Insect Control in Stored Grain - Department of Primary Industries

Insect Control in Stored Grain - Department of Primary Industries

Insect Control in Stored Grain - Department of Primary Industries

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

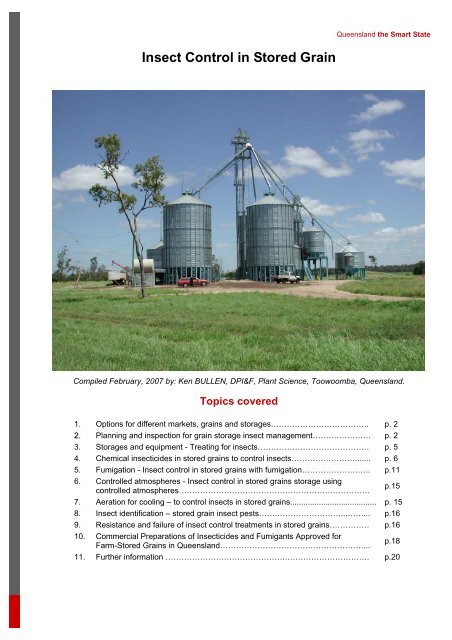

<strong>Insect</strong> <strong>Control</strong> <strong>in</strong> <strong>Stored</strong> Gra<strong>in</strong><br />

Queensland the Smart State<br />

Compiled February, 2007 by: Ken BULLEN, DPI&F, Plant Science, Toowoomba, Queensland.<br />

Topics covered<br />

1. Options for different markets, gra<strong>in</strong>s and storages………………………………. p. 2<br />

2. Plann<strong>in</strong>g and <strong>in</strong>spection for gra<strong>in</strong> storage <strong>in</strong>sect management…………………. p. 2<br />

3. Storages and equipment - Treat<strong>in</strong>g for <strong>in</strong>sects…………………………………… p. 5<br />

4. Chemical <strong>in</strong>secticides <strong>in</strong> stored gra<strong>in</strong>s to control <strong>in</strong>sects……………………....... p. 6<br />

5. Fumigation - <strong>Insect</strong> control <strong>in</strong> stored gra<strong>in</strong>s with fumigation…………………….. p.11<br />

6. <strong>Control</strong>led atmospheres - <strong>Insect</strong> control <strong>in</strong> stored gra<strong>in</strong>s storage us<strong>in</strong>g<br />

controlled atmospheres………………………………………………………………<br />

p.15<br />

7. Aeration for cool<strong>in</strong>g – to control <strong>in</strong>sects <strong>in</strong> stored gra<strong>in</strong>s....................................... p. 15<br />

8. <strong>Insect</strong> identification – stored gra<strong>in</strong> <strong>in</strong>sect pests…….……………………...……... p.16<br />

9. Resistance and failure <strong>of</strong> <strong>in</strong>sect control treatments <strong>in</strong> stored gra<strong>in</strong>s…………… p.16<br />

10. Commercial Preparations <strong>of</strong> <strong>Insect</strong>icides and Fumigants Approved for<br />

Farm-<strong>Stored</strong> Gra<strong>in</strong>s <strong>in</strong> Queensland………………………………………………...<br />

p.18<br />

11. Further <strong>in</strong>formation ……………………………………….…………………………. p.20

Key po<strong>in</strong>ts<br />

• Most markets want gra<strong>in</strong> free from <strong>in</strong>sects and some want freedom from chemical residues, so check<br />

with potential buyers before treat<strong>in</strong>g with chemicals.<br />

• Clean gra<strong>in</strong> handl<strong>in</strong>g and storage equipment and dispose <strong>of</strong>, or treat old <strong>in</strong>fested gra<strong>in</strong>.<br />

• Aeration cool<strong>in</strong>g reduces <strong>in</strong>sect breed<strong>in</strong>g activity, but does not guarantee storage pests will not be<br />

seen and may require treatment especially <strong>in</strong> the warmer period <strong>of</strong> the year.<br />

• Chemical protectant <strong>in</strong>secticide sprays are registered only for cereal gra<strong>in</strong>s, not pulses and oilseeds.<br />

• Fumigat<strong>in</strong>g with phosph<strong>in</strong>e is fully effective only <strong>in</strong> a storage that is gas-tight.<br />

Introduction<br />

If <strong>in</strong>sects <strong>in</strong> gra<strong>in</strong> are left untreated, the gra<strong>in</strong> will, be unsaleable to most buyers, be reduced to dust by the<br />

<strong>in</strong>sects feed<strong>in</strong>g on it and go mouldy because <strong>of</strong> the heat and moisture released by the <strong>in</strong>sects.<br />

Gra<strong>in</strong> <strong>in</strong>sects are present on most farms <strong>in</strong> harvest<strong>in</strong>g mach<strong>in</strong>ery, stockfeed, gra<strong>in</strong> spills, and old seed.<br />

Some <strong>of</strong> the <strong>in</strong>sects fly between farms and between storages, and others walk or are carried <strong>in</strong> handl<strong>in</strong>g<br />

equipment. Unless <strong>in</strong>sect control measures are applied, gra<strong>in</strong> quality and value is likely to be reduced.<br />

1. Options for different markets, gra<strong>in</strong>s and storages<br />

Market requirements<br />

Always check with potential markets for your gra<strong>in</strong> to ensure that they will accept the pest control methods,<br />

particularly <strong>in</strong>secticides, you <strong>in</strong>tend us<strong>in</strong>g. Gra<strong>in</strong> markets <strong>in</strong>creas<strong>in</strong>gly are demand<strong>in</strong>g freedom from live<br />

<strong>in</strong>sects and freedom from residues that result from chemical treatment <strong>of</strong> gra<strong>in</strong>.<br />

Chemical sprays are registered only for cereal gra<strong>in</strong>s. Some markets will not accept cereal gra<strong>in</strong> treated with<br />

these registered chemicals.<br />

Chemical sprays are not registered for pulses or oilseeds. Markets will not know<strong>in</strong>gly accept pulses or<br />

oilseeds contam<strong>in</strong>ated by residues <strong>of</strong> chemicals sprayed on these gra<strong>in</strong>s. Detection <strong>of</strong> residues can result <strong>in</strong><br />

loss <strong>of</strong> markets.<br />

Because <strong>of</strong> market requirements and chemical registrations that are specific to gra<strong>in</strong> types, the pest control<br />

options that can be used for various gra<strong>in</strong> types and markets are limited (see Table 1). Details <strong>of</strong> residual<br />

<strong>in</strong>secticides for treat<strong>in</strong>g storages and equipment are given <strong>in</strong> Table 3, and for particular cereal gra<strong>in</strong>s and<br />

particular markets are given <strong>in</strong> Tables 4 to 8.<br />

2

Table 1: Pest control options for various gra<strong>in</strong> types and markets.<br />

Cereal gra<strong>in</strong>s* for:<br />

Treatment<br />

Onfarm<br />

use<br />

Markets<br />

accept<strong>in</strong>g<br />

residual<br />

treatments<br />

Markets not<br />

accept<strong>in</strong>g<br />

residual<br />

treatments<br />

Pulses*or<br />

Oil-seeds*<br />

Any gra<strong>in</strong><br />

for organic<br />

markets<br />

Hygiene Yes Yes Yes Yes Yes<br />

Aeration Yes Yes Yes Yes Yes<br />

Dry<strong>in</strong>g Yes Yes Yes Yes Yes<br />

<strong>Control</strong>led atmosphere Yes Yes Yes Yes Yes<br />

Phosph<strong>in</strong>e fumigation Yes Yes Yes Yes* r<br />

Dichlorvos Yes Yes r r r<br />

Treatment <strong>of</strong><br />

storages &<br />

equipment<br />

Amorphous<br />

silica<br />

Residual<br />

chemicals<br />

Yes<br />

Yes<br />

Yes<br />

Yes<br />

Yes<br />

r<br />

Yes<br />

r<br />

r?<br />

r<br />

Mixture with<br />

Amorphous<br />

silica<br />

Yes r r r r?<br />

gra<strong>in</strong><br />

Notes:<br />

Residual<br />

chemicals<br />

Yes Yes r r r<br />

Cereals <strong>in</strong>clude: barley, maize, millets, oats, rice, sorghum, triticale, wheat.<br />

The only pulse crop for which phosph<strong>in</strong>e is registered is field pea.<br />

* Oilseeds <strong>in</strong>clude: canola, l<strong>in</strong>seed, safflower, sunflower, peanut.<br />

Yes can be used.<br />

r cannot be used.<br />

r ? some organic markets are reported to accept this treatment, others do not. Check with potential buyer<br />

and organic certify<strong>in</strong>g body.<br />

2. Gra<strong>in</strong> storage <strong>in</strong>sect management<br />

Plan for <strong>in</strong>sect control before storage<br />

There are no simple short cuts for stor<strong>in</strong>g gra<strong>in</strong> safely. If <strong>in</strong>sects are detected as gra<strong>in</strong> is out-loaded for sale,<br />

treatment is likely to delay the delivery by two to four weeks. Unless you plan for <strong>in</strong>sect control and have the<br />

necessary equipment, you should not be stor<strong>in</strong>g gra<strong>in</strong>.<br />

Management plans should <strong>in</strong>clude:<br />

• good hygiene as an essential part <strong>of</strong> <strong>in</strong>sect control,<br />

• methods to try to prevent <strong>in</strong>sect problems develop<strong>in</strong>g,<br />

• <strong>in</strong>spection for <strong>in</strong>sects and other quality problems, and<br />

• methods to control <strong>in</strong>sects if they do develop.<br />

Methods that aim to prevent <strong>in</strong>festations, <strong>in</strong>clud<strong>in</strong>g those listed as best practices <strong>in</strong> Table 2, are:<br />

• cool<strong>in</strong>g gra<strong>in</strong> with aeration,<br />

• treat<strong>in</strong>g gra<strong>in</strong> by spray<strong>in</strong>g with residual chemicals, or<br />

• treat<strong>in</strong>g gra<strong>in</strong> by mix<strong>in</strong>g amorphous silica powder.<br />

Plan to treat any <strong>in</strong>sects that are detected prior to sale by:<br />

• hav<strong>in</strong>g at least one sealed silo as a hospital b<strong>in</strong> for fumigation <strong>of</strong> <strong>in</strong>fested gra<strong>in</strong>; or<br />

• hav<strong>in</strong>g a calibrated sprayer to treat <strong>in</strong>fested gra<strong>in</strong> with dichlorvos as it goes up an auger<br />

Best stored gra<strong>in</strong> management practice and recommended equipment:<br />

• Fumigation e.g. Phosph<strong>in</strong>e tablets <strong>of</strong> stored gra<strong>in</strong> can only be successful aga<strong>in</strong>st all <strong>in</strong>sect life-cycle<br />

stages if carried out <strong>in</strong> a gas tight, sealed silo.<br />

• In most circumstances, silos should only be sealed dur<strong>in</strong>g fumigation. Leav<strong>in</strong>g a silo sealed over<br />

extended periods <strong>in</strong> Australia’s warm climatic conditions with no aeration may lead to conditions<br />

3

suitable for development <strong>of</strong> <strong>in</strong>sect pests, moisture migration, moulds and gra<strong>in</strong> quality deterioration.<br />

Gra<strong>in</strong> that is very dry or cool is less at risk.<br />

• When purchas<strong>in</strong>g a sealed silo it is worth <strong>in</strong>clud<strong>in</strong>g an aeration cool<strong>in</strong>g system. Aeration fans not<br />

only achieve the benefits listed below but also assist with silo pressure test<strong>in</strong>g and allow for faster<br />

gas ventilation times follow<strong>in</strong>g a fumigation. Pressure test a sealable silo once a year and carry out<br />

ma<strong>in</strong>tenance to ensure it is able to hold fumigation gas concentrations for the required time.<br />

• Freshly harvested gra<strong>in</strong> benefits from aeration designed to reduce gra<strong>in</strong> temperature and creat<strong>in</strong>g<br />

uniform gra<strong>in</strong> moisture conditions throughout the silo. These two factors comb<strong>in</strong>ed with good<br />

hygiene will significantly reduce problems with gra<strong>in</strong> quality and storage pests.<br />

• Follow<strong>in</strong>g this <strong>in</strong>itial post-harvest aeration cool<strong>in</strong>g for a 2-3 week period, a decision to seal the silo<br />

and fumigate may be appropriate if it was the first silo filled or there are other hygiene factors that<br />

may have <strong>in</strong>creased the risk <strong>of</strong> storage pest development.<br />

• Over the medium and long term, gra<strong>in</strong> is best held under aeration cool<strong>in</strong>g, aim<strong>in</strong>g to achieve gra<strong>in</strong><br />

temperatures <strong>of</strong> 20 0 or less. Automatic aeration controllers assist <strong>in</strong> achiev<strong>in</strong>g reliable results.<br />

• Check the silo monthly, sampl<strong>in</strong>g gra<strong>in</strong> from the headspace and outlet for <strong>in</strong>sect pests and quality.<br />

<strong>Insect</strong> traps placed <strong>in</strong> the gra<strong>in</strong> surface will aid <strong>in</strong>sect pest monitor<strong>in</strong>g. When storage pests are<br />

detected, seal the silo and fumigate. Once fumigation is completed, release the silo seal<strong>in</strong>g po<strong>in</strong>ts<br />

and return silo to aeration cool<strong>in</strong>g management.<br />

Inspection <strong>of</strong> stored gra<strong>in</strong><br />

Inspect gra<strong>in</strong> <strong>in</strong> each storage for <strong>in</strong>sects and other quality problems at least once a month. Use whatever<br />

methods are practical and safe. Ideally take samples <strong>of</strong> a few litres from all access po<strong>in</strong>ts, us<strong>in</strong>g a gra<strong>in</strong><br />

spear for the top surface, if it is safe to do so, and also from the bottom hatch. Sieve the gra<strong>in</strong> to separate<br />

<strong>in</strong>sects.<br />

If any live <strong>in</strong>sects are found you should consider treat<strong>in</strong>g the gra<strong>in</strong> before delivery to bulk handlers or to most<br />

buyers. To ensure that sufficient time is available for treatment, gra<strong>in</strong> should be <strong>in</strong>spected four weeks before<br />

the <strong>in</strong>tended sale or delivery date.<br />

In an aerated silo, the smell <strong>of</strong> the air blow<strong>in</strong>g out <strong>of</strong> the gra<strong>in</strong> is a guide to the state <strong>of</strong> the gra<strong>in</strong>. With<br />

experience, you will notice that the smell becomes fresher after a few days <strong>of</strong> aeration at the start <strong>of</strong> storage.<br />

A musty smell later <strong>in</strong> storage is an <strong>in</strong>dicator <strong>of</strong> <strong>in</strong>sect and/or moisture problems. Do not use this test just<br />

after a storage has been fumigated.<br />

High temperature is an <strong>in</strong>dicator <strong>of</strong> <strong>in</strong>sect or moisture problems. Push a rod at least one or two meters <strong>in</strong>to<br />

the gra<strong>in</strong>, leav<strong>in</strong>g it to equilibrate with the gra<strong>in</strong> for an hour if it is metal or half a day if it is wood. Pull the rod<br />

out and feel how warm it is. If it is hot, take spear samples and check for <strong>in</strong>sects and moulds. A probe fitted<br />

with a protected thermometer or thermocouple sensor can also be used to determ<strong>in</strong>e gra<strong>in</strong> temperature.<br />

Clean<strong>in</strong>g <strong>of</strong> storages and equipment<br />

Before harvest clean out all mach<strong>in</strong>ery and equipment used to handle gra<strong>in</strong>, <strong>in</strong>clud<strong>in</strong>g headers, augers, field<br />

b<strong>in</strong>s, truck b<strong>in</strong>s, silos and other storages. Any equipment used to treat or handle pickled seed must be<br />

thoroughly cleaned to prevent contam<strong>in</strong>ation <strong>of</strong> new gra<strong>in</strong>.<br />

Special care should also be taken to clean out bags <strong>of</strong> seed, feed troughs, shed floors, heaps <strong>of</strong> old bags or<br />

any other places where gra<strong>in</strong> and <strong>in</strong>sects may be present. Gra<strong>in</strong> and residues from clean<strong>in</strong>g should be<br />

fumigated with phosph<strong>in</strong>e, buried, burned, or spread th<strong>in</strong>ly over the ground away from build<strong>in</strong>gs and<br />

storages.<br />

3. Storages and equipment - treat<strong>in</strong>g for <strong>in</strong>sects<br />

Treat<strong>in</strong>g the surfaces <strong>of</strong> storages and equipment before they are used may kill <strong>in</strong>sects walk<strong>in</strong>g on those<br />

surfaces. If the storage or equipment is not cleaned before treatment, the treatment will be much less<br />

effective.<br />

4

Treat<strong>in</strong>g with amorphous silica / diatomaceous earth powder<br />

All surfaces <strong>of</strong> walls, floors, ledges, and mach<strong>in</strong>ery may be treated with amorphous silica yearly, or twice<br />

yearly <strong>in</strong> heavy traffic areas. It can be applied to surfaces <strong>in</strong> two ways:<br />

1. As a slurry - this is a very efficient method and is applied at the rate <strong>of</strong> 6 g/m 2 .<br />

2. As a dust - amorphous silica powder requires an air stream to move it <strong>in</strong>to surfaces and <strong>in</strong>to crevices<br />

at the rate <strong>of</strong> 2 g/m 2 . When apply<strong>in</strong>g the dust to large areas, use a power duster such as a Stihl<br />

SR400, or Blovac BV22. Operators <strong>of</strong> such equipment should wear disposable dust masks. Treat<strong>in</strong>g<br />

small storages can be achieved us<strong>in</strong>g a bellows type dust blower (from horticultural suppliers) or a<br />

venturi type gun. Dust treatment <strong>of</strong> headers after clean<strong>in</strong>g is recommended - follow the directions on<br />

the label.<br />

Treat<strong>in</strong>g with chemicals<br />

Residual chemicals can be sprayed onto the surfaces <strong>of</strong> storages and equipment to kill walk<strong>in</strong>g <strong>in</strong>sects, but<br />

only if the gra<strong>in</strong> to be handled and stored is dest<strong>in</strong>ed for a market that accepts residues on the gra<strong>in</strong>. Do not<br />

use these chemicals if oilseeds or pulses are to be stored, or if potential buyers will not accept treated gra<strong>in</strong><br />

(Table 3).<br />

Table 3: <strong>Insect</strong>icides to treat clean surfaces <strong>of</strong> storages and equipment to kill walk<strong>in</strong>g<br />

<strong>in</strong>sects. Apply these only if the gra<strong>in</strong> is dest<strong>in</strong>ed for a market that accepts residues on the gra<strong>in</strong>. If the<br />

market does not accept gra<strong>in</strong> residues, clean and leave, or clean and apply amorphous silica /<br />

diatomaceous earth powder.<br />

Select one <strong>of</strong> these<br />

options:<br />

Spray a mixture <strong>of</strong> two<br />

<strong>in</strong>secticides diluted <strong>in</strong><br />

water *<br />

<strong>Insect</strong>icide<br />

(for Trade names - see<br />

Table 9)<br />

Mix either:<br />

pirimiphos-methyl®<br />

or<br />

chlorpyriphos-methyl®<br />

Dilution rate<br />

per L water<br />

11 mL/L<br />

Application rate<br />

Apply 1 L <strong>of</strong> diluted mixture<br />

for every 20 m 2 <strong>of</strong> surface<br />

area<br />

or fenitrothion<br />

with<br />

20 mL/L<br />

10 mL/L<br />

carbaryl<br />

20 mL/L<br />

Spray a s<strong>in</strong>gle <strong>in</strong>secticide<br />

Either<br />

Apply 1 L <strong>of</strong> diluted<br />

diluted <strong>in</strong> water<br />

10 g/L<br />

<strong>in</strong>secticide for every 20 m<br />

azamethiphos®<br />

(may not be currently<br />

available)<br />

or<br />

dichlorvos<br />

(500 g/L formulation)<br />

or<br />

10 mL/L<br />

amorphous silica<br />

Slurry <strong>in</strong> water -<br />

as per label<br />

2<br />

<strong>of</strong> surface area<br />

Apply a dust amorphous silica Dust<br />

As per label<br />

powder<br />

application<br />

* Dilute each concentrate <strong>in</strong> a small amount <strong>of</strong> water before mix<strong>in</strong>g together the <strong>in</strong>secticides <strong>in</strong> the<br />

spray vat and mak<strong>in</strong>g up the total volume with water.<br />

Refer Table 9 for <strong>in</strong>secticide Trade names.<br />

4. Chemical <strong>in</strong>secticides <strong>in</strong> stored gra<strong>in</strong>s to control <strong>in</strong>sects<br />

5

Knock-down <strong>of</strong> <strong>Insect</strong>s <strong>in</strong> Infested <strong>Stored</strong> Gra<strong>in</strong>s<br />

There are four major methods covered here<br />

1. Knock-down with Dichlorvos alone, applied to gra<strong>in</strong> at while mov<strong>in</strong>g (Table 4)<br />

2. Mix<strong>in</strong>g dichlorvos knock-down with protectant <strong>in</strong>secticides for a s<strong>in</strong>gle application to gra<strong>in</strong><br />

3. Fumigat<strong>in</strong>g with phosph<strong>in</strong>e (“bomb<strong>in</strong>g”) <strong>of</strong> <strong>in</strong>fested stored gra<strong>in</strong> <strong>in</strong>clud<strong>in</strong>g safety, application<br />

methods, and sealed silos.<br />

4. Fumigat<strong>in</strong>g with Vapormate® (this option requires a State-licenced operator, and special application<br />

and monitor<strong>in</strong>g equipment approved by BOC Ltd).<br />

Knock-down <strong>of</strong> live <strong>in</strong>sects with gra<strong>in</strong>-applied <strong>in</strong>secticides<br />

Application <strong>of</strong> dichlorvos at the rates specified <strong>in</strong> Table 4 can be used to kill <strong>in</strong>sects <strong>in</strong> gra<strong>in</strong>. Allow three<br />

days for all <strong>in</strong>sects to die after treatment, and observe the withhold<strong>in</strong>g periods (see below) before sale.<br />

6

Table 4: Dichlorvos application rates for knockdown <strong>of</strong> live adult <strong>in</strong>sects <strong>in</strong> <strong>in</strong>fested<br />

cereal gra<strong>in</strong>. If gra<strong>in</strong> is to be sold, use <strong>in</strong>secticides only if approved by your buyer or handler. Cereal<br />

gra<strong>in</strong>s <strong>in</strong>clude: barley, maize, millets, oats, rice, sorghum, triticale, wheat.<br />

<strong>Insect</strong>s <strong>Insect</strong>icide<br />

(For Trade<br />

names –<br />

see Table<br />

9)<br />

most species dichlorvos<br />

1.14 kg/L<br />

lesser gra<strong>in</strong><br />

borer<br />

500 g/L<br />

dichlorvos<br />

1.14 kg/L<br />

moths only dichlorvos<br />

1.14 kg/L<br />

500 g/L<br />

Dilution<br />

rate 1<br />

5.3 mL<br />

12 mL<br />

10.5 mL<br />

4.4 mL<br />

10 mL<br />

Application rate Cost 2 Withhold<strong>in</strong>g period 3<br />

Apply 1 L <strong>of</strong> diluted<br />

<strong>in</strong>secticide per tonne<br />

as gra<strong>in</strong> is augured<br />

Apply 1 L <strong>of</strong> diluted<br />

<strong>in</strong>secticide per tonne<br />

as gra<strong>in</strong> is augured<br />

Apply 1 L <strong>of</strong> diluted<br />

<strong>in</strong>secticide for every<br />

20m 2 <strong>of</strong> gra<strong>in</strong> surface<br />

area<br />

12-15c<br />

30-35c<br />

24-30c<br />

10-15c<br />

24-30c<br />

7 days<br />

7 days<br />

28 days<br />

7 days<br />

7 days<br />

Notes table 4:<br />

ALWAYS CHECK LABELS<br />

For <strong>in</strong>secticide trade names, see Table 9.<br />

1. Dilute liquid concentrates <strong>in</strong> water at the specified rate per litre, then spray 1 litre <strong>of</strong> the mixture per<br />

tonne <strong>of</strong> gra<strong>in</strong> while augur<strong>in</strong>g the gra<strong>in</strong> or spray 1 litre per 20 square metres <strong>of</strong> gra<strong>in</strong> surface to control<br />

moths.<br />

2. Costs (cents per tonne or cents per 20 square metres <strong>in</strong> 2006) for chemicals only are presented as<br />

an approximate guide.<br />

3. If gra<strong>in</strong> is <strong>in</strong>fested with lesser gra<strong>in</strong> borers then the 10.5ml rate <strong>of</strong> dichlorvos is recommended<br />

because <strong>of</strong> resistance <strong>in</strong> these <strong>in</strong>sects. A withhold<strong>in</strong>g period <strong>of</strong> 28 days applies to this treatment.<br />

Residual <strong>Insect</strong>icides (Protectants) for Treat<strong>in</strong>g <strong>Stored</strong> Gra<strong>in</strong>s<br />

There are three treatment tables here which cover the follow<strong>in</strong>g on-farm treatment requirements:<br />

• Treat<strong>in</strong>g stored cereal gra<strong>in</strong> (except malt<strong>in</strong>g barley) Table 5<br />

• Treat<strong>in</strong>g stored feed gra<strong>in</strong>s and/or seed Table 6<br />

• Treat<strong>in</strong>g stored malt<strong>in</strong>g barley on-farm Table 7<br />

IMPORTANT NOTES on Protectant <strong>Insect</strong>icides:<br />

• Protectants (<strong>in</strong>secticides sprayed directly on to gra<strong>in</strong> at <strong>in</strong>-load<strong>in</strong>g) will not always kill adult <strong>in</strong>sects<br />

present at the time <strong>of</strong> treatment.These treatments are <strong>in</strong>tended to control develop<strong>in</strong>g immature<br />

<strong>in</strong>sect stages (ie, larvae), rather than exist<strong>in</strong>g mature adult stages.<br />

• Methoprene and s-methoprene (IGR ®) , are ‘<strong>in</strong>sect growth regulators’ - they control only immature<br />

stages and will not kill adult <strong>in</strong>sects.<br />

• Phosph<strong>in</strong>e or dichlorvos are recommended for use as a knock-down treatment if adult <strong>in</strong>sects are<br />

present.<br />

• If protectants are to be added to <strong>in</strong>fested gra<strong>in</strong> then the gra<strong>in</strong> should be treated (fumigated) with<br />

phosph<strong>in</strong>e before apply<strong>in</strong>g the protectants, or, alternatively, dichlorvos (Table 4) can be applied as a<br />

direct spray to gra<strong>in</strong> at the same time as the protectants.<br />

• Adhere strictly to label rates so the Maximum Residue Limits (MRL’s) are not exceeded when your<br />

gra<strong>in</strong> is sold to end-user.<br />

7

Tables <strong>of</strong> <strong>in</strong>secticides approved for treat<strong>in</strong>g stored gra<strong>in</strong>s<br />

Table 5: <strong>Stored</strong> cereal gra<strong>in</strong>s - <strong>Insect</strong>icide application rates to protect stored cereal<br />

gra<strong>in</strong>, except malt<strong>in</strong>g barley. If gra<strong>in</strong> is to be sold, use <strong>in</strong>secticides only if approved by your buyer.<br />

Cereal gra<strong>in</strong>s <strong>in</strong>clude: barley, maize, millets, oats, rice, sorghum, triticale, wheat. For trade names <strong>of</strong> these<br />

<strong>in</strong>secticides, see Table 9.<br />

Storage period<br />

<strong>Insect</strong>icide<br />

6 weeks-<br />

3 months<br />

3 months-<br />

9 months<br />

1<br />

(For Trade names see table 9)<br />

Rate/<br />

tonne Cost<br />

2<br />

3 Rate/<br />

tonne 2 Cost 3<br />

Withhold<strong>in</strong>g period<br />

(WHP) 4 Apply a mixture <strong>of</strong> -<br />

and<br />

restrictions on use<br />

Either<br />

4.5 30-35 c 4.5 mL 30-35 c No Withhold<strong>in</strong>g period<br />

pirimiphos-methyl (900g/L<br />

product)<br />

mL<br />

or chlorpyriphos-methyl 10 mL 75-80 c 20 mL 150-160c No Withhold<strong>in</strong>g period,<br />

(500 g/L product)<br />

do not apply to rice or<br />

malt<strong>in</strong>g barley<br />

or fenitrothion (1000g/L 6 mL 18-20 c 12 mL 35-40 c Withhold<strong>in</strong>g period 90<br />

product)<br />

days for the high rate<br />

or deltamethr<strong>in</strong> (eg, 4 mL 15-20c 4 mL 15-20c No Withhold<strong>in</strong>g period<br />

250g/l product) + pip.<br />

(OK for malt barley &<br />

butoxide<br />

With either<br />

sorghum). May not be<br />

generally available.<br />

methoprene (eg,<br />

200 g/L product),<br />

or s-methoprene (30 g/L<br />

5 mL 150-160c 5 mL 150-160c No Withhold<strong>in</strong>g period<br />

product)<br />

or s-methoprene<br />

20 mL<br />

20 mL<br />

No Withhold<strong>in</strong>g period<br />

(300g/L product)<br />

Notes on Table 5:<br />

2mL<br />

2mL<br />

For <strong>in</strong>secticide Trade names, see table 9.<br />

1. Always check dose rates and all other details on product label. The table above is a guide<br />

only. Products such as Relden pluS IGR ® is a s<strong>in</strong>gle t<strong>in</strong> formulation mixture conta<strong>in</strong><strong>in</strong>g both<br />

chlorphriphos-methyl (500g/L) and S-methoprene (30g/L)<br />

2. Dilute liquid concentrates <strong>in</strong> water at the specified rate per litre, then spray 1 litre <strong>of</strong> the mixture<br />

per tonne <strong>of</strong> gra<strong>in</strong> while augur<strong>in</strong>g the gra<strong>in</strong>.<br />

3. Costs (cents per tonne <strong>in</strong> 2006) for chemicals only are presented as an approximate guide.<br />

Large pack sizes are cheaper per tonne treated than small packs.<br />

4. <strong>Insect</strong>icide residues must not exceed Maximum Residue Limits (MRL). Where application rates<br />

exceed MRL you must wait the withhold<strong>in</strong>g period to allow residues <strong>in</strong> the gra<strong>in</strong> to decay to less<br />

than the MRL before sell<strong>in</strong>g the gra<strong>in</strong>.<br />

Seedl<strong>in</strong>gs <strong>of</strong> some sorghum varieties are susceptible to toxicity from organophosphorus<br />

<strong>in</strong>secticides such as pirimiphos-methyl, fenitrothion and chlorpyriphos-methyl.<br />

8

Table 6: Feed gra<strong>in</strong>s and seed- <strong>Insect</strong>icide application rates for cereal gra<strong>in</strong>s for use on<br />

farm for seed or animal feed, or for sale for animal feed. Alternatives <strong>in</strong> Table 7 can also be<br />

used. If gra<strong>in</strong> is to be sold, use <strong>in</strong>secticides only if approved by your buyer or handler. Cereal gra<strong>in</strong>s <strong>in</strong>clude:<br />

barley, maize, millets, oats, rice, sorghum 5 , triticale, wheat.<br />

<strong>Insect</strong>icide<br />

(For Trade names<br />

– see table 9)<br />

Apply a mixture<br />

<strong>of</strong><br />

either pirimiphosmethyl<br />

(900g/L<br />

product)<br />

Storage period<br />

6 weeks-<br />

3 months-<br />

3 months<br />

9 months<br />

Rate/ Cost<br />

tonne<br />

1<br />

2 Rate/<br />

tonne 1<br />

4.5<br />

mL<br />

Cost 2<br />

Withhold<strong>in</strong>g period (WHP) 3 and<br />

restrictions on use<br />

30-35c 4.5 mL 30-35 c No Withhold<strong>in</strong>g period<br />

or<br />

chlorpyriphosmethyl<br />

(500g/L<br />

product)<br />

10 mL 75-80c 20 mL 150-160c No Withhold<strong>in</strong>g period<br />

or fenitrothion 6 mL 18-20c 12 mL 35-40 c Withhold<strong>in</strong>g period 90 days for<br />

or deltamethr<strong>in</strong><br />

(250g/L product) +<br />

pip. butoxide<br />

With carbaryl<br />

(check with gra<strong>in</strong><br />

buyer)<br />

the high rate<br />

4 mL 15-20c 4 mL 15-20c No Withhold<strong>in</strong>g period. May not<br />

be generally available.<br />

10 mL 12 c 16 mL 19 c Withhold<strong>in</strong>g period 90 days for<br />

the high rate<br />

Do not use carbaryl on malt<strong>in</strong>g<br />

barley, mill<strong>in</strong>g wheat, or gra<strong>in</strong> for<br />

bulk handlers<br />

Notes on Table 6:<br />

Trade names <strong>of</strong> these <strong>in</strong>secticides are listed <strong>in</strong> Table 9.<br />

1. Dilute liquid concentrates <strong>in</strong> water at the specified rate per litre, then spray 1 litre <strong>of</strong> the mixture<br />

per tonne <strong>of</strong> gra<strong>in</strong> while augur<strong>in</strong>g the gra<strong>in</strong>. Add dusts directly to the gra<strong>in</strong>.<br />

2. Costs (cents per tonne <strong>in</strong> 2006) for chemicals only are presented as an approximate guide.<br />

Large pack sizes are cheaper per tonne treated than small packs.<br />

3. <strong>Insect</strong>icide residues must not exceed Maximum Residue Limits (MRL). Where application rates<br />

exceed MRL you must wait the withhold<strong>in</strong>g period to allow residues to decay to less than the MRL<br />

before you feed.<br />

4. Seedl<strong>in</strong>gs <strong>of</strong> some sorghum varieties are susceptible to toxicity from organophosphorus<br />

<strong>in</strong>secticides such as pirimiphos-methyl, fenitrothion and chlorpyriphos-methyl.<br />

9

Table 7: Malt<strong>in</strong>g barley on-farm - <strong>Insect</strong>icide application rates for protection <strong>of</strong> malt<strong>in</strong>g<br />

barley. Use <strong>in</strong>secticides only if approved by your buyer or handler. Maltsters prefer barley without residual<br />

treatments, and some <strong>in</strong>sects are resistant to all listed protectants, so consider non-chemical alternatives.<br />

<strong>Insect</strong>icide 1<br />

(for Trade names – see table 9)<br />

Storage period<br />

6 weeks- 3 months-<br />

3 months<br />

9 months<br />

Rate/ Cost<br />

tonne<br />

2<br />

3 Rate/<br />

tonne<br />

2<br />

Cost 3<br />

Withhold<strong>in</strong>g period 4<br />

Apply a mixture <strong>of</strong><br />

either fenitrothion 6 mL 18-20 c 12 mL 35-40 c 90 days for high rate<br />

or<br />

4 mL 15-20c 4 mL 15-20c No WHP. May not be generally<br />

deltamethr<strong>in</strong><br />

available. Note – check with<br />

(250g/l) + pip.<br />

butoxide<br />

With either<br />

maltster before us<strong>in</strong>g.<br />

methoprene<br />

(200 g/L product)<br />

5 mL 150-160c 5 mL 150-160c No WHP<br />

or methoprene<br />

(50 g/L product)<br />

20 mL 100-140c 20 mL 100-140c No WHP<br />

or S-methoprene<br />

(30 g/L product)<br />

Notes on Table 7:<br />

20 mL 230-240c 20 mL 230-240c No WHP<br />

Trade names <strong>of</strong> these <strong>in</strong>secticides are listed <strong>in</strong> Table 9.<br />

1. Always check dose rates and all other details on product label. The table above is a guide only.<br />

Products such as Relden pluS IGR ® is a s<strong>in</strong>gle t<strong>in</strong> formulation mixture conta<strong>in</strong><strong>in</strong>g both chlorphriphosmethyl<br />

(500g/L) and S-methoprene (30g/L)<br />

2. Dilute liquid concentrates <strong>in</strong> water at the specified rate per litre, then spray 1 litre <strong>of</strong> the mixture per<br />

tonne <strong>of</strong> gra<strong>in</strong> while augur<strong>in</strong>g the gra<strong>in</strong>.<br />

3. Costs (cents per tonne <strong>in</strong> 2007) for chemicals only are presented as an approximate guide. Large<br />

pack sizes are cheaper per tonne treated than small packs.<br />

4. <strong>Insect</strong>icide residues must not exceed Maximum Residue Limits (MRL). Where application rates<br />

exceed MRL you must wait the withhold<strong>in</strong>g period to allow residues <strong>in</strong> the gra<strong>in</strong> to decay to less than<br />

the MRL before sell<strong>in</strong>g the gra<strong>in</strong>.<br />

Apply<strong>in</strong>g protectant <strong>in</strong>secticides<br />

Protectant chemicals will work <strong>in</strong> all types <strong>of</strong> storages with no modifications required, but they must be<br />

applied evenly to gra<strong>in</strong> to be fully effective. Simple, correctly calibrated application equipment is needed.<br />

• Apply the correct dose – under-dos<strong>in</strong>g will result <strong>in</strong> reduced protection; over-dos<strong>in</strong>g is wasteful and<br />

may cause gra<strong>in</strong> to be rejected by buyers or held for longer until residues decl<strong>in</strong>e to levels accepted<br />

by markets.<br />

• Mix the concentrated <strong>in</strong>secticide <strong>in</strong> clean conta<strong>in</strong>ers with ra<strong>in</strong>water if possible - alkal<strong>in</strong>e water causes<br />

<strong>in</strong>secticides to break down very quickly; don’t mix concentrates directly, dilute first, then mix; don’t<br />

hold mixed pesticides for more than a few days - mix just enough spray and use it as soon as<br />

possible.<br />

• Apply protectants to gra<strong>in</strong> while it is be<strong>in</strong>g augured. Spray <strong>in</strong>to the auger hopper or <strong>in</strong>to the auger<br />

cas<strong>in</strong>g. Use a flow meter.<br />

• High-volume pumps allow bypass to agitate liquid spray mixtures; other pump types may be used<br />

with care; thoroughly wash equipment with water after use.<br />

10

• Calibrate your application equipment with water before every use. The spray equipment must be<br />

calibrated to spray 1 litre <strong>of</strong> solution per tonne <strong>of</strong> gra<strong>in</strong>; that is, the spray rate, measured <strong>in</strong> litres per<br />

hour, must equal the auger or elevator uptake <strong>in</strong> tonnes per hour.<br />

• Wear protective cloth<strong>in</strong>g - goggles, gloves and overalls when handl<strong>in</strong>g protectants; avoid breath<strong>in</strong>g<br />

the fumes: don't eat, smoke or put your f<strong>in</strong>gers <strong>in</strong> your mouth, wash well and change your clothes<br />

when you f<strong>in</strong>ish.<br />

Mix<strong>in</strong>g amorphous silica / diatomaceous earth powder with gra<strong>in</strong><br />

Amorphous silica powder (eg., Dryacide® at www.entosol.com.au or Absorba-Cide®, or Abrade®, or<br />

Permaguard D10®) can be mixed with gra<strong>in</strong> as an alternative to the chemical sprays. It can be used on feed<br />

gra<strong>in</strong> or gra<strong>in</strong> used on the farm, but should not be used for any other gra<strong>in</strong> unless potential buyers approve<br />

<strong>of</strong> its use.<br />

The major advantages <strong>of</strong> these <strong>in</strong>ert dusts are that they leave no chemical residue, have no withhold<strong>in</strong>g<br />

period and m<strong>in</strong>imise selection for resistance. They are accepted by some organic markets. Always check<br />

with the Organic certify<strong>in</strong>g body first. (Refer to NSW DPI Organic farm<strong>in</strong>g Agfact “On-Farm Storage <strong>of</strong><br />

Organic Gra<strong>in</strong>” at www.dpi.nsw.gov.au/agriculture/farm/organic,<br />

Note: These products have some serious disadvantages for mix<strong>in</strong>g with gra<strong>in</strong>. They are far more expensive<br />

than any other chemical treatments. Bulk handlers and some buyers will not accept gra<strong>in</strong> treated with<br />

amorphous silica / diatomaceous earth because they change the handl<strong>in</strong>g characteristics <strong>of</strong> gra<strong>in</strong> and slow<br />

movement <strong>of</strong> gra<strong>in</strong> through augers.<br />

Unlike protectant chemical <strong>in</strong>secticides which are applied to gra<strong>in</strong> as a liquid spray, amorphous silica /<br />

diatomaceous earth are applied to gra<strong>in</strong> as a dust. The dust collects on <strong>in</strong>sects and dries them out. A pickle<br />

applicator or a special Dryacide® applicator, available from Dryacide Australia through rural supply houses,<br />

is the best way to apply such products.<br />

Add amorphous silica powder at the rate specified on the label. If gra<strong>in</strong> is dusty or <strong>in</strong>fested, <strong>in</strong>creas<strong>in</strong>g the<br />

application rate will <strong>in</strong>crease its effectiveness. Amorphous silica is not effective on high moisture gra<strong>in</strong> above<br />

12%.<br />

5. Fumigation - <strong>Insect</strong> control <strong>in</strong> stored gra<strong>in</strong>s with fumigation<br />

The major advantage <strong>of</strong> fumigation with phosph<strong>in</strong>e (<strong>of</strong>ten referred to as “bomb<strong>in</strong>g”, or “gas<strong>in</strong>g”, us<strong>in</strong>g eg,<br />

Fostox<strong>in</strong>, Fumitox<strong>in</strong> etc), is that <strong>in</strong>sects can be controlled without mov<strong>in</strong>g the gra<strong>in</strong>. See below for dose<br />

rates and other critical recommendations.<br />

General <strong>in</strong>formation on phosph<strong>in</strong>e fumigation<br />

Phosph<strong>in</strong>e gas moves readily through gra<strong>in</strong> from the po<strong>in</strong>t <strong>of</strong> application. Phosph<strong>in</strong>e leaks quickly through<br />

holes <strong>in</strong> silos or sheet<strong>in</strong>g. W<strong>in</strong>d and large temperature changes accelerate phosph<strong>in</strong>e loss. Most phosph<strong>in</strong>e<br />

is lost with<strong>in</strong> 4 days from fumigations <strong>in</strong> ord<strong>in</strong>ary, unsealed storages.<br />

<strong>Insect</strong>s are killed slowly by phosph<strong>in</strong>e gas. The fumigant must be kept <strong>in</strong> contact with the <strong>in</strong>sects for at<br />

least 7 days to kill all stages <strong>of</strong> the <strong>in</strong>sect’s life cycle that usually exist <strong>in</strong> stored gra<strong>in</strong>s. Fumigation <strong>in</strong><br />

ord<strong>in</strong>ary, unsealed storages will kill some adults but most eggs, larvae and pupae will survive to cont<strong>in</strong>ue<br />

the breed<strong>in</strong>g cycle. A silo that is built to be sealed gas-tight is needed to conta<strong>in</strong> sufficient phosph<strong>in</strong>e<br />

concentration for long enough to kill all stages <strong>of</strong> the <strong>in</strong>sects.<br />

Fumigation gives no residual protection to stored gra<strong>in</strong>. In other words, <strong>in</strong>sects will beg<strong>in</strong> breed<strong>in</strong>g, after the<br />

phosph<strong>in</strong>e gas concentration has dropped to low levels.<br />

Phosph<strong>in</strong>e fumigant itself leaves m<strong>in</strong>imal residues, and is acceptable to most markets. However, the solid<br />

powdery residues left by phosph<strong>in</strong>e generat<strong>in</strong>g tablets when they are mixed with the gra<strong>in</strong> are a concern to<br />

some markets. It is aga<strong>in</strong>st label recommendations to mix solid phosph<strong>in</strong>e generat<strong>in</strong>g tablets directly <strong>in</strong>to<br />

the gra<strong>in</strong>.<br />

Phosph<strong>in</strong>e is effective aga<strong>in</strong>st <strong>in</strong>sects <strong>in</strong> most types <strong>of</strong> gra<strong>in</strong>. But some commodities (for example, oilseeds<br />

– l<strong>in</strong>seed, cottonseed) soak up phosph<strong>in</strong>e very quickly, leav<strong>in</strong>g little to kill <strong>in</strong>sects.<br />

11

Apply<strong>in</strong>g phosph<strong>in</strong>e<br />

Most gra<strong>in</strong> growers use phosph<strong>in</strong>e-generat<strong>in</strong>g tablets when fumigat<strong>in</strong>g. These tablets react with moisture <strong>in</strong><br />

the air to release phosph<strong>in</strong>e gas. Up to three days is needed to release all the gas, longer if the gra<strong>in</strong> is cool<br />

or very dry. The gas then moves through the gra<strong>in</strong>, usually with<strong>in</strong> a day <strong>in</strong> volumes up to a hundred tonnes.<br />

The problem <strong>of</strong> tablet residues <strong>in</strong> the gra<strong>in</strong> can be avoided by putt<strong>in</strong>g tablets on trays, suspend<strong>in</strong>g trays <strong>in</strong><br />

the head space or plac<strong>in</strong>g trays on the gra<strong>in</strong> surface. An alternative to us<strong>in</strong>g tablets is to use phosph<strong>in</strong>e<br />

products which are sold as bag cha<strong>in</strong>s, belts or blanket formulations. Do not place tablets <strong>in</strong> heaps on trays<br />

– as the tablets on the top smother the tablets underneath prevent<strong>in</strong>g full gas release.<br />

Warn<strong>in</strong>g: Do not add water to tablets. This causes a dangerous, quick release <strong>of</strong> gas which is less effective<br />

aga<strong>in</strong>st <strong>in</strong>sect pests.<br />

An ideal simple “tray” for phosph<strong>in</strong>e tablets <strong>in</strong> a<br />

small farm silo. Place tray <strong>in</strong> silo headspace,<br />

suspended or placed on gra<strong>in</strong> surface. Spent<br />

tablet residue doesn’t contam<strong>in</strong>ate gra<strong>in</strong> and is<br />

easily removed <strong>in</strong> the tray after fumigant has been<br />

vented from silo.<br />

Do not enter a fumigated storage to retrieve the spent fumigant formulation – phosph<strong>in</strong>e is toxic to humans.<br />

Once the full exposure period plus air<strong>in</strong>g period has passed, the spent formulation can be removed from<br />

outside the silo and buried. Some phosph<strong>in</strong>e will be given <strong>of</strong>f by the spent formulation dust, so do not carry<br />

it <strong>in</strong> a conf<strong>in</strong>ed space.<br />

The SIROFLO® system for apply<strong>in</strong>g phosph<strong>in</strong>e as a gas<br />

The SIROFLO ® application system cont<strong>in</strong>ually <strong>in</strong>troduces a low concentration <strong>of</strong> phosphor\<strong>in</strong>e <strong>in</strong>to a silo<br />

from a cyl<strong>in</strong>der for 21 days plus. The gas flows through the silo and out, usually at the top <strong>of</strong> the silo.<br />

Orig<strong>in</strong>ally developed for very large silos, SIROFLO® is now available for small-scale storages. The<br />

advantage <strong>of</strong> this method is that the silo does not have to be sealed to the high standard required for<br />

conventional fumigation.<br />

Although much more expensive than us<strong>in</strong>g tablets, it has application <strong>in</strong> specific bulk storage systems. The<br />

system us<strong>in</strong>g the product named Eco2Fume ® is available through Cytec Australia Hold<strong>in</strong>gs, Baulkham<br />

Hills, NSW, Ph: 02 98 466 200, website :www.cytec.com.au/<br />

Dose rate and fumigation times for solid formulations <strong>of</strong> phosph<strong>in</strong>e<br />

Effective fumigation <strong>of</strong> gra<strong>in</strong> needs 1.5 tablets per cubic metre <strong>of</strong> total storage capacity (i.e, not the<br />

tonnage <strong>of</strong> gra<strong>in</strong> actually <strong>in</strong> the storage).<br />

A tablet releases 1 gram <strong>of</strong> phosph<strong>in</strong>e, so 1.5 tablets per cubic metre is equivalent to 1.5 grams per cubic<br />

metre.<br />

Examples <strong>of</strong> application rates <strong>of</strong> tablets for storages <strong>of</strong> various sizes are shown <strong>in</strong> Table 8 below.<br />

Phosph<strong>in</strong>e moves through the whole air space, so apply the same number <strong>of</strong> tablets whether the storage is<br />

full or partly full with gra<strong>in</strong><br />

12

Table 8: Phosph<strong>in</strong>e tablets - Application rates for phosph<strong>in</strong>e tablets <strong>in</strong> storages <strong>of</strong><br />

various sizes.<br />

Storage capacity<br />

Tonnes wheat Bushels Cubic metres<br />

Number <strong>of</strong> tablets required<br />

20 730 27 40<br />

50 1830 65 100<br />

100 3660 130 200<br />

300 11000 400 600<br />

Notes on Table 8:<br />

A storage needs the same amount <strong>of</strong> fumigant regardless <strong>of</strong> whether it is full, partly full, or empty.<br />

For example, a storage with enough space to hold 100 tonnes <strong>of</strong> wheat always needs 200 tablets<br />

no matter how much gra<strong>in</strong> it conta<strong>in</strong>s.<br />

Other solid formulations release various quantities <strong>of</strong> phosph<strong>in</strong>e rang<strong>in</strong>g from 0.2 grams to one<br />

kilogram. Follow label recommendations for those formulations.<br />

M<strong>in</strong>imum fumigation times follow<strong>in</strong>g application <strong>of</strong> phosph<strong>in</strong>e are –<br />

• 7 days at gra<strong>in</strong> temperatures above 25 o C;<br />

• 10 days at 15 to 25 o C.<br />

Gra<strong>in</strong> below 15 o C should not be fumigated with phosph<strong>in</strong>e - <strong>in</strong>sects are very hard to kill at low temperatures.<br />

Fumigant takes longer to distribute <strong>in</strong> storages with more than a few hundred tonnes capacity, unless forced<br />

circulation is used. Longer exposure periods are required <strong>in</strong> larger storages. See product label for details.<br />

Air<strong>in</strong>g (ventilat<strong>in</strong>g) and withhold<strong>in</strong>g periods for phosph<strong>in</strong>e<br />

Fumigated gra<strong>in</strong> must be aired before handl<strong>in</strong>g to remove toxic gas and to m<strong>in</strong>imise phosph<strong>in</strong>e gas<br />

residues. Flow-through ventilation aided by a fan usually allows completion <strong>of</strong> air<strong>in</strong>g <strong>in</strong> 24 hours. Without a<br />

fan this could take 5 days. A withhold<strong>in</strong>g period <strong>of</strong> two days after the air<strong>in</strong>g period applies before the gra<strong>in</strong> is<br />

used for human food or stockfeed. Gra<strong>in</strong> can be legally transported dur<strong>in</strong>g this period.<br />

Total fumigation time for phosph<strong>in</strong>e<br />

The m<strong>in</strong>imum period allowable between application <strong>of</strong> phosph<strong>in</strong>e and use <strong>of</strong> the treated gra<strong>in</strong> is 7<br />

days exposure + 1 day air<strong>in</strong>g with fans + 2 days withhold<strong>in</strong>g period, or 10 days total. If gra<strong>in</strong> temperature is<br />

less than 25 o C, so that a longer exposure period is needed, or air<strong>in</strong>g is done without fans, the m<strong>in</strong>imum<br />

allowable period between application and use <strong>of</strong> the gra<strong>in</strong> can be as long as 17 days. In storages larger<br />

than 300 tonnes, an exposure period <strong>of</strong> 20 days is required, so total fumigation time is up to 27 days. Always<br />

refer to the label.<br />

Safety with phosph<strong>in</strong>e<br />

Phosph<strong>in</strong>e is very toxic to people and farm animals. Health workers specify an air concentration <strong>of</strong> 0.3 ppm<br />

as acceptable <strong>in</strong> work areas. Gas detector tubes are one method <strong>of</strong> monitor<strong>in</strong>g workplace concentrations.<br />

Two Australian firms sell<strong>in</strong>g phosph<strong>in</strong>e detectors can be contacted at the Canary Company at<br />

www.thecanaryco.com and Airmet at www.airmet.com.au. There may be other companies <strong>in</strong> this field also.<br />

Note that most gas detection / monitor<strong>in</strong>g equipment requires regular check<strong>in</strong>g and calibration to verify<br />

accuracy and reliability. So potential buyers should be aware <strong>of</strong> the cost <strong>of</strong> this check<strong>in</strong>g and service<br />

availability.<br />

13

Guidel<strong>in</strong>es for stay<strong>in</strong>g safe when us<strong>in</strong>g phosph<strong>in</strong>e:<br />

• DO NOT <strong>in</strong>hale phosph<strong>in</strong>e gas.<br />

• Open tablet conta<strong>in</strong>ers <strong>in</strong> open air and away from your face.<br />

• Do not apply tablets from <strong>in</strong>side a conf<strong>in</strong>ed space – apply from outside a silo.<br />

• Fumigate only <strong>in</strong> areas where gas can't leak <strong>in</strong>to liv<strong>in</strong>g or work<strong>in</strong>g areas.<br />

• Ventilate fumigated areas before the gra<strong>in</strong> is handled.<br />

• Do not transport gra<strong>in</strong> while it is be<strong>in</strong>g fumigated. This is illegal. F<strong>in</strong>es apply.<br />

• Spread tablets th<strong>in</strong>ly to avoid fire risk.<br />

• Never place tablets <strong>in</strong> water.<br />

• Display a clear warn<strong>in</strong>g sign: Danger – Poison Gas – Keep Away.<br />

• Dispose <strong>of</strong> the residue by bury<strong>in</strong>g 50cm deep.<br />

• Phosph<strong>in</strong>e corrodes electrical wir<strong>in</strong>g <strong>in</strong> vehicles and build<strong>in</strong>gs.<br />

Refer also to GRDC Advice Notes “Keep Phosph<strong>in</strong>e Safe” at www.grdc.com.au/director/events/factsheets,<br />

and “Sealed Silos” at www.grdc.com.au/director/events/factsheets.<br />

Improv<strong>in</strong>g effectiveness <strong>of</strong> fumigation with phosph<strong>in</strong>e<br />

Fumigation is fully effective only if it is done <strong>in</strong> a gas-tight enclosure. Silos can be made gas-tight for<br />

fumigation, preferably dur<strong>in</strong>g manufacture. Sealed silos usually cost about 7 - 12% more than the same<br />

capacity unsealed silo. Sealed silos need to pass a standard 3 m<strong>in</strong>ute half life pressure test to ensure they<br />

are capable <strong>of</strong> reta<strong>in</strong><strong>in</strong>g the required gas concentrations for sufficient exposure time.<br />

Gas-tight bag stacks should be built by lay<strong>in</strong>g a plastic sheet on the floor, build<strong>in</strong>g and cover<strong>in</strong>g the stack<br />

with another sheet, then tightly roll<strong>in</strong>g and clamp<strong>in</strong>g the top and bottom sheets together. Old sheets that<br />

have been folded or rolled many times, or roughly handled are unlikely to be gas-tight.<br />

Measur<strong>in</strong>g the phosph<strong>in</strong>e concentration dur<strong>in</strong>g the fumigation or conduct<strong>in</strong>g a pressure test prior to<br />

fumigation shows you whether the fumigation enclosure is sufficiently gas-tight.<br />

Phosph<strong>in</strong>e concentrations and times required:<br />

• A m<strong>in</strong>imum <strong>of</strong> 300ppm phosph<strong>in</strong>e for 7 days<br />

• or a m<strong>in</strong>imum 200ppm phosph<strong>in</strong>e for 10 days<br />

You can measure phosph<strong>in</strong>e concentration with a hand pump and gas detector tube. Several companies<br />

sell suitable gas detection gear and prices vary.<br />

Shortcuts for us<strong>in</strong>g phosph<strong>in</strong>e for quick treatment <strong>of</strong> gra<strong>in</strong>s<br />

A common question asked about quick cleanup <strong>of</strong> pests <strong>of</strong> stored gra<strong>in</strong> is, ‘What can I do to kill the weevils<br />

<strong>in</strong> the gra<strong>in</strong> that I’ve got to deliver today?’.<br />

There isn’t a quick, easy answer to the immediate problem. The long-term answer is to plan your storage so<br />

that the problem doesn’t arise. See treatment times for phosph<strong>in</strong>e and dichlorvos above.<br />

Dichlorvos sprayed on to gra<strong>in</strong> or phosph<strong>in</strong>e fumigation, are the only approved <strong>in</strong>secticidal “knockdown”<br />

treatments (details <strong>of</strong> use are given above). Some <strong>of</strong> the residual protectant treatments, such as Reldan +<br />

methoprene, or Actellic + methoprene (Table 4 or 5 above), do not have problems with withhold<strong>in</strong>g periods<br />

or MRLs. However chemical companies will not guarantee that these chemicals will kill adult beetles, even<br />

over three days. Methoprene alone has almost no effect aga<strong>in</strong>st adult <strong>in</strong>sects.<br />

Plan on check<strong>in</strong>g gra<strong>in</strong> (by siev<strong>in</strong>g samples look<strong>in</strong>g for <strong>in</strong>sects) one month and aga<strong>in</strong> at one fortnight prior to<br />

sale to allow time for treatment if live <strong>in</strong>sects are found. Have at least one gas-tight storage as a “hospital<br />

b<strong>in</strong>” for fumigation <strong>of</strong> <strong>in</strong>fested gra<strong>in</strong> or, have a calibrated sprayer and an empty storage <strong>in</strong>to which cereal<br />

gra<strong>in</strong> can be treated with dichlorvos.<br />

Fumigat<strong>in</strong>g stored gra<strong>in</strong> with Vapormate Fumigant® (ethyl formate)<br />

Vapormate Fumigant® (166.7 g/kg ethyl formate) has recently been approved by the Australian Pesticides<br />

and Veter<strong>in</strong>ary Medic<strong>in</strong>es Authority and released on to the Australian market by BOC, as a post-harvest<br />

fumigant for the control adult stages <strong>of</strong> certa<strong>in</strong> <strong>in</strong>sect pests <strong>in</strong> stored cereal gra<strong>in</strong>s, oilseeds, gra<strong>in</strong> storage<br />

premises and equipment (and certa<strong>in</strong> horticultural produce). Vapormate Fumigant® is supplied as a liquified<br />

14

gas under pressure and is to be applied <strong>in</strong> sealed, gas-tight chambers. Visit BOC Gases website at<br />

www.boc.gases.com/products_and_services/ for full <strong>in</strong>formation.<br />

This fumigant is to be used only by licensed fumigators who hold appropriate State/Territory license, and<br />

are tra<strong>in</strong>ed <strong>in</strong> the proper use <strong>of</strong> required detection devices. It is not to be applied to farm gra<strong>in</strong> silos as a<br />

general use recommendation, by unauthorised, untra<strong>in</strong>ed operators.<br />

Vapormate Fumigant® is approved for control <strong>of</strong> adult stages only <strong>of</strong> Rice weevil, Lesser Gra<strong>in</strong> Borer, Rust<br />

Red Flour Beetle and Psocids. Application rate <strong>in</strong> stored gra<strong>in</strong>s is 420g/m³. Required exposure period is 24<br />

hours. For treat<strong>in</strong>g gra<strong>in</strong> storage premises and equipment, application rate is 420g/m³ and exposure time is<br />

6 hours.<br />

6. <strong>Control</strong>led atmospheres - <strong>Insect</strong> control <strong>in</strong> stored gra<strong>in</strong>s storage us<strong>in</strong>g<br />

controlled atmospheres<br />

<strong>Control</strong>led or modified atmosphere (CA) refers to the process <strong>of</strong> alter<strong>in</strong>g the proportion <strong>of</strong> atmospheric gases<br />

oxygen, nitrogen and carbon dioxide (CO2) to produce a gas mixture toxic to <strong>in</strong>sects. The advantage <strong>of</strong> the<br />

CA technique is that it provides a dis<strong>in</strong>festation method that is chemical-free and suitable for "organic" gra<strong>in</strong>.<br />

A major disadvantage is that it is several times more expensive than fumigation with phosph<strong>in</strong>e.<br />

In practice, use <strong>of</strong> CA's is little different to fumigat<strong>in</strong>g with phosph<strong>in</strong>e. Currently, the only practical method<br />

available to farmers is to <strong>in</strong>troduce carbon dioxide from a gas cyl<strong>in</strong>der <strong>in</strong>to a gas-tight silo. A very high<br />

standard <strong>of</strong> gas-tightness is required, <strong>of</strong>ten with a supplementary bleed <strong>of</strong> gas, to hold at least 60% carbon<br />

dioxide for at least 10 days or 30-40% carbon dioxide for 14 days to kill all stages <strong>of</strong> the <strong>in</strong>sects’ life cycle.<br />

For further <strong>in</strong>formation on controlled atmosphere fumigation, contact the commercial suppliers <strong>of</strong> appropriate<br />

gas and equipment, BOC Gases Australia Ltd, Ph on 13 12 62, or BOC’s website at<br />

www.boc.gases.com/products_and_services/<br />

Contact Organic certify<strong>in</strong>g bodies for specific requirements for organic gra<strong>in</strong>s. You can also get basic<br />

<strong>in</strong>formation on this subject by visit<strong>in</strong>g NSW <strong>Department</strong> <strong>of</strong> <strong>Primary</strong> <strong>Industries</strong> website at<br />

www.agric.nsw.gov.au.<br />

7. Aeration for cool<strong>in</strong>g – to control <strong>in</strong>sects <strong>in</strong> stored gra<strong>in</strong>s<br />

Temperature effects on gra<strong>in</strong> <strong>in</strong>sects<br />

Numbers <strong>of</strong> common gra<strong>in</strong> pests can <strong>in</strong>crease by 20-25 times a month at typical gra<strong>in</strong> harvest temperatures<br />

<strong>of</strong> 30 0 C and gra<strong>in</strong> moisture content <strong>of</strong> 14% for wheat (equivalent to 73% relative humidity (RH)).<br />

Reduc<strong>in</strong>g gra<strong>in</strong> temperature slows <strong>in</strong>sect development. For example, flour beetles can complete their<br />

development <strong>in</strong> three weeks at 35 o C and 70%RH, but take ten weeks at 22.5 o C and 70%RH. Although adult<br />

gra<strong>in</strong> <strong>in</strong>sects live a long time at cool temperatures, their young stages stop develop<strong>in</strong>g at temperatures<br />

below 20 0 C for most species or below 15 0 C for rice weevil.<br />

Aeration cool<strong>in</strong>g can greatly reduce <strong>in</strong>sect and mould activity <strong>in</strong> stored gra<strong>in</strong>, as well as preserv<strong>in</strong>g gra<strong>in</strong><br />

quality. Aeration cool<strong>in</strong>g lowers the temperature <strong>of</strong> gra<strong>in</strong> by blow<strong>in</strong>g cool air through it. An automatic<br />

controller is more effective than thermostats, timers or manual switches <strong>in</strong> select<strong>in</strong>g the coldest air available.<br />

Some growers f<strong>in</strong>d that a comb<strong>in</strong>ation <strong>of</strong> good hygiene and well-managed aeration cool<strong>in</strong>g prevents<br />

development <strong>of</strong> problem <strong>in</strong>sect <strong>in</strong>festations. However other growers have <strong>in</strong>sect problems <strong>in</strong> aerated gra<strong>in</strong>,<br />

particularly <strong>in</strong> summer. Therefore, aeration may need to be used <strong>in</strong> conjunction with other pest control<br />

methods.<br />

Aeration may fail to control <strong>in</strong>sects because <strong>of</strong> heat<strong>in</strong>g <strong>of</strong> the surface layer, particularly <strong>in</strong> summer, or<br />

because <strong>of</strong> <strong>in</strong>sects fly<strong>in</strong>g <strong>in</strong>to the surface layer. Both these problems can be overcome by mix<strong>in</strong>g<br />

amorphous silica (see Table 9 for product names) <strong>in</strong>to the top 30cm <strong>of</strong> gra<strong>in</strong> at the rate <strong>of</strong> 1kg/tonne <strong>of</strong><br />

gra<strong>in</strong>. The amorphous silica is diluted when out-load<strong>in</strong>g to levels that are acceptable to buyers. Pa<strong>in</strong>t<strong>in</strong>g a<br />

silo white can reduce surface gra<strong>in</strong> temperature by 4-5 0 C.<br />

15

Aeration cool<strong>in</strong>g is strongly recommended for seed or malt<strong>in</strong>g barley to ma<strong>in</strong>ta<strong>in</strong> germ<strong>in</strong>ation and malt<strong>in</strong>g<br />

quality.<br />

For more detailed <strong>in</strong>formation on aeration, refer also to:<br />

• DPI&FNote Gra<strong>in</strong> Storage - “Aeration Cool<strong>in</strong>g & Dry<strong>in</strong>g”<br />

• GRDC Gra<strong>in</strong>s Research Update Advice “Aeration <strong>in</strong> On-Farm Storage – What’s Possible” at<br />

www.grdc.com.au/director/events/factsheets.<br />

• GRDC Gra<strong>in</strong>s Research Update Advice “How Aeration Works” at<br />

www.grdc.com.au/director/events/factsheets.<br />

PLEASE NOTE: DPI&F WEBPAGES ARE CURRENTLY UNDER REDEVELOPMENT. PLEASE SEARCH<br />

the DPI&F’s Field crops website at www.dpi.qld.gov./fieldcrops for the latest <strong>in</strong>formation from July 2007.<br />

8. <strong>Insect</strong> identification – stored gra<strong>in</strong> <strong>in</strong>sect pests<br />

Effective <strong>in</strong>sect management <strong>in</strong> stored gra<strong>in</strong>s requires at least a basic ability to identify the <strong>in</strong>sect species<br />

present. This is especially important where <strong>in</strong>secticide resistance is suspected as the cause <strong>of</strong> control<br />

failures.<br />

See DPI&F Notes for a basic guide to identify<strong>in</strong>g the common <strong>in</strong>sect pests <strong>in</strong> gra<strong>in</strong> storages:<br />

• Identification <strong>of</strong> <strong>Insect</strong> Pests<br />

• Psocid Pests and booklice”<br />

• Bruchids <strong>in</strong> mungbeans and other pulse crops”<br />

• Mite Pests”.<br />

PLEASE NOTE: DPI&F WEBPAGES ARE CURRENTLY UNDER REDEVELOPMENT. PLEASE SEARCH<br />

the DPI&F’s Field crops website at www.dpi.qld.gov.au/fieldcrops for latest <strong>in</strong>formation from July 2007.<br />

9. Resistance and failure <strong>of</strong> <strong>in</strong>sect control treatments <strong>in</strong> stored gra<strong>in</strong>s<br />

Manag<strong>in</strong>g resistance to protectants<br />

Resistance <strong>of</strong> gra<strong>in</strong> <strong>in</strong>sects to protectants has become a major problem <strong>in</strong> Australia. Mixtures <strong>of</strong> different<br />

protectants have become necessary to effectively manage the range <strong>of</strong> different <strong>in</strong>sect species normally<br />

occurr<strong>in</strong>g <strong>in</strong> stored gra<strong>in</strong>s. The recommended and approved <strong>in</strong>secticides for treat<strong>in</strong>g stored gra<strong>in</strong>s are fully<br />

covered <strong>in</strong> Tables 2-8 above.<br />

For the latest <strong>in</strong>formation on <strong>in</strong>secticide resistance see DPI&F Note “Gra<strong>in</strong> Storage - Resistance to<br />

Phosph<strong>in</strong>e Fumigant and Protectant <strong>Insect</strong>icides” at www.dpi.qld.gov.au/fieldcrops<br />

Resistance to protectants is <strong>of</strong> major concern <strong>in</strong> two species <strong>in</strong> the eastern states <strong>of</strong> Australia:<br />

• Saw-toothed gra<strong>in</strong> beetle is resistant to fenitrothion, chlorpyriphos-methyl and pirimiphos-methyl.<br />

• Lesser gra<strong>in</strong> borer is resistant to dichlorvos,,fenitrothion, chlorpyriphos-methyl and pirimiphosmethyl,<br />

resistance to methoprene is now also common. For further <strong>in</strong>formation on identification <strong>of</strong><br />

the common <strong>in</strong>sects <strong>of</strong> stored gra<strong>in</strong>s, see DPI&F’s Note “Gra<strong>in</strong> Storage – Identification <strong>of</strong> <strong>Insect</strong><br />

Pests” at www.dpi.qld.gov.au/fieldcrops.<br />

PLEASE NOTE: DPI&F WEBPAGES ARE CURRENTLY UNDER REDEVELOPMENT. PLEASE SEARCh<br />

DPPI&F’s Field Crops website www.dpi.qld.gov.au/fieldcrops for the latest <strong>in</strong>formation from July 2007.<br />

Resistance should be suspected when obvious numbers <strong>of</strong> <strong>in</strong>sects appear <strong>in</strong> a well-treated bulk before the<br />

end <strong>of</strong> the storage period claimed on the label for the protectant, especially if <strong>in</strong>sects <strong>of</strong> one type only are<br />

16

<strong>in</strong>volved. If this occurs use different <strong>in</strong>secticides for future treatments. However, don’t jump to the conclusion<br />

that every control failure is caused by resistance. Often the reason for control failure can be a problem with<br />

the dose rate or application technique.<br />

If you suspect <strong>in</strong>secticide resistance<br />

If you suspect resistance is caus<strong>in</strong>g control failures, you can have your <strong>in</strong>sect specimens tested for<br />

resistance. Please send live specimens <strong>in</strong> gra<strong>in</strong> to:<br />

Food Protection Team,<br />

DPI&F (Entomology)<br />

80 Meiers Road,<br />

Indooroopilly, Qld., 4068.<br />

(Phone: (07)38969433 or (07)38969807).<br />

NB: Please <strong>in</strong>clude your full contact details and details <strong>of</strong> previous gra<strong>in</strong> treatments.<br />

You can affect the build up <strong>of</strong> resistance by the control methods you use:<br />

• Repeated use <strong>of</strong> the same chemicals will speed up resistance development.<br />

• Use amorphous silica powder <strong>in</strong>stead <strong>of</strong> chemical <strong>in</strong>secticides for treat<strong>in</strong>g silo surfaces and storage<br />

areas after cleanup as this reduces selection for resistance to the chemicals.<br />

• Selection for resistance can also be m<strong>in</strong>imised by us<strong>in</strong>g the non-chemical control methods such as<br />

hygiene and aeration.<br />

17

10. Commercial Preparations <strong>of</strong> <strong>Insect</strong>icides and Fumigants Approved for Farm-<strong>Stored</strong><br />

Gra<strong>in</strong>s <strong>in</strong> Queensland<br />

Table 9: Commercial preparations <strong>of</strong> <strong>in</strong>secticides and fumigants. Product registrations, trade names<br />

and availability are all subject to change. This <strong>in</strong>formation was extracted February, 2007 from Infopest – a<br />

database <strong>of</strong> pesticides approved <strong>in</strong> Australia. (Phone 07 3239 3967 to <strong>in</strong>quire about Infopest subscription),<br />

or Email Infopest at mailto.<strong>in</strong>fopest@dpi.qld.gov.au<br />

Active<br />

constituent<br />

Amorphous silica<br />

(see notes g,s)<br />

Concentr’n<br />

<strong>of</strong> active<br />

Commercial preparation<br />

(® - full trade name)<br />

Distributor /<br />

Supplier<br />

900g/kg Dryacide Gra<strong>in</strong> Protectant® Entosol, NSW<br />

900g/kg<br />

450g/L<br />

Absorba-Cide Sorptive Dust <strong>Insect</strong>icide® Growchoice,<br />

NSW<br />

Abrade Abrasive Barrier <strong>Insect</strong>icide® Growchoice,<br />

NSW<br />

1000g/kg Permaguard D-10 <strong>Insect</strong>icide® Mara Seeds,<br />

NSW<br />

Azamethiphos 500g/L Alfacron 500 Residual <strong>Insect</strong> Spray®<br />

(currently unavailable).<br />

Carbaryl (see<br />

note g)<br />

Chlorpryriphosmethyl<br />

500g/L Carbaryl 500 Flowable® David Gray & Co,<br />

WA<br />

500g/L<br />

500g/L (+<br />

30g/L<br />

methoprene)<br />

N/A<br />

Diplomat Gra<strong>in</strong> Protectant® Imtrade Aust P/L,<br />

WA<br />

Reldan Gra<strong>in</strong> Protector®<br />

Reldan pluS IGR<br />

Gra<strong>in</strong> Protector®<br />

Dow<br />

Agrosciences<br />

Deltamethr<strong>in</strong> 250g/L Delta 250 <strong>Insect</strong>icide® Allfire Ent., WA<br />

Dichlorvos (see<br />

notes g,s)<br />

Ethyl formate<br />

(see notes s, f)<br />

500g/L<br />

Dichlorvos 500 <strong>Insect</strong>icide Barmac Ind., Qld.<br />

Dichlorvos 500EC <strong>Insect</strong>icide® Imtrade Aust.,<br />

WA<br />

D.D.V.P. 500 <strong>Insect</strong>icide® David Gray &<br />

Co., WA<br />

1140g/L Dichlorvos 1140 <strong>Insect</strong>icide® Nufarm Aust. Ltd,<br />

Vic<br />

Pressurised<br />

gas 50g/kg<br />

<strong>Insect</strong>igas-D® (for use by licenced &/or<br />

authorised personnel only, not normal farm<br />

use)<br />

166.7g/kg Vapormate Fumigant® (for use by BOC -<br />

authorised and State licenced applicators<br />

only)<br />

BOC Gases,<br />

NSW<br />

Fenitrothion (see note g) 1 kg/L<br />

18

Methoprene (see<br />

note g)<br />

S-methoprene<br />

(see note g, s)<br />

Phosph<strong>in</strong>e (see<br />

note f)<br />

Pirimiphos-methyl<br />

(see notes g, s)<br />

50 g/L IGR Gra<strong>in</strong> Protectant Aqueous<br />

Gra<strong>in</strong>-Star 50 IGR Gra<strong>in</strong> Protectant®<br />

200 g/L IGR 200 Gra<strong>in</strong> Protectant Aqueous®<br />

Gra<strong>in</strong>-Star 200 IGR Gra<strong>in</strong> Protectant®<br />

Webcot or<br />

Farmoz - as<br />

above<br />

Webcot or<br />

Farmoz - as<br />

above<br />

300 g/L Rizacon S IGR Gra<strong>in</strong> Protector® Dow<br />

Agrosciences, or<br />

Wellmark Int’nl<br />

Aust, NSW<br />

30 g/L Reldan+IGR Gra<strong>in</strong> Protector®<br />

IGR Gra<strong>in</strong> Protectant®<br />

Gra<strong>in</strong> Proctection Pack®<br />

Tablets<br />

release 1g<br />

phosph<strong>in</strong>e<br />

Bag cha<strong>in</strong>,<br />

belt release<br />

110 g<br />

phosph<strong>in</strong>e<br />

Blanket<br />

releases 1.1<br />

kg phosph<strong>in</strong>e<br />

Dow Ag-sciences<br />

Rentokil Initial<br />

Webcot<br />

Quickphos Fumigation Tablets® UPL, NSW<br />

X-phos Fumigant® Webcot<br />

Celphide Fumigation Tablets® Excel Ind., NSW<br />

Pestex Fumigation Tablets® Farmoz, NSW<br />

Fumaphos Fumigation Tablets® National<br />

Fumigants, WA<br />

Fumitox<strong>in</strong> Coated Fumigation Tablets®<br />

Fumitox<strong>in</strong> Coated <strong>Insect</strong>icide Tablets®<br />

Newfarm, Vic<br />

Gastion Phosph<strong>in</strong>e Fumigation Tablets® Rentokil Initial<br />

Sanphos Fumigation Tablets® Jedcourt P/L,<br />

Qld.<br />

Quickphos Phosph<strong>in</strong>e Fumigation Bag<br />

Cha<strong>in</strong>®<br />

Gastion Phosph<strong>in</strong>e Fumigation Belt®<br />

Gastion Phosph<strong>in</strong>e Fumigation Belt®<br />

Quickphos Fumigation Blanket®<br />

Celphide Fumigation Blanket®<br />

Fumaphos Fumigation Blanket®<br />

UPL, NSW<br />

Rentokil Initial<br />

UPL, Excel Ind.,<br />

National<br />

Fumigants<br />

900g/L Actellic 900 SF Solvent Free <strong>Insect</strong>icide® Syngenta Crop<br />

Prot, NSW<br />

Webtellic 900 Solvent Free <strong>Insect</strong>icide® Webcot<br />

Sp<strong>in</strong>osad 22.8g/L Conserve Gra<strong>in</strong> Protector® – NOT expected<br />

on market <strong>in</strong> Australia until 2007- 08.<br />

Dow<br />

AgroSciences<br />

Notes on Table 9: g - approved gra<strong>in</strong> additives: - s - approved treatment for storages and handl<strong>in</strong>g<br />

equipment; f – approved fumigant.<br />

19

11. Further <strong>in</strong>formation<br />

<strong>Department</strong> <strong>of</strong> <strong>Primary</strong> <strong>Industries</strong> and Fisheries (Queensland), The follow<strong>in</strong>g DPI&FNotes are currently<br />

available at<br />

“Gra<strong>in</strong> Storage - Identification <strong>of</strong> <strong>Insect</strong>s”<br />