Crane User's Guide - Union Wire Rope

Crane User's Guide - Union Wire Rope

Crane User's Guide - Union Wire Rope

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

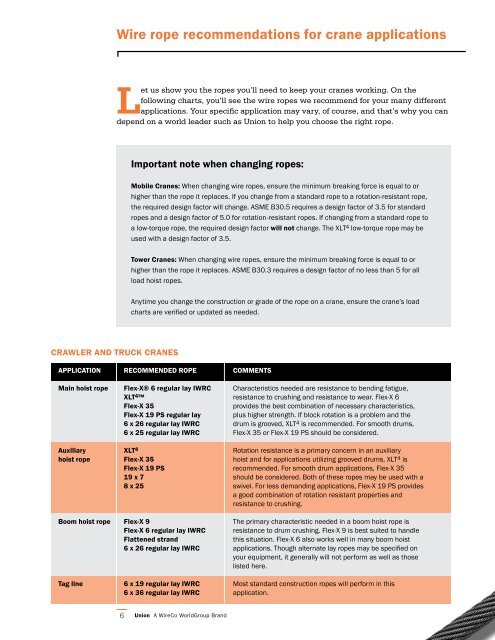

Crawler and trUCk <strong>Crane</strong>s<br />

wire rope recommendations for crane applications<br />

let us show you the ropes you’ll need to keep your cranes working. On the<br />

following charts, you’ll see the wire ropes we recommend for your many different<br />

applications. Your specific application may vary, of course, and that’s why you can<br />

depend on a world leader such as <strong>Union</strong> to help you choose the right rope.<br />

important note when changing ropes:<br />

mobile <strong>Crane</strong>s: When changing wire ropes, ensure the minimum breaking force is equal to or<br />

higher than the rope it replaces. If you change from a standard rope to a rotation-resistant rope,<br />

the required design factor will change. ASME B30.5 requires a design factor of 3.5 for standard<br />

ropes and a design factor of 5.0 for rotation-resistant ropes. If changing from a standard rope to<br />

a low-torque rope, the required design factor will not change . The XLT 4 low-torque rope may be<br />

used with a design factor of 3.5.<br />

tower <strong>Crane</strong>s: When changing wire ropes, ensure the minimum breaking force is equal to or<br />

higher than the rope it replaces. ASME B30.3 requires a design factor of no less than 5 for all<br />

load hoist ropes .<br />

Anytime you change the construction or grade of the rope on a crane, ensure the crane’s load<br />

charts are verified or updated as needed.<br />

aPPliCation reCommended roPe Comments<br />

main hoist rope flex-X® 6 regular lay iwrC<br />

Xlt 4<br />

flex-X 35<br />

flex-X 19 Ps regular lay<br />

6 x 26 regular lay iwrC<br />

6 x 25 regular lay iwrC<br />

auxiliary Xlt 4<br />

hoist rope flex-X 35<br />

flex-X 19 Ps<br />

19 x 7<br />

8 x 25<br />

boom hoist rope flex-X 9<br />

flex-X 6 regular lay iwrC<br />

flattened strand<br />

6 x 26 regular lay iwrC<br />

tag line 6 x 19 regular lay iwrC<br />

6 x 36 regular lay iwrC<br />

6<br />

Characteristics needed are resistance to bending fatigue,<br />

resistance to crushing and resistance to wear . Flex-X 6<br />

provides the best combination of necessary characteristics,<br />

plus higher strength. If block rotation is a problem and the<br />

drum is grooved, XLT 4 is recommended . For smooth drums,<br />

Flex-X 35 or Flex-X 19 PS should be considered.<br />

Rotation resistance is a primary concern in an auxiliary<br />

hoist and for applications utilizing grooved drums, XLT 4 is<br />

recommended. For smooth drum applications, Flex-X 35<br />

should be considered . Both of these ropes may be used with a<br />

swivel. For less demanding applications, Flex-X 19 PS provides<br />

a good combination of rotation resistant properties and<br />

resistance to crushing .<br />

The primary characteristic needed in a boom hoist rope is<br />

resistance to drum crushing . Flex-X 9 is best suited to handle<br />

this situation . Flex-X 6 also works well in many boom hoist<br />

applications. Though alternate lay ropes may be specified on<br />

your equipment, it generally will not perform as well as those<br />

listed here .<br />

Most standard construction ropes will perform in this<br />

application .