04-025-034 Rubber-steel gaskets.pmd - Kempchen.de

04-025-034 Rubber-steel gaskets.pmd - Kempchen.de

04-025-034 Rubber-steel gaskets.pmd - Kempchen.de

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>04</strong><br />

34<br />

<strong>Rubber</strong>-<strong>steel</strong> <strong>gaskets</strong><br />

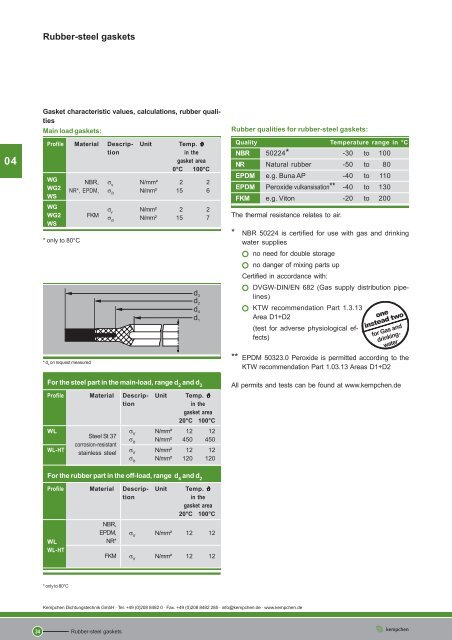

Gasket characteristic values, calculations, rubber qualities<br />

Main load <strong>gaskets</strong>:<br />

Profile Material Descrip- Unit Temp. ϑ<br />

tion in the<br />

gasket area<br />

0°C 100°C<br />

WG<br />

WG2<br />

WS<br />

WG<br />

WG2 FKM<br />

WS<br />

* only to 80°C<br />

* d 4 on request measured<br />

NBR, σ v N/mm² 2 2<br />

NR*, EPDM, σ ϑ N/mm² 15 6<br />

<strong>Kempchen</strong> Dichtungstechnik GmbH · Tel. +49 (0)208 8482 0 · Fax. +49 (0)208 8482 285 · info@kempchen.<strong>de</strong> · www.kempchen.<strong>de</strong><br />

<strong>Rubber</strong>-<strong>steel</strong> <strong>gaskets</strong><br />

<strong>Rubber</strong> qualities for rubber-<strong>steel</strong> <strong>gaskets</strong>:<br />

Quality Temperature range in °C<br />

NBR 50224* -30 to 100<br />

NR Natural rubber -50 to 80<br />

EPDM e.g. Buna AP -40 to 110<br />

EPDM Peroxi<strong>de</strong> vulkansisation** -40 to 130<br />

FKM e.g. Viton -20 to 200<br />

σ v N/mm² 2 2<br />

σ ϑ N/mm² 15 7 The thermal resistance relates to air.<br />

For the <strong>steel</strong> part in the main-load, range d2 and d3 Profile Material Descrip- Unit Temp. ϑ<br />

tion in the<br />

gasket area<br />

20°C 100°C<br />

WL<br />

WL-HT<br />

Steel St 37<br />

corrosion-resistant<br />

stainless <strong>steel</strong><br />

σV σϑ σV σϑ N/mm²<br />

N/mm²<br />

N/mm²<br />

N/mm²<br />

12<br />

450<br />

12<br />

120<br />

12<br />

450<br />

12<br />

120<br />

For the rubber part in the off-load, range d4 and d2 Profile Material Descrip- Unit Temp. ϑ<br />

tion in the<br />

gasket area<br />

20°C 100°C<br />

WL<br />

WL-HT<br />

* only to 80°C<br />

NBR,<br />

EPDM,<br />

NR*<br />

FKM<br />

σ V N/mm² 12 12<br />

σ V N/mm² 12 12<br />

* NBR 50224 is certified for use with gas and drinking<br />

water supplies<br />

no need for double storage<br />

no danger of mixing parts up<br />

Certified in accordance with:<br />

DVGW-DIN/EN 682 (Gas supply distribution pipelines)<br />

KTW recommendation Part 1.3.13<br />

Area D1+D2<br />

(test for adverse physiological effects)<br />

** EPDM 50323.0 Peroxi<strong>de</strong> is permitted according to the<br />

KTW recommendation Part 1.03.13 Areas D1+D2<br />

All permits and tests can be found at www.kempchen.<strong>de</strong>