NDSU Beef Feedlot - NDSU Agriculture - North Dakota State ...

NDSU Beef Feedlot - NDSU Agriculture - North Dakota State ...

NDSU Beef Feedlot - NDSU Agriculture - North Dakota State ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

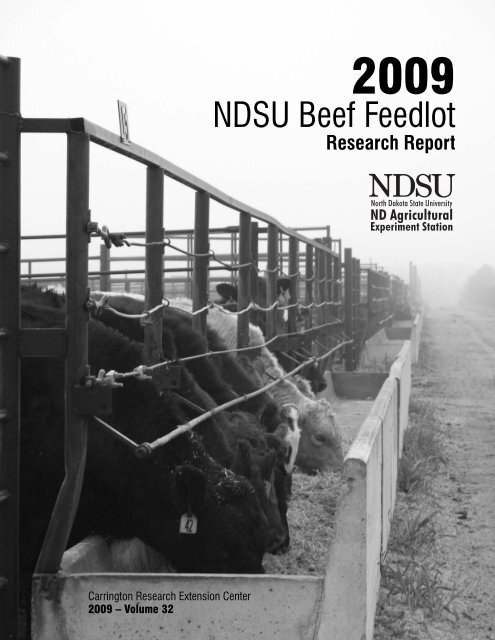

Carrington Research Extension Center<br />

2009 – Volume 32<br />

2009<br />

<strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong><br />

Research Report

Introduction to Livestock Research and Education<br />

The <strong>NDSU</strong> Carrington Research Extension Center is pleased to collaborate with our Agricultural<br />

Experiment Station colleagues in presenting the 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report. This<br />

report represents the latest results and background from beef feedlot research projects from across the<br />

<strong>NDSU</strong>-AES. The research projects reported in Vol.32 build upon the wealth of knowledge that our beef<br />

research faculty have accumulated and reported on over the years.<br />

<strong>Agriculture</strong> in <strong>North</strong> <strong>Dakota</strong> is a vibrant industry representing the primary economic sector of our state’s<br />

economy. The sustained significance of agriculture in <strong>North</strong> <strong>Dakota</strong> is partially due to the diversity of<br />

agricultural enterprises and the synergies of crop and livestock operations. The number of producers<br />

and enterprises that background or finish beef cattle in <strong>North</strong> <strong>Dakota</strong> have increased in recent years.<br />

This trend is welcome and encouraging as many of us see cattle feeding as a sector of our agricultural<br />

economy that has great potential for expansion. The state of <strong>North</strong> <strong>Dakota</strong> is blessed with a multitude<br />

of feedstuffs including the diverse grains, co-products, and forages. Expanded cattle feeding through<br />

background or finishing operations is a good opportunity to add value to these feeds. Ultimately, this<br />

abundance of product will be utilized either here in <strong>North</strong> <strong>Dakota</strong> or shipped elsewhere for use by cattle<br />

feeding operations in other states or countries.<br />

It is our hope that the 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report will again prove useful and effective<br />

in assisting the viability of our livestock industry and the broader constituency who supply the feeds<br />

investigated. We wish to thank the <strong>North</strong> <strong>Dakota</strong> state legislature, selected commodity groups and the<br />

various grant programs that have empowered our research faculty to address the beef feedlot issues<br />

that we now report upon.<br />

Blaine G. Schatz<br />

Director, <strong>NDSU</strong> Carrington Research Extension Center<br />

Thanks for taking the time to review what <strong>NDSU</strong> has to offer in the way of feedlot research. This report<br />

details the collective efforts of scientists from across the state of <strong>North</strong> <strong>Dakota</strong> and represents the latest<br />

in feedlot research. Our scientists collaborate on projects ranging from nutrition to nutrient<br />

management and do their best to bring you meaningful research which you can use to make profitable,<br />

sustainable decisions in your operation.<br />

Please feel free to provide us with feedback related to ways we can improve the research which we<br />

deliver to you each year. We’d love to hear how we can better serve the beef industry in <strong>North</strong> <strong>Dakota</strong><br />

and the region.<br />

Greg Lardy, Ph.D.<br />

Department Head, Animal Sciences<br />

A very special thank you to Myrna Friedt and Stacey Rzaszutak at the Carrington Research Extension<br />

Center for proofreading, organizing, and formatting this publication. The authors appreciate the<br />

excellent animal care, data collection and other support of the many technicians who worked in support<br />

of research presented in this publication.<br />

Page 1 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Contact Information<br />

If you have questions or comments, please e-mail individuals (see addresses below) or call the<br />

Carrington Center at (701) 652-2951. These proceedings are also published at the Carrington<br />

Research Extension Center website at www.ag.nodak.edu/carringt/ under the livestock bullet.<br />

Carrington Research Extension Center<br />

Vern Anderson, Ph.D., P.A.S., Animal Scientist Vern.Anderson@ndsu.edu<br />

Breanne Ilse, Livestock Research Specialist Breanne.Ilse@ndsu.edu<br />

Karl Hoppe, Ph.D., Area Ext. Livestock Specialist Karl.Hoppe@ndsu.edu<br />

Steve Metzger, Farm Business Management S.Metzger@ndsu.edu<br />

Ron Wiederholt, Nutrient Management Research Ron.Wiederholt@ndsu.edu<br />

Chris Augustin, Ext. Nutrient Management Specialist Chris.Augustin@ndsu.edu<br />

Department of Animal Sciences<br />

Greg Lardy, Ph.D., Department Chair Gregory.Lardy@ndsu.edu<br />

Eric Berg, Ph.D., Assoc. Prof., Meat Science Eric.P.Berg@ndsu.edu<br />

Rob Maddock, Ph.D., Assoc. Prof., Meat Science Rob.Maddock@ndsu.edu<br />

Kasey Carlin, Ph.D., Assoc. Prof., Meat Science Kasey.Maddockcarlin@ndsu.edu<br />

Charlie Stoltenow, D.V.M., Ext. Veterinarian Charles.Stoltenow@ndsu.edu<br />

Kim Vonnahme, Ph.D., Assoc. Prof., Reprod. Physiology Kimberly.Vonnahme@ndsu.edu<br />

<strong>North</strong>ern Crops Institute<br />

Kim Koch, Ph.D., Manager, Feed Production Center Kim.Koch@ndsu.edu<br />

Hettinger Research Extension Center<br />

Chris Schauer, Ph.D., Director Chris.Schauer@ndsu.edu<br />

Michele Thompson, Asst. Animal Scientist Michele.Thompson@ndsu.edu<br />

Veterinary and Microbiological Sciences Department<br />

Neil Dyer, D.V.M., Director Neil.Dyer@ndsu.edu<br />

Michelle Mostrum, D.V.M, Ph.D., Toxicologist Michelle.Mostrum@ndsu.edu<br />

Cow/calf pairs grazing summer pasture, August 2009.<br />

Page 2 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Acknowledgements<br />

Research, education, and facility development activities conducted at the <strong>NDSU</strong> Carrington Center are<br />

supported by numerous individuals and organizations. Our heartfelt appreciation is expressed to the<br />

following for their support:<br />

AgInfoLink, Longmont, CO<br />

Ameriflax, Grace City, ND<br />

ADM-Ethanol Division, Walhalla, ND<br />

Barton Meats, Carrington, ND<br />

<strong>Beef</strong> Magazine<br />

Cargill Malt, Spiritwood, ND<br />

Carrington Area Farm Business Management Program, Carrington, ND<br />

Coteau Hills Enterprises, McClusky, ND<br />

<strong>Dakota</strong> Dry Bean, Inc., Crary, ND<br />

<strong>Dakota</strong> Feeder Calf Club, Turtle Lake, ND<br />

<strong>Dakota</strong>Land Feeds, Huron, SD<br />

<strong>Dakota</strong> Growers Pasta Company, Carrington, ND<br />

FUMPA BioFuels Inc., Redwood Falls, MN<br />

G and R Grain and Feed, Inc., New Rockford, ND<br />

Haybuster Equipment, Inc., Jamestown, ND<br />

Igenity, Inc., Bismarck, ND<br />

<strong>North</strong> <strong>Dakota</strong> Barley Council<br />

<strong>North</strong> <strong>Dakota</strong> <strong>Beef</strong> Commission<br />

<strong>North</strong> <strong>Dakota</strong> Corn Utilization Council<br />

<strong>North</strong> <strong>Dakota</strong> Department of <strong>Agriculture</strong><br />

<strong>North</strong> <strong>Dakota</strong> Department of Commerce<br />

<strong>North</strong> <strong>Dakota</strong> Natural <strong>Beef</strong>, LLC<br />

<strong>North</strong> <strong>Dakota</strong> Oilseed Council<br />

<strong>North</strong> <strong>Dakota</strong> Rural Electric Cooperatives, Bismarck, ND<br />

<strong>North</strong> <strong>Dakota</strong> <strong>State</strong> Board of Agricultural Research and Education<br />

<strong>North</strong> <strong>Dakota</strong> <strong>State</strong> University<br />

Department of Animal Sciences<br />

Hettinger Research Extension Center<br />

Veterinary and Microbiological Sciences Department<br />

<strong>North</strong> <strong>Dakota</strong> Stockmen’s Association Feeder Council, Bismarck, ND<br />

<strong>North</strong>ern Crops Institute, Fargo, ND<br />

<strong>North</strong>ern Pulse Growers Association, Bismarck, ND<br />

R & B Manufacturing, Steele, ND<br />

Ralco Nutrition, Inc., Marshal, MN<br />

Sartec, Inc., Anoka, MN<br />

Schering Plough Inc., Kenilworth, NJ<br />

Tim Olson, CATL Resource PC, Sturgis, SD<br />

Tyson Fresh Meats, <strong>Dakota</strong> Dunes, SD<br />

United <strong>State</strong>s Department of <strong>Agriculture</strong><br />

National Research Initiative – Equipment Grants Program<br />

Cool Season Food Legume Program<br />

Westway Products, Inc., Mapleton, ND<br />

Trade names and companies used are for clear communication. No endorsement is intended, nor criticism<br />

implied, of products mentioned or not mentioned.<br />

Page 3 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Table of Contents<br />

<strong>Feedlot</strong> Schools Are Educational Opportunity for New or Experienced <strong>North</strong> <strong>Dakota</strong> Cattle Feeders .... 5<br />

Observations on the Palatability of an Inorganic Salt Product for Mitigation of High Sulfur Levels in<br />

<strong>Feedlot</strong> Diets .................................................................................................................................... 7<br />

Influence of Thiamin Supplementation on Hydrogen Sulfide Gas Concentrations in Ruminants Fed<br />

High-Sulfur Diets ............................................................................................................................ 11<br />

An Evaluation of a Mixed Co-product Protein Feed in Finishing Rations .............................................. 15<br />

Effects of Dried Distillers Grains With Solubles on Growing and Finishing Steer Intake, Performance,<br />

Carcass Characteristics, Color and Sensory Attributes .................................................................. 18<br />

Effect of Glycerol Level in <strong>Feedlot</strong> Diets on Animal Performance and Carcass Traits .......................... 24<br />

Impact of Weaning Date on Calf Growth and Carcass Traits ............................................................... 30<br />

Growth and <strong>Feedlot</strong> Performance of Steer Calves Born From <strong>Beef</strong> Cows Supplemented with<br />

Linseed Meal During Late Gestation .............................................................................................. 36<br />

Effect of Distillers Grains on Natural vs. Conventional Supplements and Production Methods on<br />

<strong>Feedlot</strong> Performance, and Carcass Characteristics ....................................................................... 41<br />

Discovering Value in <strong>North</strong> <strong>Dakota</strong> Calves; The <strong>Dakota</strong> Feeder Calf Show Feedout Project VIII ......... 45<br />

Forage Production Costs and Yields for South-Central <strong>North</strong> <strong>Dakota</strong> .................................................. 49<br />

Challenges and Opportunities for <strong>Beef</strong> <strong>Feedlot</strong>s in <strong>North</strong> <strong>Dakota</strong> ........................................................ 51<br />

Diagnostic Note – Infectious Bovine Keratoconjunctivitis (Pinkeye) ..................................................... 54<br />

<strong>NDSU</strong> BBQ Boot Camps 2009<br />

Celebrating the Products of Livestock Production .......................................................................... 56<br />

Creating a silage bunker.<br />

Page 4 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

<strong>Feedlot</strong> Schools Are Educational Opportunity for New or Experienced<br />

<strong>North</strong> <strong>Dakota</strong> Cattle Feeders<br />

W. Becker 1 and V.L. Anderson 2<br />

1 Foster County Extension Agent<br />

2 <strong>NDSU</strong> Carrington Research Extension Center<br />

Introduction<br />

<strong>North</strong> <strong>Dakota</strong> cattlemen produce exceptional quality feeder cattle that are in demand by feedlot<br />

operators in other states. However, resources are available for feeding cattle in <strong>North</strong> <strong>Dakota</strong> to<br />

capture value from the excellent genetics and utilize some of the available feedstocks. Many producers<br />

now background their spring-born calves at least until January, and there is increasing interest in<br />

finishing cattle for terminal markets.<br />

The <strong>North</strong> <strong>Dakota</strong> <strong>State</strong> University <strong>Feedlot</strong> School was developed to help educate and inform<br />

producers about cattle feeding. The <strong>Feedlot</strong> School is an annual program initiated in 1996. It is an<br />

intensive two-day school that offers training in all aspects of the feedlot enterprise.<br />

Background<br />

To evaluate the legitimate potential and competitiveness of feeding cattle in <strong>North</strong> <strong>Dakota</strong> versus the<br />

large commercial feedyards in Kansas and Nebraska, a multi-year research study was conducted with<br />

producer-owned calves in the early 1990s. Calves were gathered at the Carrington Research<br />

Extension Center and one group transported to commercial yards in Nebraska or Kansas during the<br />

three-year project. The results indicated that the lower feed costs per pound of gain (~$.05 advantage)<br />

and feed availability were major advantages to cattle feeding in <strong>North</strong> <strong>Dakota</strong> even though gains were<br />

slightly higher in southern yards. Subsequent research in successfully mitigating winter weather with<br />

bedding and wind protection further supports the potential for cattle feeding in <strong>North</strong> <strong>Dakota</strong>. Feeds in<br />

<strong>North</strong> <strong>Dakota</strong> are very competitively priced compared to commercial feeding regions in the High Plains.<br />

<strong>North</strong> <strong>Dakota</strong> feeds include corn, barley, field peas, oats, wheat, several oilseed meals, corn distillers<br />

grains, wheat midds, barley malt sprouts, corn gluten feed, beet pulp, field pea chips, and soyhulls plus<br />

low cost forages and crop residues. New incentive programs for upgrading or building feedlots through<br />

EPA 319 and NRCS Equip program monies and new risk protection programs are available.<br />

<strong>Feedlot</strong> School Curriculum<br />

The program is an intensive two-day educational course that is offered for cattle feeders, industry<br />

personnel, educators, and anyone interested in feedlot management. The school visits commercial and<br />

research feedlots for observations in bunk reading, facilities, animal processing, and an update on<br />

current research activities. Attendees network with experienced <strong>NDSU</strong> field staff and specialists, and<br />

fellow students. The faculty includes veterinarians, nutritionists, meat scientists, marketing experts,<br />

experienced feeders, and other qualified instructors. Comprehensive printed resource materials are<br />

provided to those attending.<br />

The topics presented at the <strong>NDSU</strong> <strong>Feedlot</strong> Schools include:<br />

1. Feeding enterprises for specific markets including backgrounding, finishing, heifer development,<br />

and cull cow feeding.<br />

2. Feed ingredients, nutritional value, and compatibility.<br />

3. Recommended usage of feeds to meet animal requirements.<br />

4. Ration formulation for optimum animal growth and profit.<br />

5. Feed supplements, additives, and implants.<br />

Page 5 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

6. Grain processing, mixing rations, and feed bunk management.<br />

7. Health management, vaccinations, detection of sick animals, and treatment.<br />

8. Facility planning and design including working facilities, pens, and containment.<br />

9. Manure management, composting, and spreading as fertilizer.<br />

10. Marketing cattle, industry grids, carcass traits and value.<br />

11. Risk management, hedges, puts and forward pricing.<br />

In the 13 years that the feedlot school has been held, there have been 20 different schools that<br />

provided information to over 500 participants, with some repeat participants. The sessions are held<br />

annually at the Carrington Research Extension Center during late January. The same basic school has<br />

been offered at other locations some years, including Fargo, Hettinger, Williston, and Sidney, Montana.<br />

A feedlot school was offered in Maine modeled after the <strong>NDSU</strong> program, and a college course and<br />

training certification program in Colby, Kansas, was spurred by the <strong>NDSU</strong> <strong>Feedlot</strong> School. The<br />

program has reached producers in eight states and one province including South <strong>Dakota</strong>, Montana,<br />

Nebraska, Minnesota, Wisconsin, Oregon, Maine, and Manitoba. An evaluation is given at the end of<br />

every school that asks participants for honest feedback. The curriculum is adapted to producer needs<br />

based on these responses and has evolved over the years of the school.<br />

According to the most recent <strong>North</strong> <strong>Dakota</strong> <strong>Agriculture</strong> Statistics Service <strong>Feedlot</strong> Survey (2008), from<br />

2004 through 2007 the total number of feeding operations with 500 head or more capacity, has<br />

increased 16% from 130 to 151 feedlots. Total capacity has increased 20% from 189,000 to 226,300<br />

head. The future of the <strong>North</strong> <strong>Dakota</strong> <strong>Feedlot</strong> School is to continue with the ongoing interest of the<br />

producers. Planning is underway for an ―advanced‖ feedlot school for those that want a deeper<br />

understanding of nutrition, marketing, and management. The goal is to provide the utmost quality<br />

programming that makes the <strong>North</strong> <strong>Dakota</strong> <strong>State</strong> University <strong>Feedlot</strong> School partnership successful.<br />

With the increasing interest in feeding cattle to slaughter weights in the <strong>North</strong>ern Plains, and the ample<br />

supply of cattle, feed grains, forages, and co-products for feedlot use across the area, the <strong>North</strong> <strong>Dakota</strong><br />

<strong>Feedlot</strong> School has helped producers increase their working knowledge of feedlot operation. In<br />

addition to the material presented, the school serves a function to network feeders and faculty for future<br />

communications. All of the principles taught in the school are relevant to other regions as well and<br />

serves any area interested in feeding cattle. This program requires extensive collaboration between<br />

cooperating agencies, industry, and private operators all with the intent to make the cattle feeding<br />

business better for all parties involved. For information on attending an <strong>NDSU</strong> <strong>Feedlot</strong> School, contact<br />

the Foster County Extension office at (701) 652-2581 or the Carrington Research Extension Center at<br />

(701) 652-2951 or email: <strong>NDSU</strong>.Carrington.REC@ndsu.edu.<br />

Page 6 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Observations on the Palatability of an Inorganic Salt Product for<br />

Mitigation of High Sulfur Levels in <strong>Feedlot</strong> Diets<br />

V.L. Anderson 1 , B.R. Ilse 1 , P. Gruel 2 and S. McLeish 2<br />

1 <strong>NDSU</strong> Carrington Research Extension Center<br />

2 Sartec, Inc.<br />

Introduction<br />

Distillers grains are often the lowest cost protein feed available for cattlemen. This ingredient can be<br />

used in cow/calf production as well as feedlot diets. However, distillers grains often contain high levels<br />

of sulfur. There is significant variation in the sulfur content of distillers grains from plant to plant and<br />

even within a plant as sulfuric acid may be added to batches to improve fermentation efficiency by<br />

altering the pH. Sulfuric acid is also used to clean equipment. While sulfur level is often between 0.65<br />

and 0.85% on a dry-matter basis, levels as high as 1.25% sulfur have been analyzed.<br />

<strong>Beef</strong> cattle can tolerate a maximum of 0.40% sulfur in the diet (NRC, 1996) before polio-like symptoms<br />

of sulfur toxicity are generally observed, with the first noticeable sign often being death. Toxic<br />

symptoms and death have been reported when a diet contains as low as 0.25% sulfur in grain-based<br />

diets. Grain diets are thought to be less tolerant to high sulfur levels but with forage diets, sulfur<br />

tolerance may be greater. It is unknown how many health and reproductive problems have occurred<br />

due to sub acute sulfur toxicity from feeding distillers grains, high-sulfate content water, or sulfur in<br />

other feed sources. Survey data may be inconclusive due to the unwillingness of producers to admit to<br />

these losses, or inconclusive diagnosis by producers or their veterinarians. Any feed ingredient or<br />

management technique that would mitigate sulfur toxicity and allow increased use of distillers grains<br />

with less potential for illness or death will be well received in the livestock industry. New feed products<br />

are under development that may tie up sulfur and reduce negative effects of higher sulfur levels in the<br />

diet of cattle. The objective of this field study was to determine the effect of adding a proprietary<br />

inorganic salt product to feedlot finishing diets on feed intake, gain, and carcass traits.<br />

Experimental Procedures<br />

Forty-eight Angus feeder calves were blocked by sex (heifers and steers) and assigned within block to<br />

one of two treatments. One pen of steers and one pen of heifers were fed the proprietary inorganic salt<br />

product developed to mitigate sulfur levels in feedlot rations. The second pen of steers and heifers was<br />

fed the same diet without the inorganic salt product. The inorganic salt product was fed at 13.8 grams<br />

per head per day based on recommendations of the manufacturer. This product was mixed into the<br />

feedlot supplement (Table 1) which was added to the grain component of the ration in the daily ration<br />

preparation. The supplements were manufactured at the <strong>North</strong>ern Crops Institute (NCI) on the campus<br />

of <strong>NDSU</strong> under the direction of Dr. Kim Koch, manager of the NCI Feed Production Center.<br />

Supplements were transported to the Carrington Research Extension Center in tote bags.<br />

Supplements were formulated to be fed at 0.33 pounds per head per day, and contain minerals,<br />

vitamins, Rumensin (300 mg/hd/d), and carrier feed products (Table 1). Supplements were formulated<br />

to be identical except for the addition of the inorganic salt product.<br />

Page 7 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Table 1. Supplements with and without organic salt to mitigate sulfur.<br />

Control Inorganic Salt<br />

Supplement Supplement<br />

% DM basis<br />

Corn, ground 25.00 25.00<br />

Distiller grains 13.75 13.75<br />

Malt sprouts 23.50 14.40<br />

Calcium carbonate 12.00 12.00<br />

Potassium chloride 11.25 11.25<br />

Zinc sulfate 0.20 0.20<br />

Dical-Phosphate (18.5%) 3.75 3.75<br />

Feed-grade salt 8.25 8.25<br />

Rumensin (80 g/lb) 1.10 1.10<br />

Vit A-D 10:1 <strong>Beef</strong> 0.30 0.30<br />

Vitamin Premix 0.90 0.90<br />

Inorganic salt 0.00 9.10<br />

Total 100.00 100.00<br />

Cattle were fed in the morning after bunk calls were made for increase, decrease or no change in the<br />

ration. Increases or decreases were done at 2.5% of the diet dry matter for each pen. Feed delivered<br />

to each pen was recorded daily. The ration was assembled, mixed and delivered using a Knight LA-9<br />

Little Augie, three-auger mixer box. The corn-based ration was formulated at 62 Mcal NEg/lb, (Table<br />

2). It included a minimum of 20% modified (50% moisture) distillers grains and solubles (dry matter<br />

basis) procured from the Blue Flint Ethanol facility in Underwood, ND. Samples of each ingredient<br />

were collected monthly and submitted to a commercial laboratory for dry matter, NEm, NEg, crude<br />

protein, fat, sulfur, calcium, and phosphorous. Water samples tested contained 74 mg/l sulfates, which<br />

is very low.<br />

Inorganic salt could become useful in high-sulfur distillers grains diets.<br />

Page 8 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Table 2. Ration for cattle fed sulfur-mitigating inorganic salt.<br />

Ingredient Percent, DM basis Percent, As Fed<br />

Corn # 2 62.00 50.83<br />

Dist grains, wet 20.00 34.84<br />

Straw 10.00 8.20<br />

Canola meal 5.00 3.87<br />

Supplement 2.00 1.55<br />

Calcium carbonate 1.00 0.71<br />

Total, Percent 100 100<br />

Nutrient content<br />

Dry Matter, %<br />

NEg, Mcal/lb<br />

Crude Protein, %<br />

Calcium, %<br />

Phosphorous, %<br />

Potassium, %<br />

Sulfur, %<br />

69.68<br />

62.71<br />

13.61<br />

0.64<br />

0.35<br />

0.59<br />

0.36<br />

All calves were weighed individually at the start of the trial on March 14, 2009, and when the trial was<br />

completed and the cattle went to market on May 4. Dry-matter intake, gain, and feed efficiency were<br />

calculated for each animal and averaged for each pen and for each treatment. Cattle were marketed<br />

as a group.<br />

Results<br />

The base diet fed in this study was 0.36% sulfur, with distillers grains as the primary source of sulfur.<br />

The primary question of the study was to determine if the inorganic salt product had any negative effect<br />

on feed intake or animal performance. There were insufficient replications to conduct confident<br />

statistical comparisons so the raw data is reported on a pen and sex-of-calf basis. The results of this<br />

field study (Table 3) suggest that feed intake was not affected. While this cannot be deduced from the<br />

limited replications, numerical values suggest some potential for positive effects on intake and gain<br />

from the addition of the inorganic salt. No health issues or illnesses were observed for the calves<br />

during the 50-day feeding period.<br />

Page 9 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Table 3. Performance of feeder cattle fed<br />

inorganic salt product for sulfur mitigation.<br />

Control<br />

Inorganic<br />

Salt<br />

No. head<br />

Heifers 11 11<br />

Steers 12 12<br />

Start wt., lb.<br />

Heifers 957.4 960.7<br />

Steers 987.5 971.4<br />

AVG 972.5 966.1<br />

End wt., lb.<br />

Heifers 1125.5 1135.3<br />

Steers 1141.1 1159.7<br />

AVG 1133.3 1147.5<br />

DMI, lb/hd/day<br />

Heifers 22.73 22.52<br />

Steers 20.89 23.76<br />

AVG 22.07 23.18<br />

ADG, lb/hd/day<br />

Heifers 3.40 3.65<br />

Steers 3.49 3.50<br />

AVG 3.45 3.58<br />

Feed Efficiency (DM/gain)<br />

Heifers 6.68 6.16<br />

Steers 5.99 6.78<br />

AVG 6.41 6.48<br />

As distillers grains continue to be a significant feed source and sulfuric acid is used in the process, a<br />

product such as the inorganic salt could become useful especially in scenarios where ethanol plants<br />

produce high-sulfur distillers grains or where the price of distillers grains is low enough to use at more<br />

than nominal levels. More research is needed to prove the efficacy of this product, however, followed<br />

by commercial availability and documented economic advantages.<br />

Page 10 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Influence of Thiamin Supplementation on Hydrogen Sulfide Gas<br />

Concentrations in Ruminants Fed High-Sulfur Diets<br />

B.W. Neville 1 , C.S. Schauer 2 , and G.P. Lardy 1<br />

1 <strong>NDSU</strong> Department of Animal Sciences<br />

2 <strong>NDSU</strong> Hettinger Research Extension Center<br />

The objective of this research was to evaluate the influence of thiamin supplementation on hydrogen<br />

sulfide gas concentration and ruminal pH in lambs fed high-sulfur diets. Moderate levels of thiamin<br />

supplementation seem to decrease hydrogen sulfide concentrations. Our data suggests that changes<br />

in ruminal hydrogen sulfide concentration cannot be attributed solely to ruminal pH and are likely<br />

affected by multiple factors that interact within the ruminal environment and in the animal.<br />

Summary<br />

The objective of this study was to evaluate the effect of increasing levels of thiamin supplementation on<br />

ruminal gas cap hydrogen sulfide (H2S) concentration and pH in lambs. Twenty crossbred lambs (84.5<br />

± 7 pounds) were adapted in 28 days to a finishing diet consisting of (dry-matter [DM] basis) 60% dried<br />

distillers grains with solubles, 21.4% corn, 15% alfalfa hay and 3.6 % supplement. Treatment diets<br />

differed in the amount of supplemental thiamin supplied; diets were formulated to provide: 1) CON (no<br />

supplemental thiamin), 2) LOW (50 milligrams per head per day [mg·hd -1 ·d -1 ] thiamin), 3) MED (100<br />

mg·hd -1 ·d -1 thiamin), 4) HIGH (150 mg·hd -1 ·d -1 thiamin) or 5) HIGH+S (150 mg·hd -1 ·d -1 thiamin with<br />

dietary sulfur [S] increased from 0.71 percent to 0.87 percent (DM basis) with the addition of dilute<br />

sulfuric acid to dried distillers grains with solubles [DDGS]). Thiamin supplementation was based on an<br />

estimated daily dry-matter intake (DMI) of 3 lb.·hd -1 ·d -1 .<br />

Hydrogen sulfide and rumen fluid pH were collected via rumen puncture on day minus 6, minus 4, 0, 3,<br />

7, 10, 14, 17, 21, 24, 28 and 31. No differences in H2S concentration (P > 0.10) among treatments<br />

were apparent until day 10, at which point lambs fed LOW had lower H2S concentrations than all other<br />

treatments. Lambs fed HIGH had the greatest concentrations of H2S on day 31 (7,700 parts per million<br />

[ppm] H2S; P < 0.009). Ruminal pH for lambs fed CON and MED were not different from day 0<br />

throughout sampling (P > 0.18). Ruminal pH of LOW, HIGH and HIGH+S groups decreased (P < 0.03)<br />

through time. Thiamin appears to influence ruminal H2S concentrations, although the mechanism by<br />

which this occurred remains unknown. Changes in H2S concentration cannot be attributed solely to<br />

ruminal pH and likely are affected by multiple factors that interact within the ruminal environment and in<br />

the animal.<br />

Introduction<br />

One of the challenges with use of ethanol coproducts is the potential for high dietary S levels. High S<br />

diets can cause polioencephalomalacia (PEM) in ruminants. Inclusion of large percentages of<br />

coproduct feeds, such as dried distillers grains with solubles (DDGS), in finishing rations has been<br />

avoided, in part, due to problems with PEM as well as concerns about optimal animal performance and<br />

carcass characteristics. Thiamin supplementation is one proposed method of reducing or preventing<br />

PEM in ruminant animals. The efficacy of thiamin supplementation in preventing PEM likely is<br />

impacted by the mechanisms by which PEM is caused (for example, long-term thiamin deficiency or<br />

high hydrogen sulfide gas concentration). Further, the effect and dose of thiamin necessary to prevent<br />

such cases of PEM requires more investigation. Hydrogen sulfide gas, as previously mentioned, has<br />

been implicated as a cause of PEM in ruminants. Both high-sulfur feed (Niles et al., 2002) and water<br />

(Loneragan et al., 2005) sources can cause increases in H2S production. No published literature that<br />

evaluates the effect of dietary thiamin concentrations on ruminal H2S gas concentration is available.<br />

Therefore, our objective was to evaluate the effect of increasing level of thiamin supplementation on<br />

Page 11 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

uminal gas cap H2S concentration and ruminal pH in lambs being adapted to a finishing diet containing<br />

60% DDGS.<br />

Procedures<br />

Twenty western white-face wether lambs (84.5 ± 7 pounds) were sampled during the adaptation period<br />

(receiving ration to a final finishing ration). Adaptation was accomplished by increasing the amount of<br />

concentrate on a weekly basis; adaptation diets are outlined in Table 1. The final finishing diet was<br />

balanced to contain 60% DDGS (DM basis; Table 2). Treatment diets differed in the amount of<br />

supplemental thiamin supplied; diets were formulated to provide: 1) CON (no supplemental thiamin), 2)<br />

LOW (50 mg·hd -1 ·d -1 thiamin), 3) MED (100 mg·hd -1 ·d -1 thiamin), 4) HIGH (150 mg·hd -1 ·d -1 thiamin) or 5)<br />

HIGH+S (150 mg·hd -1 ·d -1 thiamin with dietary S increased from 0.71 percent to 0.87 percent (DM basis)<br />

with the addition of dilute sulfuric acid to DDGS). Thiamin supplementation was based on an estimated<br />

daily DMI of 3 lb·hd -1 ·d -1 . Feed was offered daily on an ad libitum basis with refusals collected and<br />

weighed weekly.<br />

Table 1. Adaptation diets fed to lambs (% DM basis).<br />

Ingredient, %<br />

Arrival Step 1 Step 2 Step 3 Step 4 Step 5<br />

day -6 day 0 day 7 day 14 day 21 day 28<br />

Alfalfa Hay 46 46 46 35 25 15<br />

Corn 50.38 35.88 21.38 21.38 21.38 21.38<br />

DDGS 0 14.5 29 40 50 60<br />

Supplement 1<br />

3.62 3.62 3.62 3.62 3.62 3.62<br />

1 Supplement contained: (% of total diet DM) 0.5% ammonium chloride, 2.25% limestone,<br />

0.085% lasalocid, 0.78% trace mineral and 0.002% copper sulfate, and was formulated to<br />

provide one of four levels of thiamin (0, 50, 100 or 150 mg·hd -1 ·d -1 ).<br />

Page 12 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Table 2. Ingredient and nutritional composition (DM basis) of final finishing rations<br />

fed to lambs.<br />

Item CON LOW MED HIGH HIGH+S<br />

Ingredient ,%<br />

Alfalfa Hay 15.0 15.0 15.0 15.0 15.0<br />

Corn 21.4 21.4 21.4 21.4 21.4<br />

DDGS 60.0 60.0 60.0 60.0 60.0<br />

Supplement 2<br />

3.6 3.6 3.6 3.6 3.6<br />

Nutrient 3<br />

CP, % 23.3 23.6 23.4 22.7 23.5<br />

ADF, % 10.8 11.0 11.6 11.6 11.3<br />

S, % 0.8 0.7 0.8 0.7 0.9<br />

Ca, % 1.6 1.4 1.7 1.7 1.8<br />

P, % 0.8 0.8 0.9 0.9 0.9<br />

Thiamin 4<br />

0.0 50.0 100.0 150.0 150.0<br />

1 Treatments: CON (no supplemental thiamin), LOW (50 mg·hd -1 ·d -1 thiamin), MED (100 mg·hd -1 ·d -1<br />

thiamin), HIGH (150 mg·hd -1 ·d -1 thiamin) and HIGH+S (150 mg·hd -1 ·d -1 thiamin with 0.87% S).<br />

2 Supplement (% total diet): 0.5% ammonium chloride, 2.25% limestone, 0.085% lasalocid, 0.78%<br />

sheep mineral 12 (Hubbard Feeds, Mankato, Minn.), 0.002% copper sulfate and 0, 0.004, 0.007 or<br />

0.11% thiamin mononitrate.<br />

3<br />

Laboratory analysis of nutrient concentration.<br />

4<br />

Formulated level (ppm), thiamin inclusion in diet calculated based on an estimated DMI of 3.0<br />

lb·hd -1 ·d -1 .<br />

Treatments 1<br />

Sampling for ruminal H2S was conducted on 12 occasions beginning six days prior to initiation of<br />

treatment diets. Gas cap samples from these lambs were collected on day minus 6, minus 4, 0, 3, 7,<br />

10, 14, 17, 21, 24, 28 and 31 of the feeding period. Hydrogen sulfide gas was measured on H2S<br />

detector tubes (GASTEC © , Kanagawa, Japan). Ruminal fluid was collected at the same time for<br />

determination of rumen fluid pH.<br />

Results<br />

The influence of hydrogen sulfide gas on incidence of PEM in ruminants could be impacted by the way<br />

H2S concentration changes during adaptation to finishing rations. In the present study, no differences<br />

in H2S concentration among treatments (P > 0.10; Table 3) were apparent until day 10, at which point<br />

lambs fed LOW had lower H2S concentrations than all other treatments. At this point in adaptation, the<br />

amount of roughage included in the diet had not changed although the inclusion of DDGS had<br />

increased from 0% to 29% of dietary DM. Those lambs fed the HIGH treatment diet showed the most<br />

dramatic increases in ruminal H2S concentration; on day 21 of adaptation, dietary hay was decreased<br />

from 35% to 25% and DDGS increased from 40% to 50% of dietary DM. During the course of the next<br />

three days, ruminal H2S concentration increased by more than 3,000 ppm and within seven days had<br />

increased by 4,700 ppm H2S.<br />

Page 13 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Table 3. Influence of thiamin and sulfur level on hydrogen sulfide production in<br />

lambs fed a 60% DDGS-based finishing diet.<br />

Day CON LOW MED HIGH<br />

-6 0 0 0 190.6<br />

-4 66.7 0 112.5 25<br />

0 71.5 0 146.9 71.9<br />

3 531.3 375 310.5 737.5<br />

7 778.1 575 759.4 1,237.5<br />

10 2,200.0 a<br />

887.5 b<br />

2,200.0 a<br />

2,453.1 a<br />

14 2,390.6 a<br />

1,087.5 b<br />

1,875.0 a<br />

1,906.3 a<br />

17 2,852.6 a<br />

1,418.8 b<br />

2,609.4 a<br />

21 3,312.5 a<br />

1,531.3 c<br />

2,328.1 abc<br />

24 2,062.5 a<br />

3,287.5 b<br />

3,275.0 b<br />

4,991.6 c<br />

28 4,687.5 a<br />

2,662.5 b<br />

2,906.3 b<br />

6,657.8 c<br />

31 5,687.5 a<br />

2,650.0 b<br />

Treatment 1,2<br />

3,843.8 c<br />

2,406.3 ab<br />

1,958.2 bc<br />

7,701.3 d<br />

abc Means with different superscripts within a row differ at P < 0.10.<br />

Page 14 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report<br />

HIGH+S<br />

75<br />

28.1<br />

93.8<br />

475<br />

1,350.0<br />

2,378.1 a<br />

2,015.6 a<br />

2,406.3 ab<br />

3,140.6 ab<br />

3,046.9 ab<br />

4,390.6 a<br />

4,859.4 ac<br />

1 Treatments: CON (no supplemental thiamin), LOW (50 mg·hd -1 ·d -1 thiamin), MED (100<br />

mg·hd -1 ·d -1 thiamin), HIGH (150 mg·hd -1 ·d -1 thiamin) and HIGH+S (150 mg·hd -1 ·d -1 thiamin<br />

with 0.87% S).<br />

2 When tube measurement was below 100 ppm, tube was considered to read 0.<br />

While the hydrogen sulfide concentrations in the lambs did not reach the levels in steers reported by<br />

Niles et al. (2002), the peak concentrations were above those reported by Loneragan et al. (2005); both<br />

of these studies had steers with positive cases of PEM. These results indicate that the concentration of<br />

H2S required to cause symptoms of PEM may vary depending on species.<br />

Of further interest is the way the H2S concentration in lambs fed HIGH+S changed during adaptation.<br />

Specifically, on days 7, 14 and 21, the concentration of H2S was greater in HIGH+S than HIGH;<br />

however, after three days of adaptation (days 10, 17, 24) the concentration of ruminal H2S from<br />

HIGH+S was lower or equal to that found in HIGH fed lambs.<br />

Multiple factors influence the conversion of dietary S into H2S in the rumen during adaptation. Among<br />

these are decreases in ruminal fluid pH, increases in the proportion of sulfur-reducing bacteria and<br />

increases in dietary S. In this study, ruminal pH did not differ among treatments (P = 0.13) at any time<br />

point (data not shown). Lambs fed CON and MED were not different from day 0 throughout sampling<br />

(P > 0.18). However, ruminal pH of LOW, HIGH and HIGH+S groups did decrease (P < 0.03) through<br />

time. Decreases in ruminal pH also may impact incidence of PEM by other means.<br />

Our research suggests that thiamin may influence ruminal H2S concentrations, but we did not<br />

investigate the fate of the H2S. Further, our data suggests that changes in ruminal hydrogen sulfide<br />

concentration cannot be attributed solely to ruminal pH and likely are affected by multiple factors that<br />

interact within the ruminal environment and in the animal.

Literature Cited<br />

Loneragan, G, D. Gould, J. Wagner, F. Garry and M. Thoren. 2005. The magnitude and patterns of<br />

ruminal hydrogen sulfide production, blood thiamin concentration, and mean pulmonary arterial<br />

pressure in feedlot steers consuming water of different sulfate concentrations. The Bovine<br />

Practitioner. 39:16-22.<br />

Niles, G.A., S. Morgan, W.C. Edwards and D. Lalman. 2002. Effects of dietary sulfur concentrations on<br />

the incidence and pathology of polioencephalomalacia in weaned beef calves. Vet. Human Toxicol.<br />

44(2):70-72.<br />

An Evaluation of a Mixed Co-product Protein Feed in Finishing Rations<br />

V.L. Anderson and B.R. Ilse<br />

<strong>NDSU</strong> Carrington Research Extension Center<br />

Introduction<br />

<strong>North</strong> <strong>Dakota</strong> produces approximately three million tons of co-product feeds in a year including<br />

significant amounts of soybean meal and soybean hulls. Historically, we have exported these feed<br />

ingredients individually to feed markets around the world. Most of the multitude of co-products have<br />

some unique properties that could be improved upon by mixing with other co-products to improve<br />

nutritional and physical properties. Mixing three or more co-product feeds together and pelleting the<br />

mixture creates a new feed commodity. The nutrient content of the new feed is obviously based on the<br />

formulation which can potentially be adapted to specific market opportunities. The new pelleted<br />

commodities have greater bulk density for shipping advantages. They also may be more flexible in end<br />

use, nutrient profile, longer shelf life, improved flow properties, simplified feeding for end users, and<br />

improved safety.<br />

Experimental Procedures<br />

Steer calves (n=176) from 43 different ranches belonging to the <strong>Dakota</strong> Feeder Calf Club at Turtle<br />

Lake, ND, were consigned to the Carrington Research Extension center in the fall of 2008. Each ranch<br />

consigned three to eight steers for the feedout project to observe the feedlot performance and carcass<br />

value from their respective breeding program. After a preconditioning program, steers were individually<br />

weighed, blocked by weight and allotted within weight block to one of four treatments. Steers from<br />

each ranch were allotted to different treatments to reduce ―ranch‖ effects. The treatments were<br />

designed to provide increasing levels of a mixed co-product ―superfeed‖ formulated with 50% soybean<br />

meal, 35 percent distillers grains, and 15 percent field peas.The co-product protein supplement was<br />

manufactured by the <strong>North</strong>ern Crops Institute feed production center in Fargo, ND. This 35 percent<br />

crude protein feed was included in the treatment diets at 0, 5, 10, and 15 percent of the dry matter as a<br />

protein supplement. Canola meal was used as the control protein source. Ration formulations are<br />

provided in Table 1. A totally-mixed corn-based ration was fed to appetite daily in fenceline bunks.<br />

Steers were provided wind protection and bedded during the relatively severe winter. Steers were<br />

weighed every 28 days with feed intake summarized for each weigh period. Feed efficiency was<br />

calculated based on average dry matter intake and average daily gain for each period and overall.<br />

Steers were marketed to Tyson Meats, <strong>Dakota</strong> City, NE on May 6, after evaluation by visual appraisal<br />

that 60% or more would grade USDA Choice. Carcass traits were evaluated after a 24-hour chill by<br />

trained personnel.<br />

Page 15 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Table 1. Rations for steers fed increasing coproduct formulation as protein supplement.<br />

Treatment<br />

Ingredient 0% 5% 10% 15%<br />

Percent, Dry matter basis<br />

Corn, dry rolled 69.2 69.3 69.4 69.5<br />

Co-product protein suppl 0.0 5.0 10.1 15.2<br />

Canola meal 15.6 10.4 5.2 0.0<br />

Straw, chopped 6.9 6.9 6.9 6.9<br />

Corn silage 6.5 6.6 6.5 6.6<br />

Calcium carbonate 0.5 0.5 0.5 0.5<br />

Suppl (Rumensin, vit, min) 1.3 1.3 1.4 1.3<br />

Nutrient Content<br />

Dry Matter, % 78.78 78.67 78.77 78.66<br />

Neg, Mcal/lb 60.33 61.51 62.72 63.91<br />

Crude Protein, % 13.94 13.64 13.39 13.11<br />

Calcium, % 0.45 0.43 0.43 0.41<br />

Phosphorous, % 0.40 0.39 0.37 0.35<br />

Potassium, % 0.60 0.62 0.64 0.66<br />

Results and Discussion<br />

Despite the severe winter weather, steer performance in all treatment groups was very satisfactory. We<br />

observed no statistical difference between the treatments in this trial for any of the feedlot performance<br />

measures (Table 2). The energy density (NEg) increased slightly as the proportion of ―superfeed‖<br />

increased in the ration, however, protein content decreased from 13.94 to 13.11 percent from 0 to 15<br />

percent superfeed. Feed intake for the steers in the respective treatments was 21.01, 22.10, 22.43,<br />

and 22.47 for 0, 5, 10, and 15 percent superfeed treatments. Gains throughout the feeding period<br />

averaged 3.65, 3.68, 3.67, and 3.85 respectively, for 0, 5, 10, and 15 percent superfeed in the diet.<br />

Feed efficiency (feed per gain) was calculated at 4.84, 5.17, 5.24, and 4.80 for increasing superfeed.<br />

Despite severe winter weather, steer performance was very satisfactory.<br />

Page 16 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Table 2. <strong>Feedlot</strong> performance of cattle fed mixed coproduct supplement (CPS) at increasing levels.<br />

Percent Co-Product supplement Contrasts<br />

Item<br />

Live Wt, lbs<br />

0% 5% 10% 15% Std. Error P-Value<br />

CPS vs.<br />

no CPS linear quadratic<br />

Initial Wt (29-Jan) 963.8 988.5 971.6 957.9 39.7 0.24 0.51 0.50 0.14<br />

Period 1 Wt. (25-Feb) 1071.4 1093.1 1082.1 1074.5 43.8 0.60 0.42 0.99 0.28<br />

Period 2 Wt. (06-Apr) 1209.6 1237.1 1215.7 1219.8 40.7 0.60 0.41 0.89 0.46<br />

Period 3 Final Wt. (06-May) 1314.4<br />

DM Intake, lb/hd/day<br />

1346.4 1321.6 1328.1 42.7 0.57 0.38 0.83 0.47<br />

Period 1 19.05 19.92 20.45 20.65 1.38 0.87 0.44 0.41 0.82<br />

Period 2 21.92 23.06 23.09 22.96 1.18 0.87 0.42 0.55 0.60<br />

Period 3 22.08 23.31 23.73 23.80 0.91 0.54 0.19 0.22 0.56<br />

Overall DMI 21.02 22.10 22.43 22.47 1.16 0.80 0.34 0.38 0.67<br />

Average Daily Gain, lb/hd/day<br />

Period 1 (27d) 3.98 3.88 4.04 4.33 0.21 0.48 0.67 0.22 0.40<br />

Period 2 (40d) 3.45 3.63 3.67 3.63 0.16 0.65 0.65 0.72 0.81<br />

Period 3 (30d) 3.48 3.65 3.60 3.60 0.29 0.98 0.69 0.81 0.78<br />

Overall ADG<br />

Feed Efficiency<br />

3.65 3.68 3.67 3.85 0.11 0.57 0.55 0.27 0.51<br />

Gain:Feed Period 1 0.21 0.20 0.21 0.21 0.02 0.93 0.86 0.85 0.76<br />

Gain:Feed Period 2 0.16 0.16 0.15 0.16 0.01 0.92 0.83 0.93 0.63<br />

Gain:Feed Period 3 0.16 0.16 0.15 0.15 0.02 0.99 0.78 0.72 0.99<br />

Overall G:F 0.17 0.17 0.17 0.17 0.01 0.99 0.75 0.90 0.75<br />

Feed:Gain Period 1 4.84 5.17 5.24 4.80 0.56 0.91 0.72 0.98 0.50<br />

Feed:Gain Period 2 6.45 6.41 6.86 6.34 0.41 0.81 0.85 0.94 0.56<br />

Feed:Gain Period 3 6.48 6.55 6.79 6.66 0.60 0.99 0.79 0.78 0.88<br />

Overall F:G 5.79 5.97 6.17 5.83 0.37 0.90 0.65 0.84 0.51<br />

Carcass traits were similar except for backfat and USDA Yield Grade (Table 3). The steers on 5<br />

percent superfeed had more backfat than 10 percent superfeed with 0, and 15 percent treatment steers<br />

intermediate. Yield Grade was lowest for the 10% treatment, and highest for the 5 percent treatment<br />

with 0 and 15 percent intermediate. Marbling scores were not statistically different, but we observed a<br />

numerical increase in the percent USDA Choice carcasses with increasing superfeeds. The number of<br />

choice or better carcasses was 61.36, 67.44, 76.74, and 77.27 percent respectively, for 0, 5, 10, and 15<br />

percent superfeed. This factor could have significant value for the feeder as the value of a lean choice<br />

carcass such as observed with 10 percent superfeed would be attractive to the industry and return<br />

greater value per pound.<br />

Page 17 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Table 3. Carcass traits of cattle fed mixed coproduct protein supplement at increasing levels.<br />

Percent Co-Product supplement Contrasts<br />

Item 0% 5% 10% 15% Std. Error P-Value CPS vs. no CPS linear quadratic<br />

Hot Carcass Wt., lbs. 789.2 820.8 794.2 806.5 25.09 0.31 0.23 0.65 0.46<br />

Dressing Percent 63.25 64.18 63.26 63.95 0.38 0.39 0.11 0.32 0.26<br />

Back Fat, in 0.40 0.46 0.37 0.42 0.03 0.02 0.78 0.47 0.59<br />

Ribeye Area, sq in 13.50 13.62 13.62 13.71 0.27 0.85 0.47 0.43 0.93<br />

Kidney Pelvic Heart, % 2.43 2.43 2.44 2.42 0.02 0.94 0.94 0.75 0.66<br />

USDA Yield Grade* 2.66 2.90 2.51 2.71 0.10 0.07 0.67 0.50 0.84<br />

Marbling Score** 421.8 434.9 445.7 438.9 16.04 0.79 0.36 0.41 0.56<br />

Percent Choice*** 61.36 67.44 76.74 77.27 - - - - -<br />

* USDA Yield Grade is a calculated value that is determined by a formula comparing fat to lean muscle in the carcass.<br />

** Marbling score is based on intermuscular fat in the ribeye: 400-499 = low Choice , 500-599 = Avg Choice.<br />

*** Percent choice was not statisitically analyzed.<br />

Implications<br />

The results of this study suggest that a mixed co-product ―superfeed‖ may be successfully marketed<br />

based on animal performance and especially based on percentage of USDA Choice carcasses. The<br />

ease of use, safety, and handling properties of this pelleted commodity are superior to any single feed<br />

ingredient. Using soybean meal as a base ingredient helps increase the value of the meal and diversify<br />

the market potential to other species or production scenarios. This study gives confidence to livestock<br />

producers interested in using a combinatorial feed comprised of multiple co-products. It remains to be<br />

seen if feed manufacturing businesses are interested in developing commodities from combining coproducts<br />

into commercial pelleted feeds to produce products that can be labeled as <strong>North</strong> <strong>Dakota</strong><br />

―Superfeed.‖<br />

Effects of Dried Distillers Grains With Solubles on Growing and Finishing<br />

Steer Intake, Performance, Carcass Characteristics, Color and Sensory<br />

Attributes<br />

J.L. Leupp 1 , G.P. Lardy 1 , M.L. Bauer 1 , K.K. Karges 2 , M.L. Gibson 2 , J.S. Caton 1 and R.J. Maddock 1<br />

1 <strong>NDSU</strong> Department of Animal Sciences<br />

2 <strong>Dakota</strong> Gold Research Association, Sioux Falls, SD<br />

The objectives of this study were to determine the effects of dried distillers grains with solubles on<br />

growing and finishing performance, carcass characteristics and meat quality traits. These data suggest<br />

dried distillers grains with solubles (DDGS) can be included at 30 percent dietary dry matter (DM) in<br />

both the growing and finishing period, partially replacing dry-rolled corn, with no detrimental effects on<br />

performance, carcass characteristics or sensory attributes, although DDGS may affect color negatively.<br />

Summary<br />

Seventy-two crossbred and purebred beef steers (653 ± 20 pounds initial body weight [BW]) were used<br />

in a completely randomized design to determine effects of dried distillers grains with solubles (29.2%<br />

crude protein [CP], 9.7% fat, DM basis; DDGS) on growing and finishing steer intake, performance,<br />

carcass and meat quality traits. The study contained two feeding periods, growing and finishing, which<br />

resulted in four treatments: 0:0, 30:0, 0:30 and 30:30 (diet DDGS percentage fed during growing and<br />

Page 18 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

finishing periods, respectively). Steers were fed individually a growing diet (65% concentrate) for 57<br />

days then acclimated to and fed a finishing diet (90% concentrate) for 80 or 145 days. Dietary<br />

ingredients included dry-rolled corn, corn silage, grass hay, concentrated separator byproduct and<br />

supplement.<br />

During the growing period, dry-matter intake (DMI) was not different (P ≥ 0.63). Steer performance,<br />

including average daily gain (ADG) and gain:feed (G:F), were not affected (P ≥ 0.14) by treatment<br />

during the growing period and final BW at the end of the growing period was not different (P = 0.99).<br />

During the finishing period, DMI, ADG and G:F were not different (P ≥ 0.22). As a result, final BW was<br />

not different (P ≥ 0.28). Carcass traits (ribeye area; 12th rib fat; kidney, pelvic and heart fat (KPH);<br />

yield grade; and marbling) were not different (P ≥ 0.16).<br />

Results from the trained panel indicated no differences (P ≥ 0.16) in tenderness; however, steaks from<br />

steers fed 30% DDGS during the finishing period tended (P = 0.10) to be juicier and more flavorful than<br />

steaks from control steers. Inclusion of 30% DDGS in the growing period tended to lower L (muscle<br />

lightness) (P = 0.08) and lowered B (muscle yellowness) (P = 0.01) of steaks. Overall feeding of DDGS<br />

lowered B (P = 0.02) compared with feeding dry-rolled corn (0:0). Feeding DDGS during the finishing<br />

period lowered A (muscle redness) (P < 0.001) of steaks. Furthermore, overall feeding of DDGS<br />

lowered A (P < 0.001) compared with feeding dry-rolled corn (0:0). Feeding 30% DDGS did not impact<br />

any performance or carcass characteristics but did influence steak sensory attributes and color.<br />

Introduction<br />

Dried distillers grains with solubles can be used as a protein and energy source depending on the<br />

amount included in the diet (Ham et al., 1994). Feeding up to 40% wet or dry distillers grains in<br />

growing and finishing diets improves ADG and G:F in steers compared with feeding dry-rolled corn only<br />

(Ham et al., 1994).<br />

<strong>Beef</strong> consumers want a high-quality product that is tender, juicy and flavorful. Research is limited in<br />

evaluating effects of feeding DDGS to growing and finishing steers on meat quality. Roeber et al.<br />

(2005) fed finishing Holstein steers up to 50% dried distillers grains (DDG) and reported no differences<br />

in tenderness or sensory traits compared with corn-based diets.<br />

Little quantitative information is available on the effects of short- and long-term feeding of DDGS to<br />

steers on performance and carcass quality. Therefore, our objectives were to determine the effects of<br />

DDGS on growing and finishing steer intake, performance, carcass characteristics, color and sensory<br />

attributes.<br />

Materials and Methods<br />

Seventy-two crossbred and purebred beef steers were used in a completely randomized design. The<br />

study contained two feeding periods, growing and finishing, which resulted in four treatments: 0:0, 30:0,<br />

0:30 and 30:30 (diet DDGS percentage fed during growing and finishing periods, respectively). Steers<br />

were fed individually a growing diet (65% concentrate) for 57 days then acclimated for 14 days to a<br />

finishing diet (90% concentrate) and fed for 80 or 145 days. Diets were based on dry-rolled corn, corn<br />

silage, grass hay, concentrated separator byproduct and supplement (Table 1). Diets included 27.5<br />

parts per million (ppm) of Rumensin and 11 ppm of Tylan and were formulated to contain a minimum of<br />

12.5 percent CP, 0.70 percent calcium (Ca) and 0.30 percent phosphorus (P).<br />

Page 19 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Table 1. Formulated dietary composition of growing and finishing diets containing 0 or 30<br />

percent corn dried distillers grains with solubles offered to beef steers (% dietary DM).<br />

0% DDGS 1<br />

30% DDGS 0% DDGS 1<br />

Diet, % of dietary DM<br />

Growing Finishing<br />

Item<br />

30% DDGS<br />

Dry-rolled corn 50 20 80 50<br />

DDGS — 30 — 30<br />

Corn silage 20 20 5 5<br />

Grass hay 20 20 5 5<br />

CSB 2<br />

5 5 5 5<br />

Wheat middlings 2.18 2.53 1.00 2.18<br />

Soybean meal — — 1.00 —<br />

Limestone 1.40 2.10 1.58 2.45<br />

Urea 0.75 — 0.75 —<br />

Dicalcium phosphate 0.30 — 0.30 —<br />

Salt 0.25 0.25 0.25 0.25<br />

Trace mineral premix 3<br />

0.05 0.05 0.05 0.05<br />

Vitamin A, D premix 4<br />

0.02 0.02 0.02 0.02<br />

Vitamin E premix 5<br />

0.02 0.02 0.02 0.02<br />

Monensin premix 6<br />

0.02 0.02 0.02 0.02<br />

Tylosin premix 7<br />

0.01 0.01 0.01 0.01<br />

---------------Analyzed composition---------------<br />

Crude Protein 12.80 17.90 16.10 22.70<br />

Neutral Detergent Fiber 37.30 39.50 26.10 33.20<br />

Acid Detergent Fiber 20.30 18.50 9.40 10.00<br />

Calcium 1.23 1.23 1.87 2.13<br />

Phosphorus 0.32 0.44 0.54 0.71<br />

1 Dried distillers grains with solubles; nutrient content of DDGS used averaged 29.2% CP, 34.7%<br />

NDF, 9.5% ADF, 9.7% crude fat, 0.03% Ca and 0.81% P.<br />

2<br />

Concentrated separator byproduct (de-sugared molasses).<br />

3 Contained 250 ppm Co, 25.6 ppt Cu, 1.05 ppt I, 6.50 ppt Fe, 40.0 ppt Mn and 160 ppt Zn.<br />

4 Contained 22.0 kIU/pound vitamin A and 2.10 kIU/pound vitamin D.<br />

5 Contained 20 IU/kg vitamin E.<br />

6<br />

Contained 176.4 ppt monensin (Elanco Animal Health, Indianapolis, Ind.) to provide 27.5 ppm of<br />

dietary DM.<br />

7<br />

Contained 88.2 ppt tylosin (Elanco Animal Health, Indianapolis, Ind.) to provide 11 ppm of dietary DM.<br />

Steers were assigned to treatment and fed individually. Steers received a Ralgro implant on day 0 and<br />

Revalor IS on day 60. Final weights were calculated from hot carcass weight (HCW) using an average<br />

dressing percentage of 62.5 percent and a 4 percent shrink. Average daily gain and G:F were<br />

Page 20 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

calculated based on this data. Cattle were sent to a commercial abattoir for slaughter on either March<br />

24 or May 28. Steers marketed on March 24 were estimated to have at least 0.4 inch backfat as<br />

measured by ultrasound. The remaining steers were marketed on May 28 when the majority of the<br />

steers had an estimated 0.4 inch backfat as measured by ultrasound.<br />

One steak from each steer was used for simulated retail display shelf-life analysis. A colorimeter was<br />

used to measure longissimus lean L (muscle lightness), A (muscle redness) and B (muscle yellowness)<br />

color space values through the overwrap polyvinyl chloride (PVC) film for each postmortem display day<br />

at 9 a.m. each day.<br />

One steak from each steer was used for evaluation of tenderness using the Warner-Bratzler shear<br />

force machine (WBSF). Steaks were thawed for 24 hours at 35° Fahrenheit, weighed and then cooked<br />

in clamshell-style grills at 350° F until the steaks reached an internal temperature of 158° F. Six 0.5inch<br />

cores from each steak were removed parallel to the muscle fiber.<br />

Sensory panel analysis was conducted with a trained panel. Steaks were thawed at 35° F for 24 hours<br />

and cooked as previously described for WBSF evaluation. Steaks then were cut into pieces of<br />

approximately 0.5 by 0.5 by 1 inch and served to panelists for evaluation. Panelists scored 10 samples<br />

each day using an 8-point scale where 1 equaled extremely tough, dry and bland and 8 equaled<br />

extremely tender, juicy and intense beef flavor.<br />

Results<br />

During the growing period, two steers from the 30% DDGS treatment were removed from the study due<br />

to conditions unrelated to treatment. One steer was removed prior to initiation of treatments and the<br />

other removed due to chronic bloat; therefore, 70 steers were used during the growing period. Steers<br />

were fed growing diets for 57 days. Initial BW of steers was not different (P = 0.57) and averaged 653 ±<br />

20 pounds. Steer performance, including DMI (22.5 lbs./d), ADG (3.85 lbs./d) and G:F (0.17 lbs./lb.)<br />

were not affected (P ≥ 0.14) by treatment during the growing period. Final BW at the end of the<br />

growing period also was not different (P = 0.99) and averaged 937 ± 13 pounds.<br />

Three steers were removed from the data set due to low feed intakes during the finishing portion of the<br />

trial. Two of the steers removed were on the 30 percent DDGS treatment and one steer was from the 0<br />

percent DDGS treatment. Days fed during the finishing period were not different (P ≥ 0.27; Table 2)<br />

across treatments and averaged 102 ± 8 days. No treatment differences (P ≥ 0.22) were observed for<br />

DMI, ADG or G:F. Ham et al. (1994) fed cattle 40 percent DDGS, which partially replaced dry-rolled<br />

corn in finishing diets, and observed improved ADG and G:F when compared with cattle consuming<br />

dry-rolled corn diets. In the current study, no differences (P ≥ 0.28) in final BW were observed.<br />

Similar to final BW, no differences were found in HCW (P ≥ 0.28; 791 ± 22 lbs.; Table 2). Longissimus<br />

muscle area (12.1 ± 0.5 inch 2 ), 12th rib fat thickness (0.50 ± 0.04 inch) and KPH (2.48 ± 0.16%) were<br />

not different (P ≥ 0.16); therefore, no differences (P ≥ 0.35; 3.33 ± 0.17) were observed for yield grade.<br />

No differences (P ≥ 0.43) were observed for marbling, which averaged 431 (small 0 = 400; Table 2).<br />

Page 21 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Table 2. Performance and carcass characteristics of steers fed growing and finishing diets containing<br />

0 or 30 percent corn dried distillers grains with solubles.<br />

Item 0:00 30:00:00 0:30 30:30:00 SEM 2<br />

Growing Finishing<br />

Corn vs.<br />

DDGS 4<br />

Steers, number 18 15 16 18 — — — —<br />

Days on Feed 99 106 97 106 8 0.27 0.87 0.61<br />

Performance<br />

Final BW, lb. 1193 1226 1204 1239 33.00 0.28 0.73 0.41<br />

DMI, lb./hd/d 18.40 18.80 19.90 17.60 1.50 0.51 0.92 0.80<br />

ADG, lb./hd/d 3.46 3.22 3.51 3.40 0.15 0.22 0.48 0.58<br />

G:F, lb./lb. 0.22 0.19 0.19 0.21 0.03 0.91 0.89 0.52<br />

Carcass Characteristics<br />

HCW, lb. 798 783 807 22.00 0.28 0.73 0.41<br />

LM area, in 2<br />

12.10 12.50 11.80 11.80 0.50 0.60 0.34 0.95<br />

12th rib fat, in 0.46 0.53 0.48 0.52 0.04 0.16 0.90 0.21<br />

KPH, % 2.41 2.60 2.44 2.47 0.16 0.46 0.73 0.59<br />

Marbling 5<br />

430 448 440 407 21.00 0.71 0.43 0.96<br />

Yield grade 3.20 3.33 3.44 3.33 0.17 0.95 0.45 0.35<br />

1 Dietary dried distillers grains with solubles percentage fed during growing and finishing periods, respectively.<br />

2 n = 15.<br />

3<br />

Growing = main effect of feeding dried distillers grains with solubles during the growing period; Finishing =<br />

main effect of feeding dried distillers grains with solubles during the finishing period; Corn vs. DDGS = feeding<br />

dry-rolled corn (0:0) vs. feeding dried distillers grains with solubles during the growing and finishing periods<br />

(30:0 + 0:30 + 30:30).<br />

4<br />

Corn distillers dried grains with solubles.<br />

5 Marbling Score: Small 0 = 400.<br />

Treatment 1<br />

Page 22 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report<br />

Contrast 3<br />

Warner-Bratzler shear force and cooking loss were not different (P ≥ 0.13) across treatments (Table 3).<br />

Results from the trained panel indicated no differences (P ≥ 0.16) in tenderness, which averaged 6.03 ±<br />

0.16 (8-point hedonic scale; Table 3); however, steaks from steers fed 30% DDGS during the finishing<br />

period tended (P = 0.10) to be juicier and more flavorful than steaks from the control steers (6.01 vs.<br />

5.83 ± 0.11 and 6.02 vs. 5.89 ± 0.08, respectively).

Table 3. Shear force, color analysis and sensory characteristics of steaks from steers fed growing<br />

and finishing diets containing 0 or 30 percent corn dried distillers grains with solubles.<br />

Item 0:00 30:00:00 0:30 30:30:00 SEM 2<br />

Growing Finishing<br />

Corn vs.<br />

DDGS 4<br />

Steaks, number 17 15 16 18 — — — —<br />

Shear force, lb. 8.20 8.49 7.98 7.52 0.49 0.86 0.19 0.68<br />

Cooking loss 5 , oz. 1.77 1.51 1.64 1.62 0.11 0.17 0.92 0.13<br />

Color 6<br />

L 49.03 48.69 48.77 48.48 0.19 0.08 0.19 0.04<br />

A 21.69 22.33 20.27 19.99 0.24 0.41

Effect of Glycerol Level in <strong>Feedlot</strong> Diets on Animal Performance and<br />

Carcass Traits<br />

B.R. Ilse 1 , V.L. Anderson 1 , T.M. Jeske², R.J. Maddock 2 , and E.P. Berg 2<br />

1 <strong>NDSU</strong> Carrington Research Extension Center<br />

2 <strong>NDSU</strong> Department of Animal Sciences<br />

Abstract<br />

Two separate feedlot trials were conducted (receiving and finishing) to evaluate the effects of<br />

increasing levels of glycerol on animal performance. Receiving trial steers (n = 198) were allotted by<br />

BW (622.6 ± 34.32 lbs.) in a randomized complete block design and sorted into 16 identical pens (four<br />

pens per treatment). Treatments were 0, 6, 12, and 18 percent glycerol (70% DM; water was added to<br />

reach 70% DM to increase the viscosity and decrease freezing temperature) on a DM basis replacing<br />

dry-rolled corn and co-products in the diet (55 Mcal/lb NEg). Dry matter intake was quadratically<br />

affected during the 30-d feeding period (P = 0.05) with 20.38; 21.07; 21.13; 19.47 pounds consumed for<br />

0, 6, 12, and 18 percent glycerol, respectively. Gains were not affected by glycerol level (P = 0.79) and<br />

feed efficiency was similar (P > 0.92) among treatments. Finishing trial heifers (n = 132; BW = 911.5 ±<br />

33.22 lbs.) were blocked by weight and allotted to one of 16 pens, assigned to 0, 6, 12, 18 percent<br />

glycerol (85% DM) dietary treatments (60 Mcal/lb NEg). Dry matter intake linearly decreased during the<br />

102-d feeding period with increasing glycerol level (P = 0.05; 28.11; 27.97; 27.71; 26.16 lbs. for 0, 6,<br />

12, and 18% glycerol, respectively). Gains were not affected by glycerol level (P = 0.26) during any of<br />

the four individual 28-d weigh periods or overall. Feed efficiency was also similar (P > 0.22) among<br />

treatments. If the availability of feed-grade glycerol increases with the increase in biodiesel production,<br />

glycerol could be a viable alternative to corn in feedlot diets.<br />

Key words: glycerol, beef, feedlot<br />

Introduction<br />

The glycerol (or glycerine) supply may increase dramatically throughout the <strong>North</strong>ern Plains states and<br />

Canadian provinces with the development of the biodiesel industry. Glycerol is a three-carbon alcohol<br />

produced by transesterification of vegetable oil (e.g. soybean) or animal fat. Approximately 10 percent<br />

of the original weight of the vegetable oil is converted to glycerol in the process to produce biodiesel.<br />

This glycerol or glycerine product is primarily utilized in industrial products such as cosmetics, liquid<br />

soap, antifreeze, and lubricants. If glycerol can be used successfully as a feed, beef cattle are the<br />

largest potential year-around market outlet in <strong>North</strong> <strong>Dakota</strong>. A few research trials with dairy cattle<br />

support the use of glycerol as an energy source for ruminants, but no production feedlot research has<br />

been reported in the <strong>North</strong>ern Plains (DeFrain et al., 2004; Linke et al., 2004; Bodarski et al., 2005).<br />

Glycerol is currently used in some formulations of liquid feed products. The energy value of glycerol is<br />

about equal to corn on a pound for pound basis and therefore could be of great value for a livestock<br />

feed based on competitive pricing and availability. This trial was designed to study the effects of<br />

glycerol included as an energy source in receiving and finishing rations on animal performance.<br />

Page 24 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Feed-grade glycerol added to totally-mixed ration in a<br />

truck-mounted mixer wagon.<br />

Materials and Methods<br />

Animals were housed at the Carrington Research Extension Center. Individual animals were weighed,<br />

blocked by weight and randomly allotted within block to one of four ration treatments. There were four<br />

pens or replicates for each treatment utilizing 16 pens. The four treatments included glycerol in the<br />

ration at 0, 6, 12, or 18 percent of the diet DM. The diets (Table 1) were fed as a totally-mixed ration<br />

that included wheat middlings, distillers grains, field peas, and decreasing levels of corn (60, 40, 20,<br />

and 0%, respectively). Animals were fed once daily to appetite based on morning bunk readings, with<br />

feed recorded daily and summarized for each weigh period. The average daily DMI, gain, and feed<br />

efficiency were calculated for each pen for each weigh period (~ 28 d). The glycerol for this study was<br />

donated to the CREC by Westway Feeds Products, Inc. of New Orleans, LA, and FUMPA BioFuels of<br />

Redwood Falls, MN.<br />

Receiving Ration Finishing Ration<br />

Item DM% Percent of diet DM basis Percent of diet DM basis<br />

Glycerol, % 85.1 0 6 12 18 0 6 12 18<br />

Corn, % 86.6 43 37 31 25 60 40 20 10<br />

Field Peas, % 90.7 15 15 15 15 12 12 12 12<br />

Wheat Midds, % 88.9 5 5 5 5 5 13 21 29<br />

MDGS, % b<br />

Table 1. Receiving and Finishing ration formulation with increasing levels of glycerol<br />

57.5 20 20 20 20 12 18 24 30<br />

Straw, % 85.2 15 15 15 15 8 8 8 8<br />

Rumn & MGA, % 90.0 1 1 1 1 2 2 2 2<br />

CaCO3, % 95.0 1 1 1 1 1 1 1 1<br />

a .<br />

a Rations formulated to meet or exceed NRC (1996) recommendations<br />

b Modified distillers grains with solubles.<br />

Page 25 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Receiving Trial<br />

Fall 2008<br />

One hundred ninety-eight mixed breed steers (BW = 622.6 ± 34.3 lbs.) from 40 different ranches that<br />

were part of the <strong>Dakota</strong> Feeder Calf feedout program were utilized in the receiving trial. Steers were<br />

weighed individually at the initiation and completion of the receiving trial (30 d). Rations were<br />

formulated (56 Mcal/lb.) to meet or exceed NRC (1996) recommendations.<br />

<strong>Dakota</strong> Feeder Calf club steers consuming a ration<br />

with increasing levels of glycerol.<br />

Finishing Trial<br />

Summer 2008<br />

One hundred thirty-two yearling Black Angus cross heifers (BW = 911.5 ± 33.2 lbs.) were purchased<br />

from a commercial source and utilized for the finishing trial. The finishing rations (65 Mcal/lb.) were<br />

formulated to meet or exceed NRC (1996) recommendations.<br />

Glycerol levels were increased in stepped increments as follows: all glycerol treatment groups were fed<br />

the 6% glycerol ration during the first seven days of the trial; the 12 and 18% treatment groups were<br />

increased to 12% during the second week; and the 18% glycerol treatment pens were increased to the<br />

final glycerol level at the start of the third week.<br />

Heifers were weighed at 28-d intervals during the 102 days on feed. All heifers were marketed at the<br />

same time when visual appraisal of the animals determined that 60 percent would grade USDA choice.<br />

Page 26 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Heifers on glycerol finishing trial replacing corn in TMR diet up to 18%.<br />

Results and Discussion<br />

Receiving Trial<br />

Dry matter intake was quadratically affected by treatment during the 30-d feeding period (P = 0.05) with<br />

28.11; 27.97; 27.71; 26.16 pounds consumed for 0, 6, 12, and 18 percent glycerol, respectively. Gains<br />

were not affected by glycerol level (P = 0.79) and feed efficiency was similar (P = 0.92) among<br />

treatments.<br />

Table 2. Growth performance and efficiency of steers in a receiving trial with glycerol replacing corn up to 18%.<br />

Treatment % Glycerol Contrasts<br />

Item<br />

Weight, lbs.<br />

0 6 12 18 St. Error P-Value<br />

Glyc vs.<br />

No Glyc Linear Quadratic<br />

Initial Wt. 624.84 625.65 625.59 623.08 34.60 0.69 0.97 0.50 0.35<br />

Period 1 (Nov. 4) 670.33 677.16 669.20 668.58 32.50 0.53 0.80 0.90 0.42<br />

Period 2 (Dec. 4)<br />

Dry Matter Intake<br />

798.07 808.78 804.92 793.16 41.75 0.58 0.67 0.78 0.21<br />

Intake, lbs./hd/d 20.38 21.07 21.13 19.47 1.04 0.17 0.78 0.27 0.05<br />

Average Daily Gain, lbs. 4.26 4.39 4.53 4.16 0.38 0.79 0.76 0.72 0.37<br />

Finishing Trial<br />

Dry matter intake linearly decreased during the 102-d feeding period due to glycerol level (P = 0.05;<br />

28.11; 27.97; 27.71; 26.16 lbs. for 0, 6, 12, and 18% glycerol, respectively). Gains were not affected by<br />

glycerol level (P = 0.26) during any of the four individual 28-d weigh periods or overall. Feed efficiency<br />

was also similar (P = 0.22) among treatments.<br />

Page 27 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Table 3. Heifer body weight averages by treatment and period, glycerol replacing corn at 0, 6, 12, and 18% of the TMR.<br />

Treatment % Glycerol Contrasts<br />

Item 0 6 12 18 St. Err P-Value<br />

Glyc vs.<br />

No Glyc Linear Quadratic<br />