- Page 1 and 2:

1005 Catalogue Explosion-Protected

- Page 3 and 4: 2 4 6 8 10 12 EX-FLUORESCENT LIGHT

- Page 5 and 6: A Regulations on Explosion-Protecti

- Page 7 and 8: C Hazardous Areas due to Explosive

- Page 9 and 10: DHazardous Areas due to explosive D

- Page 11 and 12: PTB Nr. Ex-92.C.1801 EEx ed IIC T4

- Page 13 and 14: H Regulations and Approvals Outside

- Page 15 and 16: Chemical Stability of Plastics Mate

- Page 17 and 18: PORTABLE EX-LAMPS INFORMATION ON EX

- Page 19 and 20: Focussing Stabex HF Focussing HE 8

- Page 21 and 22: The right light for every type of o

- Page 23 and 24: I Stabex mini II I Stabex mini LED

- Page 25 and 26: I Stabex mini II I Stabex mini LED

- Page 27 and 28: Technical data Stabex M0 Marking to

- Page 29 and 30: I HE 5 EN I HE 8 N EN I HE 8 EURO/H

- Page 31 and 32: I HE 5 EN I HE 8 N EN I HE 8 EURO/H

- Page 33 and 34: SEB 8/SEB 8 L as search and work li

- Page 35 and 36: Technical data I SEB 8/9 I SEB 8/9

- Page 37 and 38: I SEB 8/9 I SEB 8/9 L I SEB 8 ADR I

- Page 39 and 40: Technical data HLE 7 L EN Marking t

- Page 41 and 42: Application range The powerful, exp

- Page 43 and 44: Ordering details Type with Lamp Lum

- Page 45 and 46: I Ex-lamps with electronic ballasts

- Page 47 and 48: Technical data Transport trolley wi

- Page 49 and 50: EX-FLUORESCENT LIGHT FITTINGS EX-LI

- Page 51 and 52: one sided through-wiring Type 1/6 I

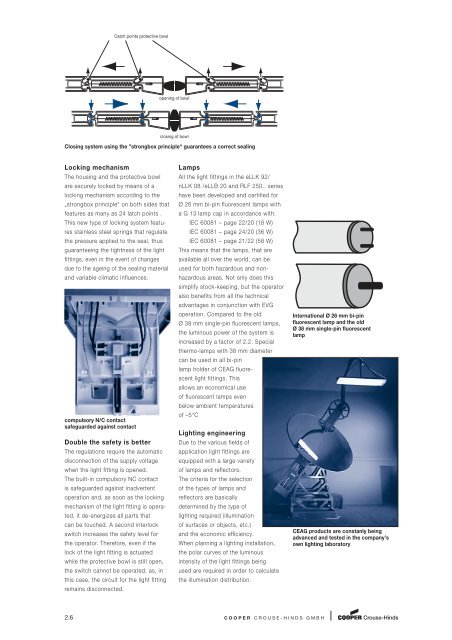

- Page 53: generously dimensioned terminal com

- Page 57 and 58: EVG-Capsulation Robust technology f

- Page 59 and 60: To be able to run on the CEAG emerg

- Page 61 and 62: Technical data eLLK 92018/18 ⎮ eL

- Page 63 and 64: Ordering details I eLLK 92... (18-5

- Page 65 and 66: 90 Dimension drawing ⎮ Polar curv

- Page 67 and 68: I Intelligent Battery Technology -

- Page 69 and 70: Technical data I eLLK 92018/18 NIB

- Page 71 and 72: Accessories I eLLK 92018/18 NIB I e

- Page 73 and 74: Dimension drawing 13 20 Eye bolt M8

- Page 75 and 76: I eLLB 20018/18 I eLLB 20036/36 I e

- Page 77 and 78: I eLLB 20018/18 I eLLB 20036/36 I e

- Page 79 and 80: I eLLB 20018/18 I eLLB 20036/36 I e

- Page 81 and 82: LED: ✴ Battery set NIB = flashing

- Page 83 and 84: Ordering details I eLLB 20018/18 NI

- Page 85 and 86: Dimension drawing ⎮ Polar curve P

- Page 87 and 88: Technical data RLF 250... / RLF-INO

- Page 89 and 90: Wall bracket set Wall-/ceiling moun

- Page 91 and 92: Wall-/ceiling mounting swivel Beste

- Page 93 and 94: Wall-/ceiling mounting Dimension dr

- Page 95 and 96: Technical data AB 12...E with elect

- Page 97 and 98: Ordering details I AB 12...E I with

- Page 99 and 100: Technical data EVF...E Marking to 9

- Page 101 and 102: Ordering details I EVF...E with ele

- Page 103 and 104: COOPER CROUSE-HINDS GMBH 2.55 1 2 3

- Page 105 and 106:

Technical data I nLLK 08018/18 I nL

- Page 107 and 108:

I nLLK 08018/18 I nLLK 08036 I nLLK

- Page 109 and 110:

90 I nLLK 08018/18 I nLLK 08036 I n

- Page 111 and 112:

I nLLK 08018/18 N I nLLK 08036/36 N

- Page 113 and 114:

I nLLK 08018/18 N I nLLK 08036/36 N

- Page 115 and 116:

COOPER CROUSE-HINDS GMBH 2.67 1 2 3

- Page 117 and 118:

Technical data SG-Ex RFE Marking to

- Page 119 and 120:

Ordering details Type Description O

- Page 121 and 122:

Dimension drawing 1900 Light pole 9

- Page 123 and 124:

Dimension drawing Accessories 250 7

- Page 125 and 126:

Cooper Crouse-Hinds © 2009 - all r

- Page 127 and 128:

Cooper Crouse-Hinds © 2009 - all r

- Page 129 and 130:

Cooper Crouse-Hinds © 2009 - all r

- Page 131 and 132:

Cooper Crouse-Hinds © 2009 - all r

- Page 133 and 134:

Cooper Crouse-Hinds © 2009 - all r

- Page 135 and 136:

Cooper Crouse-Hinds © 2009 - all r

- Page 137 and 138:

Cooper Crouse-Hinds © 2009 - all r

- Page 139 and 140:

Cooper Crouse-Hinds © 2009 - all r

- Page 141 and 142:

Cooper Crouse-Hinds © 2009 - all r

- Page 143 and 144:

Cooper Crouse-Hinds © 2009 - all r

- Page 145 and 146:

Cooper Crouse-Hinds © 2009 - all r

- Page 147 and 148:

EX-CEILING, PENDANT LIGHT FITTINGS

- Page 149 and 150:

Bulk head light fitting AB 05 I Ex-

- Page 151 and 152:

Technical data Ex-Bulkhead light fi

- Page 153 and 154:

Technical data Ex-Bulkhead light fi

- Page 155 and 156:

Ordering details Type Entry thread

- Page 157 and 158:

Technical data AB 50 ⎮ SPG 1N I E

- Page 159 and 160:

Technical data AB 51 IU ⎮ AB 51 I

- Page 161 and 162:

I Ex-Pendant light fittings I EVI 5

- Page 163 and 164:

90 Dimensions drawing ⎮ Polar cur

- Page 165 and 166:

I Ex-Pendant light fitting I EVQ 85

- Page 167 and 168:

Ordering details I Ex-Pendant light

- Page 169 and 170:

COOPER CROUSE-HINDS GMBH 4.23 1 2 3

- Page 171 and 172:

Technical data dHLS 85250 ⎮ dHLS

- Page 173 and 174:

COOPER CROUSE-HINDS GMBH 4.27 1 2 3

- Page 175 and 176:

Technical data FZD 04 Ballast enclo

- Page 177 and 178:

Technical data FZD EN Marking to 94

- Page 179 and 180:

I Ex-Floodlight I Swivel bracket Mo

- Page 181 and 182:

Technical data PX 04... Marking to

- Page 183 and 184:

90 Dimensions drawing PX 04 M25 546

- Page 185 and 186:

Technical data dTLS 85250 / dTLS 85

- Page 187 and 188:

COOPER CROUSE-HINDS GMBH 4.41 1 2 3

- Page 189 and 190:

Technical data GHG 664 Marking to 9

- Page 191 and 192:

COOPER CROUSE-HINDS GMBH 4.45 1 2 3

- Page 193 and 194:

Technical data I Ex-Tank inspection

- Page 195 and 196:

COOPER CROUSE-HINDS GMBH 4.49 1 2 3

- Page 197 and 198:

Technical data NVMV NVMV CHAMP for

- Page 199 and 200:

Dimensions drawing 285 294 Ø 254 1

- Page 201 and 202:

Technical data NFMV Marking to 94/9

- Page 203 and 204:

Technical data NSSFMV Stainless Ste

- Page 205 and 206:

COOPER CROUSE-HINDS GMBH 4.59 1 2 3

- Page 207 and 208:

Accessories Lamps for pendant light

- Page 209 and 210:

EX-AUDIO/VISUAL-SIGNALLING EQUIPMEN

- Page 211 and 212:

ALARM, SIGNAL AND CONTROLL EQUIPMEN

- Page 213 and 214:

Technical data Type BG2 E/I EC-Type

- Page 215 and 216:

Ordering details I BGI, PBI, BGE, P

- Page 217 and 218:

Ordering details I Ex-Manual call p

- Page 219 and 220:

Ordering details I Ex-Break glass c

- Page 221 and 222:

Technical data XB 11 SL Range EC-Ty

- Page 223 and 224:

Ordering details I Ex-Status lamps

- Page 225 and 226:

Temperature classifications I Ex-St

- Page 227 and 228:

Ordering details I Ex-Status lamps

- Page 229 and 230:

Technical data XB 9 EC-Type Examina

- Page 231 and 232:

Ordering details SM 87 with eXLink

- Page 233 and 234:

Ordering details XB 11 with eXLink

- Page 235 and 236:

Ordering details I Ex-10/15 Joule f

- Page 237 and 238:

Ordering details I Ex-15 joule flas

- Page 239 and 240:

Ordering details I Ex-21 joule flas

- Page 241 and 242:

Ordering details I Ex-21 joule flas

- Page 243 and 244:

Technical data TH 12 Marking to 94/

- Page 245 and 246:

COOPER CROUSE-HINDS GMBH 5.37 1 2 3

- Page 247 and 248:

Ordering details Ordering options*

- Page 249 and 250:

Ordering details I Ex-10 W steady f

- Page 251 and 252:

Ordering details I Ex-100 W steady

- Page 253 and 254:

Ordering details I Ex-100 W steady

- Page 255 and 256:

Ordering details Ordering options*

- Page 257 and 258:

COOPER CROUSE-HINDS GMBH 5.49 1 2 3

- Page 259 and 260:

Technical data DB 6 Marking to 94/9

- Page 261 and 262:

Ordering details Ordering options*

- Page 263 and 264:

Ordering details DB 3 with eXLink I

- Page 265 and 266:

Ordering options* I Ex-110 dB(A) vo

- Page 267 and 268:

Technical data DB 7 Marking to 94/9

- Page 269 and 270:

Technical data DB 10 Marking to 94/

- Page 271 and 272:

Ordering details I Ex-8/25 watt spe

- Page 273 and 274:

Ordering details I Ex-25/30 watt sp

- Page 275 and 276:

Technical data DB 19 Marking to 94/

- Page 277 and 278:

Technical data HD 1 Marking to 94/9

- Page 279 and 280:

ELECTRICAL CONNECTIVITY EXLINK 4-PO

- Page 281 and 282:

What is eXLink? I What is eXLink? I

- Page 283 and 284:

Function The self-cleaning Ex-e mul

- Page 285 and 286:

Technical data eXLink 4-pole / 4-po

- Page 287 and 288:

For customers who wants to configur

- Page 289 and 290:

I eXLink 4-pole + PE I with locking

- Page 291 and 292:

I eXLink 4-pole + PE I with locking

- Page 293 and 294:

Ordering key eXLink receptacle 4-po

- Page 295 and 296:

Ordering key eXLink inlet 4-pole +

- Page 297 and 298:

Ordering key eXLink inlet 4-pole +

- Page 299 and 300:

Ordering key eXLink plug/coupler fo

- Page 301 and 302:

Dimension drawing eXLink Plug metal

- Page 303 and 304:

Innovative connectors for Ethernet

- Page 305 and 306:

Technical data eXLink USB 4-pole I

- Page 307 and 308:

Technical data eXLink 6+1-pole / 7-

- Page 309 and 310:

For customers who wants to configur

- Page 311 and 312:

Ordering key eXLink coupler 6+1-pol

- Page 313 and 314:

Ordering key eXLink inlet 6+1-pole/

- Page 315 and 316:

Ordering key eXLink plug/coupler fo

- Page 317 and 318:

Dimension drawings eXLink 6+1-pole

- Page 319 and 320:

Y-junction-box 2 x cable glands Inl

- Page 321 and 322:

1. Pole No. 5 = 4-pole 6 = 4-pole +

- Page 323 and 324:

COOPER CROUSE-HINDS GMBH 6.45 1 2 3

- Page 325 and 326:

Technical data Type 791 01 ⎮ Type

- Page 327 and 328:

Ordering details I Explosion protec

- Page 329 and 330:

COOPER CROUSE-HINDS GMBH 6.51 1 2 3

- Page 331 and 332:

Technical data Model ExTerm Marking

- Page 333 and 334:

Ordering details I Model ExTerm - 2

- Page 335 and 336:

Internal wiring / Dimension drawing

- Page 337 and 338:

CEE plugs and receptacles A first s

- Page 339 and 340:

Technical data Ex-transformer plug

- Page 341 and 342:

Ordering details I 16A 2-pole up to

- Page 343 and 344:

Ordering details I 16A 3-pole, 4-po

- Page 345 and 346:

I 16A 3-pole, 4-pole and 5-pole up

- Page 347 and 348:

Ordering details I 32A 4-pole up to

- Page 349 and 350:

I 32A 4-pole up to 690 V I I 32A 5-

- Page 351 and 352:

Dimension drawing Transformer plug

- Page 353 and 354:

Ordering details I 63 A 4- and 5-po

- Page 355 and 356:

Technical data Ex-plugs and recepta

- Page 357 and 358:

Dimension drawing ⎮ Wiring diagra

- Page 359 and 360:

Ordering details Type h Cable entry

- Page 361 and 362:

I 20A 7-pole up to 500 V I Wall soc

- Page 363 and 364:

Technical data Ex-protected plug an

- Page 365 and 366:

Technical data I Zone 2: 16A 3-pole

- Page 367 and 368:

I Zone 2: 16A 3-pole, 4-pole and 5-

- Page 369 and 370:

Technical data I Zone 2: 32A 4-pole

- Page 371 and 372:

I Zone 2: 32A 4-pole and 5-pole up

- Page 373 and 374:

Technical data Ex-plugs and recepta

- Page 375 and 376:

Dimension drawing ⎮ Wiring diagra

- Page 377 and 378:

Ordering details I Zone 2: 125A 4-

- Page 379 and 380:

COOPER CROUSE-HINDS GMBH 6.101 1 2

- Page 381 and 382:

Technical data I Industrial use: 16

- Page 383 and 384:

I Industrial use: 16A 3-pole, 4-pol

- Page 385 and 386:

Technical data I Industrial use: 32

- Page 387 and 388:

I Industrial use: 32A 4-pole and 5-

- Page 389 and 390:

Technical data I Industrial use: 63

- Page 391 and 392:

I Industrial use: 63A 4-pole and 5-

- Page 393 and 394:

Ordering details I Industrial use:

- Page 395 and 396:

COOPER CROUSE-HINDS GMBH 6.117 1 2

- Page 397 and 398:

Technical data I Ex-Repair- and Mai

- Page 399 and 400:

I Ex-Repair- and Maintenance: 16A 3

- Page 401 and 402:

Ordering details I Ex-Repair- and M

- Page 403 and 404:

Ordering details I Ex-Repair- and M

- Page 405 and 406:

Technical data Repair receptacle di

- Page 407 and 408:

Technical data 16A 3-pole ⎮ 16A 5

- Page 409 and 410:

Technical data I Ex-Cable reel: 16A

- Page 411 and 412:

6.134 EX-PROTECTED PORTABLE POWER S

- Page 413 and 414:

I Ex-protected portable power suppl

- Page 415 and 416:

I Ex-protected portable power suppl

- Page 417 and 418:

I Ex-protected portable power suppl

- Page 419 and 420:

I Ex-protected portable power suppl

- Page 421 and 422:

I Ex-Terminal and Junction boxes I

- Page 423 and 424:

7.4 E X - J U N C T I O N B O X Pla

- Page 425 and 426:

I Ex-junction boxes 791 I GHG 791 0

- Page 427 and 428:

7.8 E X - J U N C T I O N B O X E S

- Page 429 and 430:

7.10 U N I V E R S A L T E R M I N

- Page 431 and 432:

I Ex-e/Ex-i terminal box I GHG 791

- Page 433 and 434:

I Ex-e/Ex-i terminal box I GHG 791

- Page 435 and 436:

I Ex-e/Ex-i terminal box I GHG 731

- Page 437 and 438:

I Ex-e/Ex-i terminal box I GHG 721

- Page 439 and 440:

I Ex-e/Ex-i terminal box I GHG 744

- Page 441 and 442:

I Ex-e/Ex-i terminal box I GHG 744

- Page 443 and 444:

I Ex-e/Ex-i terminal box I Ordering

- Page 445 and 446:

7.26 E X - T E R M I N A L B O X E

- Page 447 and 448:

I Ex-e/Ex-i terminal box I GHG 793

- Page 449 and 450:

I Ex-e/Ex-i terminal box I GHG 723

- Page 451 and 452:

7.32 E X - T E R M I N A L B O X E

- Page 453 and 454:

I Ex-d terminal box I Type C30 Type

- Page 455 and 456:

7.36 E X - T E R M I N A L E N C L

- Page 457 and 458:

7.38 E X - T E R M I N A L E N C L

- Page 459 and 460:

I Ex-e terminal enclosures I NEXT O

- Page 461 and 462:

I Ex-e terminal enclosures I NEXT O

- Page 463 and 464:

I Ex-e terminal enclosures I NEXT O

- Page 465 and 466:

I Ex-e terminal enclosures I NEXT O

- Page 467 and 468:

7.48 E X - T E R M I N A L E N C L

- Page 469 and 470:

I Ex-e/Ex-i terminal enclosures I 1

- Page 471 and 472:

I Ex-e/Ex-i terminal enclosures I E

- Page 473 and 474:

I Ex-e/Ex-i terminal enclosures I E

- Page 475 and 476:

I Ex-e/Ex-i terminal enclosures I E

- Page 477 and 478:

I Ex-e/Ex-i terminal enclosures I E

- Page 479 and 480:

I Ex-e/Ex-i terminal enclosures I E

- Page 481 and 482:

7.62 E X - T E R M I N A L E N C L

- Page 483 and 484:

I Ex-e Terminal enclosures I STB ST

- Page 485 and 486:

I Ex-e Terminal enclosures I STB Or

- Page 487 and 488:

I Ex-e Terminal enclosures I STB Or

- Page 489 and 490:

I Ex-e/Ex-i Terminal box I Type 744

- Page 491 and 492:

7.72 EX-INTERMEDIATE MOTOR TERMINAL

- Page 493 and 494:

I Ex-Intermediate motor terminal bo

- Page 495 and 496:

I Ex-Intermediate motor terminal bo

- Page 497 and 498:

7.78 FIXING MATERIALS AND ACCESSORI

- Page 499 and 500:

I Fitting materials and accessories

- Page 501 and 502:

I Fitting materials and accessories

- Page 503 and 504:

8.2 E X - C A B L E G L A N D S Pla

- Page 505 and 506:

I Ex-cable glands I Cable gland for

- Page 507 and 508:

I Ex-cable glands I Cable gland Scr

- Page 509 and 510:

I Ex-cable glands I Drainage plug B

- Page 511 and 512:

8.10 E X - C A B L E G L A N D S Me

- Page 513 and 514:

I Ex-cable glands I ADE 1F ISO Orde

- Page 515 and 516:

I Ex-cable glands I ADE 4F ISO Orde

- Page 517 and 518:

I Ex-cable glands I Earthing washer

- Page 519 and 520:

I Ex-cable glands I Gasket Accessor

- Page 521 and 522:

I Ex-cable glands I Shroud Accessor

- Page 523 and 524:

I Ex-cable glands I Accessories for

- Page 525 and 526:

I Ex-cable glands I Type ADL 1F Ord

- Page 527 and 528:

I Ex-cable glands I Type ADL 4F Ord

- Page 529 and 530:

I Ex-cable glands I Earth tag Lock

- Page 531 and 532:

I Ex-cable glands I Reducing rings

- Page 533 and 534:

I Ex-cable glands I Screw plugs Ord

- Page 535 and 536:

8.34 COOPER CROUSE-HINDS GMBH

- Page 537 and 538:

I Ex-control units and control stat

- Page 539 and 540:

9.4 E X - I N S T A L L A T I O N S

- Page 541 and 542:

9.6 E X - C O N T R O L S T A T I O

- Page 543 and 544:

I Ex-control stations I Type 411 81

- Page 545 and 546:

I Ex-control stations I Type 411 83

- Page 547 and 548:

I Ex-control stations I Accessories

- Page 549 and 550:

I Ex-control stations I Type 432...

- Page 551 and 552:

I Ex-control stations I Type 432...

- Page 553 and 554:

I Ex-control stations I Type 434...

- Page 555 and 556:

9.20 E X - C O N T R O L S T A T I

- Page 557 and 558:

I Ex-control stations I Type 413 84

- Page 559 and 560:

I Ex-control stations I Measuring A

- Page 561 and 562:

9.26 E X - C O N T R O L S T A T I

- Page 563 and 564:

I Ex-control stations I Type 414 81

- Page 565 and 566:

I Ex-control stations I Type 414 81

- Page 567 and 568:

9.32 E X - C O N T R O L S T A T I

- Page 569 and 570:

I Order Code for Individual Control

- Page 571 and 572:

I Ex-control stations I Type 411 81

- Page 573 and 574:

I Ex-control stations I Mounting ar

- Page 575 and 576:

I Ex-control stations I Type 413 84

- Page 577 and 578:

I Ex-control stations I Type 444 23

- Page 579 and 580:

I Ex-control stations I Type 444 23

- Page 581 and 582:

I Ex-control stations I Type 443 34

- Page 583 and 584:

I Ex-control stations I Type 444 33

- Page 585 and 586:

I Ex-control stations I Type 444 33

- Page 587 and 588:

I Built-in Components I DRT 1 x 2-p

- Page 589 and 590:

I Built-in Components I DRT 1 x 2-p

- Page 591 and 592:

I Built-in Components I SLT 1 x 2-p

- Page 593 and 594:

I Built-in Components I SLS 1 x 2-p

- Page 595 and 596:

I Built-in Components I SGTE 1 x 2-

- Page 597 and 598:

I Built-in Components I Ordering co

- Page 599 and 600:

I Built-in Components I SCT 1 x 2-p

- Page 601 and 602:

I Built-in Components I SCT 1 x 2-p

- Page 603 and 604:

I Built-in Components I Potentiomet

- Page 605 and 606:

I Built-in Components I Technical d

- Page 607 and 608:

I Built-in Components I Technical d

- Page 609 and 610:

I Built-in Components I Ex 23 Ex 29

- Page 611 and 612:

I Built-in Components I MKX 4 UT4 U

- Page 613 and 614:

I Built-in Components I Metal flang

- Page 615 and 616:

9.80 E X - C O N T R O L A N D S I

- Page 617 and 618:

I Ex-Control and signal units for p

- Page 619 and 620:

Dimension drawing 68 (Double-)pushb

- Page 621 and 622:

I Ex-Control and signal units for p

- Page 623 and 624:

I Ex-Control and signal units for p

- Page 625 and 626:

Key-operated pushbutton Dimension d

- Page 627 and 628:

I Ex-Control and signal units for p

- Page 629 and 630:

Mushroom-h.p.-button Mushroom-h.p.-

- Page 631 and 632:

I Ex-Control and signal units for p

- Page 633 and 634:

I Ex-Control and signal units for p

- Page 635 and 636:

Control switch GHG 249 Example for

- Page 637 and 638:

I Ex-Control and signal units for p

- Page 639 and 640:

Signal lamp Ordering code for Compo

- Page 641 and 642:

I Ex-Control and signal units I Mea

- Page 643 and 644:

I Accessories I Interchangeable AM7

- Page 645 and 646:

I Accessories I Flap (with O-activa

- Page 647 and 648:

9.112 E X - C O N T R O L S W I T C

- Page 649 and 650:

I Ex-Control switches I GHG 292 GHG

- Page 651 and 652:

I Ex-Control switches I GHG 292 GHG

- Page 653 and 654:

9.118 E X - C O N T R O L S W I T C

- Page 655 and 656:

I Ex-Control switches I GHG 294 GHG

- Page 657 and 658:

I Ex-Control switches I GHG 294 GHG

- Page 659 and 660:

9.124 L I G H T A L L O Y C O N T R

- Page 661 and 662:

9.126 COOPER CROUSE-HINDS GMBH

- Page 663 and 664:

I Ex-Safety and main current switch

- Page 665 and 666:

10.4 E X - S A F E T Y S W I T C H

- Page 667 and 668:

I Ex-Safety switches I Ordering det

- Page 669 and 670:

I Ex-Safety switches I Ordering det

- Page 671 and 672:

I Ex-Safety switches I Technical da

- Page 673 and 674:

Dimension drawing 225 X197 I Ex-Saf

- Page 675 and 676:

I Ex-Safety switches I Ordering det

- Page 677 and 678:

I Ex-Safety switches I Ordering det

- Page 679 and 680:

I Ex-Safety switches I Technical da

- Page 681 and 682:

I Ex-Safety switches I Technical da

- Page 683 and 684:

I Ex-Safety switches I Technical da

- Page 685 and 686:

I Ex-Safety switches I Technical da

- Page 687 and 688:

I Ex-Safety switches I 3-pole Techn

- Page 689 and 690:

I Ex-Safety switches I 3-pole, 20 A

- Page 691 and 692:

I Ex-Safety switches I 3-pole, 40 A

- Page 693 and 694:

I Ex-Safety switches I 3-pole, 80 A

- Page 695 and 696:

10.34 I N D U S T R I A L S A F E T

- Page 697 and 698:

I Industrial safety switches I Orde

- Page 699 and 700:

I Industrial safety switches I Orde

- Page 701 and 702:

I Industrial safety switches I Tech

- Page 703 and 704:

I Industrial safety switches I 3-po

- Page 705 and 706:

I Industrial safety switches I Orde

- Page 707 and 708:

I Industrial safety switches I Orde

- Page 709 and 710:

I Industrial safety switches I Tech

- Page 711 and 712:

I Industrial safety switches I 3-po

- Page 713 and 714:

I Industrial safety switches I 3-/6

- Page 715 and 716:

I Industrial safety switches I Orde

- Page 717 and 718:

I Industrial safety switches I Orde

- Page 719 and 720:

10.58 E X - M A I N C U R R E N T S

- Page 721 and 722:

I Ex-Main current switches I 3-pole

- Page 723 and 724:

I Ex-Main current switches I 3-pole

- Page 725 and 726:

I Ex-Main current switches I GHG 26

- Page 727 and 728:

I Ex-Main current switches I GHG 26

- Page 729 and 730:

I Ex-Main current switches I 6-pole

- Page 731 and 732:

10.70 E X - P O W E R C I R C U I T

- Page 733 and 734:

I Ex-Main circuit breaker I EXKO 73

- Page 735 and 736:

I Ex-Main circuit breaker I EXKO 73

- Page 737 and 738:

I Ex-Main circuit breaker I EXKO 73

- Page 739 and 740:

I Ex-Main circuit breaker I EXKO 73

- Page 741 and 742:

I Ex-Main circuit breaker I EXKO 73

- Page 743 and 744:

I Ex-Main circuit breaker I EXKO 73

- Page 745 and 746:

10.84 E X - M A N U A L M O T O R S

- Page 747 and 748:

I Ex-Manual motor starter I GHG 635

- Page 749 and 750:

I Ex-Manual motor starter I GHG 635

- Page 751 and 752:

I Ex-Manual motor starter I Accesso

- Page 753 and 754:

EX-CONTROL AND DISTRIBUTION SYSTEMS

- Page 755 and 756:

I Ex-Control and distribution syste

- Page 757 and 758:

I Ex-Control and distribution syste

- Page 759 and 760:

Technical data MCB distribution for

- Page 761 and 762:

Dimension drawing lighting distribu

- Page 763 and 764:

Dimension drawing ⎮ Wiring diagra

- Page 765 and 766:

Technical data MCB distribution for

- Page 767 and 768:

Dimension drawing lighting distribu

- Page 769 and 770:

1. mounting space height 190 mm 2.

- Page 771 and 772:

I Ex-d-Built-in components I Size 4

- Page 773 and 774:

I Ex-d-Built-in components I Size 4

- Page 775 and 776:

t (sec.) I Ex-d-Built-in components

- Page 777 and 778:

Ex-Built-in components MCB 0.5 A to

- Page 779 and 780:

Technical data I Ex-d-Built-in comp

- Page 781 and 782:

Dimension drawing ⎮ Termination d

- Page 783 and 784:

Ordering details NH 00 Main fuse up

- Page 785 and 786:

Ordering details Main switch up to

- Page 787 and 788:

Ex-Built-in components Air-break co

- Page 789 and 790:

Technical data Motor starter for di

- Page 791 and 792:

Dimension drawing ⎮ Main contacts

- Page 793 and 794:

Ex-Built-in components Installation

- Page 795 and 796:

Ex-Built-in components Installation

- Page 797 and 798:

Dimension drawing 130 X 118 Module

- Page 799 and 800:

Ordering details I Ex-d-Built-in co

- Page 801 and 802:

Ex-Built-in components Manual motor

- Page 803 and 804:

Technical data Thermal overcurrent

- Page 805 and 806:

Technical data Overvoltage arrester

- Page 807 and 808:

Technical data Star-delta timer rel

- Page 809 and 810:

Dimension drawing ⎮ Termination d

- Page 811 and 812:

Dimension drawing Ex-e Trafo B1 B H

- Page 813 and 814:

I Ex-e-Empty enclosures in plastic

- Page 815 and 816:

I Ex-e-Empty enclosures in stainles

- Page 817 and 818:

Customised enclosure, covered by Ty

- Page 819 and 820:

Technical data Ex-Key operated push

- Page 821 and 822:

SGT 1 x 4-pole Technical data I Ex

- Page 823 and 824:

Technical data Ex-Signal lamp SIL M

- Page 825 and 826:

COOPER CROUSE-HINDS GMBH 11.73 1 2

- Page 827 and 828:

Size 11 Technical data Size 9 Ex d

- Page 829 and 830:

Signal lamp Technical data Key oper

- Page 831 and 832:

COOPER CROUSE-HINDS GMBH 11.79 1 2

- Page 833 and 834:

The distributions and built-in comp

- Page 835 and 836:

Ordering details I Ex-Control and d

- Page 837 and 838:

Wiring diagram ⎮ Dimension drawin

- Page 839 and 840:

I Built-in components I Pushbutton

- Page 841 and 842:

Ordering details I Built-in compone

- Page 843 and 844:

Ordering details I Built-in compone

- Page 845 and 846:

I Ex-Control and distribution syste

- Page 847 and 848:

I Ex-Control and distribution syste

- Page 849 and 850:

I Ex-Control and distribution syste

- Page 851 and 852:

Dimension drawing Size 1 Size 2 Siz

- Page 853 and 854:

Dimension drawing B GUB 30 A C F E

- Page 855 and 856:

Technical data Mushroom-h.p.-button

- Page 857 and 858:

Technical data Ex-Control and signa

- Page 859 and 860:

COOPER CROUSE-HINDS GMBH 11.107 1 2

- Page 861 and 862:

I Keyword register (In alphabetical

- Page 863 and 864:

I Keyword register (In alphabetical

- Page 865 and 866:

I Keyword register (Chapter in alph

- Page 867 and 868:

I Keyword register (Chapter in alph

- Page 869 and 870:

I Index of order code I Order No. P

- Page 871 and 872:

I Index of order code I Order No. P

- Page 873 and 874:

I Index of order code I Order No. P

- Page 875 and 876:

I Index of order code I Order No. P

- Page 877 and 878:

I Index of order code I Order No. P

- Page 879 and 880:

I Index of order code I Order No. P

- Page 881 and 882:

I Index of order code I Order No. P

- Page 883 and 884:

I Index of order code I Order No. P

- Page 885 and 886:

I Index of order code I Order No. P

- Page 887 and 888:

I Index of order code I Order No. P

- Page 889:

I Index of order code I Order No. P