NDSU Beef Feedlot - NDSU Agriculture - North Dakota State ...

NDSU Beef Feedlot - NDSU Agriculture - North Dakota State ...

NDSU Beef Feedlot - NDSU Agriculture - North Dakota State ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

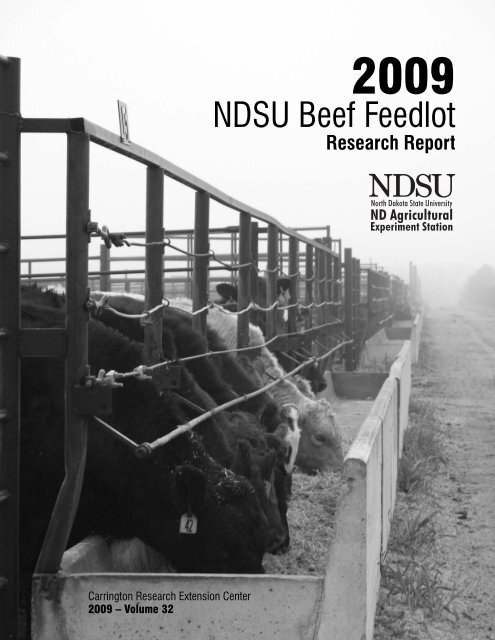

Carrington Research Extension Center<br />

2009 – Volume 32<br />

2009<br />

<strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong><br />

Research Report

Introduction to Livestock Research and Education<br />

The <strong>NDSU</strong> Carrington Research Extension Center is pleased to collaborate with our Agricultural<br />

Experiment Station colleagues in presenting the 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report. This<br />

report represents the latest results and background from beef feedlot research projects from across the<br />

<strong>NDSU</strong>-AES. The research projects reported in Vol.32 build upon the wealth of knowledge that our beef<br />

research faculty have accumulated and reported on over the years.<br />

<strong>Agriculture</strong> in <strong>North</strong> <strong>Dakota</strong> is a vibrant industry representing the primary economic sector of our state’s<br />

economy. The sustained significance of agriculture in <strong>North</strong> <strong>Dakota</strong> is partially due to the diversity of<br />

agricultural enterprises and the synergies of crop and livestock operations. The number of producers<br />

and enterprises that background or finish beef cattle in <strong>North</strong> <strong>Dakota</strong> have increased in recent years.<br />

This trend is welcome and encouraging as many of us see cattle feeding as a sector of our agricultural<br />

economy that has great potential for expansion. The state of <strong>North</strong> <strong>Dakota</strong> is blessed with a multitude<br />

of feedstuffs including the diverse grains, co-products, and forages. Expanded cattle feeding through<br />

background or finishing operations is a good opportunity to add value to these feeds. Ultimately, this<br />

abundance of product will be utilized either here in <strong>North</strong> <strong>Dakota</strong> or shipped elsewhere for use by cattle<br />

feeding operations in other states or countries.<br />

It is our hope that the 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report will again prove useful and effective<br />

in assisting the viability of our livestock industry and the broader constituency who supply the feeds<br />

investigated. We wish to thank the <strong>North</strong> <strong>Dakota</strong> state legislature, selected commodity groups and the<br />

various grant programs that have empowered our research faculty to address the beef feedlot issues<br />

that we now report upon.<br />

Blaine G. Schatz<br />

Director, <strong>NDSU</strong> Carrington Research Extension Center<br />

Thanks for taking the time to review what <strong>NDSU</strong> has to offer in the way of feedlot research. This report<br />

details the collective efforts of scientists from across the state of <strong>North</strong> <strong>Dakota</strong> and represents the latest<br />

in feedlot research. Our scientists collaborate on projects ranging from nutrition to nutrient<br />

management and do their best to bring you meaningful research which you can use to make profitable,<br />

sustainable decisions in your operation.<br />

Please feel free to provide us with feedback related to ways we can improve the research which we<br />

deliver to you each year. We’d love to hear how we can better serve the beef industry in <strong>North</strong> <strong>Dakota</strong><br />

and the region.<br />

Greg Lardy, Ph.D.<br />

Department Head, Animal Sciences<br />

A very special thank you to Myrna Friedt and Stacey Rzaszutak at the Carrington Research Extension<br />

Center for proofreading, organizing, and formatting this publication. The authors appreciate the<br />

excellent animal care, data collection and other support of the many technicians who worked in support<br />

of research presented in this publication.<br />

Page 1 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Contact Information<br />

If you have questions or comments, please e-mail individuals (see addresses below) or call the<br />

Carrington Center at (701) 652-2951. These proceedings are also published at the Carrington<br />

Research Extension Center website at www.ag.nodak.edu/carringt/ under the livestock bullet.<br />

Carrington Research Extension Center<br />

Vern Anderson, Ph.D., P.A.S., Animal Scientist Vern.Anderson@ndsu.edu<br />

Breanne Ilse, Livestock Research Specialist Breanne.Ilse@ndsu.edu<br />

Karl Hoppe, Ph.D., Area Ext. Livestock Specialist Karl.Hoppe@ndsu.edu<br />

Steve Metzger, Farm Business Management S.Metzger@ndsu.edu<br />

Ron Wiederholt, Nutrient Management Research Ron.Wiederholt@ndsu.edu<br />

Chris Augustin, Ext. Nutrient Management Specialist Chris.Augustin@ndsu.edu<br />

Department of Animal Sciences<br />

Greg Lardy, Ph.D., Department Chair Gregory.Lardy@ndsu.edu<br />

Eric Berg, Ph.D., Assoc. Prof., Meat Science Eric.P.Berg@ndsu.edu<br />

Rob Maddock, Ph.D., Assoc. Prof., Meat Science Rob.Maddock@ndsu.edu<br />

Kasey Carlin, Ph.D., Assoc. Prof., Meat Science Kasey.Maddockcarlin@ndsu.edu<br />

Charlie Stoltenow, D.V.M., Ext. Veterinarian Charles.Stoltenow@ndsu.edu<br />

Kim Vonnahme, Ph.D., Assoc. Prof., Reprod. Physiology Kimberly.Vonnahme@ndsu.edu<br />

<strong>North</strong>ern Crops Institute<br />

Kim Koch, Ph.D., Manager, Feed Production Center Kim.Koch@ndsu.edu<br />

Hettinger Research Extension Center<br />

Chris Schauer, Ph.D., Director Chris.Schauer@ndsu.edu<br />

Michele Thompson, Asst. Animal Scientist Michele.Thompson@ndsu.edu<br />

Veterinary and Microbiological Sciences Department<br />

Neil Dyer, D.V.M., Director Neil.Dyer@ndsu.edu<br />

Michelle Mostrum, D.V.M, Ph.D., Toxicologist Michelle.Mostrum@ndsu.edu<br />

Cow/calf pairs grazing summer pasture, August 2009.<br />

Page 2 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Acknowledgements<br />

Research, education, and facility development activities conducted at the <strong>NDSU</strong> Carrington Center are<br />

supported by numerous individuals and organizations. Our heartfelt appreciation is expressed to the<br />

following for their support:<br />

AgInfoLink, Longmont, CO<br />

Ameriflax, Grace City, ND<br />

ADM-Ethanol Division, Walhalla, ND<br />

Barton Meats, Carrington, ND<br />

<strong>Beef</strong> Magazine<br />

Cargill Malt, Spiritwood, ND<br />

Carrington Area Farm Business Management Program, Carrington, ND<br />

Coteau Hills Enterprises, McClusky, ND<br />

<strong>Dakota</strong> Dry Bean, Inc., Crary, ND<br />

<strong>Dakota</strong> Feeder Calf Club, Turtle Lake, ND<br />

<strong>Dakota</strong>Land Feeds, Huron, SD<br />

<strong>Dakota</strong> Growers Pasta Company, Carrington, ND<br />

FUMPA BioFuels Inc., Redwood Falls, MN<br />

G and R Grain and Feed, Inc., New Rockford, ND<br />

Haybuster Equipment, Inc., Jamestown, ND<br />

Igenity, Inc., Bismarck, ND<br />

<strong>North</strong> <strong>Dakota</strong> Barley Council<br />

<strong>North</strong> <strong>Dakota</strong> <strong>Beef</strong> Commission<br />

<strong>North</strong> <strong>Dakota</strong> Corn Utilization Council<br />

<strong>North</strong> <strong>Dakota</strong> Department of <strong>Agriculture</strong><br />

<strong>North</strong> <strong>Dakota</strong> Department of Commerce<br />

<strong>North</strong> <strong>Dakota</strong> Natural <strong>Beef</strong>, LLC<br />

<strong>North</strong> <strong>Dakota</strong> Oilseed Council<br />

<strong>North</strong> <strong>Dakota</strong> Rural Electric Cooperatives, Bismarck, ND<br />

<strong>North</strong> <strong>Dakota</strong> <strong>State</strong> Board of Agricultural Research and Education<br />

<strong>North</strong> <strong>Dakota</strong> <strong>State</strong> University<br />

Department of Animal Sciences<br />

Hettinger Research Extension Center<br />

Veterinary and Microbiological Sciences Department<br />

<strong>North</strong> <strong>Dakota</strong> Stockmen’s Association Feeder Council, Bismarck, ND<br />

<strong>North</strong>ern Crops Institute, Fargo, ND<br />

<strong>North</strong>ern Pulse Growers Association, Bismarck, ND<br />

R & B Manufacturing, Steele, ND<br />

Ralco Nutrition, Inc., Marshal, MN<br />

Sartec, Inc., Anoka, MN<br />

Schering Plough Inc., Kenilworth, NJ<br />

Tim Olson, CATL Resource PC, Sturgis, SD<br />

Tyson Fresh Meats, <strong>Dakota</strong> Dunes, SD<br />

United <strong>State</strong>s Department of <strong>Agriculture</strong><br />

National Research Initiative – Equipment Grants Program<br />

Cool Season Food Legume Program<br />

Westway Products, Inc., Mapleton, ND<br />

Trade names and companies used are for clear communication. No endorsement is intended, nor criticism<br />

implied, of products mentioned or not mentioned.<br />

Page 3 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Table of Contents<br />

<strong>Feedlot</strong> Schools Are Educational Opportunity for New or Experienced <strong>North</strong> <strong>Dakota</strong> Cattle Feeders .... 5<br />

Observations on the Palatability of an Inorganic Salt Product for Mitigation of High Sulfur Levels in<br />

<strong>Feedlot</strong> Diets .................................................................................................................................... 7<br />

Influence of Thiamin Supplementation on Hydrogen Sulfide Gas Concentrations in Ruminants Fed<br />

High-Sulfur Diets ............................................................................................................................ 11<br />

An Evaluation of a Mixed Co-product Protein Feed in Finishing Rations .............................................. 15<br />

Effects of Dried Distillers Grains With Solubles on Growing and Finishing Steer Intake, Performance,<br />

Carcass Characteristics, Color and Sensory Attributes .................................................................. 18<br />

Effect of Glycerol Level in <strong>Feedlot</strong> Diets on Animal Performance and Carcass Traits .......................... 24<br />

Impact of Weaning Date on Calf Growth and Carcass Traits ............................................................... 30<br />

Growth and <strong>Feedlot</strong> Performance of Steer Calves Born From <strong>Beef</strong> Cows Supplemented with<br />

Linseed Meal During Late Gestation .............................................................................................. 36<br />

Effect of Distillers Grains on Natural vs. Conventional Supplements and Production Methods on<br />

<strong>Feedlot</strong> Performance, and Carcass Characteristics ....................................................................... 41<br />

Discovering Value in <strong>North</strong> <strong>Dakota</strong> Calves; The <strong>Dakota</strong> Feeder Calf Show Feedout Project VIII ......... 45<br />

Forage Production Costs and Yields for South-Central <strong>North</strong> <strong>Dakota</strong> .................................................. 49<br />

Challenges and Opportunities for <strong>Beef</strong> <strong>Feedlot</strong>s in <strong>North</strong> <strong>Dakota</strong> ........................................................ 51<br />

Diagnostic Note – Infectious Bovine Keratoconjunctivitis (Pinkeye) ..................................................... 54<br />

<strong>NDSU</strong> BBQ Boot Camps 2009<br />

Celebrating the Products of Livestock Production .......................................................................... 56<br />

Creating a silage bunker.<br />

Page 4 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

<strong>Feedlot</strong> Schools Are Educational Opportunity for New or Experienced<br />

<strong>North</strong> <strong>Dakota</strong> Cattle Feeders<br />

W. Becker 1 and V.L. Anderson 2<br />

1 Foster County Extension Agent<br />

2 <strong>NDSU</strong> Carrington Research Extension Center<br />

Introduction<br />

<strong>North</strong> <strong>Dakota</strong> cattlemen produce exceptional quality feeder cattle that are in demand by feedlot<br />

operators in other states. However, resources are available for feeding cattle in <strong>North</strong> <strong>Dakota</strong> to<br />

capture value from the excellent genetics and utilize some of the available feedstocks. Many producers<br />

now background their spring-born calves at least until January, and there is increasing interest in<br />

finishing cattle for terminal markets.<br />

The <strong>North</strong> <strong>Dakota</strong> <strong>State</strong> University <strong>Feedlot</strong> School was developed to help educate and inform<br />

producers about cattle feeding. The <strong>Feedlot</strong> School is an annual program initiated in 1996. It is an<br />

intensive two-day school that offers training in all aspects of the feedlot enterprise.<br />

Background<br />

To evaluate the legitimate potential and competitiveness of feeding cattle in <strong>North</strong> <strong>Dakota</strong> versus the<br />

large commercial feedyards in Kansas and Nebraska, a multi-year research study was conducted with<br />

producer-owned calves in the early 1990s. Calves were gathered at the Carrington Research<br />

Extension Center and one group transported to commercial yards in Nebraska or Kansas during the<br />

three-year project. The results indicated that the lower feed costs per pound of gain (~$.05 advantage)<br />

and feed availability were major advantages to cattle feeding in <strong>North</strong> <strong>Dakota</strong> even though gains were<br />

slightly higher in southern yards. Subsequent research in successfully mitigating winter weather with<br />

bedding and wind protection further supports the potential for cattle feeding in <strong>North</strong> <strong>Dakota</strong>. Feeds in<br />

<strong>North</strong> <strong>Dakota</strong> are very competitively priced compared to commercial feeding regions in the High Plains.<br />

<strong>North</strong> <strong>Dakota</strong> feeds include corn, barley, field peas, oats, wheat, several oilseed meals, corn distillers<br />

grains, wheat midds, barley malt sprouts, corn gluten feed, beet pulp, field pea chips, and soyhulls plus<br />

low cost forages and crop residues. New incentive programs for upgrading or building feedlots through<br />

EPA 319 and NRCS Equip program monies and new risk protection programs are available.<br />

<strong>Feedlot</strong> School Curriculum<br />

The program is an intensive two-day educational course that is offered for cattle feeders, industry<br />

personnel, educators, and anyone interested in feedlot management. The school visits commercial and<br />

research feedlots for observations in bunk reading, facilities, animal processing, and an update on<br />

current research activities. Attendees network with experienced <strong>NDSU</strong> field staff and specialists, and<br />

fellow students. The faculty includes veterinarians, nutritionists, meat scientists, marketing experts,<br />

experienced feeders, and other qualified instructors. Comprehensive printed resource materials are<br />

provided to those attending.<br />

The topics presented at the <strong>NDSU</strong> <strong>Feedlot</strong> Schools include:<br />

1. Feeding enterprises for specific markets including backgrounding, finishing, heifer development,<br />

and cull cow feeding.<br />

2. Feed ingredients, nutritional value, and compatibility.<br />

3. Recommended usage of feeds to meet animal requirements.<br />

4. Ration formulation for optimum animal growth and profit.<br />

5. Feed supplements, additives, and implants.<br />

Page 5 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

6. Grain processing, mixing rations, and feed bunk management.<br />

7. Health management, vaccinations, detection of sick animals, and treatment.<br />

8. Facility planning and design including working facilities, pens, and containment.<br />

9. Manure management, composting, and spreading as fertilizer.<br />

10. Marketing cattle, industry grids, carcass traits and value.<br />

11. Risk management, hedges, puts and forward pricing.<br />

In the 13 years that the feedlot school has been held, there have been 20 different schools that<br />

provided information to over 500 participants, with some repeat participants. The sessions are held<br />

annually at the Carrington Research Extension Center during late January. The same basic school has<br />

been offered at other locations some years, including Fargo, Hettinger, Williston, and Sidney, Montana.<br />

A feedlot school was offered in Maine modeled after the <strong>NDSU</strong> program, and a college course and<br />

training certification program in Colby, Kansas, was spurred by the <strong>NDSU</strong> <strong>Feedlot</strong> School. The<br />

program has reached producers in eight states and one province including South <strong>Dakota</strong>, Montana,<br />

Nebraska, Minnesota, Wisconsin, Oregon, Maine, and Manitoba. An evaluation is given at the end of<br />

every school that asks participants for honest feedback. The curriculum is adapted to producer needs<br />

based on these responses and has evolved over the years of the school.<br />

According to the most recent <strong>North</strong> <strong>Dakota</strong> <strong>Agriculture</strong> Statistics Service <strong>Feedlot</strong> Survey (2008), from<br />

2004 through 2007 the total number of feeding operations with 500 head or more capacity, has<br />

increased 16% from 130 to 151 feedlots. Total capacity has increased 20% from 189,000 to 226,300<br />

head. The future of the <strong>North</strong> <strong>Dakota</strong> <strong>Feedlot</strong> School is to continue with the ongoing interest of the<br />

producers. Planning is underway for an ―advanced‖ feedlot school for those that want a deeper<br />

understanding of nutrition, marketing, and management. The goal is to provide the utmost quality<br />

programming that makes the <strong>North</strong> <strong>Dakota</strong> <strong>State</strong> University <strong>Feedlot</strong> School partnership successful.<br />

With the increasing interest in feeding cattle to slaughter weights in the <strong>North</strong>ern Plains, and the ample<br />

supply of cattle, feed grains, forages, and co-products for feedlot use across the area, the <strong>North</strong> <strong>Dakota</strong><br />

<strong>Feedlot</strong> School has helped producers increase their working knowledge of feedlot operation. In<br />

addition to the material presented, the school serves a function to network feeders and faculty for future<br />

communications. All of the principles taught in the school are relevant to other regions as well and<br />

serves any area interested in feeding cattle. This program requires extensive collaboration between<br />

cooperating agencies, industry, and private operators all with the intent to make the cattle feeding<br />

business better for all parties involved. For information on attending an <strong>NDSU</strong> <strong>Feedlot</strong> School, contact<br />

the Foster County Extension office at (701) 652-2581 or the Carrington Research Extension Center at<br />

(701) 652-2951 or email: <strong>NDSU</strong>.Carrington.REC@ndsu.edu.<br />

Page 6 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Observations on the Palatability of an Inorganic Salt Product for<br />

Mitigation of High Sulfur Levels in <strong>Feedlot</strong> Diets<br />

V.L. Anderson 1 , B.R. Ilse 1 , P. Gruel 2 and S. McLeish 2<br />

1 <strong>NDSU</strong> Carrington Research Extension Center<br />

2 Sartec, Inc.<br />

Introduction<br />

Distillers grains are often the lowest cost protein feed available for cattlemen. This ingredient can be<br />

used in cow/calf production as well as feedlot diets. However, distillers grains often contain high levels<br />

of sulfur. There is significant variation in the sulfur content of distillers grains from plant to plant and<br />

even within a plant as sulfuric acid may be added to batches to improve fermentation efficiency by<br />

altering the pH. Sulfuric acid is also used to clean equipment. While sulfur level is often between 0.65<br />

and 0.85% on a dry-matter basis, levels as high as 1.25% sulfur have been analyzed.<br />

<strong>Beef</strong> cattle can tolerate a maximum of 0.40% sulfur in the diet (NRC, 1996) before polio-like symptoms<br />

of sulfur toxicity are generally observed, with the first noticeable sign often being death. Toxic<br />

symptoms and death have been reported when a diet contains as low as 0.25% sulfur in grain-based<br />

diets. Grain diets are thought to be less tolerant to high sulfur levels but with forage diets, sulfur<br />

tolerance may be greater. It is unknown how many health and reproductive problems have occurred<br />

due to sub acute sulfur toxicity from feeding distillers grains, high-sulfate content water, or sulfur in<br />

other feed sources. Survey data may be inconclusive due to the unwillingness of producers to admit to<br />

these losses, or inconclusive diagnosis by producers or their veterinarians. Any feed ingredient or<br />

management technique that would mitigate sulfur toxicity and allow increased use of distillers grains<br />

with less potential for illness or death will be well received in the livestock industry. New feed products<br />

are under development that may tie up sulfur and reduce negative effects of higher sulfur levels in the<br />

diet of cattle. The objective of this field study was to determine the effect of adding a proprietary<br />

inorganic salt product to feedlot finishing diets on feed intake, gain, and carcass traits.<br />

Experimental Procedures<br />

Forty-eight Angus feeder calves were blocked by sex (heifers and steers) and assigned within block to<br />

one of two treatments. One pen of steers and one pen of heifers were fed the proprietary inorganic salt<br />

product developed to mitigate sulfur levels in feedlot rations. The second pen of steers and heifers was<br />

fed the same diet without the inorganic salt product. The inorganic salt product was fed at 13.8 grams<br />

per head per day based on recommendations of the manufacturer. This product was mixed into the<br />

feedlot supplement (Table 1) which was added to the grain component of the ration in the daily ration<br />

preparation. The supplements were manufactured at the <strong>North</strong>ern Crops Institute (NCI) on the campus<br />

of <strong>NDSU</strong> under the direction of Dr. Kim Koch, manager of the NCI Feed Production Center.<br />

Supplements were transported to the Carrington Research Extension Center in tote bags.<br />

Supplements were formulated to be fed at 0.33 pounds per head per day, and contain minerals,<br />

vitamins, Rumensin (300 mg/hd/d), and carrier feed products (Table 1). Supplements were formulated<br />

to be identical except for the addition of the inorganic salt product.<br />

Page 7 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Table 1. Supplements with and without organic salt to mitigate sulfur.<br />

Control Inorganic Salt<br />

Supplement Supplement<br />

% DM basis<br />

Corn, ground 25.00 25.00<br />

Distiller grains 13.75 13.75<br />

Malt sprouts 23.50 14.40<br />

Calcium carbonate 12.00 12.00<br />

Potassium chloride 11.25 11.25<br />

Zinc sulfate 0.20 0.20<br />

Dical-Phosphate (18.5%) 3.75 3.75<br />

Feed-grade salt 8.25 8.25<br />

Rumensin (80 g/lb) 1.10 1.10<br />

Vit A-D 10:1 <strong>Beef</strong> 0.30 0.30<br />

Vitamin Premix 0.90 0.90<br />

Inorganic salt 0.00 9.10<br />

Total 100.00 100.00<br />

Cattle were fed in the morning after bunk calls were made for increase, decrease or no change in the<br />

ration. Increases or decreases were done at 2.5% of the diet dry matter for each pen. Feed delivered<br />

to each pen was recorded daily. The ration was assembled, mixed and delivered using a Knight LA-9<br />

Little Augie, three-auger mixer box. The corn-based ration was formulated at 62 Mcal NEg/lb, (Table<br />

2). It included a minimum of 20% modified (50% moisture) distillers grains and solubles (dry matter<br />

basis) procured from the Blue Flint Ethanol facility in Underwood, ND. Samples of each ingredient<br />

were collected monthly and submitted to a commercial laboratory for dry matter, NEm, NEg, crude<br />

protein, fat, sulfur, calcium, and phosphorous. Water samples tested contained 74 mg/l sulfates, which<br />

is very low.<br />

Inorganic salt could become useful in high-sulfur distillers grains diets.<br />

Page 8 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Table 2. Ration for cattle fed sulfur-mitigating inorganic salt.<br />

Ingredient Percent, DM basis Percent, As Fed<br />

Corn # 2 62.00 50.83<br />

Dist grains, wet 20.00 34.84<br />

Straw 10.00 8.20<br />

Canola meal 5.00 3.87<br />

Supplement 2.00 1.55<br />

Calcium carbonate 1.00 0.71<br />

Total, Percent 100 100<br />

Nutrient content<br />

Dry Matter, %<br />

NEg, Mcal/lb<br />

Crude Protein, %<br />

Calcium, %<br />

Phosphorous, %<br />

Potassium, %<br />

Sulfur, %<br />

69.68<br />

62.71<br />

13.61<br />

0.64<br />

0.35<br />

0.59<br />

0.36<br />

All calves were weighed individually at the start of the trial on March 14, 2009, and when the trial was<br />

completed and the cattle went to market on May 4. Dry-matter intake, gain, and feed efficiency were<br />

calculated for each animal and averaged for each pen and for each treatment. Cattle were marketed<br />

as a group.<br />

Results<br />

The base diet fed in this study was 0.36% sulfur, with distillers grains as the primary source of sulfur.<br />

The primary question of the study was to determine if the inorganic salt product had any negative effect<br />

on feed intake or animal performance. There were insufficient replications to conduct confident<br />

statistical comparisons so the raw data is reported on a pen and sex-of-calf basis. The results of this<br />

field study (Table 3) suggest that feed intake was not affected. While this cannot be deduced from the<br />

limited replications, numerical values suggest some potential for positive effects on intake and gain<br />

from the addition of the inorganic salt. No health issues or illnesses were observed for the calves<br />

during the 50-day feeding period.<br />

Page 9 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Table 3. Performance of feeder cattle fed<br />

inorganic salt product for sulfur mitigation.<br />

Control<br />

Inorganic<br />

Salt<br />

No. head<br />

Heifers 11 11<br />

Steers 12 12<br />

Start wt., lb.<br />

Heifers 957.4 960.7<br />

Steers 987.5 971.4<br />

AVG 972.5 966.1<br />

End wt., lb.<br />

Heifers 1125.5 1135.3<br />

Steers 1141.1 1159.7<br />

AVG 1133.3 1147.5<br />

DMI, lb/hd/day<br />

Heifers 22.73 22.52<br />

Steers 20.89 23.76<br />

AVG 22.07 23.18<br />

ADG, lb/hd/day<br />

Heifers 3.40 3.65<br />

Steers 3.49 3.50<br />

AVG 3.45 3.58<br />

Feed Efficiency (DM/gain)<br />

Heifers 6.68 6.16<br />

Steers 5.99 6.78<br />

AVG 6.41 6.48<br />

As distillers grains continue to be a significant feed source and sulfuric acid is used in the process, a<br />

product such as the inorganic salt could become useful especially in scenarios where ethanol plants<br />

produce high-sulfur distillers grains or where the price of distillers grains is low enough to use at more<br />

than nominal levels. More research is needed to prove the efficacy of this product, however, followed<br />

by commercial availability and documented economic advantages.<br />

Page 10 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Influence of Thiamin Supplementation on Hydrogen Sulfide Gas<br />

Concentrations in Ruminants Fed High-Sulfur Diets<br />

B.W. Neville 1 , C.S. Schauer 2 , and G.P. Lardy 1<br />

1 <strong>NDSU</strong> Department of Animal Sciences<br />

2 <strong>NDSU</strong> Hettinger Research Extension Center<br />

The objective of this research was to evaluate the influence of thiamin supplementation on hydrogen<br />

sulfide gas concentration and ruminal pH in lambs fed high-sulfur diets. Moderate levels of thiamin<br />

supplementation seem to decrease hydrogen sulfide concentrations. Our data suggests that changes<br />

in ruminal hydrogen sulfide concentration cannot be attributed solely to ruminal pH and are likely<br />

affected by multiple factors that interact within the ruminal environment and in the animal.<br />

Summary<br />

The objective of this study was to evaluate the effect of increasing levels of thiamin supplementation on<br />

ruminal gas cap hydrogen sulfide (H2S) concentration and pH in lambs. Twenty crossbred lambs (84.5<br />

± 7 pounds) were adapted in 28 days to a finishing diet consisting of (dry-matter [DM] basis) 60% dried<br />

distillers grains with solubles, 21.4% corn, 15% alfalfa hay and 3.6 % supplement. Treatment diets<br />

differed in the amount of supplemental thiamin supplied; diets were formulated to provide: 1) CON (no<br />

supplemental thiamin), 2) LOW (50 milligrams per head per day [mg·hd -1 ·d -1 ] thiamin), 3) MED (100<br />

mg·hd -1 ·d -1 thiamin), 4) HIGH (150 mg·hd -1 ·d -1 thiamin) or 5) HIGH+S (150 mg·hd -1 ·d -1 thiamin with<br />

dietary sulfur [S] increased from 0.71 percent to 0.87 percent (DM basis) with the addition of dilute<br />

sulfuric acid to dried distillers grains with solubles [DDGS]). Thiamin supplementation was based on an<br />

estimated daily dry-matter intake (DMI) of 3 lb.·hd -1 ·d -1 .<br />

Hydrogen sulfide and rumen fluid pH were collected via rumen puncture on day minus 6, minus 4, 0, 3,<br />

7, 10, 14, 17, 21, 24, 28 and 31. No differences in H2S concentration (P > 0.10) among treatments<br />

were apparent until day 10, at which point lambs fed LOW had lower H2S concentrations than all other<br />

treatments. Lambs fed HIGH had the greatest concentrations of H2S on day 31 (7,700 parts per million<br />

[ppm] H2S; P < 0.009). Ruminal pH for lambs fed CON and MED were not different from day 0<br />

throughout sampling (P > 0.18). Ruminal pH of LOW, HIGH and HIGH+S groups decreased (P < 0.03)<br />

through time. Thiamin appears to influence ruminal H2S concentrations, although the mechanism by<br />

which this occurred remains unknown. Changes in H2S concentration cannot be attributed solely to<br />

ruminal pH and likely are affected by multiple factors that interact within the ruminal environment and in<br />

the animal.<br />

Introduction<br />

One of the challenges with use of ethanol coproducts is the potential for high dietary S levels. High S<br />

diets can cause polioencephalomalacia (PEM) in ruminants. Inclusion of large percentages of<br />

coproduct feeds, such as dried distillers grains with solubles (DDGS), in finishing rations has been<br />

avoided, in part, due to problems with PEM as well as concerns about optimal animal performance and<br />

carcass characteristics. Thiamin supplementation is one proposed method of reducing or preventing<br />

PEM in ruminant animals. The efficacy of thiamin supplementation in preventing PEM likely is<br />

impacted by the mechanisms by which PEM is caused (for example, long-term thiamin deficiency or<br />

high hydrogen sulfide gas concentration). Further, the effect and dose of thiamin necessary to prevent<br />

such cases of PEM requires more investigation. Hydrogen sulfide gas, as previously mentioned, has<br />

been implicated as a cause of PEM in ruminants. Both high-sulfur feed (Niles et al., 2002) and water<br />

(Loneragan et al., 2005) sources can cause increases in H2S production. No published literature that<br />

evaluates the effect of dietary thiamin concentrations on ruminal H2S gas concentration is available.<br />

Therefore, our objective was to evaluate the effect of increasing level of thiamin supplementation on<br />

Page 11 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

uminal gas cap H2S concentration and ruminal pH in lambs being adapted to a finishing diet containing<br />

60% DDGS.<br />

Procedures<br />

Twenty western white-face wether lambs (84.5 ± 7 pounds) were sampled during the adaptation period<br />

(receiving ration to a final finishing ration). Adaptation was accomplished by increasing the amount of<br />

concentrate on a weekly basis; adaptation diets are outlined in Table 1. The final finishing diet was<br />

balanced to contain 60% DDGS (DM basis; Table 2). Treatment diets differed in the amount of<br />

supplemental thiamin supplied; diets were formulated to provide: 1) CON (no supplemental thiamin), 2)<br />

LOW (50 mg·hd -1 ·d -1 thiamin), 3) MED (100 mg·hd -1 ·d -1 thiamin), 4) HIGH (150 mg·hd -1 ·d -1 thiamin) or 5)<br />

HIGH+S (150 mg·hd -1 ·d -1 thiamin with dietary S increased from 0.71 percent to 0.87 percent (DM basis)<br />

with the addition of dilute sulfuric acid to DDGS). Thiamin supplementation was based on an estimated<br />

daily DMI of 3 lb·hd -1 ·d -1 . Feed was offered daily on an ad libitum basis with refusals collected and<br />

weighed weekly.<br />

Table 1. Adaptation diets fed to lambs (% DM basis).<br />

Ingredient, %<br />

Arrival Step 1 Step 2 Step 3 Step 4 Step 5<br />

day -6 day 0 day 7 day 14 day 21 day 28<br />

Alfalfa Hay 46 46 46 35 25 15<br />

Corn 50.38 35.88 21.38 21.38 21.38 21.38<br />

DDGS 0 14.5 29 40 50 60<br />

Supplement 1<br />

3.62 3.62 3.62 3.62 3.62 3.62<br />

1 Supplement contained: (% of total diet DM) 0.5% ammonium chloride, 2.25% limestone,<br />

0.085% lasalocid, 0.78% trace mineral and 0.002% copper sulfate, and was formulated to<br />

provide one of four levels of thiamin (0, 50, 100 or 150 mg·hd -1 ·d -1 ).<br />

Page 12 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Table 2. Ingredient and nutritional composition (DM basis) of final finishing rations<br />

fed to lambs.<br />

Item CON LOW MED HIGH HIGH+S<br />

Ingredient ,%<br />

Alfalfa Hay 15.0 15.0 15.0 15.0 15.0<br />

Corn 21.4 21.4 21.4 21.4 21.4<br />

DDGS 60.0 60.0 60.0 60.0 60.0<br />

Supplement 2<br />

3.6 3.6 3.6 3.6 3.6<br />

Nutrient 3<br />

CP, % 23.3 23.6 23.4 22.7 23.5<br />

ADF, % 10.8 11.0 11.6 11.6 11.3<br />

S, % 0.8 0.7 0.8 0.7 0.9<br />

Ca, % 1.6 1.4 1.7 1.7 1.8<br />

P, % 0.8 0.8 0.9 0.9 0.9<br />

Thiamin 4<br />

0.0 50.0 100.0 150.0 150.0<br />

1 Treatments: CON (no supplemental thiamin), LOW (50 mg·hd -1 ·d -1 thiamin), MED (100 mg·hd -1 ·d -1<br />

thiamin), HIGH (150 mg·hd -1 ·d -1 thiamin) and HIGH+S (150 mg·hd -1 ·d -1 thiamin with 0.87% S).<br />

2 Supplement (% total diet): 0.5% ammonium chloride, 2.25% limestone, 0.085% lasalocid, 0.78%<br />

sheep mineral 12 (Hubbard Feeds, Mankato, Minn.), 0.002% copper sulfate and 0, 0.004, 0.007 or<br />

0.11% thiamin mononitrate.<br />

3<br />

Laboratory analysis of nutrient concentration.<br />

4<br />

Formulated level (ppm), thiamin inclusion in diet calculated based on an estimated DMI of 3.0<br />

lb·hd -1 ·d -1 .<br />

Treatments 1<br />

Sampling for ruminal H2S was conducted on 12 occasions beginning six days prior to initiation of<br />

treatment diets. Gas cap samples from these lambs were collected on day minus 6, minus 4, 0, 3, 7,<br />

10, 14, 17, 21, 24, 28 and 31 of the feeding period. Hydrogen sulfide gas was measured on H2S<br />

detector tubes (GASTEC © , Kanagawa, Japan). Ruminal fluid was collected at the same time for<br />

determination of rumen fluid pH.<br />

Results<br />

The influence of hydrogen sulfide gas on incidence of PEM in ruminants could be impacted by the way<br />

H2S concentration changes during adaptation to finishing rations. In the present study, no differences<br />

in H2S concentration among treatments (P > 0.10; Table 3) were apparent until day 10, at which point<br />

lambs fed LOW had lower H2S concentrations than all other treatments. At this point in adaptation, the<br />

amount of roughage included in the diet had not changed although the inclusion of DDGS had<br />

increased from 0% to 29% of dietary DM. Those lambs fed the HIGH treatment diet showed the most<br />

dramatic increases in ruminal H2S concentration; on day 21 of adaptation, dietary hay was decreased<br />

from 35% to 25% and DDGS increased from 40% to 50% of dietary DM. During the course of the next<br />

three days, ruminal H2S concentration increased by more than 3,000 ppm and within seven days had<br />

increased by 4,700 ppm H2S.<br />

Page 13 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Table 3. Influence of thiamin and sulfur level on hydrogen sulfide production in<br />

lambs fed a 60% DDGS-based finishing diet.<br />

Day CON LOW MED HIGH<br />

-6 0 0 0 190.6<br />

-4 66.7 0 112.5 25<br />

0 71.5 0 146.9 71.9<br />

3 531.3 375 310.5 737.5<br />

7 778.1 575 759.4 1,237.5<br />

10 2,200.0 a<br />

887.5 b<br />

2,200.0 a<br />

2,453.1 a<br />

14 2,390.6 a<br />

1,087.5 b<br />

1,875.0 a<br />

1,906.3 a<br />

17 2,852.6 a<br />

1,418.8 b<br />

2,609.4 a<br />

21 3,312.5 a<br />

1,531.3 c<br />

2,328.1 abc<br />

24 2,062.5 a<br />

3,287.5 b<br />

3,275.0 b<br />

4,991.6 c<br />

28 4,687.5 a<br />

2,662.5 b<br />

2,906.3 b<br />

6,657.8 c<br />

31 5,687.5 a<br />

2,650.0 b<br />

Treatment 1,2<br />

3,843.8 c<br />

2,406.3 ab<br />

1,958.2 bc<br />

7,701.3 d<br />

abc Means with different superscripts within a row differ at P < 0.10.<br />

Page 14 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report<br />

HIGH+S<br />

75<br />

28.1<br />

93.8<br />

475<br />

1,350.0<br />

2,378.1 a<br />

2,015.6 a<br />

2,406.3 ab<br />

3,140.6 ab<br />

3,046.9 ab<br />

4,390.6 a<br />

4,859.4 ac<br />

1 Treatments: CON (no supplemental thiamin), LOW (50 mg·hd -1 ·d -1 thiamin), MED (100<br />

mg·hd -1 ·d -1 thiamin), HIGH (150 mg·hd -1 ·d -1 thiamin) and HIGH+S (150 mg·hd -1 ·d -1 thiamin<br />

with 0.87% S).<br />

2 When tube measurement was below 100 ppm, tube was considered to read 0.<br />

While the hydrogen sulfide concentrations in the lambs did not reach the levels in steers reported by<br />

Niles et al. (2002), the peak concentrations were above those reported by Loneragan et al. (2005); both<br />

of these studies had steers with positive cases of PEM. These results indicate that the concentration of<br />

H2S required to cause symptoms of PEM may vary depending on species.<br />

Of further interest is the way the H2S concentration in lambs fed HIGH+S changed during adaptation.<br />

Specifically, on days 7, 14 and 21, the concentration of H2S was greater in HIGH+S than HIGH;<br />

however, after three days of adaptation (days 10, 17, 24) the concentration of ruminal H2S from<br />

HIGH+S was lower or equal to that found in HIGH fed lambs.<br />

Multiple factors influence the conversion of dietary S into H2S in the rumen during adaptation. Among<br />

these are decreases in ruminal fluid pH, increases in the proportion of sulfur-reducing bacteria and<br />

increases in dietary S. In this study, ruminal pH did not differ among treatments (P = 0.13) at any time<br />

point (data not shown). Lambs fed CON and MED were not different from day 0 throughout sampling<br />

(P > 0.18). However, ruminal pH of LOW, HIGH and HIGH+S groups did decrease (P < 0.03) through<br />

time. Decreases in ruminal pH also may impact incidence of PEM by other means.<br />

Our research suggests that thiamin may influence ruminal H2S concentrations, but we did not<br />

investigate the fate of the H2S. Further, our data suggests that changes in ruminal hydrogen sulfide<br />

concentration cannot be attributed solely to ruminal pH and likely are affected by multiple factors that<br />

interact within the ruminal environment and in the animal.

Literature Cited<br />

Loneragan, G, D. Gould, J. Wagner, F. Garry and M. Thoren. 2005. The magnitude and patterns of<br />

ruminal hydrogen sulfide production, blood thiamin concentration, and mean pulmonary arterial<br />

pressure in feedlot steers consuming water of different sulfate concentrations. The Bovine<br />

Practitioner. 39:16-22.<br />

Niles, G.A., S. Morgan, W.C. Edwards and D. Lalman. 2002. Effects of dietary sulfur concentrations on<br />

the incidence and pathology of polioencephalomalacia in weaned beef calves. Vet. Human Toxicol.<br />

44(2):70-72.<br />

An Evaluation of a Mixed Co-product Protein Feed in Finishing Rations<br />

V.L. Anderson and B.R. Ilse<br />

<strong>NDSU</strong> Carrington Research Extension Center<br />

Introduction<br />

<strong>North</strong> <strong>Dakota</strong> produces approximately three million tons of co-product feeds in a year including<br />

significant amounts of soybean meal and soybean hulls. Historically, we have exported these feed<br />

ingredients individually to feed markets around the world. Most of the multitude of co-products have<br />

some unique properties that could be improved upon by mixing with other co-products to improve<br />

nutritional and physical properties. Mixing three or more co-product feeds together and pelleting the<br />

mixture creates a new feed commodity. The nutrient content of the new feed is obviously based on the<br />

formulation which can potentially be adapted to specific market opportunities. The new pelleted<br />

commodities have greater bulk density for shipping advantages. They also may be more flexible in end<br />

use, nutrient profile, longer shelf life, improved flow properties, simplified feeding for end users, and<br />

improved safety.<br />

Experimental Procedures<br />

Steer calves (n=176) from 43 different ranches belonging to the <strong>Dakota</strong> Feeder Calf Club at Turtle<br />

Lake, ND, were consigned to the Carrington Research Extension center in the fall of 2008. Each ranch<br />

consigned three to eight steers for the feedout project to observe the feedlot performance and carcass<br />

value from their respective breeding program. After a preconditioning program, steers were individually<br />

weighed, blocked by weight and allotted within weight block to one of four treatments. Steers from<br />

each ranch were allotted to different treatments to reduce ―ranch‖ effects. The treatments were<br />

designed to provide increasing levels of a mixed co-product ―superfeed‖ formulated with 50% soybean<br />

meal, 35 percent distillers grains, and 15 percent field peas.The co-product protein supplement was<br />

manufactured by the <strong>North</strong>ern Crops Institute feed production center in Fargo, ND. This 35 percent<br />

crude protein feed was included in the treatment diets at 0, 5, 10, and 15 percent of the dry matter as a<br />

protein supplement. Canola meal was used as the control protein source. Ration formulations are<br />

provided in Table 1. A totally-mixed corn-based ration was fed to appetite daily in fenceline bunks.<br />

Steers were provided wind protection and bedded during the relatively severe winter. Steers were<br />

weighed every 28 days with feed intake summarized for each weigh period. Feed efficiency was<br />

calculated based on average dry matter intake and average daily gain for each period and overall.<br />

Steers were marketed to Tyson Meats, <strong>Dakota</strong> City, NE on May 6, after evaluation by visual appraisal<br />

that 60% or more would grade USDA Choice. Carcass traits were evaluated after a 24-hour chill by<br />

trained personnel.<br />

Page 15 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Table 1. Rations for steers fed increasing coproduct formulation as protein supplement.<br />

Treatment<br />

Ingredient 0% 5% 10% 15%<br />

Percent, Dry matter basis<br />

Corn, dry rolled 69.2 69.3 69.4 69.5<br />

Co-product protein suppl 0.0 5.0 10.1 15.2<br />

Canola meal 15.6 10.4 5.2 0.0<br />

Straw, chopped 6.9 6.9 6.9 6.9<br />

Corn silage 6.5 6.6 6.5 6.6<br />

Calcium carbonate 0.5 0.5 0.5 0.5<br />

Suppl (Rumensin, vit, min) 1.3 1.3 1.4 1.3<br />

Nutrient Content<br />

Dry Matter, % 78.78 78.67 78.77 78.66<br />

Neg, Mcal/lb 60.33 61.51 62.72 63.91<br />

Crude Protein, % 13.94 13.64 13.39 13.11<br />

Calcium, % 0.45 0.43 0.43 0.41<br />

Phosphorous, % 0.40 0.39 0.37 0.35<br />

Potassium, % 0.60 0.62 0.64 0.66<br />

Results and Discussion<br />

Despite the severe winter weather, steer performance in all treatment groups was very satisfactory. We<br />

observed no statistical difference between the treatments in this trial for any of the feedlot performance<br />

measures (Table 2). The energy density (NEg) increased slightly as the proportion of ―superfeed‖<br />

increased in the ration, however, protein content decreased from 13.94 to 13.11 percent from 0 to 15<br />

percent superfeed. Feed intake for the steers in the respective treatments was 21.01, 22.10, 22.43,<br />

and 22.47 for 0, 5, 10, and 15 percent superfeed treatments. Gains throughout the feeding period<br />

averaged 3.65, 3.68, 3.67, and 3.85 respectively, for 0, 5, 10, and 15 percent superfeed in the diet.<br />

Feed efficiency (feed per gain) was calculated at 4.84, 5.17, 5.24, and 4.80 for increasing superfeed.<br />

Despite severe winter weather, steer performance was very satisfactory.<br />

Page 16 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Table 2. <strong>Feedlot</strong> performance of cattle fed mixed coproduct supplement (CPS) at increasing levels.<br />

Percent Co-Product supplement Contrasts<br />

Item<br />

Live Wt, lbs<br />

0% 5% 10% 15% Std. Error P-Value<br />

CPS vs.<br />

no CPS linear quadratic<br />

Initial Wt (29-Jan) 963.8 988.5 971.6 957.9 39.7 0.24 0.51 0.50 0.14<br />

Period 1 Wt. (25-Feb) 1071.4 1093.1 1082.1 1074.5 43.8 0.60 0.42 0.99 0.28<br />

Period 2 Wt. (06-Apr) 1209.6 1237.1 1215.7 1219.8 40.7 0.60 0.41 0.89 0.46<br />

Period 3 Final Wt. (06-May) 1314.4<br />

DM Intake, lb/hd/day<br />

1346.4 1321.6 1328.1 42.7 0.57 0.38 0.83 0.47<br />

Period 1 19.05 19.92 20.45 20.65 1.38 0.87 0.44 0.41 0.82<br />

Period 2 21.92 23.06 23.09 22.96 1.18 0.87 0.42 0.55 0.60<br />

Period 3 22.08 23.31 23.73 23.80 0.91 0.54 0.19 0.22 0.56<br />

Overall DMI 21.02 22.10 22.43 22.47 1.16 0.80 0.34 0.38 0.67<br />

Average Daily Gain, lb/hd/day<br />

Period 1 (27d) 3.98 3.88 4.04 4.33 0.21 0.48 0.67 0.22 0.40<br />

Period 2 (40d) 3.45 3.63 3.67 3.63 0.16 0.65 0.65 0.72 0.81<br />

Period 3 (30d) 3.48 3.65 3.60 3.60 0.29 0.98 0.69 0.81 0.78<br />

Overall ADG<br />

Feed Efficiency<br />

3.65 3.68 3.67 3.85 0.11 0.57 0.55 0.27 0.51<br />

Gain:Feed Period 1 0.21 0.20 0.21 0.21 0.02 0.93 0.86 0.85 0.76<br />

Gain:Feed Period 2 0.16 0.16 0.15 0.16 0.01 0.92 0.83 0.93 0.63<br />

Gain:Feed Period 3 0.16 0.16 0.15 0.15 0.02 0.99 0.78 0.72 0.99<br />

Overall G:F 0.17 0.17 0.17 0.17 0.01 0.99 0.75 0.90 0.75<br />

Feed:Gain Period 1 4.84 5.17 5.24 4.80 0.56 0.91 0.72 0.98 0.50<br />

Feed:Gain Period 2 6.45 6.41 6.86 6.34 0.41 0.81 0.85 0.94 0.56<br />

Feed:Gain Period 3 6.48 6.55 6.79 6.66 0.60 0.99 0.79 0.78 0.88<br />

Overall F:G 5.79 5.97 6.17 5.83 0.37 0.90 0.65 0.84 0.51<br />

Carcass traits were similar except for backfat and USDA Yield Grade (Table 3). The steers on 5<br />

percent superfeed had more backfat than 10 percent superfeed with 0, and 15 percent treatment steers<br />

intermediate. Yield Grade was lowest for the 10% treatment, and highest for the 5 percent treatment<br />

with 0 and 15 percent intermediate. Marbling scores were not statistically different, but we observed a<br />

numerical increase in the percent USDA Choice carcasses with increasing superfeeds. The number of<br />

choice or better carcasses was 61.36, 67.44, 76.74, and 77.27 percent respectively, for 0, 5, 10, and 15<br />

percent superfeed. This factor could have significant value for the feeder as the value of a lean choice<br />

carcass such as observed with 10 percent superfeed would be attractive to the industry and return<br />

greater value per pound.<br />

Page 17 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Table 3. Carcass traits of cattle fed mixed coproduct protein supplement at increasing levels.<br />

Percent Co-Product supplement Contrasts<br />

Item 0% 5% 10% 15% Std. Error P-Value CPS vs. no CPS linear quadratic<br />

Hot Carcass Wt., lbs. 789.2 820.8 794.2 806.5 25.09 0.31 0.23 0.65 0.46<br />

Dressing Percent 63.25 64.18 63.26 63.95 0.38 0.39 0.11 0.32 0.26<br />

Back Fat, in 0.40 0.46 0.37 0.42 0.03 0.02 0.78 0.47 0.59<br />

Ribeye Area, sq in 13.50 13.62 13.62 13.71 0.27 0.85 0.47 0.43 0.93<br />

Kidney Pelvic Heart, % 2.43 2.43 2.44 2.42 0.02 0.94 0.94 0.75 0.66<br />

USDA Yield Grade* 2.66 2.90 2.51 2.71 0.10 0.07 0.67 0.50 0.84<br />

Marbling Score** 421.8 434.9 445.7 438.9 16.04 0.79 0.36 0.41 0.56<br />

Percent Choice*** 61.36 67.44 76.74 77.27 - - - - -<br />

* USDA Yield Grade is a calculated value that is determined by a formula comparing fat to lean muscle in the carcass.<br />

** Marbling score is based on intermuscular fat in the ribeye: 400-499 = low Choice , 500-599 = Avg Choice.<br />

*** Percent choice was not statisitically analyzed.<br />

Implications<br />

The results of this study suggest that a mixed co-product ―superfeed‖ may be successfully marketed<br />

based on animal performance and especially based on percentage of USDA Choice carcasses. The<br />

ease of use, safety, and handling properties of this pelleted commodity are superior to any single feed<br />

ingredient. Using soybean meal as a base ingredient helps increase the value of the meal and diversify<br />

the market potential to other species or production scenarios. This study gives confidence to livestock<br />

producers interested in using a combinatorial feed comprised of multiple co-products. It remains to be<br />

seen if feed manufacturing businesses are interested in developing commodities from combining coproducts<br />

into commercial pelleted feeds to produce products that can be labeled as <strong>North</strong> <strong>Dakota</strong><br />

―Superfeed.‖<br />

Effects of Dried Distillers Grains With Solubles on Growing and Finishing<br />

Steer Intake, Performance, Carcass Characteristics, Color and Sensory<br />

Attributes<br />

J.L. Leupp 1 , G.P. Lardy 1 , M.L. Bauer 1 , K.K. Karges 2 , M.L. Gibson 2 , J.S. Caton 1 and R.J. Maddock 1<br />

1 <strong>NDSU</strong> Department of Animal Sciences<br />

2 <strong>Dakota</strong> Gold Research Association, Sioux Falls, SD<br />

The objectives of this study were to determine the effects of dried distillers grains with solubles on<br />

growing and finishing performance, carcass characteristics and meat quality traits. These data suggest<br />

dried distillers grains with solubles (DDGS) can be included at 30 percent dietary dry matter (DM) in<br />

both the growing and finishing period, partially replacing dry-rolled corn, with no detrimental effects on<br />

performance, carcass characteristics or sensory attributes, although DDGS may affect color negatively.<br />

Summary<br />

Seventy-two crossbred and purebred beef steers (653 ± 20 pounds initial body weight [BW]) were used<br />

in a completely randomized design to determine effects of dried distillers grains with solubles (29.2%<br />

crude protein [CP], 9.7% fat, DM basis; DDGS) on growing and finishing steer intake, performance,<br />

carcass and meat quality traits. The study contained two feeding periods, growing and finishing, which<br />

resulted in four treatments: 0:0, 30:0, 0:30 and 30:30 (diet DDGS percentage fed during growing and<br />

Page 18 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

finishing periods, respectively). Steers were fed individually a growing diet (65% concentrate) for 57<br />

days then acclimated to and fed a finishing diet (90% concentrate) for 80 or 145 days. Dietary<br />

ingredients included dry-rolled corn, corn silage, grass hay, concentrated separator byproduct and<br />

supplement.<br />

During the growing period, dry-matter intake (DMI) was not different (P ≥ 0.63). Steer performance,<br />

including average daily gain (ADG) and gain:feed (G:F), were not affected (P ≥ 0.14) by treatment<br />

during the growing period and final BW at the end of the growing period was not different (P = 0.99).<br />

During the finishing period, DMI, ADG and G:F were not different (P ≥ 0.22). As a result, final BW was<br />

not different (P ≥ 0.28). Carcass traits (ribeye area; 12th rib fat; kidney, pelvic and heart fat (KPH);<br />

yield grade; and marbling) were not different (P ≥ 0.16).<br />

Results from the trained panel indicated no differences (P ≥ 0.16) in tenderness; however, steaks from<br />

steers fed 30% DDGS during the finishing period tended (P = 0.10) to be juicier and more flavorful than<br />

steaks from control steers. Inclusion of 30% DDGS in the growing period tended to lower L (muscle<br />

lightness) (P = 0.08) and lowered B (muscle yellowness) (P = 0.01) of steaks. Overall feeding of DDGS<br />

lowered B (P = 0.02) compared with feeding dry-rolled corn (0:0). Feeding DDGS during the finishing<br />

period lowered A (muscle redness) (P < 0.001) of steaks. Furthermore, overall feeding of DDGS<br />

lowered A (P < 0.001) compared with feeding dry-rolled corn (0:0). Feeding 30% DDGS did not impact<br />

any performance or carcass characteristics but did influence steak sensory attributes and color.<br />

Introduction<br />

Dried distillers grains with solubles can be used as a protein and energy source depending on the<br />

amount included in the diet (Ham et al., 1994). Feeding up to 40% wet or dry distillers grains in<br />

growing and finishing diets improves ADG and G:F in steers compared with feeding dry-rolled corn only<br />

(Ham et al., 1994).<br />

<strong>Beef</strong> consumers want a high-quality product that is tender, juicy and flavorful. Research is limited in<br />

evaluating effects of feeding DDGS to growing and finishing steers on meat quality. Roeber et al.<br />

(2005) fed finishing Holstein steers up to 50% dried distillers grains (DDG) and reported no differences<br />

in tenderness or sensory traits compared with corn-based diets.<br />

Little quantitative information is available on the effects of short- and long-term feeding of DDGS to<br />

steers on performance and carcass quality. Therefore, our objectives were to determine the effects of<br />

DDGS on growing and finishing steer intake, performance, carcass characteristics, color and sensory<br />

attributes.<br />

Materials and Methods<br />

Seventy-two crossbred and purebred beef steers were used in a completely randomized design. The<br />

study contained two feeding periods, growing and finishing, which resulted in four treatments: 0:0, 30:0,<br />

0:30 and 30:30 (diet DDGS percentage fed during growing and finishing periods, respectively). Steers<br />

were fed individually a growing diet (65% concentrate) for 57 days then acclimated for 14 days to a<br />

finishing diet (90% concentrate) and fed for 80 or 145 days. Diets were based on dry-rolled corn, corn<br />

silage, grass hay, concentrated separator byproduct and supplement (Table 1). Diets included 27.5<br />

parts per million (ppm) of Rumensin and 11 ppm of Tylan and were formulated to contain a minimum of<br />

12.5 percent CP, 0.70 percent calcium (Ca) and 0.30 percent phosphorus (P).<br />

Page 19 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Table 1. Formulated dietary composition of growing and finishing diets containing 0 or 30<br />

percent corn dried distillers grains with solubles offered to beef steers (% dietary DM).<br />

0% DDGS 1<br />

30% DDGS 0% DDGS 1<br />

Diet, % of dietary DM<br />

Growing Finishing<br />

Item<br />

30% DDGS<br />

Dry-rolled corn 50 20 80 50<br />

DDGS — 30 — 30<br />

Corn silage 20 20 5 5<br />

Grass hay 20 20 5 5<br />

CSB 2<br />

5 5 5 5<br />

Wheat middlings 2.18 2.53 1.00 2.18<br />

Soybean meal — — 1.00 —<br />

Limestone 1.40 2.10 1.58 2.45<br />

Urea 0.75 — 0.75 —<br />

Dicalcium phosphate 0.30 — 0.30 —<br />

Salt 0.25 0.25 0.25 0.25<br />

Trace mineral premix 3<br />

0.05 0.05 0.05 0.05<br />

Vitamin A, D premix 4<br />

0.02 0.02 0.02 0.02<br />

Vitamin E premix 5<br />

0.02 0.02 0.02 0.02<br />

Monensin premix 6<br />

0.02 0.02 0.02 0.02<br />

Tylosin premix 7<br />

0.01 0.01 0.01 0.01<br />

---------------Analyzed composition---------------<br />

Crude Protein 12.80 17.90 16.10 22.70<br />

Neutral Detergent Fiber 37.30 39.50 26.10 33.20<br />

Acid Detergent Fiber 20.30 18.50 9.40 10.00<br />

Calcium 1.23 1.23 1.87 2.13<br />

Phosphorus 0.32 0.44 0.54 0.71<br />

1 Dried distillers grains with solubles; nutrient content of DDGS used averaged 29.2% CP, 34.7%<br />

NDF, 9.5% ADF, 9.7% crude fat, 0.03% Ca and 0.81% P.<br />

2<br />

Concentrated separator byproduct (de-sugared molasses).<br />

3 Contained 250 ppm Co, 25.6 ppt Cu, 1.05 ppt I, 6.50 ppt Fe, 40.0 ppt Mn and 160 ppt Zn.<br />

4 Contained 22.0 kIU/pound vitamin A and 2.10 kIU/pound vitamin D.<br />

5 Contained 20 IU/kg vitamin E.<br />

6<br />

Contained 176.4 ppt monensin (Elanco Animal Health, Indianapolis, Ind.) to provide 27.5 ppm of<br />

dietary DM.<br />

7<br />

Contained 88.2 ppt tylosin (Elanco Animal Health, Indianapolis, Ind.) to provide 11 ppm of dietary DM.<br />

Steers were assigned to treatment and fed individually. Steers received a Ralgro implant on day 0 and<br />

Revalor IS on day 60. Final weights were calculated from hot carcass weight (HCW) using an average<br />

dressing percentage of 62.5 percent and a 4 percent shrink. Average daily gain and G:F were<br />

Page 20 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

calculated based on this data. Cattle were sent to a commercial abattoir for slaughter on either March<br />

24 or May 28. Steers marketed on March 24 were estimated to have at least 0.4 inch backfat as<br />

measured by ultrasound. The remaining steers were marketed on May 28 when the majority of the<br />

steers had an estimated 0.4 inch backfat as measured by ultrasound.<br />

One steak from each steer was used for simulated retail display shelf-life analysis. A colorimeter was<br />

used to measure longissimus lean L (muscle lightness), A (muscle redness) and B (muscle yellowness)<br />

color space values through the overwrap polyvinyl chloride (PVC) film for each postmortem display day<br />

at 9 a.m. each day.<br />

One steak from each steer was used for evaluation of tenderness using the Warner-Bratzler shear<br />

force machine (WBSF). Steaks were thawed for 24 hours at 35° Fahrenheit, weighed and then cooked<br />

in clamshell-style grills at 350° F until the steaks reached an internal temperature of 158° F. Six 0.5inch<br />

cores from each steak were removed parallel to the muscle fiber.<br />

Sensory panel analysis was conducted with a trained panel. Steaks were thawed at 35° F for 24 hours<br />

and cooked as previously described for WBSF evaluation. Steaks then were cut into pieces of<br />

approximately 0.5 by 0.5 by 1 inch and served to panelists for evaluation. Panelists scored 10 samples<br />

each day using an 8-point scale where 1 equaled extremely tough, dry and bland and 8 equaled<br />

extremely tender, juicy and intense beef flavor.<br />

Results<br />

During the growing period, two steers from the 30% DDGS treatment were removed from the study due<br />

to conditions unrelated to treatment. One steer was removed prior to initiation of treatments and the<br />

other removed due to chronic bloat; therefore, 70 steers were used during the growing period. Steers<br />

were fed growing diets for 57 days. Initial BW of steers was not different (P = 0.57) and averaged 653 ±<br />

20 pounds. Steer performance, including DMI (22.5 lbs./d), ADG (3.85 lbs./d) and G:F (0.17 lbs./lb.)<br />

were not affected (P ≥ 0.14) by treatment during the growing period. Final BW at the end of the<br />

growing period also was not different (P = 0.99) and averaged 937 ± 13 pounds.<br />

Three steers were removed from the data set due to low feed intakes during the finishing portion of the<br />

trial. Two of the steers removed were on the 30 percent DDGS treatment and one steer was from the 0<br />

percent DDGS treatment. Days fed during the finishing period were not different (P ≥ 0.27; Table 2)<br />

across treatments and averaged 102 ± 8 days. No treatment differences (P ≥ 0.22) were observed for<br />

DMI, ADG or G:F. Ham et al. (1994) fed cattle 40 percent DDGS, which partially replaced dry-rolled<br />

corn in finishing diets, and observed improved ADG and G:F when compared with cattle consuming<br />

dry-rolled corn diets. In the current study, no differences (P ≥ 0.28) in final BW were observed.<br />

Similar to final BW, no differences were found in HCW (P ≥ 0.28; 791 ± 22 lbs.; Table 2). Longissimus<br />

muscle area (12.1 ± 0.5 inch 2 ), 12th rib fat thickness (0.50 ± 0.04 inch) and KPH (2.48 ± 0.16%) were<br />

not different (P ≥ 0.16); therefore, no differences (P ≥ 0.35; 3.33 ± 0.17) were observed for yield grade.<br />

No differences (P ≥ 0.43) were observed for marbling, which averaged 431 (small 0 = 400; Table 2).<br />

Page 21 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Table 2. Performance and carcass characteristics of steers fed growing and finishing diets containing<br />

0 or 30 percent corn dried distillers grains with solubles.<br />

Item 0:00 30:00:00 0:30 30:30:00 SEM 2<br />

Growing Finishing<br />

Corn vs.<br />

DDGS 4<br />

Steers, number 18 15 16 18 — — — —<br />

Days on Feed 99 106 97 106 8 0.27 0.87 0.61<br />

Performance<br />

Final BW, lb. 1193 1226 1204 1239 33.00 0.28 0.73 0.41<br />

DMI, lb./hd/d 18.40 18.80 19.90 17.60 1.50 0.51 0.92 0.80<br />

ADG, lb./hd/d 3.46 3.22 3.51 3.40 0.15 0.22 0.48 0.58<br />

G:F, lb./lb. 0.22 0.19 0.19 0.21 0.03 0.91 0.89 0.52<br />

Carcass Characteristics<br />

HCW, lb. 798 783 807 22.00 0.28 0.73 0.41<br />

LM area, in 2<br />

12.10 12.50 11.80 11.80 0.50 0.60 0.34 0.95<br />

12th rib fat, in 0.46 0.53 0.48 0.52 0.04 0.16 0.90 0.21<br />

KPH, % 2.41 2.60 2.44 2.47 0.16 0.46 0.73 0.59<br />

Marbling 5<br />

430 448 440 407 21.00 0.71 0.43 0.96<br />

Yield grade 3.20 3.33 3.44 3.33 0.17 0.95 0.45 0.35<br />

1 Dietary dried distillers grains with solubles percentage fed during growing and finishing periods, respectively.<br />

2 n = 15.<br />

3<br />

Growing = main effect of feeding dried distillers grains with solubles during the growing period; Finishing =<br />

main effect of feeding dried distillers grains with solubles during the finishing period; Corn vs. DDGS = feeding<br />

dry-rolled corn (0:0) vs. feeding dried distillers grains with solubles during the growing and finishing periods<br />

(30:0 + 0:30 + 30:30).<br />

4<br />

Corn distillers dried grains with solubles.<br />

5 Marbling Score: Small 0 = 400.<br />

Treatment 1<br />

Page 22 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report<br />

Contrast 3<br />

Warner-Bratzler shear force and cooking loss were not different (P ≥ 0.13) across treatments (Table 3).<br />

Results from the trained panel indicated no differences (P ≥ 0.16) in tenderness, which averaged 6.03 ±<br />

0.16 (8-point hedonic scale; Table 3); however, steaks from steers fed 30% DDGS during the finishing<br />

period tended (P = 0.10) to be juicier and more flavorful than steaks from the control steers (6.01 vs.<br />

5.83 ± 0.11 and 6.02 vs. 5.89 ± 0.08, respectively).

Table 3. Shear force, color analysis and sensory characteristics of steaks from steers fed growing<br />

and finishing diets containing 0 or 30 percent corn dried distillers grains with solubles.<br />

Item 0:00 30:00:00 0:30 30:30:00 SEM 2<br />

Growing Finishing<br />

Corn vs.<br />

DDGS 4<br />

Steaks, number 17 15 16 18 — — — —<br />

Shear force, lb. 8.20 8.49 7.98 7.52 0.49 0.86 0.19 0.68<br />

Cooking loss 5 , oz. 1.77 1.51 1.64 1.62 0.11 0.17 0.92 0.13<br />

Color 6<br />

L 49.03 48.69 48.77 48.48 0.19 0.08 0.19 0.04<br />

A 21.69 22.33 20.27 19.99 0.24 0.41

Effect of Glycerol Level in <strong>Feedlot</strong> Diets on Animal Performance and<br />

Carcass Traits<br />

B.R. Ilse 1 , V.L. Anderson 1 , T.M. Jeske², R.J. Maddock 2 , and E.P. Berg 2<br />

1 <strong>NDSU</strong> Carrington Research Extension Center<br />

2 <strong>NDSU</strong> Department of Animal Sciences<br />

Abstract<br />

Two separate feedlot trials were conducted (receiving and finishing) to evaluate the effects of<br />

increasing levels of glycerol on animal performance. Receiving trial steers (n = 198) were allotted by<br />

BW (622.6 ± 34.32 lbs.) in a randomized complete block design and sorted into 16 identical pens (four<br />

pens per treatment). Treatments were 0, 6, 12, and 18 percent glycerol (70% DM; water was added to<br />

reach 70% DM to increase the viscosity and decrease freezing temperature) on a DM basis replacing<br />

dry-rolled corn and co-products in the diet (55 Mcal/lb NEg). Dry matter intake was quadratically<br />

affected during the 30-d feeding period (P = 0.05) with 20.38; 21.07; 21.13; 19.47 pounds consumed for<br />

0, 6, 12, and 18 percent glycerol, respectively. Gains were not affected by glycerol level (P = 0.79) and<br />

feed efficiency was similar (P > 0.92) among treatments. Finishing trial heifers (n = 132; BW = 911.5 ±<br />

33.22 lbs.) were blocked by weight and allotted to one of 16 pens, assigned to 0, 6, 12, 18 percent<br />

glycerol (85% DM) dietary treatments (60 Mcal/lb NEg). Dry matter intake linearly decreased during the<br />

102-d feeding period with increasing glycerol level (P = 0.05; 28.11; 27.97; 27.71; 26.16 lbs. for 0, 6,<br />

12, and 18% glycerol, respectively). Gains were not affected by glycerol level (P = 0.26) during any of<br />

the four individual 28-d weigh periods or overall. Feed efficiency was also similar (P > 0.22) among<br />

treatments. If the availability of feed-grade glycerol increases with the increase in biodiesel production,<br />

glycerol could be a viable alternative to corn in feedlot diets.<br />

Key words: glycerol, beef, feedlot<br />

Introduction<br />

The glycerol (or glycerine) supply may increase dramatically throughout the <strong>North</strong>ern Plains states and<br />

Canadian provinces with the development of the biodiesel industry. Glycerol is a three-carbon alcohol<br />

produced by transesterification of vegetable oil (e.g. soybean) or animal fat. Approximately 10 percent<br />

of the original weight of the vegetable oil is converted to glycerol in the process to produce biodiesel.<br />

This glycerol or glycerine product is primarily utilized in industrial products such as cosmetics, liquid<br />

soap, antifreeze, and lubricants. If glycerol can be used successfully as a feed, beef cattle are the<br />

largest potential year-around market outlet in <strong>North</strong> <strong>Dakota</strong>. A few research trials with dairy cattle<br />

support the use of glycerol as an energy source for ruminants, but no production feedlot research has<br />

been reported in the <strong>North</strong>ern Plains (DeFrain et al., 2004; Linke et al., 2004; Bodarski et al., 2005).<br />

Glycerol is currently used in some formulations of liquid feed products. The energy value of glycerol is<br />

about equal to corn on a pound for pound basis and therefore could be of great value for a livestock<br />

feed based on competitive pricing and availability. This trial was designed to study the effects of<br />

glycerol included as an energy source in receiving and finishing rations on animal performance.<br />

Page 24 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Feed-grade glycerol added to totally-mixed ration in a<br />

truck-mounted mixer wagon.<br />

Materials and Methods<br />

Animals were housed at the Carrington Research Extension Center. Individual animals were weighed,<br />

blocked by weight and randomly allotted within block to one of four ration treatments. There were four<br />

pens or replicates for each treatment utilizing 16 pens. The four treatments included glycerol in the<br />

ration at 0, 6, 12, or 18 percent of the diet DM. The diets (Table 1) were fed as a totally-mixed ration<br />

that included wheat middlings, distillers grains, field peas, and decreasing levels of corn (60, 40, 20,<br />

and 0%, respectively). Animals were fed once daily to appetite based on morning bunk readings, with<br />

feed recorded daily and summarized for each weigh period. The average daily DMI, gain, and feed<br />

efficiency were calculated for each pen for each weigh period (~ 28 d). The glycerol for this study was<br />

donated to the CREC by Westway Feeds Products, Inc. of New Orleans, LA, and FUMPA BioFuels of<br />

Redwood Falls, MN.<br />

Receiving Ration Finishing Ration<br />

Item DM% Percent of diet DM basis Percent of diet DM basis<br />

Glycerol, % 85.1 0 6 12 18 0 6 12 18<br />

Corn, % 86.6 43 37 31 25 60 40 20 10<br />

Field Peas, % 90.7 15 15 15 15 12 12 12 12<br />

Wheat Midds, % 88.9 5 5 5 5 5 13 21 29<br />

MDGS, % b<br />

Table 1. Receiving and Finishing ration formulation with increasing levels of glycerol<br />

57.5 20 20 20 20 12 18 24 30<br />

Straw, % 85.2 15 15 15 15 8 8 8 8<br />

Rumn & MGA, % 90.0 1 1 1 1 2 2 2 2<br />

CaCO3, % 95.0 1 1 1 1 1 1 1 1<br />

a .<br />

a Rations formulated to meet or exceed NRC (1996) recommendations<br />

b Modified distillers grains with solubles.<br />

Page 25 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Receiving Trial<br />

Fall 2008<br />

One hundred ninety-eight mixed breed steers (BW = 622.6 ± 34.3 lbs.) from 40 different ranches that<br />

were part of the <strong>Dakota</strong> Feeder Calf feedout program were utilized in the receiving trial. Steers were<br />

weighed individually at the initiation and completion of the receiving trial (30 d). Rations were<br />

formulated (56 Mcal/lb.) to meet or exceed NRC (1996) recommendations.<br />

<strong>Dakota</strong> Feeder Calf club steers consuming a ration<br />

with increasing levels of glycerol.<br />

Finishing Trial<br />

Summer 2008<br />

One hundred thirty-two yearling Black Angus cross heifers (BW = 911.5 ± 33.2 lbs.) were purchased<br />

from a commercial source and utilized for the finishing trial. The finishing rations (65 Mcal/lb.) were<br />

formulated to meet or exceed NRC (1996) recommendations.<br />

Glycerol levels were increased in stepped increments as follows: all glycerol treatment groups were fed<br />

the 6% glycerol ration during the first seven days of the trial; the 12 and 18% treatment groups were<br />

increased to 12% during the second week; and the 18% glycerol treatment pens were increased to the<br />

final glycerol level at the start of the third week.<br />

Heifers were weighed at 28-d intervals during the 102 days on feed. All heifers were marketed at the<br />

same time when visual appraisal of the animals determined that 60 percent would grade USDA choice.<br />

Page 26 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Heifers on glycerol finishing trial replacing corn in TMR diet up to 18%.<br />

Results and Discussion<br />

Receiving Trial<br />

Dry matter intake was quadratically affected by treatment during the 30-d feeding period (P = 0.05) with<br />

28.11; 27.97; 27.71; 26.16 pounds consumed for 0, 6, 12, and 18 percent glycerol, respectively. Gains<br />

were not affected by glycerol level (P = 0.79) and feed efficiency was similar (P = 0.92) among<br />

treatments.<br />

Table 2. Growth performance and efficiency of steers in a receiving trial with glycerol replacing corn up to 18%.<br />

Treatment % Glycerol Contrasts<br />

Item<br />

Weight, lbs.<br />

0 6 12 18 St. Error P-Value<br />

Glyc vs.<br />

No Glyc Linear Quadratic<br />

Initial Wt. 624.84 625.65 625.59 623.08 34.60 0.69 0.97 0.50 0.35<br />

Period 1 (Nov. 4) 670.33 677.16 669.20 668.58 32.50 0.53 0.80 0.90 0.42<br />

Period 2 (Dec. 4)<br />

Dry Matter Intake<br />

798.07 808.78 804.92 793.16 41.75 0.58 0.67 0.78 0.21<br />

Intake, lbs./hd/d 20.38 21.07 21.13 19.47 1.04 0.17 0.78 0.27 0.05<br />

Average Daily Gain, lbs. 4.26 4.39 4.53 4.16 0.38 0.79 0.76 0.72 0.37<br />

Finishing Trial<br />

Dry matter intake linearly decreased during the 102-d feeding period due to glycerol level (P = 0.05;<br />

28.11; 27.97; 27.71; 26.16 lbs. for 0, 6, 12, and 18% glycerol, respectively). Gains were not affected by<br />

glycerol level (P = 0.26) during any of the four individual 28-d weigh periods or overall. Feed efficiency<br />

was also similar (P = 0.22) among treatments.<br />

Page 27 2009 <strong>NDSU</strong> <strong>Beef</strong> <strong>Feedlot</strong> Research Report

Table 3. Heifer body weight averages by treatment and period, glycerol replacing corn at 0, 6, 12, and 18% of the TMR.<br />

Treatment % Glycerol Contrasts<br />

Item 0 6 12 18 St. Err P-Value<br />

Glyc vs.<br />

No Glyc Linear Quadratic<br />