Spectral Optimization of the Suspension System of High-speed Trains

Spectral Optimization of the Suspension System of High-speed Trains

Spectral Optimization of the Suspension System of High-speed Trains

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

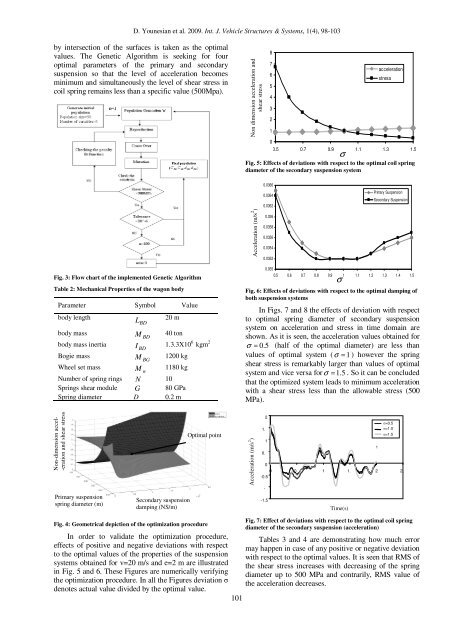

D. Younesian et al. 2009. Int. J. Vehicle Structures & <strong>System</strong>s, 1(4), 98-103<br />

by intersection <strong>of</strong> <strong>the</strong> surfaces is taken as <strong>the</strong> optimal<br />

values. The Genetic Algorithm is seeking for four<br />

optimal parameters <strong>of</strong> <strong>the</strong> primary and secondary<br />

suspension so that <strong>the</strong> level <strong>of</strong> acceleration becomes<br />

minimum and simultaneously <strong>the</strong> level <strong>of</strong> shear stress in<br />

coil spring remains less than a specific value (500Mpa).<br />

Fig. 3: Flow chart <strong>of</strong> <strong>the</strong> implemented Genetic Algorithm<br />

Table 2: Mechanical Properties <strong>of</strong> <strong>the</strong> wagon body<br />

Parameter Symbol Value<br />

body length<br />

body mass<br />

body mass inertia<br />

L BD<br />

20 m<br />

M 40 ton<br />

BD<br />

I 1.3.3X10<br />

BD<br />

6 kgm 2<br />

Bogie mass<br />

M BG<br />

1200 kg<br />

Wheel set mass M w<br />

1180 kg<br />

Number <strong>of</strong> spring rings N 10<br />

Springs shear module G 80 GPa<br />

Spring diameter D 0.2 m<br />

Non-dimension accel-<br />

-eration and shear stress<br />

Primary suspension<br />

spring diameter (m)<br />

Secondary suspension<br />

damping (NS/m)<br />

Optimal point<br />

Fig. 4: Geometrical depiction <strong>of</strong> <strong>the</strong> optimization procedure<br />

In order to validate <strong>the</strong> optimization procedure,<br />

effects <strong>of</strong> positive and negative deviations with respect<br />

to <strong>the</strong> optimal values <strong>of</strong> <strong>the</strong> properties <strong>of</strong> <strong>the</strong> suspension<br />

systems obtained for v=20 m/s and e=2 m are illustrated<br />

in Fig. 5 and 6. These Figures are numerically verifying<br />

<strong>the</strong> optimization procedure. In all <strong>the</strong> Figures deviation σ<br />

denotes actual value divided by <strong>the</strong> optimal value.<br />

101<br />

Non dimension acceleration and<br />

shear stress<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

acceleration<br />

stress<br />

0<br />

0.5 0.7 0.9 1.1 1.3 1.5<br />

Fig. 5: Effects <strong>of</strong> deviations with respect to <strong>the</strong> optimal coil spring<br />

diameter <strong>of</strong> <strong>the</strong> secondary suspension system<br />

Acceleration (m/s 2 )<br />

0.0366<br />

0.0364<br />

0.0362<br />

0.036<br />

0.0358<br />

0.0356<br />

0.0354<br />

0.0352<br />

Primary <strong>Suspension</strong><br />

Secondary <strong>Suspension</strong><br />

0.035<br />

0.5 0.6 0.7 0.8 0.9 1 1.1 1.2 1.3 1.4 1.5<br />

Fig. 6: Effects <strong>of</strong> deviations with respect to <strong>the</strong> optimal damping <strong>of</strong><br />

both suspension systems<br />

In Figs. 7 and 8 <strong>the</strong> effects <strong>of</strong> deviation with respect<br />

to optimal spring diameter <strong>of</strong> secondary suspension<br />

system on acceleration and stress in time domain are<br />

shown. As it is seen, <strong>the</strong> acceleration values obtained for<br />

σ = 0.<br />

5 (half <strong>of</strong> <strong>the</strong> optimal diameter) are less than<br />

values <strong>of</strong> optimal system ( σ = 1 ) however <strong>the</strong> spring<br />

shear stress is remarkably larger than values <strong>of</strong> optimal<br />

system and vice versa for σ = 1.<br />

5 . So it can be concluded<br />

that <strong>the</strong> optimized system leads to minimum acceleration<br />

with a shear stress less than <strong>the</strong> allowable stress (500<br />

MPa).<br />

Acceleration (m/s 2 )<br />

1.<br />

0.<br />

0<br />

0 0. 1 1. 2 2.<br />

-0.5<br />

-<br />

2<br />

1<br />

-1.5<br />

Time(s)<br />

Fig. 7: Effect <strong>of</strong> deviations with respect to <strong>the</strong> optimal coil spring<br />

diameter <strong>of</strong> <strong>the</strong> secondary suspension (acceleration)<br />

Tables 3 and 4 are demonstrating how much error<br />

may happen in case <strong>of</strong> any positive or negative deviation<br />

with respect to <strong>the</strong> optimal values. It is seen that RMS <strong>of</strong><br />

<strong>the</strong> shear stress increases with decreasing <strong>of</strong> <strong>the</strong> spring<br />

diameter up to 500 MPa and contrarily, RMS value <strong>of</strong><br />

<strong>the</strong> acceleration decreases.<br />

σ<br />

σ<br />

1<br />

σ=0.5<br />

σ=1.0<br />

σ=1.5