to view a PDF of the - National Maple Syrup Festival

to view a PDF of the - National Maple Syrup Festival

to view a PDF of the - National Maple Syrup Festival

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

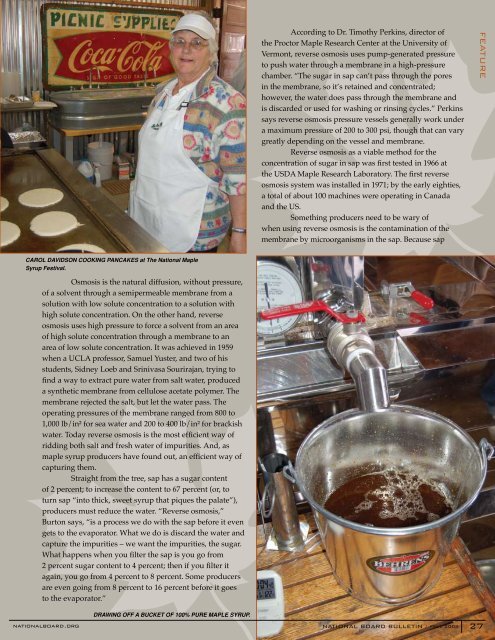

CAROL DAVIDSON COOKING PANCAKES at The <strong>National</strong> <strong>Maple</strong><br />

<strong>Syrup</strong> <strong>Festival</strong>.<br />

Osmosis is <strong>the</strong> natural diffusion, without pressure,<br />

<strong>of</strong> a solvent through a semipermeable membrane from a<br />

solution with low solute concentration <strong>to</strong> a solution with<br />

high solute concentration. On <strong>the</strong> o<strong>the</strong>r hand, reverse<br />

osmosis uses high pressure <strong>to</strong> force a solvent from an area<br />

<strong>of</strong> high solute concentration through a membrane <strong>to</strong> an<br />

area <strong>of</strong> low solute concentration. It was achieved in 1959<br />

when a UCLA pr<strong>of</strong>essor, Samuel Yuster, and two <strong>of</strong> his<br />

students, Sidney Loeb and Srinivasa Sourirajan, trying <strong>to</strong><br />

find a way <strong>to</strong> extract pure water from salt water, produced<br />

a syn<strong>the</strong>tic membrane from cellulose acetate polymer. The<br />

membrane rejected <strong>the</strong> salt, but let <strong>the</strong> water pass. The<br />

operating pressures <strong>of</strong> <strong>the</strong> membrane ranged from 800 <strong>to</strong><br />

1,000 lb/in! for sea water and 200 <strong>to</strong> 400 lb/in! for brackish<br />

water. Today reverse osmosis is <strong>the</strong> most efficient way <strong>of</strong><br />

ridding both salt and fresh water <strong>of</strong> impurities. And, as<br />

maple syrup producers have found out, an efficient way <strong>of</strong><br />

capturing <strong>the</strong>m.<br />

Straight from <strong>the</strong> tree, sap has a sugar content<br />

<strong>of</strong> 2 percent; <strong>to</strong> increase <strong>the</strong> content <strong>to</strong> 67 percent (or, <strong>to</strong><br />

turn sap “in<strong>to</strong> thick, sweet syrup that piques <strong>the</strong> palate”),<br />

producers must reduce <strong>the</strong> water. “Reverse osmosis,”<br />

Bur<strong>to</strong>n says, “is a process we do with <strong>the</strong> sap before it even<br />

gets <strong>to</strong> <strong>the</strong> evapora<strong>to</strong>r. What we do is discard <strong>the</strong> water and<br />

capture <strong>the</strong> impurities – we want <strong>the</strong> impurities, <strong>the</strong> sugar.<br />

What happens when you filter <strong>the</strong> sap is you go from<br />

2 percent sugar content <strong>to</strong> 4 percent; <strong>the</strong>n if you filter it<br />

again, you go from 4 percent <strong>to</strong> 8 percent. Some producers<br />

are even going from 8 percent <strong>to</strong> 16 percent before it goes<br />

<strong>to</strong> <strong>the</strong> evapora<strong>to</strong>r.”<br />

nationalboard.org<br />

DRAWING OFF A BUCKET OF 100% PURE MAPLE SYRUP.<br />

According <strong>to</strong> Dr. Timothy Perkins, direc<strong>to</strong>r <strong>of</strong><br />

<strong>the</strong> Proc<strong>to</strong>r <strong>Maple</strong> Research Center at <strong>the</strong> University <strong>of</strong><br />

Vermont, reverse osmosis uses pump-generated pressure<br />

<strong>to</strong> push water through a membrane in a high-pressure<br />

chamber. “The sugar in sap can’t pass through <strong>the</strong> pores<br />

in <strong>the</strong> membrane, so it’s retained and concentrated;<br />

however, <strong>the</strong> water does pass through <strong>the</strong> membrane and<br />

is discarded or used for washing or rinsing cycles.” Perkins<br />

says reverse osmosis pressure vessels generally work under<br />

a maximum pressure <strong>of</strong> 200 <strong>to</strong> 300 psi, though that can vary<br />

greatly depending on <strong>the</strong> vessel and membrane.<br />

Reverse osmosis as a viable method for <strong>the</strong><br />

concentration <strong>of</strong> sugar in sap was first tested in 1966 at<br />

<strong>the</strong> USDA <strong>Maple</strong> Research Labora<strong>to</strong>ry. The first reverse<br />

osmosis system was installed in 1971; by <strong>the</strong> early eighties,<br />

a <strong>to</strong>tal <strong>of</strong> about 100 machines were operating in Canada<br />

and <strong>the</strong> US.<br />

Something producers need <strong>to</strong> be wary <strong>of</strong><br />

when using reverse osmosis is <strong>the</strong> contamination <strong>of</strong> <strong>the</strong><br />

membrane by microorganisms in <strong>the</strong> sap. Because sap<br />

NATIONAL BOARD BULLETIN / FALL 2008<br />

t27<br />

FEATURE