Determination of Mixing and Compaction Temperatures ... - ijcebm

Determination of Mixing and Compaction Temperatures ... - ijcebm

Determination of Mixing and Compaction Temperatures ... - ijcebm

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Mixing</strong>/<strong>Compaction</strong> temp. o C<br />

250<br />

240<br />

230<br />

220<br />

210<br />

200<br />

190<br />

180<br />

170<br />

160<br />

150<br />

International Journal <strong>of</strong> Civil Engineering <strong>and</strong> Building Materials (ISSN 2223-487X) Vol. 2 No.4 2012<br />

© 2012 International Science <strong>and</strong> Engineering Research Center<br />

Hydrated lime mix.temp<br />

Lime mix.temp<br />

Cement mix.temp<br />

Hydrated lime comp.temp<br />

lime comp.temp<br />

Portl<strong>and</strong> cement comp.temp<br />

Hydrated lime mixing temp.polyline<br />

Hydrated lime com.temp. polyline<br />

Portl<strong>and</strong> cement mix.temp. polyline<br />

Portl<strong>and</strong> cement comp.temp. polyline<br />

Limestone mix.temp. polyline<br />

Limestone comp.temp polyline<br />

140<br />

0 0.3 0.6 0.9 1.2 1.5<br />

Dust to binder ratio<br />

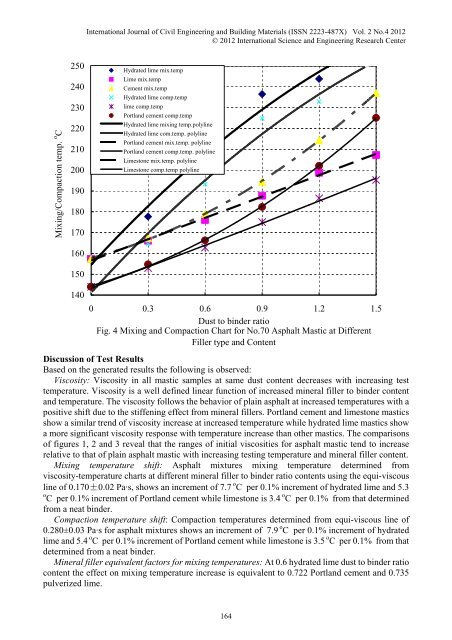

Fig. 4 <strong>Mixing</strong> <strong>and</strong> <strong>Compaction</strong> Chart for No.70 Asphalt Mastic at Different<br />

Filler type <strong>and</strong> Content<br />

Discussion <strong>of</strong> Test Results<br />

Based on the generated results the following is observed:<br />

Viscosity: Viscosity in all mastic samples at same dust content decreases with increasing test<br />

temperature. Viscosity is a well defined linear function <strong>of</strong> increased mineral filler to binder content<br />

<strong>and</strong> temperature. The viscosity follows the behavior <strong>of</strong> plain asphalt at increased temperatures with a<br />

positive shift due to the stiffening effect from mineral fillers. Portl<strong>and</strong> cement <strong>and</strong> limestone mastics<br />

show a similar trend <strong>of</strong> viscosity increase at increased temperature while hydrated lime mastics show<br />

a more significant viscosity response with temperature increase than other mastics. The comparisons<br />

<strong>of</strong> figures 1, 2 <strong>and</strong> 3 reveal that the ranges <strong>of</strong> initial viscosities for asphalt mastic tend to increase<br />

relative to that <strong>of</strong> plain asphalt mastic with increasing testing temperature <strong>and</strong> mineral filler content.<br />

<strong>Mixing</strong> temperature shift: Asphalt mixtures mixing temperature determined from<br />

viscosity-temperature charts at different mineral filler to binder ratio contents using the equi-viscous<br />

line <strong>of</strong> 0.170±0.02 Pa·s, shows an increment <strong>of</strong> 7.7 o C per 0.1% increment <strong>of</strong> hydrated lime <strong>and</strong> 5.3<br />

o o<br />

C per 0.1% increment <strong>of</strong> Portl<strong>and</strong> cement while limestone is 3.4 C per 0.1% from that determined<br />

from a neat binder.<br />

<strong>Compaction</strong> temperature shift: <strong>Compaction</strong> temperatures determined from equi-viscous line <strong>of</strong><br />

0.280±0.03 Pa·s for asphalt mixtures shows an increment <strong>of</strong> 7.9 o C per 0.1% increment <strong>of</strong> hydrated<br />

lime <strong>and</strong> 5.4 o C per 0.1% increment <strong>of</strong> Portl<strong>and</strong> cement while limestone is 3.5 o C per 0.1% from that<br />

determined from a neat binder.<br />

Mineral filler equivalent factors for mixing temperatures: At 0.6 hydrated lime dust to binder ratio<br />

content the effect on mixing temperature increase is equivalent to 0.722 Portl<strong>and</strong> cement <strong>and</strong> 0.735<br />

pulverized lime.<br />

164