Manuale Mirella (GB) - TOP-EL, spol. s ro

Manuale Mirella (GB) - TOP-EL, spol. s ro

Manuale Mirella (GB) - TOP-EL, spol. s ro

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

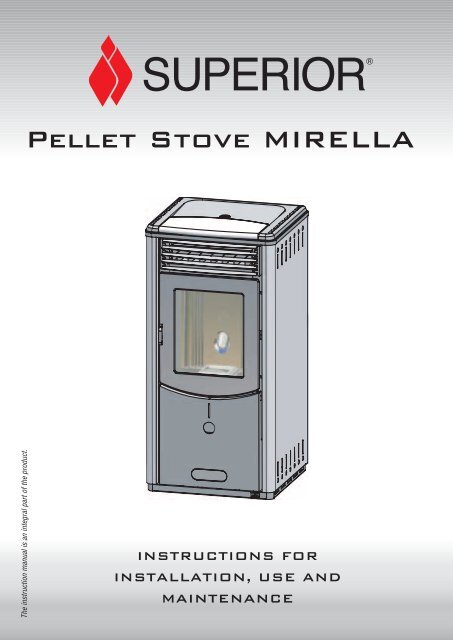

The instruction manual is an integral part of the p<strong>ro</strong>duct.<br />

SUPERIOR®<br />

Pellet Stove MIR<st<strong>ro</strong>ng>EL</st<strong>ro</strong>ng>LA<br />

INSTRUCTIONS FOR<br />

INSTALLATION, USE AND<br />

MAINTENANCE

English<br />

Dear client,<br />

We thank you for choosing one of our p<strong>ro</strong>ducts, the result of technological expertise and continued research in pursuit of a superior p<strong>ro</strong>duct<br />

in terms of safety, reliability and features.<br />

In this manual you will find all the information and useful advice necessary to get the most out of your appliance in total safety.<br />

2<br />

DT2010001-00<br />

IMPORTANT INFORMATION DT2010208-02<br />

• This manual has been prepared by the manufacturer and constitutes an integral part<br />

of the p<strong>ro</strong>duct, and must accompany it th<strong>ro</strong>ughout its life. In the event of sale or relocation<br />

of the p<strong>ro</strong>duct make sure this booklet accompanies it, since the information<br />

contained in it is addressed to the purchaser and to anyone involved in the installation,<br />

use and maintenance of the p<strong>ro</strong>duct.<br />

• Read the instructions and the technical information contained in this manual carefully,<br />

before p<strong>ro</strong>ceeding with installation, use or any repairs.<br />

• The observance of the instructions and technical information in this manual guarantees<br />

the safety of the user and the p<strong>ro</strong>duct, a more efficient operation and an<br />

increased lifespan.<br />

• The p<strong>ro</strong>duct’s installation and use should conform to the manufacturer’s instructions<br />

and to local bylaws.<br />

• However, when carrying out any operation we recommend that you follow carefully<br />

the instructions contained in this manual, and that you keep it at your disposal.<br />

• Installation, electrical connection, checks, maintenance and repairs are operations<br />

which must be carried out exclusively by qualified and authorised personal with specialised<br />

knowledge of the p<strong>ro</strong>duct.<br />

• Before installing the p<strong>ro</strong>duct read all instruction booklets relating to installation of the<br />

cladding, the ventilation kit and any other accessories.<br />

• Be very careful when moving any ceramic components.<br />

• Check that the floor where the p<strong>ro</strong>duct is to be installed is exactly level.<br />

• To help correct potential unevenness and irregularities a sheet of adhesive fibreglass<br />

accompanies the p<strong>ro</strong>duct.<br />

• Do not block the electrical socket; it should be close to the unit but accessible.<br />

• Connect the pellet stove to the electricity supply only after it has been connected by<br />

an expert to the flue system.<br />

• The plug at the end of the power supply cable must be easily accessible after installation.<br />

• Use only regulation wood pellets (refer to section entitled “Technical charateristics<br />

and specifications” ).<br />

• Never use liquid fuels to light the stove or to relight the embers.<br />

• Ensure that the area where the stove is installed is p<strong>ro</strong>perly ventilated while the stove<br />

is lit.<br />

• In the event of technical faults the fuel supply will be interrupted. Restart the stove<br />

only after having eliminated the cause of the fault.<br />

• The wall where the p<strong>ro</strong>duct is to be placed should not be of wood or any other flammable<br />

material; furthermore it is important to maintain safety distances (refer to section<br />

entitled ‘Prevention of domestic fires’ contained in the stove’s manual for use<br />

and maintenance).<br />

• Do not remove the p<strong>ro</strong>tective grille f<strong>ro</strong>m the fuel storage tank.<br />

• Any build-up of unused pellets in the burner left over f<strong>ro</strong>m repeated failed ignitions<br />

must be removed before lighting the stove.<br />

• The operation of the stove can cause surfaces, handles, flue system and glass to<br />

become extremely hot.Touch these parts during operation only with p<strong>ro</strong>tective clothing<br />

or other specialised equipment.<br />

• Because of the build-up of heat on the glass, take care that those who are unaware<br />

of the workings of the stove do not delay in the installation area.<br />

• Keep children informed of safety measures to be followed when the stove is operational<br />

and at other times.<br />

In the event of difficulties or if you are unable to understand the instruction<br />

manual contact your local Piazzetta dealer.<br />

It is forbidden to place objects which are not heat-resistant on top of the<br />

stove or within the prescribed minimum safety zone.<br />

It is forbidden to open the door while the stove is in operation or to operate<br />

the stove when the glass is b<strong>ro</strong>ken.<br />

The assembly of the cover should be undertaken by two people (follow the assembly instructions in the attached booklet).<br />

Plans and diagrams are supplied as examples at the manufacturer’s discretion; in the pursuit of a policy of continuous development and innovation<br />

the manufacturer may, without prior warning, make any modifications deemed app<strong>ro</strong>priate.<br />

This document is the p<strong>ro</strong>perty of Gruppo Piazzetta S.p.A.; it may not be divulged in part or in whole to third parties without written permission f<strong>ro</strong>m<br />

Gruppo Piazzetta S.p.A. Gruppo Piazzetta S.p.A. reserves all its statutory rights.<br />

REFERENCE STANDARDS DT2010209-00<br />

DIN 18894 Solid fuel stoves and fireplaces - Pellet-fired stoves - Requirements, testing and marking<br />

UNI 10344 Heating of buildings. Calculation of energy requirements<br />

UNI 10683 Wood-fired heat generators, Installation requirements<br />

UNI 10847 Single flue systems for liquid and solid fuel generators - Maintenance and cont<strong>ro</strong>l - Guidelines and<br />

p<strong>ro</strong>cedures<br />

UNI 7129 Gas installations for domestic use fired by mains gas supply<br />

DIN 51731 class HP2 Fuels<br />

®<br />

SUPERIOR

DT2010187-00<br />

Section Title Page Code<br />

1.0 General rules 4 DT2010216-02<br />

1.1 Single flueway or chimney 5 DT2010024-00<br />

1.2 Soot inspection 5 DT2010031-00<br />

1.3 Chimney stack 6 DT2010025-00<br />

1.4 Fresh air intake 7 DT2010026-00<br />

1.5 Installation envi<strong>ro</strong>nment 7 DT2010215-00<br />

1.6 Capacity load of the floor 8 DT2010032-00<br />

1.7 Heating capacità 8 DT2010130-00<br />

1.8 Minimum safety distances 9 DT2010224-02<br />

1.9 Flue system 9 DT2010229-01<br />

1.10 Connecting to a conventional chimney 11 DT2010230-00<br />

1.11 Using external flue ducts 12 DT2010232-00<br />

1.12 Prevention of domestic fires 12 DT2010027-00<br />

2.0 Technical characteristics and specifications 13 DT2010102-01<br />

2.1 Technical data 13 DT2010103-01<br />

2.2 Plan 13 DT2030134-00<br />

2.3 P<strong>ro</strong>duct identification data 14 DT2010041-00<br />

2.4 Electrical diagram 14 DT2030072-00<br />

3.0 Fuel 15 DT2010233-00<br />

4.0 Before unpacking your p<strong>ro</strong>duct 15 DT2010074-00<br />

5.0 Installation 16 DT2010075-00<br />

5.1 Electrical connection and the temperature sensor 16 DT2010078-00<br />

5.2 Installing the external thermostat 17 DT2010079-00<br />

6.0 Use 17 DT2010080-01<br />

6.1 Cont<strong>ro</strong>l panel 18 DT2010081-00<br />

6.2 Startup 18 DT2010082-00<br />

6.3 Startup and normal operation 19 DT2010083-01<br />

6.4 Remote cont<strong>ro</strong>l 23 DT2010084-00<br />

6.5 Timer 23 DT2010085-00<br />

6.6 Safety features 29 DT2010086-00<br />

6.7 Opening the door 32 DT2010087-01<br />

6.8 Removing the ash 32 DT2010049-00<br />

7.0 Maintenance 33 DT2010111-01<br />

7.1 Cleaning the burner and the burner support 33 DT2010089-01<br />

7.2 Cleaning the ash drawer 33 DT2010100-00<br />

7.3 Cleaning the combustion chamber 33 DT2010090-00<br />

7.4 Cleaning the smoke chamber 34 DT2010091-00<br />

7.5 Cleaning the exhaust system 34 DT2010092-00<br />

7.6 Cleaning the ceramic cover 34 DT2010059-00<br />

7.7 Cleaning the metal parts 34 DT2010061-00<br />

7.8 Cleaning the window 34 DT2010062-00<br />

7.9 Replacing the window 35 DT2010093-00<br />

7.10 Replacing the remote cont<strong>ro</strong>l battery 35 DT2010094-00<br />

7.11 Cleaning the fans 35 DT2010095-00<br />

7.12 When not in use 35 DT2010096-00<br />

7.13 Extraordinary maintenance 35 DT2010097-00<br />

8.0 T<strong>ro</strong>ubleshooting 36 DT2010098-01<br />

Declaration of conformity 39 DT2010101-00<br />

This booklet code H07010500 / DT2000009 - Rev. 02 (04/2005) comprises 40 pages.<br />

®<br />

SUPERIOR<br />

INDEX<br />

3<br />

English

English<br />

4<br />

1.0 GENERAL RULES DT2010216-02<br />

Ensure that the installation of your p<strong>ro</strong>duct conforms to all the following instructions.<br />

Fig. 1<br />

CHIMNEY COMIGNOLO STACK<br />

SINGLE FLUEWAY CANNA<br />

OR CHIMNEY FUMARIA<br />

COLLEGAMENTO<br />

FLUE ALLA SYSTEM CANNA FUMARIA<br />

ISPEZIONE PER<br />

SOOT RACCOLTA INSPECTION FULIGGINE<br />

PRESA FRESH AIR D'ARIA INTAKEESTERNA<br />

END <st<strong>ro</strong>ng>EL</st<strong>ro</strong>ng>BOW WITH<br />

INSPECTION RACCORDO WINDOW<br />

CON ISPEZIONE<br />

MINIMUM DISTANZE SAFETY DI SICUREZZA<br />

DISTANCES<br />

CAPACITY VERIFICALOAD<br />

OF PORTATA THE FLOOR SOLAIO<br />

DT2030321-00<br />

®<br />

SUPERIOR

1.1 Single flueway or chimney - Fig. 2÷6<br />

Every appliance must have a vertical flue pipe operating by natural<br />

draught to discharge the combustion gases outdoors.<br />

The flue must:<br />

- comply with regulations in force in the place of installation of the<br />

appliance;<br />

- be tight to the p<strong>ro</strong>ducts of combustion, waterp<strong>ro</strong>of, suitably insulated,<br />

made with materials resistant to the cor<strong>ro</strong>sion of the gases and to<br />

stress;<br />

- be connected to just one stove, fireplace or extraction hood;<br />

- be p<strong>ro</strong>perly sized, with constant free internal section, equal to or<br />

greater than the diameter of the flue pipe of the stove and at least 3.5<br />

m in length;<br />

- be mainly in a vertical position with a deflection f<strong>ro</strong>m the axis of no<br />

more than 45° (Fig. 2);<br />

- be at a suitable distance f<strong>ro</strong>m combustible or flammable materials,<br />

ensured by an air gap or suitable insulating material;<br />

- be of uniform internal section, preferably <strong>ro</strong>und. Square or rectangular<br />

sections must have <strong>ro</strong>unded corners with a radius of at least<br />

20mm and a maximum ratio between the sides of 1.5 (Fig. 4). The<br />

walls must be smooth if possible and without nar<strong>ro</strong>wing. Bends must<br />

be regular and without discontinuity (Fig. 3 - 4 - 5).<br />

It is forbidden to make fixed or mobile apertures on the flue<br />

pipe to connect appliances other than the one to which it is<br />

already connected.<br />

It is forbidden to pass other air ducts or service pipes inside<br />

the flue pipe, however large it is.<br />

If the flue pipe is an incorrect size or installed other than in<br />

compliance with the above instructions, Gruppo Piazzetta<br />

S.p.A. cannot be held liable for malfunctioning of the p<strong>ro</strong>duct,<br />

damage to p<strong>ro</strong>perty or injury to persons or animals.<br />

1.2 Soot inspection - Fig. 1<br />

- The flue must have a chamber for collecting solid matter and any<br />

condensate located below the connection and which may be easily<br />

inspected by means of an airtight door. (Fig.1)<br />

- The bends connecting to the flue must have inspection points that<br />

allow the system to be checked, cleaned and maintained.<br />

®<br />

SUPERIOR<br />

Fig. 2<br />

3.5 Minimo M MINIMUM 3,5 m<br />

Fig. 3<br />

Fig. 5<br />

Deposit of Creosoto<br />

Ø<br />

Accumulo di Creosoto<br />

R (min. 20)<br />

L ( 1,5 x P)<br />

MAX 45°<br />

DT2030050-00<br />

P<br />

DT2030189-00<br />

Fig. 4<br />

Fig. 6<br />

NO<br />

X<br />

NO<br />

R (min. 20)<br />

Accumulo di Creosoto<br />

Deposit of Creosoto<br />

DT2030049-00<br />

DT2030188-00<br />

DT2030190-00<br />

5<br />

English

English<br />

1.3 Chimney stack - Fig. 7 ÷ 11<br />

The flue must be fitted at the top with a device called a chimney stack,<br />

designed to aid dispersion of the p<strong>ro</strong>ducts of combustion in the atmosphere.<br />

The chimney stack must comply with the following requirements:<br />

- it must have an internal section and shape the same as the flue;<br />

- it must have a useful outlet section of not less than twice that of the flue;<br />

- the part of the flue that emerges f<strong>ro</strong>m the <strong>ro</strong>of or remains in contact with the<br />

outside (e.g. in the case of an open loft), must be covered with brick or tile elements<br />

and in any case well insulated. It must be built in such a way as to prevent<br />

the penetration of rain, snow and foreign matter into the flue and to ensure<br />

that in the event of winds f<strong>ro</strong>m all directions and angle, discharge of the<br />

combustion p<strong>ro</strong>ducts is assured (chimney stack with down-draught cowl);<br />

- any buildings or other obstacles that are higher than the chimney stack must<br />

not be too close to the actual stack Fig.8 - Fig.9;<br />

- the chimney stack must be positioned in such a way as to ensure adequate<br />

dispersion and dilution of the p<strong>ro</strong>ducts of combustion and in any case outside<br />

the reflux area.The size and shape of this area differ according to the angle<br />

of inclination of the <strong>ro</strong>of and it is therefore necessary to adopt the minimum<br />

heights shown in Fig.10;<br />

Example: Check the slope of the <strong>ro</strong>of (column α), and the anticipated<br />

distance of the chimney stack f<strong>ro</strong>m the axis of the ridge (column A), if<br />

the distance is greater than “A” lthe height of the chimney stack may<br />

be read in (column H); if the distance is less than “A” the chimney stack<br />

must rise above the ridge by 0.5 metres.<br />

Fig. 10<br />

Fig. 11<br />

6<br />

Pitch of the <strong>ro</strong>of<br />

H min.<br />

H min.<br />

pari 5 o minore m<br />

pari or 5o less mminore<br />

5 m<br />

0.50 m<br />

0.50 m<br />

distanza maggiore A<br />

distanza distance maggiore more distanza than AA<br />

min. distanza distance uguale A<br />

min. at least uguale A<br />

α<br />

Horizontal width of reflux<br />

area f<strong>ro</strong>m ridge axis<br />

Fig. 9<br />

asse colmo<br />

asse ridge colmo axis<br />

maggiore over 5 m5<br />

m<br />

maggiore 5 m<br />

0.50 m oltre il colmo<br />

0.50 above m oltre the il colmo ridge<br />

6-8 m<br />

TETTO PIANO<br />

TETTO PIANO<br />

pari 5 o minore m<br />

pari or 5o less mminore<br />

5 m<br />

Minimum height of<br />

outlet f<strong>ro</strong>m <strong>ro</strong>of<br />

0.50 m<br />

0.50 m<br />

TETTO INCLINATO<br />

TETTO INCLINATO<br />

altezza zona di<br />

reflusso height altezza of zona Z di<br />

reflux reflusso area Z Z<br />

Height of reflux<br />

area<br />

α A H minimo Z<br />

15° 1.85 m 1.00 m 0.50 m<br />

30° 1.50 m 1.30 m 0.80 m<br />

45° 1.30 m 2.00 m 1.50 m<br />

60° 1.20 m 2.60 m 2.10 m<br />

Fig. 7<br />

A<br />

B*<br />

* B equivale it is twiceal<br />

doppio of to Adi<br />

A<br />

DT2030051-00<br />

FLAT ROOF<br />

Fig. 8<br />

SLOPING ROOF<br />

B<br />

A<br />

B<br />

DT2030191-00<br />

DT2030052-00<br />

DT2030053-00<br />

DT2030192-00<br />

®<br />

SUPERIOR

1.4 Fresh air intake - Fig. 12÷15<br />

The stove/fireplace must have the necessary air available to ensure<br />

p<strong>ro</strong>per combustion.<br />

- Make sure that the <strong>ro</strong>om in which the stove/fireplace is to be installed<br />

has an air intake of at least the size indicated in the paragraph<br />

“TECHNICAL DATA”.<br />

- The fresh air intake may be p<strong>ro</strong>tected by an external grille p<strong>ro</strong>vided it<br />

does not reduce the minimum section of the recommended airflow<br />

and is in a position whereby it cannot be obstructed.<br />

The air necessary for the fire may be obtained in different ways:<br />

- Figure 12 th<strong>ro</strong>ugh an external grille direct to the <strong>ro</strong>om of installation;<br />

- Figure 13 with ducting th<strong>ro</strong>ugh pipes direct to the <strong>ro</strong>om of installation,<br />

increasing the recommended minimum free c<strong>ro</strong>ss section by at<br />

least 15%;<br />

- Figure 14 th<strong>ro</strong>ugh a communicating hole f<strong>ro</strong>m an adjacent <strong>ro</strong>om to<br />

the place of installation: this system may only be used if the air flows<br />

freely f<strong>ro</strong>m the outside th<strong>ro</strong>ugh fixed apertures;<br />

- Figure 15 f<strong>ro</strong>m an adjacent <strong>ro</strong>om to the place of installation, but only<br />

if the air flows freely th<strong>ro</strong>ugh apertures communicating with the outside.<br />

1.5 Installation envi<strong>ro</strong>nment<br />

The appliance should be installed in a location which allows safe and<br />

convenient use as well as easy maintenance. If the p<strong>ro</strong>duct being<br />

installed requires an electrical socket, the <strong>ro</strong>om must also be p<strong>ro</strong>vided<br />

with an earthed power supply in accordance with current regulations.<br />

The installation of a wood-burning appliance in a bed<strong>ro</strong>om,<br />

bath or shower <strong>ro</strong>om or in any <strong>ro</strong>om where another heating<br />

system not equipped with its own air supply (fireplace, stove<br />

etc.) has already been installed is forbidden.<br />

The <strong>ro</strong>om or <strong>ro</strong>oms adjacent to that where the appliance is to be installed<br />

must conform to the following requirements:<br />

It must not be used as a car bay, a store for combustible material,<br />

nor for any activity which carries a risk of fire.<br />

It must not be pressurised relative to normal atmospheric pressure<br />

as a result of the draught created by a prior installation of<br />

an open fire or of an extractor system.<br />

In the same location do not install two stoves, a stove and a fireplace,<br />

a stove and a wood-burning range etc, since the draught<br />

f<strong>ro</strong>m one device can interfere with the draught f<strong>ro</strong>m another.<br />

- The use of equipment adapted for cooking food with non-extractor<br />

hoods is permissible only in <strong>ro</strong>oms to be used as kitchens.<br />

- Equipment using gas type C is permitted (refer to regulations in force<br />

in the place of installation).<br />

®<br />

SUPERIOR<br />

Fig. 12<br />

Fig. 14<br />

Fig. 15<br />

DT2030054-00<br />

Fig. 13<br />

DT2030193-00<br />

DT2030194-00<br />

DT2030195-00<br />

7<br />

English

English<br />

8<br />

Equipment using gas type B is not permitted (refer to regulations<br />

in force in the place of installation).<br />

Using the stove or flue simultaneously with shared ventilation<br />

systems is not permitted, whether with or without extractor<br />

fans. Similarly the use of other devices or equipment, such as<br />

air-conditioning systems or other heating systems which use<br />

fans to circulate air, is not permitted. These devices can cause<br />

the atmosphere a<strong>ro</strong>und the stove to become pressurised even<br />

if installed in adjacent, communicating <strong>ro</strong>oms.<br />

1.6 Capacity load of the floor<br />

Check the load-bearing capacity of the floor, referring to the weight of the<br />

p<strong>ro</strong>duct given in the paragraph “TECHNICAL DATA”.<br />

If the floor does not have a suitable load-bearing capacity, adequate countermeasures<br />

must be taken, for example, by using a sheet metal plate to<br />

distribute the load.<br />

1.7 Heating capacity<br />

Check the heating capacity of the appliance by comparing the rated power<br />

given in the paragraph “TECHNICAL DATA” with the power required by the<br />

envi<strong>ro</strong>nment to be heated.<br />

The energy requirement may be calculated app<strong>ro</strong>ximately by multiplying<br />

the square metres of area by the height of the ceiling; the result is then<br />

multiplied by a coefficient, which depends on the degree of insulation of<br />

the building, that is, on internal and external factors of the dwelling:<br />

a) Internal factors: type of window and door frames, thickness of the<br />

insulation and walls, type of building materials, presence of stairwells,<br />

walls with extensive glazing, high ceilings, position of the <strong>ro</strong>oms to be<br />

heated in relation to other adjacent heated or unheated <strong>ro</strong>oms, …<br />

b) External factors: geographical position, average outdoor temperature,<br />

exposure, wind speed, latitude, altitude, …<br />

Example of app<strong>ro</strong>ximate calculation of the energy requirement to<br />

heat a fixed volume to 18/20° C:<br />

The coefficient that is normally used is determined according to the real<br />

conditions as they occur case by case.<br />

- F<strong>ro</strong>m 0.04 to 0.05 kW per cubic metre in a well insulated envi<strong>ro</strong>nment<br />

- F<strong>ro</strong>m 0.05 to 0.06 kW per cubic metre in a poorly insulated envi<strong>ro</strong>nment.<br />

3 <strong>ro</strong>oms measuring 20m2 X (H ceiling) 2.7m = 162 m3 (volume)<br />

In an envi<strong>ro</strong>nment with a good degree of insulation, an average value<br />

(coefficient) of 0.045 kW may be taken<br />

162 (volume) X 0.045 (kW) = 7.3 kW necessary (6300 kcal/h)<br />

Conversion 1kW = 860 kcal/h<br />

Consult a heating technician or engineer for a correct check<br />

and calculation of the requirement of the envi<strong>ro</strong>nments to be<br />

heated (see “REFERENCE STANDARDS”).<br />

Rated power being equal, p<strong>ro</strong>ducts with the Multi-fire system<br />

can evenly distribute heat th<strong>ro</strong>ughout the <strong>ro</strong>oms to be heated.<br />

®<br />

SUPERIOR

1.8 Minimum safety distances - Fig. 16÷18<br />

With reference to the above diagram, the minimum safe distances f<strong>ro</strong>m<br />

heat sensitive or inflammable materials, such as load bearing and other<br />

walls are:<br />

A 20 cm f<strong>ro</strong>m the wall behind the stove<br />

B 60 cm f<strong>ro</strong>m the side wall<br />

C 100 cm in the radiating area<br />

In the case of flooring that is heat sensitive or inflammable the floor<br />

should be p<strong>ro</strong>tected (using for example sheets of steel plate, marble or<br />

tiles).<br />

The minimum distances are:<br />

D 50 cm;<br />

E 30 cm (measured f<strong>ro</strong>m the internal corner of the door opening).<br />

Keep any combustible p<strong>ro</strong>duct well away f<strong>ro</strong>m the stove when it<br />

is lit (minimum distance f<strong>ro</strong>m the heat radiation area), for example:<br />

wooden furniture, curtains, carpets, combustible liquids, etc.<br />

1.9 Flue system - Fig. 19-20<br />

The pellet stove is not the same as other stoves. The smoke is<br />

p<strong>ro</strong>pelled by a fan which keeps the combustion chamber pressurised<br />

and the entire flue system slightly pressurised. For this<br />

reason the flue must be completely airtight and correctly installed<br />

to ensure both t<strong>ro</strong>uble-free operation and user safety.<br />

- The construction of the exhaust system must be undertaken by specialised<br />

personnel or firms, as outlined in the following pages.<br />

- Installation of the flue should be completed in such a way as to guarantee<br />

that periodic cleaning can be carried out without dismantling<br />

the entire system.<br />

- Pipes should always be sealed with silicone (not cement-based<br />

sealants) or specially adapted washers which will retain their elastic<br />

and resistant p<strong>ro</strong>perties at high temepratures (250°C). These should<br />

be attached with 3.9mm-diameter self-threading screws.<br />

The installation of flaps or valves which might block the passage<br />

of the smoke is not permitted.<br />

The installation of other devices (boilers, extractor hoods etc)<br />

which might release fumes or vapours into the flue system is<br />

not permitted.<br />

®<br />

SUPERIOR<br />

Fig. 16<br />

Fig. 17<br />

Parete Side wall laterale<br />

Parete Rear posteriore wall<br />

A<br />

B STUFA STOVE<br />

B<br />

E<br />

P<strong>ro</strong>tezione Floor p<strong>ro</strong>tection a pavimento<br />

D<br />

Radiating zone<br />

Zona radiante dell'apertura del focolare<br />

MIN 40 cm<br />

DT2030335-00<br />

Fig. 18<br />

C<br />

E<br />

Parete Side wall laterale<br />

DT2030059-01<br />

MIN 40 cm<br />

DT2030336-00<br />

9<br />

English

English<br />

Pipes and maximum usable lengths<br />

Pipes of aluminium-clad painted steel (minimum thickness<br />

1.5mm), stainless steel (Aisi 316) or enamelled steel (minimum<br />

thickness 0.5mm) with a nominal diameter of 80 or 100mm (for<br />

pipes which run inside the flue maximum diameter 150mm) can be<br />

used.<br />

The male-female connectors must have a minimum length of<br />

50mm.<br />

The diameter of the pipes used depends on the type of installation.<br />

The stove was designed to take 80mm-diameter pipes but, as<br />

shown in Table 1, in some cases the use of double-lined 100mmdiameter<br />

pipes is recommended.<br />

TYPE OF INSTALLATION<br />

TABLE 1 LENGHT PIPES<br />

WITH 80mm Ø PIPE<br />

WITH DOUBLE-WAL-<br />

LED 100mm Ø PIPE<br />

Maximum length (with three 90° bends) 4.5 m 8 m<br />

For installations more than 1200m above sea level - Required<br />

Maximum number of bends 3 4<br />

Length of horizontal sections with minimum 5% gradient 2 m 2 m<br />

10<br />

Losses associated with a 90° bend can be compared to those<br />

incurred by one metre of pipe. An inspectable T-connector<br />

can be considered equivalent to a 90° bend.<br />

EXAMPLE: If installing a section greater than 4.5m in length with<br />

80mm-diameter pipe, calculate the maximum usable length in the following<br />

ways:<br />

- If in the section to be fitted a maximum of three 90° bends are used,<br />

the maximum length of the section will be 4.5m.<br />

- If in the section to be fitted a maximum of two 90° bends are used<br />

and bearing in mind that a 90° bend can be replaced by one meter of<br />

pipe, the maximum length of the section will be 4.5m+1m=5.5m.<br />

- If in the section to be fitted a maximum of one 90° bend is used and<br />

bearing in mind that a 90° bend can be replaced by one meter of<br />

pipe, the maximum length of the section will be<br />

4.5m+1m+1m=6.5m.<br />

Where 100mm-diameter pipe must be used, connect it to the stove’s<br />

exhaust outlet with a 80mm T-connector then use a 80mm-100mm<br />

adaptor (not supplied by Piazzetta) (Fig 19).<br />

T-connector<br />

The use of this type of connector must allow for the collection of condensation<br />

mixed with suit which builds up inside the pipe. It must also<br />

permit the periodic cleaning of the flue without the need to dismantle<br />

the pipes.<br />

This type of connctor can be bought at Piazzetta outlets together with<br />

the pipes.<br />

Outlined below is an example of a set-up which can be cleaned entirely<br />

without the need to dismantle the pipes (Fig 20).<br />

Fig. 19<br />

Fig. 20<br />

Tee RACCORDO A T<br />

Direction DIREZIONE of<br />

cleaning DI PULIZIA<br />

ø 100mm<br />

RACCORDO<br />

ø 80 > ø 100<br />

ø 80mm<br />

RACCORDO A T CON TAPPO<br />

Tee with sealing plug<br />

A CHIUSURA ERMETICA<br />

ISOLANTE Insulating material<br />

Tee RACCORDO A T<br />

Max 2m<br />

(min. 3%)<br />

DIREZIONE Direction of DI cleaning<br />

PULIZIA<br />

Straight reducer<br />

ø 80 > ø 100<br />

DT2030337-00<br />

DIREZIONE Direction of DI cleaning PULIZIA<br />

DT2030338-00<br />

®<br />

SUPERIOR

1.10 Connecting to a conventional chimney - Fig. 21-22<br />

If you wish to use an existing chimney it is st<strong>ro</strong>ngly recommended that<br />

you have it checked by a p<strong>ro</strong>fessional chimney-sweep to ensure that it<br />

is completely airtight. The reason for this is that the smoke, because it<br />

is slightly pressurised, can infiltrate any cracks in the system and escape<br />

into living spaces. If upon inspection you find that the chimney is not<br />

completely sound, it is recommended that you insert piping made of<br />

new material. If the existing chimney is wide enough we recommend a<br />

pipe with a maximum diameter of 150mm. It is also recommended that<br />

you insulate the chimney flue (Fig. 21-22).<br />

For connection to the chimney the use of Piazzetta’s own pipes and<br />

bends is recommended - the stove’s outlet is the right size to connect<br />

to these.<br />

Other types of pipe can be used, p<strong>ro</strong>vided that they are suitable or that<br />

the compatibility of the connecting sleeve can be verified. Bear in mind<br />

also that pipes and bends must be constructed according to existing<br />

regulations. In such cases however Gruppo Piazzetta S.p.A guarantees<br />

the p<strong>ro</strong>per functioning of the stove only where its own equipment has<br />

been employed in accordance with its own instructions.<br />

The connection to the flue system must respect the 40cm minimum<br />

safety distance f<strong>ro</strong>m objects which are sensitive to heat and f<strong>ro</strong>m<br />

inflammable materials (wooden veneers, beams or ceilings etc). (See<br />

figures 17-18)<br />

- If the connector has to pass th<strong>ro</strong>ugh partitions or walls constructed<br />

f<strong>ro</strong>m inflammable or heat-sensitive materials, or th<strong>ro</strong>ugh weight-bearing<br />

walls, you must int<strong>ro</strong>duce:<br />

an insulated barrier equal to or greater than 10cm a<strong>ro</strong>und the connector<br />

using a mineral-based insulating material (<strong>ro</strong>ck wool, ceramic<br />

fibre) with a nominal density greater than 80kg/m 3<br />

- If the connector has to pass th<strong>ro</strong>ugh partitions or walls constructed<br />

f<strong>ro</strong>m heat-resistant materials, you must int<strong>ro</strong>duce:<br />

an insulated barrier equal to or greater than 5cm a<strong>ro</strong>und the connector<br />

using a mineral-based insulating material (<strong>ro</strong>ck wool, ceramic<br />

fibre) with a nominal density greater than 80kg/m 3.<br />

- Check that the connection to the flue system has been carried out so<br />

as to guarantee that smoke will not leak f<strong>ro</strong>m it under the equipment’s<br />

pressurised operating conditions.<br />

- Check that the pipe does enter too far into the flue creating a nar<strong>ro</strong>wing<br />

of the exhaust passage. Figure 22-23<br />

Ensure that all installation work is carried out to p<strong>ro</strong>fessional<br />

standards.<br />

®<br />

SUPERIOR<br />

Fig. 21<br />

Tee RACCORDO A T<br />

Fig. 22<br />

INSERIMENTO DI<br />

Pipe<br />

UN TUBO<br />

insertion<br />

Closing FLANGIA flange DI CHIUSURA<br />

ø 80 mm<br />

Sealing FLANGIA flange DI CHIUSURA in stainless ERMETICA<br />

steel IN ACCIAIO or aluminium INOX O ALLUMINATO<br />

Chimney COMIGNOLO stack<br />

Fresh air PRESA intake D'ARIA with ESTERNA<br />

non-closable CON GRIGLIA NON grilleRICHIUDIBILE<br />

With CON CANNA damaged FUMARIA flue<br />

NON INTEGRA<br />

Max ø150 mm<br />

Inspection SPORT<st<strong>ro</strong>ng>EL</st<strong>ro</strong>ng>LI PER<br />

windows ISPEZIONE<br />

Insulating ISOLANTE material<br />

DT2030339-00<br />

DT2030340-00<br />

11<br />

English

English<br />

1.11 Using external flue ducts<br />

You can use external flue ducts only when they correspond to the following<br />

requirements:<br />

- Use only insulated pipes (double-lined) in stainless steel attached to<br />

the outside wall (Fig 23).<br />

- At the base of the duct there must be an inspection hatch to permit<br />

periodic checks and maintenance.<br />

- The installation must be equipped with an windp<strong>ro</strong>of chimney and<br />

respect the safety distance f<strong>ro</strong>m the high point of the <strong>ro</strong>of as outlined<br />

in the chapter entitled “GENERAL RULES”, under “Chimney top”.<br />

12<br />

Ensure that all installation work is carried out to p<strong>ro</strong>fessional<br />

standards.<br />

1.12 Prevention of domestic fires<br />

The p<strong>ro</strong>duct must be installed and used in compliance with the manufacturer’s<br />

instructions and Eu<strong>ro</strong>pean and national standards as well as<br />

local regulations.<br />

When a flue pipe passes th<strong>ro</strong>ugh a wall or a ceiling, special<br />

installation methods must be applied (p<strong>ro</strong>tection, thermal<br />

insulation, distances f<strong>ro</strong>m heat-sensitive materials, etc.) See<br />

the paragraph “Connection to the flueway”.<br />

- It is also recommended that all elements made of combustible or<br />

inflammable material, such as beams, wooden furniture, curtaining,<br />

flammable liquids, etc. be kept outside the heat radiation range of the<br />

stove and in any case at a distance of at least 1m f<strong>ro</strong>m the heating<br />

block.<br />

- For other information, see the paragraph “Safety distances” and<br />

“Connection to the flueway”.<br />

- The flue pipe, chimney stack, chimney and fresh air intake must<br />

always be free of obstructions, clean and checked periodically, that is,<br />

at least twice during the seasonal period f<strong>ro</strong>m the lighting of the stove<br />

and during its use. When the stove has not been used for some time<br />

it is advisable to carry out the checks mentioned above. For further<br />

information, consult a chimneysweep.<br />

- Only use recommended fuels (See paragraph “Fuels”).<br />

Fig. 23<br />

d<br />

PRESA Fresh D'ARIA air intake ESTERNA withCON<br />

GRIGLIA non-closable NON RICHIUDIBILE grille<br />

DT2030341-00<br />

®<br />

SUPERIOR

DT2010102-01<br />

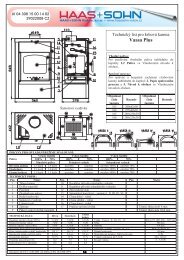

2.1 Technical data<br />

• Fuel: Natural wood pellets • Length: < 30mm<br />

• Diameter: ca. 6 - 6.5 mm<br />

• Water content: ca. 6% - 8%.<br />

Data obtained under laboratory conditions with pellets of heat p<strong>ro</strong>duction rated at 5kwh/kg.<br />

2.2 Plan (cm)<br />

®<br />

SUPERIOR<br />

2.0 TECHNICAL CHARACTERISTICS AND SPECIFICATIONS<br />

UNIT MIR<st<strong>ro</strong>ng>EL</st<strong>ro</strong>ng>LA<br />

Hourly fuel consumption (max/min) kg/h 1,4 / 0,75<br />

Nominal thermal power (max/min) kW 5,5 / 2,5<br />

Efficiency % > 80<br />

Draught when connected to chimney Pa 10÷15<br />

Fuel tank capacity kg / (l) 15 / (23)<br />

Electrical power supply V 230<br />

Frequenz Hz 50<br />

Maximum power rating W 320<br />

Power rating (max / min) W 110 / 70<br />

Exhaust outlet diameter cm Ø 8<br />

Fresh air intake with minimum useful section cm 2 100<br />

Weight with majolica kg 85<br />

Packing cladding kg 95<br />

Packing sizes (DxWxH) cm 58,5X54X119<br />

Diameter Ø 8<br />

15 7<br />

17,5<br />

94<br />

43<br />

46<br />

DT2030071-00<br />

13<br />

English

English<br />

2.3 P<strong>ro</strong>duct identification data<br />

The rating plate gives the data and ratings of the appliance.<br />

If the rating plate is missing, has been removed or tampered with,<br />

any installation and maintenance operations are made difficult due<br />

to lack of p<strong>ro</strong>duct identification.<br />

In the event of damage, please ask the Piazzetta after-sales service<br />

centre for a copy.<br />

2.4 Electrical diagram<br />

14<br />

Flat cable<br />

DB 9<br />

LN<br />

ROOM SENSOR<br />

CN2<br />

IC10<br />

SERIAL<br />

FAN 1<br />

FAN 2<br />

EXTERNAL<br />

THERMOSTAT<br />

F<br />

N<br />

SMOKE<br />

SMOKE<br />

POINTS<br />

POINTS<br />

FU<st<strong>ro</strong>ng>EL</st<strong>ro</strong>ng>-LOADING CHUTE<br />

FU<st<strong>ro</strong>ng>EL</st<strong>ro</strong>ng>-LOADING CHUTE<br />

PILOT LIGHT<br />

PILOT LIGHT<br />

AL . 2<br />

AL . 1<br />

N<br />

Black<br />

Black<br />

Blue<br />

Red<br />

THERMO<st<strong>ro</strong>ng>EL</st<strong>ro</strong>ng>EMENT ABGASE<br />

Display<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

Light blue<br />

B<strong>ro</strong>wn<br />

Light blue<br />

B<strong>ro</strong>wn<br />

White<br />

White<br />

Yellow-green<br />

Yellow-green<br />

White<br />

Grau<br />

Red<br />

Red<br />

Black<br />

Light blue<br />

Yellow-green<br />

Smoke fan<br />

Blue<br />

Black<br />

B<strong>ro</strong>wn<br />

Black<br />

Fuel-loading chute<br />

Capacitor<br />

N.A. PRESSURE SWITCH<br />

2<br />

80 1 2<br />

N. C.<br />

P<br />

Weiß<br />

2 1 THERMOSTATS<br />

N. C. 180<br />

P<br />

G<br />

N<br />

L<br />

POWER<br />

3<br />

Black<br />

P<strong>ro</strong>duct name<br />

Serial number<br />

Room fan<br />

PILOT LIGHT<br />

SMOKE SENSOR<br />

DT2030624-00<br />

DT2030072-00<br />

®<br />

SUPERIOR

DT2010233-00<br />

The pellet stove has been designed to burn only wood in pellet form.<br />

The wood pellet is obtained by pressing wood sawdust left over f<strong>ro</strong>m the<br />

working of natural dried wood. The typical small, cylindrical form is obtained<br />

by a p<strong>ro</strong>cess similar to wire-drawing. Thanks to lignin, a natural element<br />

which is released during the pressing of the raw material, the pellets acquire<br />

a good consistency and compactness without requiring treatment with additives<br />

or caking agents.<br />

There are various types of pellet on the market with qualities and characteristics<br />

which vary depending on the p<strong>ro</strong>cesses they have undergone<br />

and the type of wood used in their p<strong>ro</strong>duction.<br />

Since the pellet’s characteristics and quality affect to a considerably<br />

degree the stove’s performance, p<strong>ro</strong>ductivity and p<strong>ro</strong>per<br />

functioning we recommend that you USE high-quality pellets.<br />

Gruppo Piazzetta S.p.A has tested and p<strong>ro</strong>grammed its stoves and<br />

can p<strong>ro</strong>mise optimum performance and t<strong>ro</strong>uble-free functioning<br />

using pellets with these specific characteristics:<br />

• Material: wood<br />

• Length: not greater than 30mm<br />

• Diameter: 6-6.5mm<br />

• Inferior heat energy: 5kWh/kg<br />

• Humidity: not greater than 8%<br />

• Residual ash: 0.34%<br />

To assure t<strong>ro</strong>uble-free operation:<br />

DO NOT use pellets with dimensions different to those stipulated by the<br />

manufacturer.<br />

DO NOT use pellets which are out of date or which contain loose sawdust,<br />

resins, chemical substances, additives or caking agents.<br />

DO NOT use damp pellets.<br />

DT2010074-00<br />

During operation, some parts of the stove (door, handle, display,<br />

ceramic parts) can reach high temperatures. Therefore take due<br />

precautions, above all in the presence of children, elderly and disabled<br />

persons and pets.<br />

In order to avoid accidents or damage to the p<strong>ro</strong>duct, the following<br />

recommendations are made:<br />

• Unpacking and installation must be carried out by at least two<br />

people.<br />

• Every operation involving movement of the p<strong>ro</strong>duct must be carried<br />

out with the p<strong>ro</strong>per tools in full compliance with current safety<br />

regulations.<br />

®<br />

SUPERIOR<br />

Choosing pellets different to those stipulated:<br />

- obstructs the burner and flue ducts<br />

- increases fuel consumption<br />

- reduces efficiency<br />

- cannot guarantee the stove’s p<strong>ro</strong>per functioning<br />

- causes dirt to build up on the glass<br />

- leaves particles which have failed to burn and heavy cinders.<br />

3.0 FU<st<strong>ro</strong>ng>EL</st<strong>ro</strong>ng><br />

The presence of dampness in the pellets increases their volume and<br />

causes them to split which in turn causes:<br />

- malfunction of the fuel-loading system<br />

- inefficient combustion.<br />

Pellets should be stored in a sealed, dry place.<br />

If you wish to use good-quality pellets with different dimensions and heatp<strong>ro</strong>ducing<br />

p<strong>ro</strong>perties to those stipulated you will need to alter the operating<br />

parameters of the stove. This “customisation” of the stove’s settings must<br />

be carried out at one of Gruppo Piazzetta S.p.A.’s Centres for Technical<br />

Assistance or by specially qualified personnel authorised by Gruppo<br />

Piazzetta S.p.A.<br />

Using out of date pellets or those which do not conform to the<br />

manufacturer’s stipulations damages the stove and comp<strong>ro</strong>mises<br />

performance as well as can nullifying the guarantee<br />

and excusing the manufacturer f<strong>ro</strong>m his responsibilities.<br />

DT2030346-00<br />

4.0 BEFORE UNPACKING YOUR PRODUCT<br />

• The orientation of the packaged p<strong>ro</strong>duct must conform to the<br />

directions given in the diagrams and notices on the package.<br />

• If cables, straps or chains are used, ensure that they are able to<br />

take the weight of the package and that they are in good condition.<br />

• While moving the package use slow continuous movements to<br />

avoid tearing cables, chains etc.<br />

• To avoid toppling do not lean the package excessively.<br />

• Do not stop in the path of loading/unloading equipment (cradles,<br />

cranes etc).<br />

15<br />

English

English<br />

16<br />

5.0 INSTALLATION DT2010075-00<br />

External pressure switch<br />

• The stove is equipped with an external socket for measuring the<br />

air pressure in the flue. This verifying and checking operation<br />

should be carried out by authorised personnel whilst the stove is<br />

being installed.<br />

5.1 Electrical connection and the temperature sensor - Fig. 24-25<br />

• The stove comes equipped with a power cable which must be<br />

connected to a 230v/50Hz supply. Connection to the rear of the<br />

stove is illustrated in fig 25.<br />

• The power rating is indicated in the section ‘technical characteristics<br />

and data’ in this manual.<br />

• According to law the installation must be earthed and include a<br />

differential switch.<br />

• Ensure that in its normal position the power cable does not come<br />

into contact with any heated parts.<br />

Ensure that the electrical socket is accessible after the<br />

stove’s installation.<br />

• At the same time as installing the stove, it is necessary to connect<br />

the temperature sensor (p<strong>ro</strong>vided) in the correct socket (fig<br />

25). The sensor can be positioned as illustrated in fig 25, or<br />

uncoil the nar<strong>ro</strong>w strip and place the sensor in a spot where a<br />

more accurate <strong>ro</strong>om temperature reading can be obtained.<br />

Covering<br />

• Having carried out the assembly and the installation of the external<br />

thermostat, p<strong>ro</strong>ceed with the assembly of the stove’s cover.<br />

For this operation refer to the booklet entitled Instructions manual<br />

ceramic cladding p<strong>ro</strong>vided with the stove.<br />

Fig. 24<br />

Fig. 25<br />

1<br />

2<br />

DT2030074-00<br />

1 External socket for connection of temperature sensor.<br />

2 Socket for power lead.<br />

3 External pressure sockets.<br />

4 Socket for inserting cable PG7 for connection of external thermostat.<br />

5 Connecting the temperature sensor.<br />

6 Connecting the power cable.<br />

5<br />

6<br />

3<br />

4<br />

DT2010071-00<br />

DT2030075-00<br />

®<br />

SUPERIOR

5.2 Installing the external thermostat - Fig. 24 - 26 - 27 - 28<br />

• To connect the external thermostat use cable type 2x0.5mm 2<br />

stopped with a PG7 connector to be inserted in the app<strong>ro</strong>priate<br />

socket in the rear panel (fig 24). This operation should be carried<br />

out by authorised personnel.<br />

Installation can be carried out with any type of thermostat<br />

but requires connector PG7 similar to that shown in fig 26.<br />

To connect the thermostat to the elect<strong>ro</strong>nic board, refer to<br />

the electrical diagram.<br />

• To install, stop the thermostat cable with connector PG7 and<br />

insert this in the socket at the rear (fig 25 ÷ 28). Finally connect<br />

the thermostat’s terminal to the two-pin terminal of the elect<strong>ro</strong>nic<br />

board (fig 27).<br />

DT2010080-01<br />

• Do not use the stove as a cooker<br />

• Ensure that the <strong>ro</strong>om in which the stove is installed is sufficiently<br />

well ventilated.<br />

• Ensure that all joints in the flue are hermetically sealed using a<br />

silicone- (not cement-) based sealant which is resistant to temperatures<br />

of up to 250ºC and which shows no sign of deterioration.<br />

• Check (or have checked) regularly that the flue is clean.<br />

• It is p<strong>ro</strong>hibited to use fuels other than pellets.<br />

• Remove any deposits of unused pellets left by failed ignitions<br />

before restarting the stove.<br />

The removal of the p<strong>ro</strong>tective grille inside the fuel tank is<br />

strictly p<strong>ro</strong>hibited.<br />

®<br />

SUPERIOR<br />

Fig. 26<br />

Fig. 27<br />

Fig. 28<br />

1 2<br />

1 Thermostat.<br />

2 Elect<strong>ro</strong>nic board 2-pin terminal.<br />

3 Cable clamp.<br />

4 Thermostat cable terminal.<br />

3<br />

DT2030076-00<br />

DT2030077-00<br />

DT2030078-00<br />

6.0 USE<br />

If replenishing the pellets while the stove is lit, ensure that<br />

the bag does not come into contact with any hot surfaces.<br />

Keep any inflammable object well away f<strong>ro</strong>m the stove<br />

while it is in use (MINIMUM 100 cm f<strong>ro</strong>m the f<strong>ro</strong>nt panel).<br />

While in use the door must remain closed and the glass<br />

must be present and intact.<br />

4<br />

DT2010035-00<br />

17<br />

English

English<br />

6.1 Cont<strong>ro</strong>l 6<br />

4<br />

panel - Fig. 29<br />

4<br />

6<br />

• The stove is equipped with a digital cont<strong>ro</strong>l panel which allows<br />

6<br />

6 the user to cont<strong>ro</strong>l the various functions.<br />

6<br />

6<br />

The cont<strong>ro</strong>l panel keys and their various functions are listed below.<br />

6<br />

These have been numbered in order to make identification easier..<br />

18<br />

1<br />

1<br />

1<br />

1<br />

1<br />

1<br />

1<br />

1<br />

2<br />

2<br />

21<br />

21<br />

2<br />

321<br />

2<br />

321<br />

32<br />

3<br />

32<br />

32<br />

3<br />

2<br />

3<br />

3 2<br />

3<br />

SET<br />

SET<br />

SET<br />

SET<br />

3<br />

OK<br />

3 OK<br />

OK<br />

OK<br />

OK<br />

OK<br />

OK<br />

OK<br />

OK<br />

OK<br />

OK<br />

SET<br />

OK<br />

SET<br />

SET<br />

SET<br />

SET<br />

SET<br />

SET<br />

SET<br />

SET SET<br />

6<br />

45<br />

4<br />

5<br />

4<br />

5<br />

45<br />

5<br />

5<br />

6<br />

65<br />

5<br />

65<br />

6<br />

5<br />

5<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

5<br />

5<br />

4<br />

SET<br />

SET<br />

SET<br />

SET<br />

SET<br />

SET<br />

SET<br />

ON-OFF key<br />

Power key<br />

Fan and timer cont<strong>ro</strong>l Keys<br />

Function select<br />

AL. C<br />

AL. CC<br />

AL. C<br />

AL. C<br />

AL. C<br />

AL. AL. AL. FC<br />

FCC<br />

AL. F<br />

AL.<br />

FC<br />

AL.<br />

C<br />

AL. FF<br />

AL. FC<br />

AL. FF<br />

AL. F<br />

AL. F<br />

AL. F<br />

GRUPPO AL. PIAZZETTA F<br />

GRUPPO PIAZZETTA Display<br />

GRUPPO PIAZZETTA<br />

GRUPPO GRUPPO<br />

GRUPPO<br />

PIAZZETTA<br />

PIAZZETTA<br />

GRUPPO<br />

GRUPPO<br />

PIAZZETTA<br />

PIAZZETTA<br />

GRUPPO<br />

GRUPPO<br />

PIAZZETTA<br />

PIAZZETTA<br />

GRUPPO PIAZZETTA<br />

Fig. 29<br />

1<br />

2<br />

OK<br />

3 4<br />

SET<br />

SET<br />

• Manual startup and shutdown.<br />

• Exit f<strong>ro</strong>m p<strong>ro</strong>gramming mode.<br />

GRUPPO PIAZZETTA<br />

AL. C<br />

AL. F<br />

6<br />

5<br />

DT2030080-00<br />

• Cont<strong>ro</strong>ls heat distribution with settings 1 (minimum power) to 4 (maximum<br />

power). This in turn affects refuelling times.<br />

Allows:<br />

• setting the desired <strong>ro</strong>om temperature f<strong>ro</strong>m 10 to 30ºC.<br />

• p<strong>ro</strong>gramming the timer.<br />

Key 2 allows the user to display the current time and temperature.<br />

Allows:<br />

• access to the various p<strong>ro</strong>gramming modes: clock, timer and technical settings.<br />

• setting the desired <strong>ro</strong>om temperature.<br />

Timer functions The LED lights up if the timer is activated.<br />

Temperature The LED lights up when the desired temperature is reached.<br />

Remote cont<strong>ro</strong>l reception The LED lights up when data f<strong>ro</strong>m the remote cont<strong>ro</strong>l is received.<br />

P<strong>ro</strong>gramming The LED lights up when p<strong>ro</strong>gramming is in p<strong>ro</strong>gress.<br />

Fuel loading The LED lights up when the automatic fuel-loading spiral chute is in use.<br />

Pilot light The LED lights up when the pilot light is on.<br />

Thermostat alarm The LED lights up when the thermostat alarm is activated.<br />

Pressure reader alarm The LED lights up when the pressure reader alarm is activated.<br />

6.2 Startup<br />

Before lighting the stove check that the burner is pushed back<br />

towards the shield.<br />

For the stove’s first ignition - also when it has been out of use for<br />

some time - we recommend that you do not run the stove at full<br />

power. For the first few days running at medium power is recommended,<br />

to allow all components and mechanical parts a running<br />

in period.<br />

Shows:<br />

• Current time/temperature<br />

• Multifuoco/power levels<br />

• P<strong>ro</strong>gramming codes<br />

• Alarm indicators.<br />

DT2040001-00<br />

Upon first ignitions certain odours may be given off due to the<br />

evaporation of paint or grease. To alleviate the p<strong>ro</strong>blem merely air<br />

the <strong>ro</strong>om, thus avoiding the p<strong>ro</strong>longed exposure which may render<br />

these emissions harmful to people or animals.<br />

When the fuel tank is loaded for the first time the fuel-loading chute<br />

has to fill up; during this period the pellets will not be fed into the<br />

combustion chamber.<br />

®<br />

SUPERIOR

6.3 Startup and normal operation<br />

Before p<strong>ro</strong>ceeding with the ignition remember:<br />

ensure that the furnace door is well closed;<br />

• that the fuel tank is full or at least contains enough fuel to run for the desired period.<br />

When the stove is connected to the power supply, but is not yet lit, the display will show the current time on its top half (example 12:30)<br />

and the word OFF on its lower half.<br />

®<br />

SUPERIOR<br />

STARTUP<br />

Action Description Display<br />

Hold the on/off key<br />

down for several<br />

seconds:<br />

4<br />

Starts a cycle of three phases which take the<br />

stove into normal operation:<br />

• Phase one: CHECK UP (first 10 seconds)<br />

- The extractor fan activates for a few seconds.<br />

• Phase two: IGNITION<br />

- The fuel-loading chute is activated and<br />

starts to feed pellets into the burner (the<br />

LED on the display lights up at fixed time<br />

intervals).<br />

- The pilot light ignites (the LED on the display<br />

lights up).<br />

- The extractor fan starts up.<br />

• Phase three: STARTUP<br />

- If the pilot light has triggered the combustion<br />

p<strong>ro</strong>cess, the fuel-loading chute will<br />

slow down to allow a period of stabilisation<br />

and therefore a complete combustion of the<br />

pellets in the subsequent operation.<br />

- If during the startup phase the sensor on<br />

the exhaust outlet shows an increase in<br />

temperature (sign that the combustion<br />

p<strong>ro</strong>cess is underway), the stove is considered<br />

to be lit and operating normally.<br />

- If during the startup phase the sensor at the<br />

exhaust outlet does NOT show an increase<br />

in temperature (sign that the combustion<br />

p<strong>ro</strong>cess is not underway), the stove should<br />

be considered off; a new ignition cycle will<br />

begin automatically and the three preceding<br />

phases will be repeated in succession.<br />

On the lower part three circles will appear in succession<br />

indicating the current phase of ignition.<br />

1<br />

3 OK<br />

4<br />

GRUPPO PIAZZETTA<br />

SET<br />

2<br />

1<br />

SET<br />

FLASHING SCRIPT<br />

AL. C<br />

AL. F<br />

PHASE ONE<br />

3 OK<br />

4<br />

GRUPPO PIAZZETTA<br />

SET<br />

2<br />

SET<br />

FLASHING SCRIPT<br />

AL. C<br />

AL. F<br />

PHASE TWO<br />

6<br />

5<br />

6<br />

5<br />

LED ON<br />

3 OK<br />

4<br />

GRUPPO PIAZZETTA<br />

SET<br />

1<br />

2<br />

SET<br />

FLASHING SCRIPT<br />

AL. C<br />

AL. F<br />

PHASE THREE<br />

6<br />

5<br />

DT2040002-00<br />

19<br />

English

English<br />

20<br />

FAILED IGNITION<br />

Action Description Display<br />

4<br />

A second failed ignition will be indicated by an<br />

alarm (a single tone every five seconds) and on<br />

the display.<br />

This p<strong>ro</strong>cess is activated if the fuel doesn’t<br />

light, if the tank is empty, or if the temperature<br />

fails to rise as expected.<br />

1<br />

3 OK<br />

4<br />

GRUPPO PIAZZETTA<br />

SET<br />

DISPLAY TIME/TEMPERATURE<br />

Action Description Display<br />

At whatever time the<br />

display will show the<br />

<strong>ro</strong>om temperature<br />

and the correct time,<br />

whether the stove is<br />

lit or not.<br />

FAILED IGNITION: WHAT TO DO<br />

Action Description Display<br />

Shut the stove down<br />

by holding the on/off<br />

key down for several<br />

seconds.<br />

4<br />

Restart the stove<br />

using the same key.<br />

4<br />

• The alarm should stop<br />

• Verify the cause of the failed ignition.<br />

Always remove any fuel in the burner<br />

before starting a new ignition p<strong>ro</strong>cess.<br />

• The startup up p<strong>ro</strong>cess will be activated as<br />

detailed above.<br />

1<br />

2<br />

2<br />

1<br />

SET<br />

AL. C<br />

AL. F<br />

6<br />

5<br />

DT2040003-00<br />

3 OK<br />

4<br />

GRUPPO PIAZZETTA<br />

If the appliance does not ignite p<strong>ro</strong>perly the main cause could be either insufficient maintenance (consequently refer to<br />

the “Maintenance” paragraph) or the poor quality of the pellets (refer to the “Fuel” paragraph). It is therefore recommended<br />

to check as above before attempting to relight the appliance.<br />

DT2040004-01<br />

Hold down key 2 for<br />

several seconds.<br />

SET<br />

3 OK<br />

4<br />

GRUPPO PIAZZETTA<br />

SET<br />

1<br />

2<br />

2<br />

SET<br />

SET<br />

AL. C<br />

AL. F<br />

AL. C<br />

AL. F<br />

6<br />

5<br />

6<br />

5<br />

DT2040006-00<br />

®<br />

SUPERIOR

®<br />

SUPERIOR<br />

NORMAL OPERATION<br />

Action Description Display<br />

Once ignited successfully, the stove will function<br />

normally.<br />

• In the lower part of the display the word ‘on’<br />

will appear followed by the chosen power<br />

setting (1-4). The upper part will show the<br />

<strong>ro</strong>om temperature or the current time<br />

(SEE ‘ACTIVATION/DEACTIVATION OF THE<br />

TEMPERATURE/TIME DISPLAY’ B<st<strong>ro</strong>ng>EL</st<strong>ro</strong>ng>OW).<br />

During normal operation the user can regulate:<br />

• power level, choosing one of FOUR settings<br />

(keys 5 and 6)<br />

• The desired <strong>ro</strong>om temperature f<strong>ro</strong>m 10ºC to<br />

30 ºC (press SET then keys 1 and 2).<br />

If during normal operation the power level is<br />

lowered f<strong>ro</strong>m 4 to 1, the fan (after a pause of<br />

15 seconds) will run at maximum power for<br />

a<strong>ro</strong>und four minutes, allowing the stove to cool<br />

down.<br />

During normal operation the burner’s automatic<br />

cleaning system will activate periodically, the<br />

frequency varying according to the settings<br />

pre-p<strong>ro</strong>grammed by Gruppo Piazzetta personnel.<br />

This operation removes ash deposits and<br />

other buildups which impede the correct functioning<br />

of the stove.<br />

Example:<br />

1<br />

3 OK<br />

4<br />

GRUPPO PIAZZETTA<br />

SET<br />

2<br />

Example:<br />

1<br />

SET<br />

AL. C<br />

AL. F<br />

3 OK<br />

4<br />

GRUPPO PIAZZETTA<br />

SET<br />

2<br />

SET<br />

AL. C<br />

AL. F<br />

3 OK<br />

4<br />

GRUPPO PIAZZETTA<br />

INTERRUPTION OF <st<strong>ro</strong>ng>EL</st<strong>ro</strong>ng>ECTRICITY SUPPLY<br />

Action Description Display<br />

In the event of a brief interruption of the electricity<br />

supply the stove will restart automatically.<br />

• the burner’s automatic cleaning system will<br />

activate.<br />

• the fan will run at full power to allow the stove<br />

to cool.<br />

• the automatic restart cycle will begin (functions<br />

detailed above in ‘STARTUP’ will activate<br />

automatically)<br />

• once the ignition cycle has been completed the<br />

stove will operate normally at power level 2.<br />

The stove will continue running normally at<br />

power level 2.<br />

SET<br />

1<br />

2<br />

SET<br />

AL. C<br />

AL. F<br />

6<br />

5<br />

6<br />

5<br />

6<br />

5<br />

DT2040005-00<br />

3 OK<br />

4<br />

GRUPPO PIAZZETTA<br />

SET<br />

1<br />

2<br />

SET<br />

AL. C<br />

AL. F<br />

6<br />

5<br />

DT2040010-00<br />

21<br />

English

English<br />

22<br />

INTERNAL THERMOSTAT (setting desired <strong>ro</strong>om temperature)<br />

Action Description Display<br />

To change the temperature<br />

setting<br />

press key 3 SET.<br />

3<br />

SET<br />

Then press key 1 to<br />

increase the temperature,<br />

key 2 to<br />

reduce the temperature.<br />

1<br />

2<br />

EXTERNAL THERMOSTAT<br />

Action Description Display<br />

Set the temperature<br />

of the <strong>ro</strong>om sensor -<br />

minimum value<br />

(10ºC)<br />

The stove is equipped with an internal thermostat<br />

which regulates the power according to the<br />

desired <strong>ro</strong>om temperature (10ºC-30ºC).<br />

To function p<strong>ro</strong>perly the sensor p<strong>ro</strong>vided with<br />

the stove must be positioned correctly.<br />

If during normal operation the <strong>ro</strong>om temperature<br />

is lower than that p<strong>ro</strong>grammed:<br />

The corresponding LED remains off.<br />

OK<br />

• The stove will run at the power level that has<br />

been input. This will be shown on the display.<br />

When the <strong>ro</strong>om temperature reaches the p<strong>ro</strong>grammed<br />

level: The corresponding LED on the<br />

display lights up.<br />

OK<br />

• The stove will run at minimum power even if<br />

the p<strong>ro</strong>grammed power level continues to be<br />

shown on the display.<br />

The running of the stove can be regulated by<br />

any kind of external thermostat connected to<br />

the elect<strong>ro</strong>nic board (see electrical diagram).<br />

The thermostat is connected using cable type<br />

2x0.5mm2 stopped with a PG7 connector and<br />

inserted in the app<strong>ro</strong>priate socket on the rear<br />

panel (fig 3, 4). This operation should be<br />

undertaken by authorised personnel.<br />

To check on the display if the stove is operating<br />

using the external thermostat, you must input a<br />

special code which will allow the temperature to<br />

be shown. If not, the stove will still run with an<br />

external thermostat but there will be no reading<br />

on the display. If during normal operation the<br />

temperature is lower than that p<strong>ro</strong>grammed:<br />

• the corresponding LED on the display remains<br />

off<br />

• the display indicates the chosen power level<br />

• the stove will operate at the power level input.<br />

When the <strong>ro</strong>om temperature reaches the p<strong>ro</strong>grammed<br />

value:<br />

• the corresponding LED lights up<br />

• the stove runs at minimum power even if the<br />

input power level is shown on the display.<br />

Example:<br />

3 OK<br />

4<br />

GRUPPO PIAZZETTA<br />

SET<br />

1<br />

3 OK<br />

4<br />

GRUPPO PIAZZETTA<br />

SET<br />

2<br />

1<br />

SET<br />

ROOM SENSOR TEMPERATURE<br />

FLASHING SCRIPT<br />

LED OFF<br />

AL. C<br />

AL. F<br />

3 OK<br />

4<br />

GRUPPO PIAZZETTA<br />

SET<br />

1<br />

2<br />

Example:<br />

2<br />

SET<br />

SET<br />

LED ON<br />

AL. C<br />

AL. F<br />

3 OK<br />

4<br />

GRUPPO PIAZZETTA<br />

SET<br />

1<br />

2<br />

Example:<br />

Example:<br />

SET<br />

LED OFF<br />

LED ON<br />

AL. C<br />

AL. F<br />

FLASHING SCRIPT<br />

AL. C<br />

AL. F<br />

6<br />

5<br />

6<br />

5<br />

6<br />

5<br />

6<br />

5<br />

DT2040007-00<br />

DT2040008-00<br />

®<br />

SUPERIOR

®<br />

SUPERIOR<br />

SHUTDOWN<br />

Action Description Anzeige auf dem Display<br />

Hold the ON/OFF key<br />

down for several seconds<br />

4<br />

Fuel loading will stop, while the cooling fan and<br />

the extractor fan will continue to run for another<br />

ten minutes until the stove has cooled<br />

1<br />

3 OK<br />

4<br />

GRUPPO PIAZZETTA<br />

Do not unplug the stove f<strong>ro</strong>m the power supply at this stage as this could cause internal p<strong>ro</strong>blems and comp<strong>ro</strong>mise future<br />

startup operations.<br />

DT2040009-00<br />

6.4 Remote cont<strong>ro</strong>l - Fig. 30<br />

The stove’s cont<strong>ro</strong>l panel has been set to receive some commands<br />

by remote cont<strong>ro</strong>l.<br />

• Startup/Shutdown: by pressing the two ‘+’ keys simultaneously<br />

the stove can be turned on or off.<br />

• Power level: when operating normally, pressing the ‘+’ and ‘-’ keys<br />

above the flame symbol will select one the stove’s four power levels.<br />

• Temperature: when operating normally, pressing the ‘+’ and ‘-’<br />

keys above the thermometer symbol will select the desired <strong>ro</strong>om<br />

temperature (10-30ºC).<br />

6.5 Timer<br />

The timer allows the user to p<strong>ro</strong>gramme the stove to start up and<br />

shut down automatically without any manual intervention.<br />

A maximum of two cycles can be p<strong>ro</strong>grammed:<br />

For example: Cycle one: f<strong>ro</strong>m 6 until 9 am<br />

Cycle two: f<strong>ro</strong>m 8.30 until 11 pm<br />

The two cycles can be activated or deactivated on each of the days<br />

of the week (eg, if you want the stove to be lit f<strong>ro</strong>m 6 until 9 on<br />

Monday, Tuesday but not on Wednesday, and so on…)<br />

P<strong>ro</strong>gramming codes and relative functions<br />

During p<strong>ro</strong>gramming certain codes will appear in the lower part of<br />

the display. These represent the functions described below:<br />

Fig. 30<br />

SET<br />

2<br />

SET<br />

Code FUNCTION<br />

01u<br />

02u<br />

03u<br />

05u<br />

06u<br />

07u<br />

08u<br />

09u<br />

10u<br />

11u<br />

12u<br />

13u<br />

Sets the current day of the week.<br />

Sets the current time.<br />

AL. C<br />

AL. F<br />

6<br />

5<br />

DT2030079-00<br />

Activates/deactivates the alarm during operation.<br />

Activates/deactivates the display of time and temperature.<br />

Activates/deactivates timer p<strong>ro</strong>gramming mode.<br />

Inputs startup time for first operating cycle.<br />

Inputs shutdown time for first operating cycle.<br />

Selects the days of the week (shown as: Lu, Ma, Me,… Do) on<br />

which first cycle will be activated ON or deactivated OFF<br />

Selects the desired temperature<br />

Selects the power level: 1 minimum, 4 maximum<br />

Inputs the ignition time in the second operating cycle<br />

Inputs shutdown time in the second operating cycle<br />

Selects the days of the week (shown as: Lu, Ma, Me,… Do) on<br />

which first cycle will be activated ON or deactivated OFF<br />

Selects the desired temperature<br />

Selects the power level: 1 minimum, 4 maximum<br />

23<br />

English

English<br />

Setting the timer<br />

SETTING THE TIMER FOR THE FIRST TIME, REMEMBER TO SET THE CLOCK, INPUTTING THE CURRENT DAY, HOUR AND MINUTE,<br />

AS WITH A NEW WATCH. This will be neccessary only the first time that the clock is activated.<br />

To access the timer set mode, press the keys in the sequence described below.<br />

(NB: at any time exit the timer set mode and change any data er<strong>ro</strong>neously confirmed by pressing the ON/OFF key. Re-enter the mode<br />

by repeating the sequence f<strong>ro</strong>m the beginning and using the SET key to advance to the point at which you exited.)<br />

24<br />

Set the day<br />

SETTING THE CLOCK (current day/time)<br />

Function Action Display<br />

Confirm setting and<br />

move to next section.<br />

Set the hour.<br />

Set the minutes<br />

Confirm selections<br />

and moving to next<br />

section<br />

Exiting clock setting<br />

mode<br />

Press the SET key then key 6.<br />

Press key 1 to advance th<strong>ro</strong>ugh the<br />

days of the week.<br />

Press key 2 to return th<strong>ro</strong>ugh the<br />

sequence.<br />

Press the SET key to confirm.<br />

3<br />

SET<br />

Press key 1 to advance th<strong>ro</strong>ugh the<br />

hours.<br />

Press key 2 to return th<strong>ro</strong>ugh the<br />

sequence.<br />

Press key 6 to advance th<strong>ro</strong>ugh the<br />

minutes.<br />

Press key 5 to return th<strong>ro</strong>ugh the<br />

sequence.<br />

Press the SET key to confirm<br />

3<br />

SET<br />

1<br />

3 OK<br />

4<br />

GRUPPO PIAZZETTA<br />

SET<br />

2<br />

1<br />

SET<br />

AL. C<br />

AL. F<br />

3 OK<br />

4<br />

GRUPPO PIAZZETTA<br />

SET<br />

2<br />

SET<br />

AL. C<br />

AL. F<br />

Upper half: 01:00, 02:00,… … 23:00<br />

Lower half: 02 u<br />

Upper half: 00, 01, 02,… … 59<br />

Lower half: 02 u<br />

3 OK<br />

4<br />

GRUPPO PIAZZETTA<br />

SET<br />

Press the ON/OFF key. OK<br />

SET<br />

4<br />

3<br />

SET<br />

1<br />

2<br />

6<br />

5<br />

6<br />

5<br />

Example:<br />

1<br />

2<br />

1<br />

2<br />

SET<br />

SET<br />

GRUPPO PIAZZETTA<br />

AL. C<br />

AL. F<br />

3 4<br />

AL. C<br />

AL. F<br />

6<br />

5<br />

6<br />

5<br />

6<br />

5<br />

6<br />

5<br />

DT2040011-00<br />

®<br />

SUPERIOR

®<br />

SUPERIOR<br />

ACTIVATION/DEACTIVATION OF THE ALARM SIGNAL<br />

Function Action Display<br />

Activation/deactivation<br />

of the alarm signal<br />

during operation<br />

of the stove.<br />

Set the code<br />

Confirm selection<br />

P<strong>ro</strong>ceed f<strong>ro</strong>m the previous<br />

section or press the SET<br />

key then key 6<br />

Press the set<br />

key twice in succession and on the<br />

lower part of the display the code<br />

03u will appear.<br />

Press key 1 to advance th<strong>ro</strong>ugh the sequence<br />

of the codes:<br />

(09 = alarm activated;<br />

10 = alarm deactivated).<br />

Press key 2 to return th<strong>ro</strong>ugh the sequence.<br />

1<br />

3 OK<br />

4<br />

GRUPPO PIAZZETTA<br />

SET<br />

1<br />

2<br />

SET<br />

AL. C<br />

AL. F<br />

3 OK<br />

4<br />

GRUPPO PIAZZETTA<br />

SET<br />

Press SET to confirm OK<br />

SET<br />

3<br />

SET<br />

3<br />

SET<br />

6<br />

5<br />

Example: you want the alarm to be active during operation of the<br />

stove: select code 09.<br />

Example:<br />

2<br />

1<br />

2<br />

SET<br />

SET<br />

GRUPPO PIAZZETTA<br />

AL. C<br />

AL. F<br />

3 4<br />

ACTIVATION/DEACTIVATION OF THE TEMPERATURE/TIME DISPLAY<br />

Function Action Display<br />

Activation/deactivation<br />

of the temperature/time<br />

display<br />

during operation.<br />

Set the code<br />

Confirm selection<br />