage for the whole cycle.<br />

AGMA American Gear Manutacturers Association<br />

ANSI American National Standard lnstitute<br />

Ballast Resistors Inserted in the power lines to an induction motor, ballast<br />

resistors control trolley acceleration for smoother starts by reducing the voltage<br />

while starting; in turn reducing torque; increasing the motor acceleration time,<br />

allowing the motor to come to speed smoothly. Ballast resistors are field adjustable.<br />

CSA Canadian Standards Association<br />

Contactors Electro-mechanical devices for establishing and interrupting an elec"<br />

tric power circuit.<br />

CMAA Crane Manufacturers Association of America<br />

End Approach The minimum distance that a hoist can travel to the end of a crane<br />

bridge or track without impacting a wall or some other obstruction. Cross<br />

mounted hoists have a lower minimum end approach than standard parallel<br />

mounted hoists.<br />

Explosion Prool The property of an enclosure to contain internal sparking without<br />

causing external hazard. Explosion proof hoists are used in operating environments<br />

where flammable gases are present.<br />

FPM (Feet per minute) The standard measurement of hoist litting speed, trolley<br />

travel and crane bridge travel.<br />

Headroom The distance from the bottom of the beam or monorail on which the<br />

hoist travels to the bearing point of the load hook when the hook is raised to its<br />

highest position. On a top running hoist, it is the distance from the operating tread<br />

of the trolley wheels to the hook high position.<br />

lmpact Loading The initial impact of the load that creates greater stress to the<br />

block, wire rope, drum, hoist frame and the other load bearing parts of the hoist.<br />

Inching Control Extra push buttons that permit small movements of the load hook<br />

or hoist trolley through relays. The control can be adjusted to meet hook motion or<br />

hoist movement requirements for particular applications.<br />

Invertor A solid state electronic device that allows inf inite sDeed variation of electric<br />

motors used in hoists, trolley motors and crane drives.<br />

An invertor closely controls the frequency of the AC current; the motor gets only<br />

enough current to supply the required torque for a specific speed. lt eliminates inefficient<br />

and dangerous overheating resulting from unused electrical energy, a<br />

common problem of many other infinitely variable speed control methods.<br />

Limit Swiich Electro-mechanical devices that limit travel of the load block hook.<br />

There are two types of limit switches: gravity type and geared type.<br />

Gravity type limit switches use a weight, paddle or a lever thal when it contacts

the load block, trips a switch to the open position, that opens the raising circuit<br />

that causes hoist contactors to open and breaks the power supplied to the motor.<br />

Geared limit switches are driven by either the drum or gear reduction; a geared<br />

limit switch operates on a definite ratio of drum revolutibns. lt is adjustable and<br />

can be activated at any predetermined point of the hoist lift range, unlike ihe gravi.<br />

ty switch which can only limit upper hook travel. In the event of the wire rooebverwrapping<br />

or jumping the drum grooves through misapplication of the hoisl, the<br />

geared limit switch is no longer synchronized and will not be activated when the<br />

hook reaches its upper limit. For this reason geared limit switches should be used<br />

with a gravity limit switch as a back.up.<br />

MMA Monorail Manufacturers Association<br />

Mainline Contactor A manually operated magnetic device that shuts off all power<br />

to the hoist and crane motors in the event of a malfunction.<br />

Mechanical Load Brake Part of the<br />

gear train of the hoist, the load<br />

brake serves as a back-up to the<br />

electric motor brake. lt automatically<br />

slows and controls lowering<br />

speed and, if the motor brake fails, B,<br />

holds the load while the motor or<br />

motor brake is repaired or replaced.<br />

A Weston type load brake (see il- Brake L nins<br />

lustration) uses a brake gear with an<br />

internal helical thread which mates<br />

with and rotates on a threaded<br />

shaft. Brake linings bonded on both<br />

sides of a ratchet gear are engaged<br />

by the screw actuated axial movement<br />

of the brake gear along the<br />

threaded shaft...to ihe teft toward<br />

the brake gear again moves to the<br />

left slowing lowering speed and<br />

preventing the load overdriving the<br />

hoist motor.<br />

c''e"""SCJ<br />

Eake Gear<br />

Axa Movement By Screw<br />

Check Sleeve<br />

Adjusl ng Lugs<br />

the brake disc while raising the load $1<br />

and to the right away from the disc \<br />

while lowering the load. lf the load /<br />

s.tarts to accelerate during lowering, p"r,n,{c...<br />

Motor Th€rmostal A bi-metallic, automatic reset thermostat is standard equipment<br />

on all Wright hoists. lt is a thermally operated device that protects the hoist<br />

motor from damage due to operating at a higher-than-normal current. Built into<br />

the motor windings, it causes the motor control to be de.energized when the<br />

temperature of the motor winding exceeds its predetermined limit.<br />

NEMA National Electric Manufacturers Assocation<br />

True Vertical Litt A lift without lateral hook movement. Requires that the hoist be<br />

double reeved (see reeving section on page 20).<br />

IURIGHT"<br />

8ra(e Shatt<br />

27

. J<br />

'tl<br />

EH<br />

eitp<br />

,nt*<br />

ft<br />

zt<br />

.,j,u;<br />

-. )lt<br />

,.* \

CANC<br />

OFFICES & MANUFACTUFING PLANT<br />

335 LYNN AVE<br />

CBANES & NORTH VANCOUVEF B C V7J 2C4<br />

PHONI (604) 9BB '8r<br />

E0UIPMENT tTO. ie, ,,,u0, esd tjrttu<br />

ENGINEERS, DESIGNERS AND SUPPLIERS OF I\4AIERIAL HANDLING EOUIPI/IENT