ABR/S-BVR/S INSTALLATION INSTRUCTIONS - LSI Industries Inc.

ABR/S-BVR/S INSTALLATION INSTRUCTIONS - LSI Industries Inc.

ABR/S-BVR/S INSTALLATION INSTRUCTIONS - LSI Industries Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

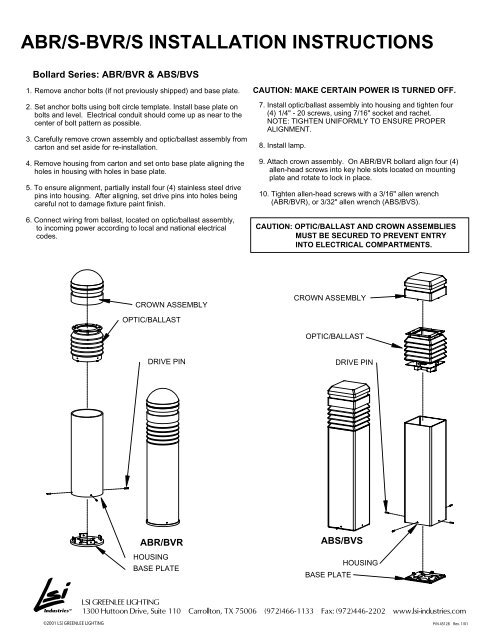

<strong>ABR</strong>/S-<strong>BVR</strong>/S <strong>INSTALLATION</strong> <strong>INSTRUCTIONS</strong><br />

Bollard Series: <strong>ABR</strong>/<strong>BVR</strong> & ABS/BVS<br />

1. Remove anchor bolts (if not previously shipped) and base plate.<br />

2. Set anchor bolts using bolt circle template. Install base plate on<br />

bolts and level. Electrical conduit should come up as near to the<br />

center of bolt pattern as possible.<br />

3. Carefully remove crown assembly and optic/ballast assembly from<br />

carton and set aside for re-installation.<br />

4. Remove housing from carton and set onto base plate aligning the<br />

holes in housing with holes in base plate.<br />

5. To ensure alignment, partially install four (4) stainless steel drive<br />

pins into housing. After aligning, set drive pins into holes being<br />

careful not to damage fixture paint finish.<br />

6. Connect wiring from ballast, located on optic/ballast assembly,<br />

to incoming power according to local and national electrical<br />

codes.<br />

©2001 <strong>LSI</strong> GREENLEE LIGHTING<br />

CROWN ASSEMBLY<br />

OPTIC/BALLAST<br />

DRIVE PIN<br />

<strong>ABR</strong>/<strong>BVR</strong><br />

HOUSING<br />

BASE PLATE<br />

CAUTION: MAKE CERTAIN POWER IS TURNED OFF.<br />

7. Install optic/ballast assembly into housing and tighten four<br />

(4) 1/4" - 20 screws, using 7/16" socket and rachet.<br />

NOTE: TIGHTEN UNIFORMLY TO ENSURE PROPER<br />

ALIGNMENT.<br />

8. Install lamp.<br />

9. Attach crown assembly. On <strong>ABR</strong>/<strong>BVR</strong> bollard align four (4)<br />

allen-head screws into key hole slots located on mounting<br />

plate and rotate to lock in place.<br />

10. Tighten allen-head screws with a 3/16" allen wrench<br />

(<strong>ABR</strong>/<strong>BVR</strong>), or 3/32" allen wrench (ABS/BVS).<br />

CAUTION: OPTIC/BALLAST AND CROWN ASSEMBLIES<br />

MUST BE SECURED TO PREVENT ENTRY<br />

INTO ELECTRICAL COMPARTMENTS.<br />

CROWN ASSEMBLY<br />

OPTIC/BALLAST<br />

DRIVE PIN<br />

ABS/BVS<br />

BASE PLATE<br />

HOUSING<br />

<strong>LSI</strong> GREENLEE LIGHTING<br />

1300 Huttoon Drive, Suite 110 Carrollton, TX 75006 (972)466-1133 Fax: (972)446-2202 www.lsi-industries.com<br />

P/N 45128 Rev. 1/01

WARNING:<br />

CAUTION:<br />

ATTENTION:<br />

ATTENTION:<br />

NOTE:<br />

Fixture Installation:<br />

This Fixture Must Be Installed Per Local And National Electric Codes. This Fixture Must Be Grounded!<br />

Failure To Do So May Result In Serious Personal Injury.<br />

This Fixture Must Be Installed By A Qualified Licensed Electrician.<br />

Hid Versions Of This Fixture Are Equipped With A Multi-Tap Ballast And Have Been Factory Wired For Operation On A<br />

277 Volt Circuit (347V In Canada). If Other Than 277V Is Required, I.E. 120V, 208V, 240V, Connect <strong>Inc</strong>oming Voltage Lead<br />

To Selected Voltage On Ballast. All Unused Leads Must Be Insulated.<br />

Fluorescent Versions Are Equipped With A Universal Voltage Electronic Fluorescent Ballast. The Electronic Ballast Will<br />

Accomodate Input Voltages From 120V Thru 277V 50/60Hz. The Electronic Ballast Will Operate Pl-T 26W/4P, Pl-T 32W/4P,<br />

Pl-T 42W/4P Lamps. The Lampholder Provided Will Accept Any Of These Lamps. See Page 2 For Fluorescent Lamp Installation Detail.<br />

KEEP THESE <strong>INSTRUCTIONS</strong> FOR FUTURE REFERENCE.<br />

Refer to the bollard anchor bolt template<br />

for proper installation of anchor bolts<br />

Level base plate with bubble level before<br />

securing top nuts & washers<br />

Concrete<br />

(By Others)<br />

FIGURE 1<br />

Electrical Conduit<br />

(By Others)<br />

TOOLS REQUIRED: • T-25 TORX DRIVER<br />

• 1/8" L-TYPE HEX KEY<br />

VBR/VBS Bollard Series<br />

Installation Instructions<br />

VBS ID<br />

Shown<br />

• 5/32" HEX KEY<br />

• BUBBLE LEVEL<br />

ID<br />

Reflector<br />

Lamp Access<br />

Cap Assy<br />

Ballast/Optic<br />

Assy<br />

Housing<br />

Extrusion<br />

1/4-20 X 1/2<br />

Cap Screw<br />

Base Plate<br />

IL<br />

Reflector<br />

Assy<br />

• 9/16" OPEN END WRENCH<br />

VBR IL<br />

Shown<br />

1. Make certain the power supply is turned off before starting installation.<br />

2. Mount base plate on anchor bolts. See figure 1 & anchor bolt mounting template.<br />

3. Slide the housing extrusion over the base plate, align the machined holes in the bottom of the housing extrusion with the holes in the base<br />

plate. Insert four 1/4-20 x 1/2 cap screws and tighten with the 5/32" hex key.<br />

4. Make all supply lead connections to the ballast, refer to schematic on ballast if necessary. All ballast leads must be insulated.<br />

Slide ballast/optic assy into top of housing extrusion.<br />

5. Remove the lamp & reflector and tighten all set screws on the ballast/optic assy with a 1/8" l-type hex key. See page 2 for ballast/optic<br />

assy installation details.<br />

6. Replace lamp & reflector and insert lamp access cap onto top of ballast/optic assy. Align the (2) #10-24 captive screws before pushing<br />

cap gasket into top of ballast/optic assy. once aligned, press the cap in firmly and tighten the (2) #10-24 captive screws. See page 2 for<br />

lamp access cap installation details.<br />

PAGE 1<br />

P/N 45209 REV. 2-9-01

Figure 2. Ballast/Optic Assembly Installation<br />

BALLAST/OPTIC ASSY<br />

MOUNTING SET SCREW<br />

LOCATIONS<br />

VBR SET SCREW (3X) VBS SET SCREW (4X)<br />

After connecting all supply leads, insert ballast/optic assy into housing extrusion. With lamp & reflector removed, tighten all<br />

1/4-20 set screws to 25 IN/LB torque with a 1/8" L-type hex key.<br />

Figure 4. Captive Screw Details<br />

Maintenance:<br />

VBR/VBS Bollard Series<br />

Installation Instructions<br />

Figure 3. Lamp Access Cap Installation<br />

Align the #10-24 captive screws in the lamp access cap with the holes on the weldment<br />

tabs, and tighten 1 to 2 turns. Press the lamp access cap in place firmly. Tighten the<br />

captive screws to 30 IN/LB with a T-25 torx driver.<br />

Stainless Steel Washer<br />

Lamp Access Cap Screw Hole Seal<br />

(Prevents Water Entry Into Fixture)<br />

Captive Screw Retainer<br />

(Prevents Screw From Falling<br />

Out Of Lamp Access Cap)<br />

CAPTIVE SCREWS<br />

WELDMENT TAB<br />

Figure 5. Fluorescent Relamping<br />

OFF ON<br />

Fluorescent fixtures are<br />

supplied with "twist-lock"<br />

lampholders. To install<br />

lamp, press the lamp into the<br />

lampholder & turn clockwise<br />

until the lampholder clicks.<br />

Turn the lamp counterclockwise<br />

until the<br />

lampholder clicks to release<br />

lamp.<br />

This fixture should be periodically maintained. If service parts are required a parts list can be obtained bycontacting your local distributor or calling<br />

<strong>LSI</strong> GREENLEE LIGHTING customer service @ 972-466-1133. Failure to follow the manufacturers instructions, or making any modifications to the<br />

product can void the warranty. Fixture failures resulting from poor maintenance or abuse will not be covered by warranty. consult<br />

warranty for full details.<br />

<strong>LSI</strong> GREENLEE LIGHTING 1300 Hutton Dr. Ste. 110 Carrollton, TX 75006 (972)466-1133.<br />

PAGE 2<br />

© Copyright 2001 <strong>LSI</strong> GREENLEE LIGHTING<br />

P/N 45209 REV.