Automated Ingot Inspection System.pdf - DWFritz Automation

Automated Ingot Inspection System.pdf - DWFritz Automation

Automated Ingot Inspection System.pdf - DWFritz Automation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

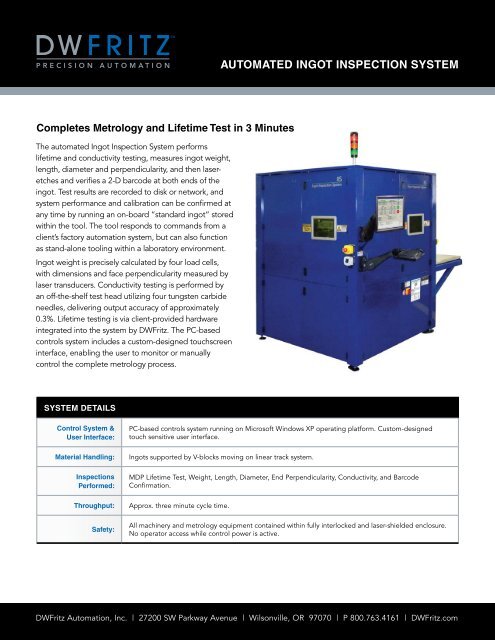

Completes metrology and Lifetime test in 3 minutes<br />

The automated <strong>Ingot</strong> <strong>Inspection</strong> <strong>System</strong> performs<br />

lifetime and conductivity testing, measures ingot weight,<br />

length, diameter and perpendicularity, and then laseretches<br />

and verifies a 2-D barcode at both ends of the<br />

ingot. Test results are recorded to disk or network, and<br />

system performance and calibration can be confirmed at<br />

any time by running an on-board “standard ingot” stored<br />

within the tool. The tool responds to commands from a<br />

client’s factory automation system, but can also function<br />

as stand-alone tooling within a laboratory environment.<br />

<strong>Ingot</strong> weight is precisely calculated by four load cells,<br />

with dimensions and face perpendicularity measured by<br />

laser transducers. Conductivity testing is performed by<br />

an off-the-shelf test head utilizing four tungsten carbide<br />

needles, delivering output accuracy of approximately<br />

0.3%. Lifetime testing is via client-provided hardware<br />

integrated into the system by <strong>DWFritz</strong>. The PC-based<br />

controls system includes a custom-designed touchscreen<br />

interface, enabling the user to monitor or manually<br />

control the complete metrology process.<br />

SYStem detAILS<br />

Control <strong>System</strong> &<br />

user Interface:<br />

AutomAted INGot INSPeCtIoN SYStem<br />

PC-based controls system running on Microsoft Windows XP operating platform. Custom-designed<br />

touch sensitive user interface.<br />

material Handling: <strong>Ingot</strong>s supported by V-blocks moving on linear track system.<br />

<strong>Inspection</strong>s<br />

Performed:<br />

MDP Lifetime Test, Weight, Length, Diameter, End Perpendicularity, Conductivity, and Barcode<br />

Confirmation.<br />

throughput: Approx. three minute cycle time.<br />

Safety:<br />

All machinery and metrology equipment contained within fully interlocked and laser-shielded enclosure.<br />

No operator access while control power is active.<br />

<strong>DWFritz</strong> <strong>Automation</strong>, Inc. | 27200 SW Parkway Avenue | Wilsonville, OR 97070 | P 800.763.4161 | <strong>DWFritz</strong>.com

measure<br />

diameter<br />

2X laser<br />

displacement<br />

transducer<br />

ingot<br />

under test<br />

linear<br />

actuator<br />

AutomAted INGot INSPeCtIoN SYStem<br />

conductivity<br />

test<br />

pallet w/4X load<br />

cell (rotates)<br />

process<br />

testing (client)<br />

barcode<br />

etch<br />

calibration<br />

ingot<br />

barcode<br />

read (n/s)<br />

<strong>DWFritz</strong> <strong>Automation</strong>, Inc. | 27200 SW Parkway Avenue | Wilsonville, OR 97070 | P 800.763.4161 | <strong>DWFritz</strong>.com<br />

© 2012 <strong>DWFritz</strong> <strong>Automation</strong> Inc. All rights reserved.