A Novel Copovidone Binder for Dry Granulation and

A Novel Copovidone Binder for Dry Granulation and

A Novel Copovidone Binder for Dry Granulation and

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

A <strong>Novel</strong> <strong>Copovidone</strong> <strong>Binder</strong><br />

<strong>for</strong> <strong>Dry</strong> <strong>Granulation</strong> <strong>and</strong><br />

Direct-Compression Tableting<br />

Antonio Moroni<br />

Plasdone S-630 copovidone, a<br />

synthetic r<strong>and</strong>om copolymer of<br />

vinyl pyrrolidone <strong>and</strong> vinyl<br />

acetate, has been developed <strong>for</strong><br />

use as a binder in pharmaceutical<br />

tableting. Vinyl acetate in the<br />

<strong>for</strong>mulation makes the polymer<br />

more plastic <strong>and</strong> less hygroscopic<br />

than st<strong>and</strong>ard Plasdone<br />

homopolymers without<br />

compromising its solubility in<br />

water.These properties make<br />

Plasdone S-630 copovidone a dry<br />

binder that is effective at a lowuse<br />

level <strong>and</strong> a suitable material<br />

<strong>for</strong> applications in dry<br />

granulation <strong>and</strong> directcompression<br />

tableting.<br />

Antonio Moroni, PhD, is the manager<br />

of pharmaceutical research at International<br />

Specialty Products, 1361 Alps Rd., Wayne,<br />

NJ 07040, tel. 973.628.3346, fax 973.628.<br />

3759, e-mail amoroni@ispcorp.com, www.<br />

isp-pharma.com.<br />

Direct compression <strong>and</strong>, to some extent, dry granulation<br />

are becoming increasingly popular methods in<br />

the manufacture of tablets because they are easier <strong>and</strong><br />

quicker techniques than wet granulation. To ensure<br />

tablets are produced with acceptable hardness <strong>and</strong> low friability,<br />

a component with good dry-binding properties usually is<br />

necessary in the <strong>for</strong>mulation. Most dry binders consist of highly<br />

compressible fillers or filler binders, which improve the binding<br />

capacity of the active <strong>and</strong> make up a significant proportion<br />

of the tablet weight. In some cases, high-per<strong>for</strong>mance dry binders<br />

that do not appreciably add to the tablet weight are required,<br />

e.g., with high-dose drugs or to improve the per<strong>for</strong>mance of<br />

filler binders. Under these circumstances, the binder must be<br />

finely divided <strong>and</strong> have exceptional powder-flow properties to<br />

ensure ideal distribution, particularly in direct compression.<br />

Physical <strong>and</strong> chemical properties<br />

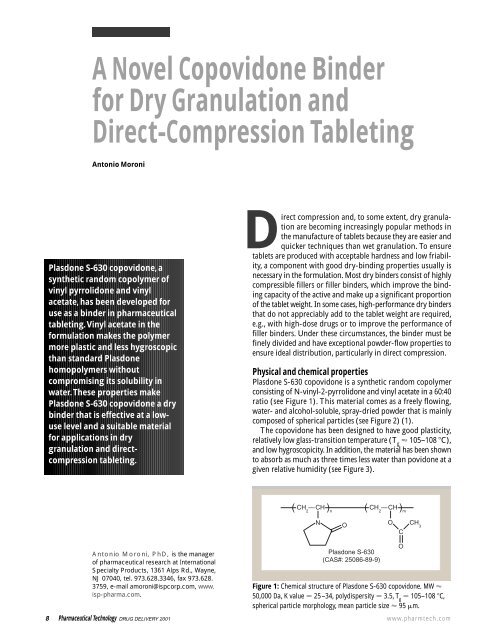

Plasdone S-630 copovidone is a synthetic r<strong>and</strong>om copolymer<br />

consisting of N-vinyl-2-pyrrolidone <strong>and</strong> vinyl acetate in a 60:40<br />

ratio (see Figure 1). This material comes as a freely flowing,<br />

water- <strong>and</strong> alcohol-soluble, spray-dried powder that is mainly<br />

composed of spherical particles (see Figure 2) (1).<br />

The copovidone has been designed to have good plasticity,<br />

relatively low glass-transition temperature (T g 105–108 C),<br />

<strong>and</strong> low hygroscopicity. In addition, the material has been shown<br />

to absorb as much as three times less water than povidone at a<br />

given relative humidity (see Figure 3).<br />

( CH 2 —CH ) n<br />

Plasdone S-630<br />

(CAS#: 25086-89-9)<br />

( CH 2 —CH ) m<br />

8 Pharmaceutical Technology DRUG DELIVERY 2001 www.pharmtech.com<br />

N<br />

O<br />

O<br />

C<br />

O<br />

CH 3<br />

Figure 1: Chemical structure of Plasdone S-630 copovidone. MW <br />

50,000 Da, K value 25–34, polydispersity 3.5, T g 105–108 C,<br />

spherical particle morphology, mean particle size 95 m.

Figure 2: SEM micrography of Plasdone S-630 copovidone.<br />

The copovidone’s flowability, hygroscopicity, <strong>and</strong> plasticity<br />

make it a highly suitable excipient <strong>for</strong> hard-to-compress or<br />

moisture-sensitive drugs <strong>and</strong> may improve storage stability.<br />

Figure 4 shows its compressibility in comparison with other<br />

direct-compression binders.<br />

This material is listed in several pharmacopeia under the following<br />

nomenclature:<br />

● <strong>Copovidone</strong> NF (draft published)<br />

● Copolyvidonum Ph Eur<br />

● Copolyvidon DAB<br />

● Copolyvidone JSPI<br />

Applications<br />

The physical properties of Plasdone S-630 copovidone (flowability,<br />

hygroscopicity, spherical particle shape, binding strength,<br />

glass-transition temperature, <strong>and</strong> hydrophobic–hydrophilic<br />

balance) may offer significant advantages in the roller-compaction<br />

<strong>and</strong> direct-compression processes involved in pharmaceutical<br />

tablet manufacturing. The copovidone can be used<br />

separately or in combination with lactose, dicalcium phosphate<br />

(DCP), <strong>and</strong> microcrystalline cellulose (MCC) as a dry binder<br />

in the roller-compaction process to produce granules with good<br />

flow <strong>and</strong> bulk density. The product also can be used to make<br />

effervescent tablets by direct-compression techniques, instead<br />

of the use of solvent-based anhydrous wet granulation. The<br />

material is water soluble <strong>and</strong> will produce a clear liquid upon<br />

dissolution.<br />

The properties of Plasdone S-630 copovidone were evaluated<br />

in a study targeted to assess the compressibility of Plasdone<br />

S-630 copovidone–based tablet <strong>for</strong>mulations both in<br />

roller compaction <strong>and</strong> direct compression. Two factors were<br />

studied: the effect of the presence or absence of a filler or binder<br />

(MCC) <strong>and</strong> the tableting properties in the presence of both<br />

water-soluble (e.g., directly compressible [DC] lactose) <strong>and</strong> insoluble<br />

(e.g., DCP) fillers, thus comparing hydrophobic <strong>and</strong><br />

hydrophilic excipients.<br />

Experimental conditions<br />

Directly compressed <strong>for</strong>mulations. Hydrochlorothiazide (HCTZ)<br />

was used as a model drug <strong>for</strong> eight different <strong>for</strong>mulations. Table<br />

I lists the components of the <strong>for</strong>mulations <strong>and</strong> their percentages.<br />

Formulations were either directly compressed or roller<br />

compacted, granulated, <strong>and</strong> then compressed.<br />

% Moisture<br />

100<br />

80<br />

60<br />

40<br />

20<br />

Plasdone K-29/32<br />

Plasdone S-630<br />

0<br />

0 20 40 60 80 100<br />

% Relative humidity<br />

Figure 3: Moisture absorption profiles of Plasdone S-630 copovidone<br />

<strong>and</strong> povidone.<br />

Hardness (kp)<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

<br />

<br />

Roller-compacted <strong>for</strong>mulations. HCTZ <strong>and</strong> acetylsalicylic acid<br />

(ASA) were used as model drugs <strong>for</strong> roller-compacted <strong>for</strong>mulations.<br />

Table II lists the components of the HCTZ <strong>for</strong>mulations<br />

<strong>and</strong> their percentages, <strong>and</strong> Table III lists these <strong>for</strong> the ASA<br />

<strong>for</strong>mulations.<br />

Roller-compacted <strong>for</strong>mulation ribbons were prepared as<br />

described in Table IV to evaluate, in addition to the binder<br />

type, the effect of the roller-compaction factors on the final<br />

tablets’ per<strong>for</strong>mances through a fractional factorial experimental<br />

design. Tableting was per<strong>for</strong>med in a rotary press<br />

(Stokes, Bristol, PA) at compression <strong>for</strong>ces of 6000 lbs (1 lb<br />

<strong>for</strong>ce 4.448 N). Tablets were subjected to various physical<br />

tests, including tests to evaluate hardness, friability, disintegration,<br />

<strong>and</strong> dissolution.<br />

Results <strong>and</strong> discussion<br />

Directly compressed <strong>for</strong>mulations. Initial <strong>for</strong>mulations were prepared<br />

keeping MCC fixed at 18% <strong>and</strong> using Plasdone S-630<br />

copovidone at either 0% or 10% levels. As levels of copovidone<br />

were increased, the <strong>for</strong>mulation was compensated with decreasing<br />

amounts of filler (lactose or DCP) while maintaining<br />

the level of MCC. The following results were obtained (2):<br />

<br />

<br />

2000 4000<br />

Compression <strong>for</strong>ce (lb)<br />

6000<br />

Plasdone S-630 MCC Lactose DT<br />

HPMC 15 cps Dicalcium phosphate<br />

Figure 4: Compressibility profiles of Plasdone S-630 copovidone <strong>and</strong><br />

other binders.<br />

Pharmaceutical Technology DRUG DELIVERY 2001 9

Table I: HCTZ directly compressed <strong>for</strong>mulations.<br />

Component Percentage Range (% w/w)<br />

Hydrochlorothiazide (HCTZ) 25<br />

MCC 101 18–28<br />

DC lactose or dicalcium phosphate 44–54<br />

Plasdone S-630 copovidone 10–0<br />

Polyplasdone crospovidone XL 2<br />

Colloidal silicon dioxide 0.5<br />

Magnesium stearate 0.5<br />

Total 100<br />

Table III: ASA roller-compacted <strong>for</strong>mulations.<br />

Component Percentage Range (% w/w)<br />

Acetylsalicylic acid (ASA) 80<br />

<strong>Binder</strong> (Plasdone S-630 copovidone,<br />

HPMC 15 cps, MCC 101) 5<br />

DC lactose filler 10<br />

Polyplasdone crospovidone XL 3<br />

Colloidal silicon dioxide 1<br />

Magnesium stearate 1<br />

Total 100<br />

● Hardness. Higher levels of Plasdone S-630 copovidone led to<br />

a marginal increase in tablet hardness when DC lactose was<br />

used. Tablets <strong>for</strong>mulated with DCP had a greater increase in<br />

tablet hardness.<br />

● Ejection <strong>for</strong>ce. Ejection <strong>for</strong>ce was reduced in <strong>for</strong>mulations<br />

that contained Plasdone S-630 copovidone.<br />

● Friability <strong>and</strong> disintegration. Marginal improvements were<br />

observed in <strong>for</strong>mulations that contained Plasdone S-630<br />

copovidone <strong>and</strong> DCP or DC lactose.<br />

● Dissolution. Increasing the level of Plasdone S-630 copovi-<br />

(a) DC Lactose filler (b) DCP filler<br />

Hardness (KPa)<br />

20<br />

15<br />

10<br />

5<br />

S-630 10%<br />

No S-630<br />

0<br />

0 2000 4000 6000 8000<br />

Compression <strong>for</strong>ce (lb)<br />

Table V: Hardness of HCTZ <strong>and</strong> ASA tablets compressed at 6000 lb<br />

from roller-compacted <strong>for</strong>mulations.*<br />

Plasdone S-630 copovidone MCC HPMC 15 cps<br />

Drug 4 rpm 8 rpm 4 rpm 8 rpm 4 rpm 8 rpm<br />

HCTZ 6.7 5.7 4.7 4.4 5.4 5.2<br />

ASA 6.9 6.5 6.8 6.1 6.9 6.4<br />

* Values are shown <strong>for</strong> roll speeds of 4 <strong>and</strong> 8 rpm.<br />

Hardness (KPa)<br />

20<br />

16<br />

12<br />

8<br />

4<br />

S-630 10%<br />

No S-630<br />

Table II: HCTZ roller-compacted <strong>for</strong>mulations.<br />

Component Percentage Range (% w/w)<br />

Hydrochlorothiazide (HCTZ) 76.5<br />

<strong>Binder</strong> (Plasdone S-630 copovidone,<br />

HPMC 15 cps, MCC 101) 5<br />

DC lactose filler 15<br />

Polyplasdone crospovidone XL 2<br />

Colloidal silicon dioxide 0.5<br />

Magnesium stearate 0.5<br />

Total 100<br />

Table IV: Roller compaction factors.<br />

Factor Low Level High Level<br />

Feed-screw rate (rpm) 8 24<br />

Roll speed (rpm) 4 8<br />

Roll pressure (ton) 1 2<br />

done from 0% to 10% did not alter the dissolution profiles<br />

of tablets <strong>for</strong>mulated with DC lactose or DCP. All <strong>for</strong>mulations<br />

passed the USP dissolution tolerance criteria.<br />

Figure 5 shows the hardness profiles of tablets containing 0%<br />

or 10% Plasdone S-630 copovidone substituting filler.<br />

A second set of <strong>for</strong>mulations then was prepared keeping filler<br />

level constant (DC lactose or DCP) but substituting as much<br />

as 10% MCC with Plasdone S-630 copovidone. The goal was<br />

to compare these <strong>for</strong>mulations directly with those containing<br />

MCC.<br />

The following results were obtained:<br />

● Hardness. Tablets <strong>for</strong>mulated with DC lactose <strong>and</strong> those <strong>for</strong>mulated<br />

with DCP were as hard or harder when Plasdone S-<br />

630 copovidone was used in place of 10% MCC.<br />

● Disintegration. Disintegration times were less than 1 min <strong>for</strong><br />

all tablets at all compression <strong>for</strong>ces,<br />

<strong>and</strong> no significant differences were<br />

observed in dissolution profiles<br />

among concentrations at 30 min.<br />

0<br />

0 2000 4000 6000 8000<br />

Compression <strong>for</strong>ce (lb)<br />

Figure 5: Hardness of directly compressed HCTZ <strong>for</strong>mulations in which Plasdone S-630 copovidone has<br />

replaced 10% filler <strong>for</strong> (a) DC lactose filler <strong>and</strong> (b) DCP filler.<br />

Figure 6 shows the tablet responses<br />

measured at 0% <strong>and</strong><br />

10% concentration levels of the<br />

Plasdone S-630 copovidone,<br />

keeping MCC levels at 28% <strong>and</strong><br />

18% respectively.<br />

From these results, it appears<br />

that the addition of Plasdone S-<br />

630 copovidone (as much as 10%)<br />

to <strong>for</strong>mulations can improve hardness,<br />

lower ejection <strong>for</strong>ce, <strong>and</strong> reduce<br />

friability without loss in dissolution<br />

per<strong>for</strong>mance. MCC can<br />

be partly substituted by Plasdone<br />

S-630 copovidone to achieve enhanced<br />

compressibility, <strong>and</strong> thus<br />

it can be used as a direct-compression<br />

binder aid <strong>for</strong> the augmentation<br />

of tablet characteristics.<br />

Roller-compacted <strong>for</strong>mulations.<br />

Roller-compacted <strong>for</strong>mulations<br />

10 Pharmaceutical Technology DRUG DELIVERY 2001 www.pharmtech.com

(a) DC Lactose filler (b) DCP filler<br />

Hardness (KPa)<br />

Ejection <strong>for</strong>ce (lb)<br />

20<br />

15<br />

10<br />

5<br />

S-630 10%MCC 28%<br />

MCC 28%<br />

0<br />

0 2000 4000 6000 8000<br />

Compression <strong>for</strong>ce (lb)<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

S-630 10%MCC 18%<br />

MCC 28%<br />

0 2000 4000 6000 8000<br />

Compression <strong>for</strong>ce (lb)<br />

Hardness (KPa)<br />

(c) DC Lactose filler (d) DCP filler<br />

Ejection <strong>for</strong>ce (lb)<br />

(e) DC Lactose filler (f) DCP filler<br />

Friability (%)<br />

4<br />

3<br />

2<br />

1<br />

S-630 10%MCC 18%<br />

MCC 28%<br />

Friability (%)<br />

20<br />

15<br />

10<br />

5<br />

S-630 10%MCC 18%<br />

MCC 28%<br />

0<br />

0 2000 4000 6000 8000<br />

Compression <strong>for</strong>ce (lb)<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

S-630 10%MCC 18%<br />

MCC 28%<br />

0 2000 4000 6000 8000<br />

Compression <strong>for</strong>ce (lb)<br />

0<br />

0<br />

0 2000 4000 6000 8000 0 2000 4000 6000 8000<br />

Compression <strong>for</strong>ce (lb)<br />

Compression <strong>for</strong>ce (lb)<br />

3<br />

2.5<br />

2<br />

1.5<br />

1<br />

0.5<br />

S-630 10%MCC 18%<br />

MCC 28%<br />

Figure 6: Characteristics of directly compressed HCTZ <strong>for</strong>mulations in which Plasdone S-630 has<br />

replaced 10% MCC: hardness of HCTZ tablets <strong>for</strong> (a) DC lactose filler <strong>and</strong> (b) DCP filler; ejection <strong>for</strong>ce of<br />

HCTZ tablets <strong>for</strong> (c) DC lactose filler <strong>and</strong> (d) DCP filler; <strong>and</strong> friability of HCTZ tablets <strong>for</strong> (e) DC lactose<br />

filler <strong>and</strong> (f) DCP filler.<br />

% Dissolved<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

Plasdone S-630<br />

HPMC 15 cps<br />

MCC<br />

0<br />

0 20 40<br />

Time (min)<br />

60 80<br />

Figure 7: Dissolution profiles of roller-compacted ASA <strong>for</strong>mulations<br />

(6000 lb, 4 rpm) with 5% of Plasdone S-630 copovidone, MCC 101, or<br />

HPMC 15 cps binder.<br />

were prepared at higher drug loading,<br />

<strong>and</strong> the binding per<strong>for</strong>mance<br />

of Plasdone S-630 copovidone was<br />

compared with those of commonly<br />

used binders such as MCC<br />

or hydroxypropylmethyl cellulose<br />

(HPMC) 15 cps.<br />

Results obtained show the following<br />

trends (3):<br />

● Effect of compaction parameters<br />

on final tablet hardness. The<br />

use of a lower roll speed produced<br />

harder tablets with both<br />

drugs, a confirmation of the<br />

plastic behavior of the three<br />

binders. Feed-screw rate <strong>and</strong> roll<br />

pressure did not have a significant<br />

effect on final hardness.<br />

● Hardness. As shown in Table V,<br />

HCTZ tablets made with Plasdone<br />

S-630 copovidone show a<br />

substantially improved hardness<br />

in comparison with tablets<br />

made with HPMC or MCC.<br />

ASA tablets made with Plasdone<br />

S-630 copovidone showed similar<br />

hardness to tablets made<br />

with both MCC <strong>and</strong> HPMC 15<br />

cps.<br />

● Dissolution. HCTZ tablets made<br />

with all three binders showed<br />

similar dissolution profiles. ASA<br />

tablets made with MCC showed<br />

slower dissolution profiles than<br />

did tablets made with either<br />

Plasdone S-630 copovidone or<br />

HPMC 15 cps (see Figure 7).<br />

Conclusion<br />

Plasdone S-630 copovidone has been shown to be a good rollercompaction<br />

binder, <strong>and</strong> its addition to directly compressed <strong>for</strong>mulations<br />

has been shown to improve tablet hardness substantially.<br />

Tablets made with Plasdone S-630 copovidone show<br />

higher hardness <strong>and</strong>/or better drug dissolution profiles than<br />

those made with other binders. For additional in<strong>for</strong>mation<br />

about Plasdone S-630 copovidone, contact the author.<br />

References<br />

1. ISP technical bulletin, Pharma/PLASS630.0800.<br />

2. A. Moroni, M. Nerella, <strong>and</strong> G. DuBrowny, “Plasdone S-630 as High-<br />

Per<strong>for</strong>mance <strong>Binder</strong> <strong>for</strong> <strong>Dry</strong> <strong>Granulation</strong>,” presented at the 2000 AAPS<br />

meeting, Indianapolis, Indiana, 29 October–2 November 2000.<br />

3. A. Moroni, M. Nerella, <strong>and</strong> G. DuBrowny, “Plasdone S-630 Mixes as<br />

<strong>Dry</strong> <strong>Granulation</strong> <strong>Binder</strong>s with Improved Per<strong>for</strong>mance,” presented at<br />

the AAPS Pharmaceutical Congress of the Americas, Orl<strong>and</strong>o, Florida,<br />

24–29 March 2001. PT<br />

12 Pharmaceutical Technology DRUG DELIVERY 2001 www.pharmtech.com