Strategies to Control Salmonella in poultry Farms and ... - cid lines

Strategies to Control Salmonella in poultry Farms and ... - cid lines

Strategies to Control Salmonella in poultry Farms and ... - cid lines

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Strategies</strong> <strong>to</strong> <strong>Control</strong> <strong>Salmonella</strong> <strong>in</strong> <strong>poultry</strong><br />

<strong>Farms</strong> <strong>and</strong> Process<strong>in</strong>g Plants<br />

Poultry is considered one of the most important <strong>Salmonella</strong> reservoirs, it<br />

has been public health concern over the past 100 years <strong>and</strong> cont<strong>in</strong>ues <strong>to</strong> be<br />

a major food borne pathogen effect<strong>in</strong>g humans.<br />

<strong>Strategies</strong> <strong>to</strong> prevent transmission of salmonella <strong>to</strong> humans should focus on<br />

the whole production cha<strong>in</strong> of broiler meat <strong>and</strong> on the subsequent s<strong>to</strong>rage<br />

<strong>and</strong> h<strong>and</strong>l<strong>in</strong>g of meat, thus from FARM TO FORK<br />

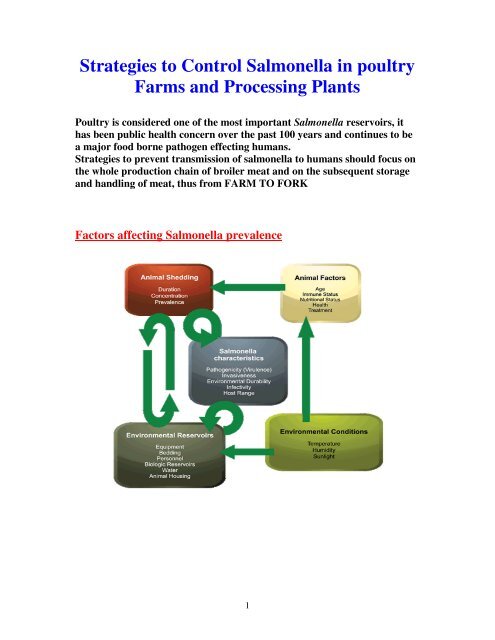

Fac<strong>to</strong>rs affect<strong>in</strong>g <strong>Salmonella</strong> prevalence<br />

1

<strong>Salmonella</strong> can be <strong>in</strong>troduced on the broiler farm by:<br />

o Vehicles<br />

o People<br />

o Cloth<strong>in</strong>g<br />

o Footwear<br />

o Equipment<br />

o Utensils<br />

o Water<br />

o Feed<br />

o Feathers<br />

o Carcass of dead birds<br />

o Litter<br />

o Insects<br />

o Rodents<br />

o Wild birds<br />

o Pets<br />

Salmonelaa control strategies <strong>in</strong> broilers are the follow<strong>in</strong>g:<br />

• Pre-harvest phase (breed<strong>in</strong>g farms <strong>and</strong> broiler farms)<br />

• Harvest phase (catch<strong>in</strong>g <strong>and</strong> transport)<br />

• Post harvest phase (at the slaughter house, at retail <strong>and</strong> <strong>in</strong> the consumer’s kitchen or<br />

restaurants)<br />

<strong>Salmonella</strong> control <strong>in</strong> the Production phase (Pre-Harvest)<br />

Biosecurity <strong>and</strong> hygiene Measures<br />

General hygienic <strong>and</strong> bioscurity measures should be part of the overall management plan of<br />

<strong>poultry</strong> produc<strong>in</strong>g <strong>in</strong>tegra<strong>to</strong>rs <strong>and</strong> companies. These measures are of utmost importance <strong>to</strong><br />

control <strong>in</strong>fections <strong>and</strong> all other measures lose their efficacy when the overall biosecurity plan<br />

is not function<strong>in</strong>g.<br />

• Introduc<strong>in</strong>g salmonella free birds is the most important start<strong>in</strong>g po<strong>in</strong>t <strong>to</strong> prevent<br />

<strong>in</strong>fections<br />

• Incom<strong>in</strong>g birds should be of good health status<br />

• Restricted access is an important issue<br />

• Shower <strong>and</strong> chang<strong>in</strong>g room facilities for workers <strong>and</strong> visi<strong>to</strong>rs<br />

• Limit the entry of nonessential visi<strong>to</strong>rs<br />

Only essential visi<strong>to</strong>rs, wear<strong>in</strong>g protective cloth<strong>in</strong>g (coveralls, gloves, mask, etc) <strong>and</strong><br />

dis<strong>in</strong>fected boots should be allowed on-farm.<br />

Simple measures such as foot baths, wheel baths, h<strong>and</strong> hygiene <strong>and</strong> m<strong>in</strong>imiz<strong>in</strong>g<br />

movement between different animal houses need <strong>to</strong> be implemented properly.<br />

2

Build<strong>in</strong>gs, surfaces, fans, cool<strong>in</strong>g pads <strong>and</strong> equipments should be cleaned <strong>and</strong> dis<strong>in</strong>fected<br />

properly.<br />

Establish clear zone free from vegetation around build<strong>in</strong>g <strong>to</strong> discourage rodent <strong>and</strong> <strong>in</strong>sect<br />

traffic <strong>in</strong> the build<strong>in</strong>g<br />

In an overall management plan, clean<strong>in</strong>g <strong>and</strong> dis<strong>in</strong>fection after each production cycle<br />

must be rout<strong>in</strong>ely performed as described below (CID LINES SANITATION PROGRAM)<br />

5 basic pr<strong>in</strong>ciples for <strong>Salmonella</strong> control<br />

1. <strong>Salmonella</strong> free day-old-chicks (parent s<strong>to</strong>ck, hatchery, transport)<br />

<strong>Salmonella</strong> is transmitted vertically (via the egg from parent <strong>to</strong> chick), thus an obvious<br />

start<strong>in</strong>g po<strong>in</strong>t for any <strong>Salmonella</strong> control strategy is <strong>to</strong> ensure <strong>poultry</strong> breed<strong>in</strong>g flocks<br />

are kept <strong>Salmonella</strong> free<br />

2. Rear<strong>in</strong>g chicks <strong>in</strong> <strong>Salmonella</strong> free environment<br />

a. All-<strong>in</strong>/all-out management<br />

b. Vec<strong>to</strong>r control: Wild birds, flies <strong>and</strong> rodents<br />

c. Visi<strong>to</strong>rs<br />

d. Good clean<strong>in</strong>g <strong>and</strong> dis<strong>in</strong>fection pro<strong>to</strong>col<br />

3. <strong>Salmonella</strong> free water <strong>and</strong> feed<br />

• Pelleted feed 10 times less <strong>Salmonella</strong> than non-pelleted feed (thanks <strong>to</strong> heat<br />

treatment)<br />

• Antibiotics: can cause resistance <strong>Salmonella</strong>, affect the resistance of the animal<br />

aga<strong>in</strong>st colonization<br />

• Addition of organic a<strong>cid</strong>s enhance <strong>Salmonella</strong> destruction<br />

• Dr<strong>in</strong>k<strong>in</strong>g water sanitizer<br />

4. Regular moni<strong>to</strong>r<strong>in</strong>g of <strong>to</strong>tal production cha<strong>in</strong><br />

Accord<strong>in</strong>g European legislation the production cha<strong>in</strong> is regular moni<strong>to</strong>red by sampl<strong>in</strong>g<br />

of <strong>poultry</strong> flocks<br />

5. Immediate action when <strong>Salmonella</strong> is detected<br />

• Determ<strong>in</strong>ation of the orig<strong>in</strong> of the <strong>in</strong>fection.<br />

• Movement of <strong>poultry</strong> flocks at the end of the production cycle should only be<br />

allowed for slaughter or destruction.<br />

3

• Poultry litter/feces <strong>and</strong> other potentially contam<strong>in</strong>ated farm waste should be<br />

disposed of <strong>in</strong> a safe manner.<br />

• Particular care should be taken <strong>in</strong> clean<strong>in</strong>g <strong>and</strong> dis<strong>in</strong>fection of the <strong>poultry</strong> house<br />

<strong>and</strong> equipment.<br />

• Before res<strong>to</strong>ck<strong>in</strong>g the facility, a bacteriological exam<strong>in</strong>ation should be carried out.<br />

• Adequate time should be allowed between flocks if previous flock was<br />

<strong>Salmonella</strong>-positive<br />

• Build<strong>in</strong>gs, surfaces <strong>and</strong> equipment should be cleaned <strong>and</strong> dis<strong>in</strong>fected properly<br />

CID LINES SANITATION PROGRAM<br />

1. Dry clean<strong>in</strong>g<br />

2. Soak with water, remove most of dirt<br />

3. Clean water system with CID 2000<br />

4. Clean the:<br />

a. Ventilation fans, air <strong>in</strong>lets <strong>and</strong> cool<strong>in</strong>g Pads<br />

b. Ceil<strong>in</strong>gs<br />

c. Outside water system <strong>and</strong> out/<strong>in</strong>side of feed<strong>in</strong>g system<br />

d. Floors <strong>and</strong> walls<br />

e. Sanitary <strong>and</strong> s<strong>to</strong>rage rooms<br />

f. Environment of the <strong>poultry</strong> house <strong>in</strong>clud<strong>in</strong>g silos<br />

With CID LINES alkal<strong>in</strong>e foam<strong>in</strong>g detergents at the correct dilution <strong>and</strong> contact time<br />

(see label).<br />

5. R<strong>in</strong>se with water <strong>and</strong> let it dry<br />

6. Dis<strong>in</strong>fect with VIROCID (Spray, foam or fog)<br />

There are a lot of critical po<strong>in</strong>ts that often forgotten dur<strong>in</strong>g the clean<strong>in</strong>g process:<br />

i. Lights<br />

ii. Heaters<br />

iii. Water tubes<br />

iv. Cracks <strong>in</strong> the floors<br />

4

<strong>Salmonella</strong> control dur<strong>in</strong>g transport (Harvest)<br />

Feed should be withdrawn from the birds between 8-12 hours before the slaughter time <strong>to</strong><br />

reduce the amount of defecation <strong>and</strong> contam<strong>in</strong>ation of the carcass. Transpiration of a<br />

salmonella positive flock leads <strong>to</strong> contam<strong>in</strong>ation of the crates <strong>and</strong> conta<strong>in</strong>ers.<br />

Each time, after unload<strong>in</strong>g the flock; crates, conta<strong>in</strong>ers, vehicles have <strong>to</strong> be cleaned <strong>and</strong><br />

dis<strong>in</strong>fected.<br />

Clean with CID LINES alkal<strong>in</strong>e detergents (none foam<strong>in</strong>g for tunnel washers, foam<strong>in</strong>g for<br />

manual clean<strong>in</strong>g with a HP cleaner <strong>and</strong> foam lance). R<strong>in</strong>se with water <strong>and</strong> dis<strong>in</strong>fect with<br />

VIROCID.<br />

<strong>Salmonella</strong> control practices dur<strong>in</strong>g Slaughter <strong>and</strong> Process<strong>in</strong>g<br />

(post Harvest)<br />

Slaughter house is divided <strong>in</strong><strong>to</strong> two man zones:<br />

1. Dirty zone where slaughter<strong>in</strong>g, bleed<strong>in</strong>g, scald<strong>in</strong>g, defeather<strong>in</strong>g <strong>and</strong> evisceration takes<br />

place<br />

2. Clean Zone where all procedures are carried out at low temperatures <strong>and</strong> under strict<br />

hyg<strong>in</strong>e controls<br />

Defeather<strong>in</strong>g, evisceration, Scald<strong>in</strong>g <strong>and</strong> chill<strong>in</strong>g are critical control po<strong>in</strong>ts at process<strong>in</strong>g<br />

stages where cross contam<strong>in</strong>ation may occur<br />

• <strong>Salmonella</strong> positive birds dur<strong>in</strong>g defeather<strong>in</strong>g <strong>and</strong> evisceration process contam<strong>in</strong>ate<br />

the carcass contam<strong>in</strong>ate the slaughter equipment cross contam<strong>in</strong>ation of the<br />

carcasses of the subsequently slaughtered flocks.<br />

• S<strong>in</strong>gle counter flow water movement <strong>and</strong> ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g the pH of scalder bath water<br />

below 6.5 by add<strong>in</strong>g CID LINES water a<strong>cid</strong>ifier will reduce microbial contam<strong>in</strong>ation<br />

both of the birds <strong>and</strong> the scald<strong>in</strong>g water<br />

• Scalder water temperature must be between 51-53 o C<br />

• <strong>Control</strong> of chill<strong>in</strong>g parameters: air temperature, air movement, relative humidity <strong>and</strong><br />

filter<strong>in</strong>g air can reduce <strong>Salmonella</strong> or other microbial growth<br />

• Us<strong>in</strong>g per acetic a<strong>cid</strong> <strong>in</strong> the water chiller with exact dosage <strong>and</strong> contact time reduces<br />

<strong>Salmonella</strong> <strong>and</strong> other microbial contam<strong>in</strong>ation on the sk<strong>in</strong>.<br />

A control Measure <strong>to</strong> reduce or elim<strong>in</strong>ate cross-contam<strong>in</strong>ation is logistic slaughter; <strong>in</strong><br />

other words, <strong>Salmonella</strong> negative flocks should be slaughtered before <strong>Salmonella</strong> positive<br />

flocks<br />

Slaughter equipments <strong>and</strong> especially killer blade, scald<strong>in</strong>g tanks, plucker <strong>and</strong> defeather<strong>in</strong>g;<br />

must be cleaned with CID LINES alkal<strong>in</strong>e Chlor<strong>in</strong>ated or Non Chlor<strong>in</strong>ated foam<strong>in</strong>g<br />

detergents, r<strong>in</strong>se with water <strong>and</strong> dis<strong>in</strong>fect with CID LINES food grade dis<strong>in</strong>fectants<br />

5

Conclusion<br />

High level of biosecurity (Clean<strong>in</strong>g <strong>and</strong> Dis<strong>in</strong>fection) will help <strong>to</strong> reduce the <strong>in</strong><strong>cid</strong>ence<br />

of diseases <strong>in</strong> <strong>poultry</strong> farms <strong>and</strong> food process<strong>in</strong>g plants; while poor levels of biosecurity, can<br />

cause disease outbreaks where <strong>to</strong>tal slaughter<strong>in</strong>g of the whole flock will be a must.<br />

So, when biosecurity measures are taken it means that the risk of reach<strong>in</strong>g <strong>Salmonella</strong> or other<br />

microorganisms <strong>to</strong> humans will be reduced <strong>to</strong> m<strong>in</strong>imum<br />

Dur<strong>in</strong>g Production phase, both hygienic measures <strong>and</strong> general farm management strategies<br />

are the most important<br />

Dur<strong>in</strong>g slaughter <strong>and</strong> process<strong>in</strong>g phase, hygienic measures <strong>and</strong> logistic slaughter<strong>in</strong>g are<br />

important <strong>to</strong>ols <strong>to</strong> <strong>Salmonella</strong> <strong>and</strong> other food borne microorganisms<br />

For more detailed <strong>in</strong>formation about <strong>Salmonella</strong> control practices contact CID LINES<br />

N.V. vatche.sagherian@<strong>cid</strong>l<strong>in</strong>es.com<br />

6