Dead Block Coiler Drawing Dead Block

Dead Block Coiler Drawing Dead Block

Dead Block Coiler Drawing Dead Block

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

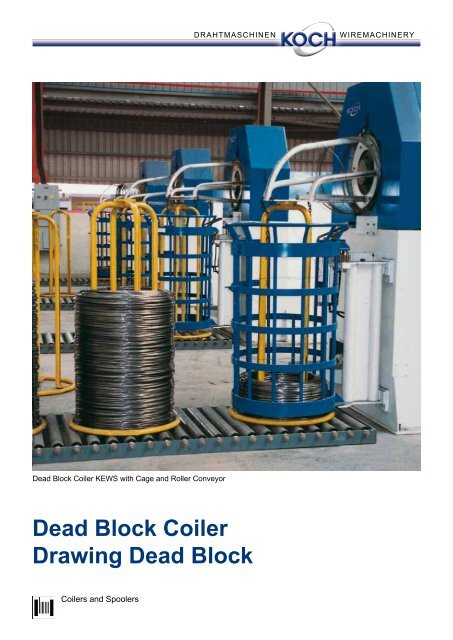

<strong>Dead</strong> <strong>Block</strong> <strong>Coiler</strong> KEWS with Cage and Roller Conveyor<br />

<strong>Dead</strong> <strong>Block</strong> <strong>Coiler</strong><br />

<strong>Drawing</strong> <strong>Dead</strong> <strong>Block</strong><br />

<strong>Coiler</strong>s and Spoolers<br />

DRAHTMASCHINEN WIREMACHINERY

<strong>Dead</strong> <strong>Block</strong> <strong>Coiler</strong> KEWS<br />

... with horizontal block and pattern laying device<br />

Modern wire drawing equipment provides<br />

maximum utilization and efficient operation by:<br />

High drawing speeds<br />

Simple operation<br />

Reduced downtimes<br />

Large coil weights<br />

Technical Data (for reference)<br />

Model KEWS<br />

Wire range<br />

Capstan size - Standard<br />

- Optional<br />

Speed<br />

Carrier height - Standard<br />

- Filling<br />

Carrier core<br />

Coil weight<br />

Drive power<br />

abt. mm-Ø<br />

mm-Ø<br />

max. m/s<br />

mm<br />

mm<br />

mm-Ø<br />

abt. kg<br />

max. kW<br />

DRAHTMASCHINEN WIREMACHINERY<br />

I<br />

0,5-1,6<br />

300<br />

20<br />

800<br />

675<br />

240<br />

100<br />

7,5<br />

II<br />

0,7-2,0<br />

450<br />

560<br />

25<br />

1000<br />

850<br />

340<br />

500<br />

30<br />

III<br />

1,5-5,0<br />

600<br />

700<br />

25<br />

1600<br />

1450<br />

450<br />

1250<br />

30<br />

Dancer / Input straightener<br />

Pay-off turntable<br />

for catch weight coils<br />

We offer a comprehensive series of coiling<br />

equipment in all standard block sizes<br />

commonly employed in ferrous wire mills.<br />

Our horizontal coiling dead block is preferred<br />

because of its sturdy construction, high<br />

operating speeds, and ease of “stringing up”<br />

during wire diameter changes as well as for carrier<br />

exchange. The benefit of using a drawing dead<br />

block in the wire drawing process is to eliminate<br />

one block on the wire drawing machine.<br />

IV<br />

2,3-7,0<br />

750<br />

900<br />

20<br />

1600<br />

1450<br />

520<br />

1250<br />

37

<strong>Drawing</strong> <strong>Dead</strong> <strong>Block</strong> KEWS-Z<br />

Wire retention<br />

and controlling device<br />

<strong>Block</strong> with straigthening rim<br />

and flyer<br />

Special straightening system<br />

for high speed operation<br />

Technical Data (for reference)<br />

Cooling water heat exchanger<br />

This reduces investment costs,<br />

saves valuable plant floor space and provides<br />

similar drawing capabilities of the longer<br />

machine. The horizontal drawing dead block<br />

is provided with an integral closed loop<br />

water-cooled capstan and die. This is especially<br />

useful when drawing high carbon wire where<br />

constant cooling and temperature control<br />

is required.<br />

Model KEWS-Z<br />

Wire range<br />

Capstan size - Standard<br />

- Optional<br />

Speed<br />

Carrier height - Standard<br />

- Filling<br />

Carrier core<br />

Coil weight<br />

Drive power<br />

abt. mm-Ø<br />

mm-Ø<br />

max. m/s<br />

mm<br />

mm<br />

mm-Ø<br />

abt. kg<br />

max. kW<br />

DRAHTMASCHINEN WIREMACHINERY<br />

II<br />

0,7-2,0<br />

450<br />

500<br />

25<br />

1200<br />

1050<br />

340<br />

400<br />

30<br />

... with horizontal block, pattern laying and lowering device<br />

<strong>Dead</strong> blocks accommodate common<br />

carrier sizes by using easily installed<br />

interchangeable spacers. This allows a single<br />

machine to meet the customers’ packaging<br />

requirements without any special modifications.<br />

A fully automatic custom designed system<br />

for cutting the wire and changing the carriers<br />

is available. This equipment helps to reduce<br />

manpower when a single operator is servicing<br />

multiple high-speed machines.<br />

III*<br />

1,2-4,0<br />

600<br />

660<br />

25<br />

1600<br />

1450<br />

450<br />

1000<br />

55<br />

*High speed version up to 30 m/s for low carbon steel (w/o water cooling and straightener) available<br />

IV<br />

1,8-5,0<br />

700<br />

760<br />

20<br />

1800<br />

1600<br />

550<br />

1300<br />

75

<strong>Drawing</strong> <strong>Dead</strong> <strong>Block</strong> KEWS-Z<br />

Our fully trained team – with their many years<br />

of experience and their continuous research<br />

and development in the area of machine<br />

construction – are at your disposal at all times.<br />

Our wide ranking Know-How and experience<br />

of wire products and production systems<br />

are available to our customers.<br />

Engineering planners calculate submitted<br />

performance requirements and adapt these on<br />

the basis of our standard component programme<br />

to your individual production requirements.<br />

DRAHTMASCHINEN WIREMACHINERY<br />

Detailed discussions and information right<br />

from the stage of the quotation guarantee<br />

a maximum of quality assurance and thus<br />

customer satisfaction.<br />

ERNST KOCH GmbH & CO. KG<br />

Sternstr. 9, 5048<br />

D-58665 Hemer-Ihmert<br />

Tel.: +49 (0) 2372 / 985-500<br />

Fax: +49 (0) 2372 / 985-167<br />

email: sales@koch-ihmert.de<br />

web: www.koch-ihmert.de