Keys Mortise Through Tenon Mortised Timber King Post Collar ...

Keys Mortise Through Tenon Mortised Timber King Post Collar ...

Keys Mortise Through Tenon Mortised Timber King Post Collar ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

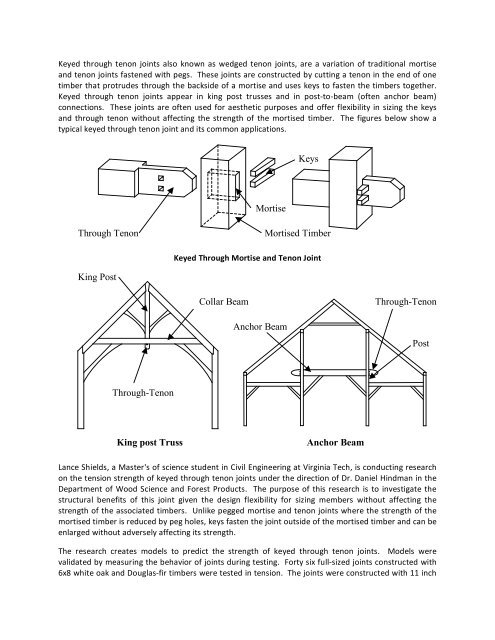

Keyed through tenon joints also known as wedged tenon joints, are a variation of traditional mortise <br />

and tenon joints fastened with pegs. These joints are constructed by cutting a tenon in the end of one <br />

timber that protrudes through the backside of a mortise and uses keys to fasten the timbers together. <br />

Keyed through tenon joints appear in king post trusses and in post‐to‐beam (often anchor beam) <br />

connections. These joints are often used for aesthetic purposes and offer flexibility in sizing the keys <br />

and through tenon without affecting the strength of the mortised timber. The figures below show a <br />

typical keyed through tenon joint and its common applications. <br />

<br />

<strong>Mortise</strong><br />

<strong>Keys</strong><br />

<strong>Through</strong> <strong>Tenon</strong> <strong>Mortise</strong>d <strong>Timber</strong><br />

<strong>King</strong> <strong>Post</strong><br />

<strong>Through</strong>-<strong>Tenon</strong><br />

Keyed <strong>Through</strong> <strong>Mortise</strong> and <strong>Tenon</strong> Joint <br />

<strong>Collar</strong> Beam <strong>Through</strong>-<strong>Tenon</strong><br />

Anchor Beam<br />

<strong>King</strong> post Truss Anchor Beam<br />

Lance Shields, a Master's of science student in Civil Engineering at Virginia Tech, is conducting research <br />

on the tension strength of keyed through tenon joints under the direction of Dr. Daniel Hindman in the <br />

Department of Wood Science and Forest Products. The purpose of this research is to investigate the <br />

structural benefits of this joint given the design flexibility for sizing members without affecting the <br />

strength of the associated timbers. Unlike pegged mortise and tenon joints where the strength of the <br />

mortised timber is reduced by peg holes, keys fasten the joint outside of the mortised timber and can be <br />

enlarged without adversely affecting its strength. <br />

The research creates models to predict the strength of keyed through tenon joints. Models were <br />

validated by measuring the behavior of joints during testing. Forty six full‐sized joints constructed with <br />

6x8 white oak and Douglas‐fir timbers were tested in tension. The joints were constructed with 11 inch <br />

<strong>Post</strong>

or four inch tenons, one or two keys, and keys of either white oak or ipe (a tropical hardwood). <br />

Currently, samples of wood cut from the joints are being tested to provide input strength values for the <br />

mathematical equations. These models will provide predicted joint strength values for comparison to <br />

the experimentally tested joint strengths for model validation. <br />

Below is a photograph of a joint tested. The joint is loaded upward in the testing machine causing <br />

withdrawal of the tenon from the mortised timber by upward movement of the machine cross‐head on <br />

the end to the tenoned timber and the holding down of the mortised timber with steel tubes and bolts. <br />

The red arrows indicate the load directions. <br />

<strong>Tenon</strong>ed <strong>Timber</strong> <br />

Steel Tube <br />

<strong>Tenon</strong> <br />

Courtesy of Lance Shields <br />

Below are photographs (courtesy of Lance Shields) of some tested joints. The first three photographs <br />

are of a Douglas‐fir joint with an 11 inch‐long tenon and two keys. The first photograph shows the joint <br />

before testing, the second photograph shows the joint in the testing machine under tension loading <br />

(notice the separation between the mortise and tenon member), and the last photograph shows the <br />

failure of keys after testing. <br />

Joint before Test Joint during Test <strong>Keys</strong> after Test (Bending & Crushing) <br />

The next three photographs show a white oak joint with a four inch‐long tenon and two keys. The first <br />

photograph shows the joint before testing, and the second and third photographs show the joint during <br />

and after testing (note the tenon relish underneath the left key). Typically, joints subject to tension <br />

tests with 11 inch tenons produce key crushing and bending failures while the joints with four inch <br />

<br />

Cross‐head <br />

<strong>Mortise</strong>d <strong>Timber</strong> <br />

Key <br />

tenons produce tenon relish failures as shown below. The use of ipe keys increased the joint strength <br />

compared to the use of white oak keys. <br />

Joint before Test Joint during Test <strong>Tenon</strong> after Test (<strong>Tenon</strong> Relish) <br />

Lance Shields first learned about timber framing in Powhatan High School under the guidance of Jim <br />

Henderson in a vocational class called Carpentry Building Trades (CBT). He also learned about Dreaming <br />

Creek <strong>Timber</strong> Frame Homes who sponsored many of the projects in the class and later worked for them <br />

during his last semester of under graduate school at Virginia Tech. Dreaming Creek <strong>Timber</strong> Frame <br />

Homes has made this research possible by providing much support and materials. <br />

<br />

<br />

For more information please contact either: <br />

<br />

Lance Shields, EIT <br />

Emial: lshie06@vt.edu <br />

<br />

Dr. Daniel Hindman, Ph.D <br />

Email: dhindman@vt.edu <br />

<br />

<br />

<br />

<br />