Little Belt Suspension Bridge – Durable Long Life ... - Icsboc.com

Little Belt Suspension Bridge – Durable Long Life ... - Icsboc.com

Little Belt Suspension Bridge – Durable Long Life ... - Icsboc.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

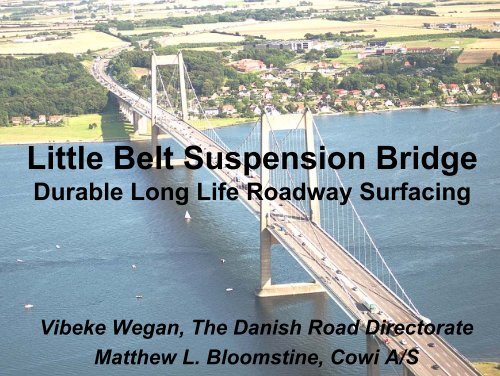

<strong>Little</strong> <strong>Belt</strong> <strong>Suspension</strong> <strong>Bridge</strong><br />

<strong>Durable</strong> <strong>Long</strong> <strong>Life</strong> Roadway Surfacing<br />

Vibeke Wegan, The Danish Road Directorate<br />

Matthew L. Bloomstine, Cowi A/S

Presentation<br />

• The <strong>Little</strong> <strong>Belt</strong> <strong>Suspension</strong> <strong>Bridge</strong><br />

• Original Surfacing<br />

• Replacement Project<br />

•Conclusion

<strong>Little</strong> <strong>Belt</strong> <strong>Suspension</strong> <strong>Bridge</strong><br />

Facts:<br />

Opened in 1970<br />

ADT = 50,000 vehicles<br />

Main span: 600 m<br />

Two side spans: 240 m<br />

Steel deck: 1080 m<br />

Total length: 1,700 m

Steel box girder<br />

Total width: 33,3 m<br />

Each direction : 3 lanes of trafic (3.5 m wide)<br />

1 emergency lane (2 m wide)<br />

Total surfacing: 29,000 m 2

Original surfacing<br />

Metallic cleanness Sa 3<br />

8/12 mm chippings<br />

30 mm mastic asphalt<br />

20 mm mastic asphalt<br />

4 mm waterproofing mastix<br />

Adhesive primer, 300 g/m 2

Development of surfacing<br />

Performance tests<br />

• Fatigue, 0 and -20ºC<br />

Load: 5 <strong>–</strong> 45 kN<br />

Frequency: 3 Hz<br />

• Rutting, 30 and 50ºC<br />

• Sliding, 60ºC<br />

0 and -20ºC

Maintenance<br />

Annual inspections since early 80’ies <br />

Before 95: crack sealing<br />

After 95: open cracks, stone tearing and tracking:

☺<br />

Main repair strategies<br />

1. Replacement of the entire<br />

surfacing including waterproofing<br />

2. Replacement of the wearing<br />

course and a total replacement of<br />

the surfacing 15 years later

Alternative wearing course<br />

New SMA material:<br />

• Surface with low air void and high binder content<br />

• Highly polymer modified binder and special<br />

limestone filler with high stabilizing effect<br />

Advantages:<br />

• Keener <strong>com</strong>petition at tender<br />

• Fast application - less traffic disruption<br />

• Cheaper at procurement<br />

• Greater evenness - improved driving <strong>com</strong>fort

Project tender<br />

Removal of existing wearing course<br />

Local repair of waterproofing and mastic<br />

asphalt bearing course<br />

Application of new SMA wearing course<br />

Establishment of elastic joints at the<br />

expansion joints<br />

Road markings on wearing course

Replacement<br />

1. Milling off original wearing course + app. 5 mm<br />

bearing course<br />

2. New wearing course of 35 mm Stone Mastic<br />

Asphalt

1995, North side <strong>–</strong> Test trial<br />

Working days: 15<br />

Area: 2,700 m²<br />

Bearing course: 35 m² ~ 1.3 %<br />

Waterproofing: 10 m² ~ 0.4 %<br />

Damaged<br />

waterproofing layer

1999, North side<br />

Working days: 33<br />

Area: 6,000 m²<br />

Bearing course: 90 m² ~ 1.5 %<br />

Waterproofing: 55 m² ~ 0.9 %<br />

Markingofdamageto<br />

bearing course

2000, South side<br />

Working days: 65<br />

Area: 10,000 m²<br />

Bearing course: 284 m² ~ 2.8 %<br />

Waterproofing: 133 m² ~ 1.3 %<br />

Repair of damaged<br />

bearing course

Replacement - summary<br />

Replacements/repairs<br />

South side, 2000<br />

North side, 1999<br />

North side, 1995<br />

Total in m 2<br />

Total in % of the <strong>Bridge</strong><br />

Wearing course<br />

10,000 m 2<br />

6,000 m 2<br />

2,700 m 2<br />

18,700 m 2<br />

64 %<br />

Bearing course<br />

284 m 2<br />

90 m 2<br />

35 m 2<br />

409 m 2<br />

1.4 %<br />

Mastix<br />

133 m 2<br />

55 m 2<br />

10 m 2<br />

198 m 2<br />

0.7 %

Replacement - execution<br />

64 % wearing course replaced<br />

36 % original surfacing<br />

Avarage daily progress: 180 <strong>–</strong> 185 m²

Economy<br />

Replacements<br />

Side span, 1995<br />

North side, 1999<br />

South side, 2000<br />

Total<br />

replacement<br />

2,700 m 2<br />

6,000 m 2<br />

10,000 m 2<br />

Total<br />

expenses<br />

DKK/ m 2<br />

282<br />

306<br />

322<br />

Average price adjusted to December 2003: 48 Euro/m 2

☺ ☺<br />

☺ ☺<br />

☺<br />

☺<br />

☺ ☺<br />

☺ ☺<br />

Extraordinarily long lifetime<br />

• Optimization of each layer and the entire surfacing<br />

• A stiff bridge deck structure, which minimizes<br />

stress in the surfacing<br />

• A system with a separate wearing course allowing<br />

relatively simple life prolonging repair<br />

• Quality workmanship during the original works<br />

• Regular maintenance from an early stage<br />

• Design provides a good water runoff

Conclusion<br />

• 45 years lifetime<br />

• 64 % of the bridge area repaired after<br />

25 years<br />

• Avarage daily progress: 180 <strong>–</strong> 185 m²<br />

• Avarage price: 48 Euro/m² ex. traffic

Other Steel <strong>Bridge</strong> Decks in DK<br />

Farø <strong>Bridge</strong> (1985)<br />

Great <strong>Belt</strong> East <strong>Bridge</strong> (1998)<br />

<strong>–</strong> primer<br />

<strong>–</strong> 4 mm Waterproofing Mastix<br />

<strong>–</strong> 25 mm Mastic Asphalt<br />

<strong>–</strong> 30 mm Mastic Asphalt<br />

<strong>–</strong> Chippings