Insect Control in Stored Grain - Department of Primary Industries

Insect Control in Stored Grain - Department of Primary Industries

Insect Control in Stored Grain - Department of Primary Industries

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

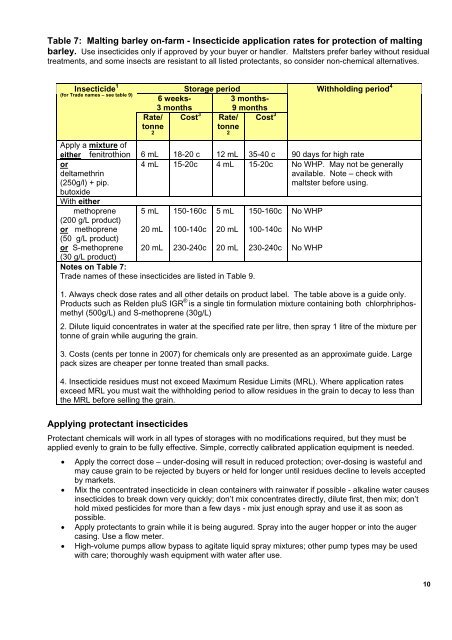

Table 7: Malt<strong>in</strong>g barley on-farm - <strong>Insect</strong>icide application rates for protection <strong>of</strong> malt<strong>in</strong>g<br />

barley. Use <strong>in</strong>secticides only if approved by your buyer or handler. Maltsters prefer barley without residual<br />

treatments, and some <strong>in</strong>sects are resistant to all listed protectants, so consider non-chemical alternatives.<br />

<strong>Insect</strong>icide 1<br />

(for Trade names – see table 9)<br />

Storage period<br />

6 weeks- 3 months-<br />

3 months<br />

9 months<br />

Rate/ Cost<br />

tonne<br />

2<br />

3 Rate/<br />

tonne<br />

2<br />

Cost 3<br />

Withhold<strong>in</strong>g period 4<br />

Apply a mixture <strong>of</strong><br />

either fenitrothion 6 mL 18-20 c 12 mL 35-40 c 90 days for high rate<br />

or<br />

4 mL 15-20c 4 mL 15-20c No WHP. May not be generally<br />

deltamethr<strong>in</strong><br />

available. Note – check with<br />

(250g/l) + pip.<br />

butoxide<br />

With either<br />

maltster before us<strong>in</strong>g.<br />

methoprene<br />

(200 g/L product)<br />

5 mL 150-160c 5 mL 150-160c No WHP<br />

or methoprene<br />

(50 g/L product)<br />

20 mL 100-140c 20 mL 100-140c No WHP<br />

or S-methoprene<br />

(30 g/L product)<br />

Notes on Table 7:<br />

20 mL 230-240c 20 mL 230-240c No WHP<br />

Trade names <strong>of</strong> these <strong>in</strong>secticides are listed <strong>in</strong> Table 9.<br />

1. Always check dose rates and all other details on product label. The table above is a guide only.<br />

Products such as Relden pluS IGR ® is a s<strong>in</strong>gle t<strong>in</strong> formulation mixture conta<strong>in</strong><strong>in</strong>g both chlorphriphosmethyl<br />

(500g/L) and S-methoprene (30g/L)<br />

2. Dilute liquid concentrates <strong>in</strong> water at the specified rate per litre, then spray 1 litre <strong>of</strong> the mixture per<br />

tonne <strong>of</strong> gra<strong>in</strong> while augur<strong>in</strong>g the gra<strong>in</strong>.<br />

3. Costs (cents per tonne <strong>in</strong> 2007) for chemicals only are presented as an approximate guide. Large<br />

pack sizes are cheaper per tonne treated than small packs.<br />

4. <strong>Insect</strong>icide residues must not exceed Maximum Residue Limits (MRL). Where application rates<br />

exceed MRL you must wait the withhold<strong>in</strong>g period to allow residues <strong>in</strong> the gra<strong>in</strong> to decay to less than<br />

the MRL before sell<strong>in</strong>g the gra<strong>in</strong>.<br />

Apply<strong>in</strong>g protectant <strong>in</strong>secticides<br />

Protectant chemicals will work <strong>in</strong> all types <strong>of</strong> storages with no modifications required, but they must be<br />

applied evenly to gra<strong>in</strong> to be fully effective. Simple, correctly calibrated application equipment is needed.<br />

• Apply the correct dose – under-dos<strong>in</strong>g will result <strong>in</strong> reduced protection; over-dos<strong>in</strong>g is wasteful and<br />

may cause gra<strong>in</strong> to be rejected by buyers or held for longer until residues decl<strong>in</strong>e to levels accepted<br />

by markets.<br />

• Mix the concentrated <strong>in</strong>secticide <strong>in</strong> clean conta<strong>in</strong>ers with ra<strong>in</strong>water if possible - alkal<strong>in</strong>e water causes<br />

<strong>in</strong>secticides to break down very quickly; don’t mix concentrates directly, dilute first, then mix; don’t<br />

hold mixed pesticides for more than a few days - mix just enough spray and use it as soon as<br />

possible.<br />

• Apply protectants to gra<strong>in</strong> while it is be<strong>in</strong>g augured. Spray <strong>in</strong>to the auger hopper or <strong>in</strong>to the auger<br />

cas<strong>in</strong>g. Use a flow meter.<br />

• High-volume pumps allow bypass to agitate liquid spray mixtures; other pump types may be used<br />

with care; thoroughly wash equipment with water after use.<br />

10