R&D FACTS Electric Arc Furnace Research Facility - National ...

R&D FACTS Electric Arc Furnace Research Facility - National ...

R&D FACTS Electric Arc Furnace Research Facility - National ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Electric</strong> <strong>Arc</strong> <strong>Furnace</strong> <strong>Research</strong> <strong>Facility</strong><br />

The electric arc furnace (EAF) research facility located at the NETL Albany site,<br />

Oregon, has a 50 year history of pyrometallurgical research into primary smelting,<br />

steelmaking, waste treatment, and recycling. The EAF research facility includes a<br />

unique set of furnaces sized from bench- to pilot-scale.<br />

The furnaces include:<br />

• 50 kW, single-phase AC,<br />

tilting-shell<br />

• 300 kW, single-phase AC,<br />

tilting-shell EAF<br />

• 0.8 MW, three-phase AC,<br />

static-shell EAF<br />

Case Histories Melting (Vitrification)<br />

• Simulated low-level radioactive wastes<br />

• Cr- and Pb-contaminated soils<br />

• Dredging spoils<br />

• Coal boiler bottom ash<br />

• Mineral wool<br />

Smelting<br />

• Primary Fe, Cr, Ni & Ti ores<br />

• Zn smelter wastes<br />

• Aluminum potliner<br />

• PGM-bearing catalyst wastes<br />

• Silicon smelting<br />

• Iron ore sands<br />

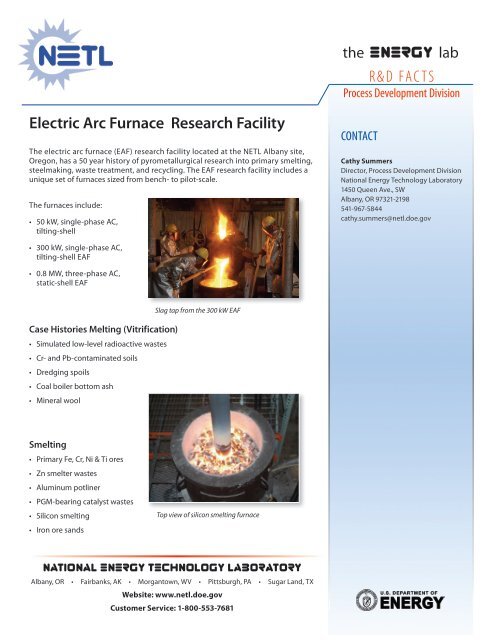

Slag tap from the 300 kW EAF<br />

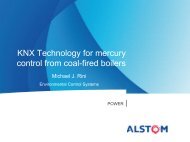

Top view of silicon smelting furnace<br />

Albany, OR • Fairbanks, AK • Morgantown, WV • Pittsburgh, PA • Sugar Land, TX<br />

Website: www.netl.doe.gov<br />

Customer Service: 1-800-553-7681<br />

R&D <strong>FACTS</strong><br />

Process Development Division<br />

CONTACT<br />

Cathy Summers<br />

Director, Process Development Division<br />

<strong>National</strong> Energy Technology Laboratory<br />

1450 Queen Ave., SW<br />

Albany, OR 97321-2198<br />

541-967-5844<br />

cathy.summers@netl.doe.gov

Iron/Steelmaking<br />

• Cast iron scrap<br />

• Steel scrap<br />

• Steel casting<br />

consolidation<br />

The 50 kW EAF is a<br />

versatile unit, with<br />

interchangeable shells<br />

for acid/basic/carbon<br />

practice, and is utilized<br />

to develop a smelting/<br />

melting practice for<br />

virtually all materials<br />

to be processed in the<br />

larger scale EAF. The<br />

150 kW Si-smelting<br />

furnace consists of a<br />

Pouring iron pigs from ladle<br />

single top electrode with<br />

a carbon (graphite) hearth and is scaled for a production rate<br />

of roughly 5 kg Si per hour. In the past year, direct smelting<br />

of iron ore sands has been conducted in the 300 kW, singlephase<br />

AC EAF. Roughly 2 tons of briquetted ore was smelted<br />

in 6 heats conducted over 3 days, producing over 1,100 lb of<br />

pig iron at a reduction efficiency of nearly 90 percent.<br />

Schematic of 0.8 MW EAF system<br />

The 0.8 MW EAF is a dual-purpose smelter/melter, and has<br />

been used for several pilot-scale demonstrations in both<br />

modes of operation. The furnace is sealed and can be kept<br />

at a slight negative pressure for environment control. The<br />

system includes continuous feeding by metered screw<br />

conveyors, and a dedicated air pollution control system,<br />

including a close-coupled thermal oxidizer, with particulate<br />

and acid gas control.<br />

Emissions monitoring can be conducted by gas chromatograph<br />

and individual gas analyzers on both of the pilotscale<br />

EAF. Gases analyzed include C 2 H 6 , CH 4 , CO, CO 2 , H 2 , O 2 ,<br />

NO x , and SO 2 .<br />

Much of the work conducted at the NETL EAF research<br />

facility has been funded through Cooperative <strong>Research</strong><br />

and Development Agreements (CRADA) and Contributed<br />

Funds-In Agreements. These agreements have included<br />

both industry and federal agency partners. The scale and<br />

variety of furnaces available make the facility a unique<br />

research and development tool for the U.S. Department<br />

of Energy.<br />

Metal tap and 0.8 MW EAF system<br />

R&D112, March 2012