DTM Gloss - Frazee Paint

DTM Gloss - Frazee Paint

DTM Gloss - Frazee Paint

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

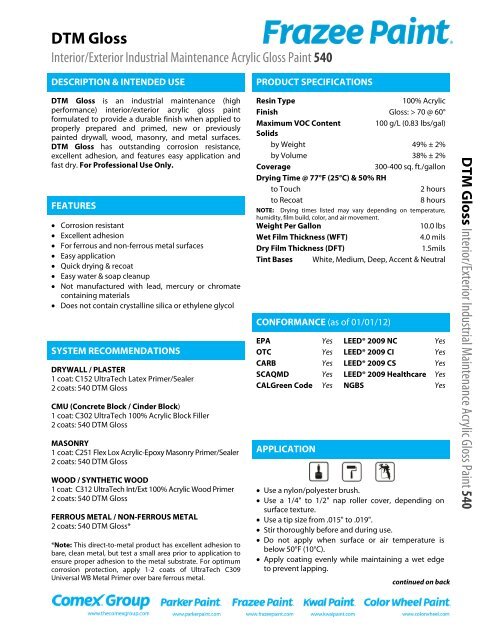

<strong>DTM</strong> <strong>Gloss</strong><br />

Interior/Exterior Industrial Maintenance Acrylic <strong>Gloss</strong> <strong>Paint</strong> 540<br />

DESCRIPTION & INTENDED USE<br />

<strong>DTM</strong> <strong>Gloss</strong> is an industrial maintenance (high<br />

performance) interior/exterior acrylic gloss paint<br />

formulated to provide a durable finish when applied to<br />

properly prepared and primed, new or previously<br />

painted drywall, wood, masonry, and metal surfaces.<br />

<strong>DTM</strong> <strong>Gloss</strong> has outstanding corrosion resistance,<br />

excellent adhesion, and features easy application and<br />

fast dry. For Professional Use Only.<br />

FEATURES<br />

Corrosion resistant<br />

Excellent adhesion<br />

For ferrous and non-ferrous metal surfaces<br />

Easy application<br />

Quick drying & recoat<br />

Easy water & soap cleanup<br />

Not manufactured with lead, mercury or chromate<br />

containing materials<br />

Does not contain crystalline silica or ethylene glycol<br />

SYSTEM RECOMMENDATIONS<br />

DRYWALL / PLASTER<br />

1 coat: C152 UltraTech Latex Primer/Sealer<br />

2 coats: 540 <strong>DTM</strong> <strong>Gloss</strong><br />

CMU (Concrete Block / Cinder Block)<br />

1 coat: C302 UltraTech 100% Acrylic Block Filler<br />

2 coats: 540 <strong>DTM</strong> <strong>Gloss</strong><br />

MASONRY<br />

1 coat: C251 Flex Lox Acrylic-Epoxy Masonry Primer/Sealer<br />

2 coats: 540 <strong>DTM</strong> <strong>Gloss</strong><br />

WOOD / SYNTHETIC WOOD<br />

1 coat: C312 UltraTech Int/Ext 100% Acrylic Wood Primer<br />

2 coats: 540 <strong>DTM</strong> <strong>Gloss</strong><br />

FERROUS METAL / NON-FERROUS METAL<br />

2 coats: 540 <strong>DTM</strong> <strong>Gloss</strong>*<br />

*Note: This direct-to-metal product has excellent adhesion to<br />

bare, clean metal, but test a small area prior to application to<br />

ensure proper adhesion to the metal substrate. For optimum<br />

corrosion protection, apply 1-2 coats of UltraTech C309<br />

Universal WB Metal Primer over bare ferrous metal.<br />

PRODUCT SPECIFICATIONS<br />

Resin Type 100% Acrylic<br />

Finish <strong>Gloss</strong>: > 70 @ 60°<br />

Maximum VOC Content 100 g/L (0.83 lbs/gal)<br />

Solids<br />

by Weight 49% ± 2%<br />

by Volume 38% ± 2%<br />

Coverage 300-400 sq. ft./gallon<br />

Drying Time @ 77°F (25°C) & 50% RH<br />

to Touch 2 hours<br />

to Recoat 8 hours<br />

NOTE: Drying times listed may vary depending on temperature,<br />

humidity, film build, color, and air movement.<br />

Weight Per Gallon 10.0 lbs<br />

Wet Film Thickness (WFT) 4.0 mils<br />

Dry Film Thickness (DFT) 1.5mils<br />

Tint Bases White, Medium, Deep, Accent & Neutral<br />

CONFORMANCE (as of 01/01/12)<br />

EPA Yes LEED® 2009 NC Yes<br />

OTC Yes LEED® 2009 CI Yes<br />

CARB Yes LEED® 2009 CS Yes<br />

SCAQMD Yes LEED® 2009 Healthcare Yes<br />

CALGreen Code Yes NGBS Yes<br />

APPLICATION<br />

Use a nylon/polyester brush.<br />

Use a 1/4" to 1/2" nap roller cover, depending on<br />

surface texture.<br />

Use a tip size from .015" to .019".<br />

Stir thoroughly before and during use.<br />

Do not apply when surface or air temperature is<br />

below 50°F (10°C).<br />

Apply coating evenly while maintaining a wet edge<br />

to prevent lapping.<br />

continued on back<br />

<strong>DTM</strong> <strong>Gloss</strong> Interior/Exterior Industrial Maintenance Acrylic <strong>Gloss</strong> <strong>Paint</strong> 540

<strong>DTM</strong> <strong>Gloss</strong> Interior/Exterior Industrial Maintenance Acrylic <strong>Gloss</strong> <strong>Paint</strong> 540<br />

<strong>DTM</strong> <strong>Gloss</strong><br />

Interior/Exterior Industrial Maintenance Acrylic <strong>Gloss</strong> <strong>Paint</strong> 540<br />

SURFACE PREPARATION<br />

General Surface Preparation: All surfaces must be clean, dry,<br />

sound, and free from contaminants such as loose and peeling<br />

paint, dirt, dust, grease, oil, wax, concrete curing agents and<br />

bond breakers, efflorescence, rust, and chalk. Mold and<br />

mildew must be treated and any residues removed. Dull any<br />

glossy surfaces, repair damaged areas with appropriate<br />

patching material, and allow to dry. Prime all new surfaces and<br />

repaired areas with an appropriate primer.<br />

Substrate Specific:<br />

Drywall / Plaster<br />

Allow new drywall and plaster finishes to properly cure<br />

before application of primer and finish coats.<br />

Masonry<br />

Allow new masonry surfaces to cure before application of<br />

primer and finish coats.<br />

Power-wash all tilt-up and poured-in-place concrete to<br />

remove any bond-breakers or other construction residue.<br />

Wood / Synthetic Wood<br />

Two coats of stain-blocking wood primer may be necessary<br />

on lumber subject to tannin bleed, such as, redwood and<br />

cedar.<br />

Ferrous Metal<br />

Minimum surface preparation for all ferrous metals is Hand<br />

Tool Cleaning per SSPC-SP2. Remove all oil and grease from<br />

the surface per SSPC-SP1. For optimum performance, use<br />

Commercial Blast Cleaning per SSPC-SP6. Sandblasted or<br />

newly cleaned metal must be primed the same day.<br />

Non-Ferrous Metal<br />

Allow galvanized metal to weather a minimum of six<br />

months prior to coating. Solvent clean per SSPC-SP1. If<br />

weathering is not feasible, or if the surface has been treated<br />

with chromates or silicates, first solvent clean per SSPC-SP1,<br />

then check adhesion of the primer by applying a test patch.<br />

Allow primer to dry at least one week before testing<br />

adhesion. If adhesion is poor, brush blasting per SSPC-SP7 is<br />

necessary to remove these treatments.<br />

Rusty galvanizing requires a minimum of Hand Tool<br />

Cleaning per SSPC-SP2, then primed the same day.<br />

Galvanized steel and aluminum should be solvent cleaned in<br />

accordance with SSPC-SP1 and then etched either<br />

chemically or via light blast cleaning with non-metallic<br />

abrasive.<br />

WARNING! If you scrape, sand, or remove old paint, you may<br />

release lead dust. LEAD IS TOXIC. EXPOSURE TO LEAD DUST<br />

CAN CAUSE SERIOUS ILLNESS, SUCH AS BRAIN DAMAGE,<br />

ESPECIALLY IN CHILDREN. PREGNANT WOMEN SHOULD<br />

ALSO AVOID EXPOSURE. Wear a NIOSH approved respirator<br />

to control lead exposure. Clean up carefully with a HEPA<br />

vacuum and a wet mop. Before you start, find out how to<br />

protect yourself and your family by contacting the National<br />

Lead Information Hotline at 1-800-424-LEAD or log on to<br />

www.epa.gov/lead.<br />

THINNING & CLEANUP<br />

This product is designed to be used at package consistency.<br />

Do not thin. Clean tools, equipment, and work area with<br />

warm, soapy water.<br />

STORAGE & DISPOSAL<br />

Protect during storage from freezing and temperatures above<br />

95°F. Consult your local city or environmental regulatory agency<br />

for guidance on disposal options. Do not pour down a drain or<br />

storm sewer.<br />

LIMITATIONS<br />

Do not use on floors.<br />

Wait after 30 days or when paint has fully cured before cleaning<br />

the surface with non-abrasive, mild detergent solution and<br />

cellulose sponge.<br />

High humidity and/or cooler temperatures will prolong dry time<br />

of this product. Do not expose to moisture or extreme<br />

temperature change for at least 48 hours after painting. Avoid<br />

frost, fog and damp conditions.<br />

CAUTIONS<br />

WARNING!<br />

HARMFUL IF SWALLOWED<br />

IMPORTANT! Spray mist of any material may be hazardous. Spray<br />

equipment must be in good condition and used with care in<br />

accordance with manufacturer’s instructions. The use of an<br />

appropriate respirator, eye protection and protective clothing is<br />

recommended. Close container after use.<br />

FIRST AID: If you experience difficulty in breathing, leave the area<br />

to obtain fresh air. If continued difficulty is experienced, get<br />

medical assistance immediately. In case of eye contact, flush<br />

immediately with plenty of water for at least 15 minutes and get<br />

medical attention, for skin, wash thoroughly with soap and water.<br />

If swallowed, do not induce vomiting. Get medical attention<br />

immediately. In case of spillage, absorb with inert material and<br />

dispose of in accordance with applicable regulations.<br />

KEEP OUT OF REACH OF CHILDREN<br />

KEEP FROM FREEZING<br />

SEE MATERIAL SAFETY DATA SHEET<br />

For Chemical Emergency ONLY (spill, leak, fire, exposure or<br />

accident), call ChemTrec at 1-800-424-9300.<br />

WARRANTY<br />

<strong>Frazee</strong> warrants that at the time of sale this product conforms<br />

with applicable <strong>Frazee</strong> specifications and is free of manufacturing<br />

defects. <strong>Frazee</strong>’s sole liability for products proven defective, and<br />

Purchaser’s sole remedy, if any, shall be replacement of the<br />

product or refund of the purchase price paid, at the sole option of<br />

<strong>Frazee</strong>. This warranty is not transferable. TO THE MAXIMUM<br />

EXTENT PERMITTED BY APPLICABLE LAW, FRAZEE MAKES NO<br />

OTHER WARRANTIES, GUARANTEES, OR REPRESENTATIONS<br />

OF ANY KIND, EITHER EXPRESS OR IMPLIED, OR BY USAGE OF<br />

TRADE, AND HEREBY EXPRESSLY EXCLUDES AND DISCLAIMS<br />

ALL IMPLIED WARRANTIES, OF MERCHANTABILITY AND<br />

FITNESS FOR A PARTICULAR PURPOSE. IN NO EVENT SHALL<br />

KWAL BE LIABLE FOR PUNITIVE, SPECIAL, INCIDENTAL, OR<br />

CONSEQUENTIAL DAMAGES OF ANY KIND.<br />

Some states do not allow the exclusion or limitation of incidental<br />

or consequential damages, so the above limitation may not apply<br />

to you. This Limited Warranty gives you specific legal rights and<br />

you may have other rights which vary from State to State.<br />

<strong>Frazee</strong> Industries, Inc.<br />

6625 Miramar Road<br />

San Diego, CA 92121<br />

Information Phone: 1-800-477-9991<br />

08/2012<br />

The information provided on this product data sheet (“Information”) is correct to the best of our knowledge, information, and belief at the date of its publication. The Information given is designed only as a general<br />

guide and is not to be considered as a warranty or quality specification. The Information is subject to change without prior notice. Consult your sales representative to obtain the most recent product data sheet.