Highly Efficient Vertical Axis Wind Turbine for Low-Moderate Speed ...

Highly Efficient Vertical Axis Wind Turbine for Low-Moderate Speed ...

Highly Efficient Vertical Axis Wind Turbine for Low-Moderate Speed ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

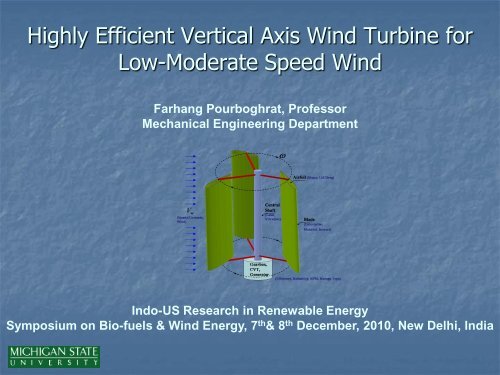

<strong>Highly</strong> <strong>Efficient</strong> <strong>Vertical</strong> <strong>Axis</strong> <strong>Wind</strong> <strong>Turbine</strong> <strong>for</strong><br />

<strong>Low</strong>-<strong>Moderate</strong> <strong>Speed</strong> <strong>Wind</strong><br />

Farhang Pourboghrat, Professor<br />

Mechanical Engineering Department<br />

Indo-US Research in Renewable Energy<br />

Symposium on Bio-fuels & <strong>Wind</strong> Energy, 7 th & 8 th December, 2010, New Delhi, India

Presentation Outline<br />

Introduction & Motivations<br />

MSU <strong>Wind</strong> Energy Research Team<br />

Design of <strong>Highly</strong> <strong>Efficient</strong> VAWT<br />

Continuous Variable Transmission (CVT)<br />

Blade Materials and Manufacturing<br />

Testing of FRP Composites<br />

FEA of FRP Composite Forming<br />

..<br />

Ideas <strong>for</strong> Collaboration

Motivating Factors:<br />

Introduction<br />

Reduce Dependence on Petroleum to Generate Electricity<br />

Generate Electricity From Clean, Renewable <strong>Wind</strong><br />

US Statistics:<br />

Total US Electric Capacity in 2007 – 1 TW<br />

Available Resources From <strong>Wind</strong> in the US – 5.5 TW<br />

Generation of Electricity From <strong>Wind</strong> - 2% of Total US<br />

Energy<br />

DOE Goal <strong>for</strong> Generating Electricity From <strong>Wind</strong> By 2030 -<br />

20%<br />

Prevalent Type of <strong>Wind</strong> <strong>Turbine</strong> in the US – HAWT<br />

HAWTs Generate kWatt-MWatt Range of Power<br />

VAWTs Generate Watt-kWatt Range of Power<br />

VAWTs Are Rated to Be Less <strong>Efficient</strong> Than HAWTs

World <strong>Wind</strong> Map

US <strong>Wind</strong> Map

Michigan <strong>Wind</strong> Map<br />

MSU

NREL Chart of Efficiency <strong>for</strong> Various<br />

Types of <strong>Wind</strong> <strong>Turbine</strong>s

Advantages<br />

Disadvantages<br />

Advantages<br />

Disadvantages<br />

VAWT vs. HAWT<br />

Horizontal <strong>Axis</strong> <strong>Wind</strong> <strong>Turbine</strong> (HAWT)<br />

Higher efficiency due to variable blade pitch.<br />

Consistent wind loading over the course of a rotation reduces vibration and noise.<br />

Established manufacturing know-how and market acceptability.<br />

Increased costs of transporting tall towers and long blades.<br />

Installation requires very tall and expensive cranes and skilled operators.<br />

Massive tower and heavy foundation to support blades, gearbox, and generator.<br />

Complex design of twisted blades is difficult and expensive to fabricate.<br />

Large size may disrupt the landscape and create local opposition.<br />

Requires yaw control to turn the blades and nacelle toward the wind.<br />

A distance of 5 rotor diameters siting is needed in order to minimize wake effects.<br />

Difficult, expensive, and frequent maintenance required.<br />

<strong>Vertical</strong> <strong>Axis</strong> <strong>Wind</strong> <strong>Turbine</strong> (VAWT)<br />

Smaller tower structure, since lower bearings are mounted near the ground.<br />

The generator and gearbox are installed near the ground.<br />

Suitable <strong>for</strong> low speed winds, due to lower wind startup speed.<br />

May be built at locations where taller structures are prohibited.<br />

Can take advantage of locations where landscape increases wind speed near the ground.<br />

May have a lower noise signature.<br />

Needs less space than HAWT to generate the same amount of power.<br />

Straight blades are much easier and economical to fabricate or extrude.<br />

<strong>Low</strong>er overall maintenance and transportation costs.<br />

<strong>Low</strong>er aerodynamic efficiency compared to HAWT.<br />

Blade fatigue failure due to change in stress sign during each revolution.<br />

May require dismantling the entire structure to fix the generator or gearbox.

GOAL: Develop Lighter, Stronger, Reliable,<br />

<strong>Highly</strong> <strong>Efficient</strong> Straight-Blade VAWT<br />

V<br />

w<br />

(Steady/Unsteady,<br />

<strong>Low</strong> <strong>Speed</strong> <strong>Wind</strong>)<br />

Blade Orientation<br />

Mechanism<br />

Central<br />

Shaft<br />

(Load,<br />

Vibration)<br />

Gearbox, CVT<br />

Electric<br />

Generator<br />

(Optimum Tip<br />

Velocity Ratio)<br />

Airfoil<br />

(Shape,<br />

Lift/Drag)<br />

Blade<br />

(Orientation,<br />

Material,<br />

Sensors)<br />

(Efficiency, Reliability,<br />

RPM, Storage Type)

Industrial Partners<br />

MSU<br />

<strong>Wind</strong><br />

Energy<br />

Team<br />

University and<br />

Research Lab<br />

Partners<br />

Develop <strong>Efficient</strong>, and<br />

Reliable Transmission<br />

Systems, Including CVT <strong>for</strong><br />

Variable <strong>Wind</strong> Conditions<br />

Pourboghrat, Feeney

On-Going Projects..<br />

Experimental Research <strong>Wind</strong> <strong>Turbine</strong> (W/T):<br />

The W/T is Comprised of a Variable <strong>Speed</strong> Motor to<br />

Simulate Variable <strong>Wind</strong> Conditions; a CVT; an<br />

Induction Generator; and a Battery.<br />

The Set Up Will be Used to Verify Computational<br />

Modeling.<br />

The CVT will Control RPM and Tip <strong>Speed</strong> Ratio (TSR),<br />

to Insure that Generator’s Output Remains at 60 Hz.<br />

Lightweight Composite Blades Will be Added Later.<br />

Developing a FAST/Simulink Model of W/T with CVT to<br />

Optimize Power Output and Mitigate Vibration Loads.<br />

Pressure Sensors <strong>for</strong> Real Time Monitoring of Blades.<br />

Finite Element Analysis of Vibration Loads in Gear Train<br />

Systems (Using Romax software)..<br />

Fabricating a High Efficiency VAWT with Blade Pitch<br />

Control Mechanism.

Grid<br />

t<br />

g<br />

Air<br />

<strong>Wind</strong> <strong>Turbine</strong>:<br />

1<br />

2<br />

3<br />

Power t g Air CP V A<br />

Drivetrain Efficiency<br />

Generator Efficiency<br />

AirDenisty 1.2 Kg m<br />

C Power Coefficient ( Betz Limit, Max 0.59)<br />

P<br />

50 Hz<br />

Inverter<br />

Asynchronous<br />

Generator<br />

3<br />

Fixed<br />

Gear<br />

Problem Areas<br />

Rotor<br />

V D<br />

D Rotor Diameter m<br />

V <strong>Wind</strong> Velocity m s<br />

1 2 2<br />

A Sweep Area D ( m )<br />

4

Grid<br />

60 Hz<br />

1. <strong>Wind</strong> <strong>Turbine</strong> with CVT<br />

NuVinci CVT<br />

Inverter<br />

Asynchronous<br />

Generator<br />

Variable<br />

Gear<br />

(CVT)<br />

BENEFITS:<br />

•Maximum efficiency even with sudden changes in wind speed.<br />

• The generator produces electric current at a constant frequency.<br />

• Improved output, efficiency, and reduced vibrations.<br />

Fixed<br />

Gear<br />

Rotor<br />

V D

NuVinci CVT

Experimental Set Up Representing W/T<br />

Motor<br />

Controller<br />

CVT<br />

• NuVinci CVT gear ratios range between 0.5:1.75 (350%)<br />

• The CVT will control the “tip-speed ratio” <strong>for</strong> optimum W/T per<strong>for</strong>mance.<br />

V T<br />

V<br />

“tip-speed ratio”: . D 2V<br />

V<br />

D .<br />

2<br />

Generator

PID Control of HAWT + CVT with FAST/Simulink*<br />

The control objective is to track the ideal tip-speed ratio.<br />

Simulation of the system’s per<strong>for</strong>mance in response to five turbulent wind<br />

conditions show an improvement in the electric energy output compared with<br />

the standard fixed-speed operation ranging from 3.9% to 29.8%.<br />

A mitigation of fatigue loading is also possible but not done.<br />

Control scheme can be optimized to take full advantage of CVT capabilities.<br />

*Andrew H. Rex and Kathryn E. Johnson, Journal of Solar Energy Engineering, 2009.

FAST/Simulink Modeling of HAWT/VAWT with CVT<br />

Rotor<br />

Gear<br />

train<br />

CVT<br />

Aerodynamics Dynamics Dynamics &<br />

Controls<br />

Apply SISO/MIMO Controls Strategies to<br />

both mitigate load and improve efficiency<br />

Simulink®<br />

Induction<br />

Generator<br />

Electromagnetics

Objective<br />

2. Nonlinear Dynamic Loading and Responses <strong>for</strong><br />

<strong>Wind</strong> <strong>Turbine</strong> Reliability<br />

Brian Feeny, Michigan State University, Award # CBET-0933292<br />

Understanding of wind turbine blade<br />

dynamics, and how dynamic loading<br />

affects gearbox reliability.<br />

Issues<br />

• Cyclic gravitational <strong>for</strong>ce F<br />

• Direct cyclic component<br />

• Parametric cyclic component<br />

• Aerodynamic <strong>for</strong>ces (e.g. distributed f a)<br />

• Cyclic via wind shear, shadowing<br />

• Self excitation (flutter)<br />

• Responses cause gearbox loadings<br />

Collaboration: MSU, Romax Tech., NREL<br />

Gearbox Reliability Collaborative. Modal<br />

analysis of gearbox housing. FEM of<br />

gearbox, under vibration loading.<br />

f a<br />

F p<br />

F d<br />

F = mg<br />

wind

Nonlinear Dynamic Loading and Responses <strong>for</strong><br />

<strong>Wind</strong> <strong>Turbine</strong> Reliability<br />

Brian Feeny, Michigan State University, Award # CBET-0933292<br />

Loaded Romax Model:<br />

NREL Gearbox<br />

HS<br />

LS<br />

Contact stress, outer race HS<br />

shaft bearing<br />

FEM Modal Analysis on<br />

Housing<br />

Contact stress, HS shaft<br />

pinion gear tooth

3. Blade Material Options<br />

Light Weight, Strong, Impact Resistant, Durable, Inexpensive<br />

Matrix Choices:<br />

Thermoplastic (Polypropylene, Polyethylene,..)<br />

Thermoset (Polyester,..)<br />

Biobased (Polyurethane, PLA, PHBV,..)<br />

Non-Renewable Fiber Rein<strong>for</strong>cement Choices:<br />

Glass and Carbon Fibers<br />

Hybrid of Glass/Carbon Fibers (applied to select areas)<br />

Graphene nano-platelets<br />

Renewable Fiber Rein<strong>for</strong>cement Choices:<br />

Straw Bio-Fibers (Corn/Wheat/Rice)<br />

Non-Wood Bio-Fibers (Kenaf/Sisel/Henequen/Coir)<br />

Wood Bio-Fibers<br />

Nano-Whiskers

E (BTUs)/1 lb. fiber<br />

U.S. Cents/lb.<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

30,000<br />

25,000<br />

20,000<br />

15,000<br />

10,000<br />

5,000<br />

0<br />

Why Bio Fibers <strong>for</strong> Blades?<br />

Cost comparison<br />

70<br />

23,500<br />

Energy savings<br />

6,500<br />

Glass Kenaf<br />

- Mechanical PERFORMANCE<br />

- Biodegradable and Recyclable<br />

- CO 2 Neutral & Sequesterization<br />

25<br />

Glass Biofiber<br />

Density, g/cm3<br />

4<br />

3<br />

2<br />

1<br />

0<br />

2.6<br />

Weight savings<br />

1.3<br />

Glass Biofiber<br />

Biodegradable<br />

Materials

Specific Modulus (E-Modulus/Density)<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

Comparison of Specific Modulus <strong>for</strong> Various<br />

Fibers<br />

Kenaf<br />

Hemp<br />

Modulus/Cost<br />

Comparison<br />

1 Sisal Coir E-Glass<br />

Modulus/Cost (E-Modulus/($/kg))<br />

160<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

Mechanical<br />

Per<strong>for</strong>mance:<br />

Modulus<br />

Comparison<br />

Comparison of Modulus Per Cost <strong>for</strong> Various<br />

Fibers<br />

1<br />

Kenaf Sisal Coir E-Glass<br />

Ref.: Zampaloni, M., Pourboghrat, F., Yankovich, S. A., Rodgers, B. N., James Moore, Misra, M.,<br />

Mohanty, A. K., and Drzal, L. T., Composite A, 2007

Flexural Strength (MPa)<br />

80<br />

40<br />

0<br />

Flex Strength (MPa)<br />

Flex Modulus (GPa)<br />

34<br />

46<br />

1.7 1.5<br />

Ref.: A. K. Mohanty, S. Desai, P.<br />

Mulukutla, M. Misra, L. T. Drzal, 2004<br />

6.2<br />

37<br />

PHB PP PHB + 30%<br />

KENAF<br />

Impact<br />

Strength<br />

PHB +30% Kenaf<br />

superior to PP +<br />

30%Glass<br />

35<br />

3.5<br />

36<br />

3.8<br />

Impact Strength (J/m)<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

67<br />

5.4<br />

Kenaf HENQ Glass<br />

PHB +<br />

30% HENQ<br />

PHB +<br />

30% PALF<br />

PP + 30%<br />

GLASS<br />

24<br />

5.8<br />

35<br />

PHB + 30%<br />

GLASS<br />

9<br />

6<br />

3<br />

0<br />

PHB+ 30%Henequen<br />

comparable to PP+30%Glass<br />

48<br />

36<br />

PHB PP PHB + 30%<br />

KENAF<br />

Flexural Modulus (GPa)<br />

Natural Fibers +<br />

Biocomposites:<br />

58<br />

Kenaf HENQ<br />

PHB + 30%<br />

HENQ<br />

Flexural<br />

Modulus<br />

29<br />

PHB +<br />

30%PALF<br />

65<br />

Glass<br />

PP + 30%<br />

GLASS<br />

46<br />

PHB + 30%<br />

GLASS

Effect of Fiber Length and Volume Fraction:<br />

Modulus (MPa)<br />

12<br />

9<br />

6<br />

3<br />

0<br />

2.9<br />

3<br />

4.6<br />

5.9<br />

6.2<br />

A B C D E F<br />

11<br />

A= 30% kenaf 6mm fiber/ soy composites injection molding<br />

B= 33% Kenaf 6mm fiber/ soy compression molding<br />

C= 55% Kenaf 2mm fiber/ soy compression molding<br />

D= 56% Kenaf 6mm fiber/ soy compression molding<br />

E= 57% Kenaf 2 inch fiber /soy compression molding<br />

F= 54% Kenaf long fiber/ soy compression molding<br />

Impact strength (J/m)<br />

400<br />

350<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

0<br />

Impact strength<br />

Fiber length on impact surface<br />

50<br />

0.2<br />

92<br />

0.8<br />

125<br />

0.7<br />

184<br />

1.2<br />

289<br />

2.0<br />

A B C D E F<br />

370<br />

2.7<br />

3<br />

2.5<br />

2<br />

1.5<br />

1<br />

0.5<br />

0<br />

Fiber length on Impact<br />

surface (mm)

CNT Nanoparticle<br />

Modification of CF<br />

Surface<br />

CNT - high modulus, high strength,<br />

high electrical conductivity etc.<br />

Expected CFRP properties<br />

a. Fiber direction<br />

- tensile strength<br />

- compressive strength (-> OHC)<br />

b. Transverse direction<br />

- interlaminar fracture toughness (-><br />

CAI)<br />

- electrical conductivities<br />

(-> lightning striking resistance)<br />

c. Others<br />

- damping property<br />

Additional Improvements:<br />

Exfoliated graphene Nanoplatelets at 5wt%<br />

functionalized with a CTBN toughening agent increased<br />

the unnotched impact strength by 238% of the base<br />

vinyl ester resin without any loss of modulus.<br />

MWCNT at 0.5 wt% coated on the CF surface increased<br />

the Mode II fracture toughness by 7% without loss of<br />

modulus or strength.<br />

Compressive strength<br />

CF CNT<br />

preventing fiber buckling by<br />

enhancement of modulus<br />

and yield strength of matrix<br />

Interlaminar fracture toughness<br />

stopping crack propagation<br />

by bridging effect

[MPa] [MPa] [MPa]<br />

[MPa] [MPa] [MPa] [MPa]<br />

200<br />

180<br />

160<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

14000<br />

12000<br />

10000<br />

6000<br />

4000<br />

Flexural Strength<br />

0<br />

0 5 10 15<br />

[Vol%]<br />

20 25 30<br />

Flexural Modulus<br />

Flexural Modulus Of<br />

1um Graphite<br />

Nylon 66 15um Rein<strong>for</strong>ced<br />

Graphite<br />

In-situ<br />

CF<br />

With Up VGCF To 20 v%<br />

CB<br />

8000 Nanofillers.<br />

Flexural Modulus<br />

[MPa]<br />

14000<br />

12000<br />

10000<br />

8000<br />

6000<br />

4000<br />

2000<br />

0<br />

1um Graphite<br />

15um Graphite<br />

In-situ<br />

CF<br />

VGCF<br />

CB<br />

Flexural Modulus<br />

1um Graphite<br />

15um Graphite<br />

In-situ<br />

CF<br />

VGCF<br />

CB<br />

Flexural Strength Of<br />

Nylon 66 Rein<strong>for</strong>ced<br />

With Up To 20 v%<br />

Nanofillers.<br />

Flexural Modulus<br />

0 5 10 15 20 25<br />

[Vol%]

4. Experimental Testing of FRP Laminate<br />

Glass mat fiber rein<strong>for</strong>ced thermoplastic<br />

Continuous fiber rein<strong>for</strong>cement (40% glass)<br />

Long, chopped fiber rein<strong>for</strong>cement (32% glass)<br />

“long” -> 50-100 mm in length<br />

Polypropylene resin matrix<br />

Processing at 0-30 psi Pressure

Glass Mat<br />

207 kPa (30 psi)<br />

0 kPa<br />

Glass Mat<br />

Delamination

Squeeze Flow Test –<br />

A Method to Measure Anisotropy<br />

Metal Plates<br />

Preferred fiber orientation determination<br />

Fiber Rein<strong>for</strong>ced Sample<br />

Heated Platens

Distance from center (in)<br />

4.2<br />

4.1<br />

4<br />

3.9<br />

3.8<br />

3.7<br />

3.6<br />

3.5<br />

3.4<br />

3.3<br />

3.2<br />

3.1<br />

3<br />

Determining the Preferred Fiber Orientations from Compression Tests <strong>for</strong> R401-B01<br />

0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360<br />

Angle along part (deg)<br />

Chopped Fiber<br />

Length (in)<br />

4<br />

3.75<br />

3.5<br />

3.25<br />

3<br />

2.75<br />

2.5<br />

Continuous Fiber<br />

Determining the Preferred Fiber Orientations using the Distance from the<br />

Center Point after Compression Testing <strong>for</strong> C321- Chopped Fiber Mat<br />

0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360<br />

Degrees from Zero (deg)

Stress (kPa)<br />

140000<br />

120000<br />

100000<br />

80000<br />

60000<br />

40000<br />

20000<br />

0<br />

Stress-Strain Curve <strong>for</strong> R401-B01, Continuous Fiber Mat, 60 Degree Direction<br />

Ef = 6.95 Gpa (1008 ksi)<br />

0 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.1 0.11 0.12 0.13<br />

Strain (mm/mm)<br />

Stress-Strain Curve<br />

<strong>for</strong> a sample along<br />

the 30 o Direction<br />

Stress (kPa)<br />

60000<br />

50000<br />

40000<br />

30000<br />

20000<br />

10000<br />

0<br />

Uniaxial Tension Test Specimen<br />

Stress-Strain Curve<br />

<strong>for</strong> a sample along<br />

the 60 o Direction<br />

Stress-Strain Plot <strong>for</strong> C321-B01, Chopped Fiber Mat Thermoplastic,<br />

30 Degree Direction<br />

E f = 3.56 Gpa (516 ksi)<br />

0 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.1 0.11<br />

Strain (mm/mm)

5. Finite Element Modeling of FRP<br />

Initial<br />

configuration<br />

Final<br />

configuration

Constitutive Relationship <strong>for</strong><br />

Multiple Preferred Fiber<br />

Multiple Preferred<br />

Fiber Orientations<br />

Orientations<br />

1-Fiber<br />

Direction<br />

2-Fiber<br />

Direction<br />

t 1 2<br />

...<br />

n<br />

jk jk jk jk<br />

Q Q Q Q<br />

Q<br />

t<br />

jk<br />

3-Fiber<br />

Direction<br />

Stresses and Strains based on rotated material frame<br />

n-Fiber<br />

Directions

Components of the Stiffness<br />

Q E<br />

Matrix<br />

11 11 12 21<br />

Q E<br />

22 22 12 21<br />

Q E<br />

12 12 11 12 21<br />

Q G<br />

33 12<br />

13 31 23 32<br />

21 12<br />

/(1 )<br />

/(1 )<br />

/(1 )<br />

Q Q Q Q<br />

Q Q<br />

Material properties defined along the fiber directions<br />

0

Material Properties Needed as<br />

Model Input<br />

Input parameters<br />

Young’s modulus of the fiber (E f)<br />

Young’s modulus of the resin (E m)<br />

Poisson’s ratio <strong>for</strong> the fiber ( f)<br />

Poisson’s ratio <strong>for</strong> the resin ( m)<br />

Shear modulus <strong>for</strong> the fiber (G f)<br />

Shear modulus <strong>for</strong> the resin (G m)<br />

Initial volume fraction (V fo)

Input Parameters <strong>for</strong><br />

Constitutive Model - Glass Fiber<br />

Continuous Fiber Mat Chopped Fiber Mat<br />

E f, 0 5.15 GPa E f, 30 3.56 GPa<br />

E f, 60 6.95 GPa E f, 105 6.5 GPa<br />

E f, 90 6.69 GPa E f, 120 4.9 GPa<br />

E m, all 1.5 GPa E f, 150 3.95 GPa<br />

f, all 0.361 E m, all 1.5 GPa<br />

m, all 0.1 f, all 0.317<br />

G f, all 29.9 GPa m, all 0.1<br />

G m, all 0.2 MPa G f, all 29.9 GPa<br />

G m, all<br />

0.2 MPa

De<strong>for</strong>med Shape<br />

Experiment: U.Mohammed et al., Composites Part A, p.1414, 2000

Continuous Glass Fiber Mat

Pressure Effect (on Fiber Angle)<br />

Without pressure With pressure<br />

Fluid Pressure Reduces Fiber Rotation.

Pressure Effect (on Shape)<br />

Without Fluid Pressure 137 kPa (20 psi)<br />

274 kPa (40 psi) 689 kPa (100 psi)

6. Composite Hydro<strong>for</strong>ming*<br />

Prepregs<br />

Processing Steps:<br />

1. Heat Thermoplastic Sheet (in the die).<br />

2. Close Die, Fluid Fill, Pressurization.<br />

3. Displace Punch, Control Pressure.<br />

4. Cool Punch and Part. Remove Part.<br />

1 2<br />

3 4<br />

* Farhang Pourboghrat, Zampaloni, M., and Benard, A., “Hydro<strong>for</strong>ming of<br />

Composite Materials”, US Patent No. 6,631,630, October 14, 2003.

Woven<br />

Glass<br />

Kenaf<br />

Fiber

7. FRP Composite Blade Manufacturing<br />

1) Design Blade Cross Section (Airfoil) For Maximum Lift:<br />

Vorticity Contours over SD7003 Airfoil as obtained<br />

by Large Eddy Simulation.<br />

2) Split The Blade Into Two Halves (Asymmetric):<br />

Top Half<br />

Bottom Half<br />

VAWT Blade

Blade Manufacturing Process<br />

Stamping Process Stamping Process<br />

(a)<br />

Compression Molded Flat Composite Panel<br />

Stamped Flat Panels Forming; (a) Bottom Half, and (b) Top Half.<br />

Adhesively Glued Halves Form the Blade<br />

(b)

Remove<br />

Mold<br />

Adhesive<br />

Pressurized<br />

Medium<br />

Trim Excess<br />

Material<br />

Adhesive<br />

Hybrid<br />

Thermoplastic<br />

Sandwich Sheet<br />

Final<br />

Blade

VAWT with Lightweight<br />

CFPP Blades

8. Effect of Blade Orientation<br />

Adjustment Strategy During the<br />

Rotation on the Efficiency of VAWT<br />

Table 1. Computed Effect of Blade Orientation Adjustment Strategy on VAWT Efficiency<br />

FREQUENCY OF<br />

BLADE<br />

ORIENTATION<br />

ADJUSTMENT<br />

Every 1/2 o<br />

Every 4 o<br />

Every 8 o<br />

WIND<br />

VELOCITY,<br />

V (M/S)<br />

w<br />

TIP SPEED<br />

RATIO,<br />

R V<br />

w<br />

TORQUE,<br />

T (N.M)<br />

POWER,<br />

(WATT)<br />

P T<br />

EFFICIENCY,<br />

C P P<br />

p wind<br />

5.0 1.0 35.3 176.5 47.5%<br />

7.5 1.0 79.5 596.3 47.5%<br />

5.0 1.0 18.8 94 25.3%<br />

7.5 1.0 42.2 316.5 25.3%<br />

5.0 0.81 6.53 26.4 7.1%<br />

7.5 0.81 14.7 89.1 7.1%

Cascade Model Prediction of Power<br />

Generated by High Efficiency VAWT<br />

with Pitched Blade<br />

Table – Numbers and Sizes of VAWTs Needed to Generate 30 MWh Energy per month<br />

WIND<br />

CATEGORY<br />

AND<br />

LOCATION<br />

HEIGHT<br />

FROM<br />

GROUND,<br />

H (M)<br />

VAWT<br />

DIAMETER,<br />

D, AND<br />

BLADE<br />

HEIGHT, H<br />

(M)<br />

WIND<br />

VELOCITY,<br />

V (M/S)<br />

POWER<br />

(KW)<br />

ENERGY<br />

(MWH/MONTH)<br />

NUMBER<br />

OF WIND<br />

TURBINES<br />

3 (Lansing) 10 10, 12 4.71 3.54 2.55 12<br />

3 (Lansing) 30 10, 12 5.62 6.0 4.32 7<br />

3 (Lansing) 50 10, 12 6.09 7.67 5.52 6<br />

3 (Lansing) 30 16,18 5.62 13.89 10.0 3<br />

3 (Lansing) 50 14,16 6.09 13.89 10.0 3<br />

5 (Shore) 50 14, 16 8.8 41.7 30.0 1<br />

6 (Shore) 50 12, 14 9.6 41.7 30.0 1

Areas of Collaboration<br />

<strong>Wind</strong> Tunnel Testing of Medium Size <strong>Highly</strong> <strong>Efficient</strong> VAWT.<br />

Construction and Field Testing of <strong>Highly</strong> <strong>Efficient</strong> VAWT in <strong>Low</strong>-<strong>Moderate</strong> <strong>Speed</strong><br />

<strong>Wind</strong> Regions.<br />

Scaling Up of the <strong>Highly</strong> <strong>Efficient</strong> VAWT.<br />

Mechanisms <strong>for</strong> Pitching W/T Blades <strong>for</strong> Optimum Per<strong>for</strong>mance.<br />

Blade Shape Morphing Mechanisms, Materials and Related Technologies.<br />

Computational Model Development<br />

Multi-Scale Computational Models to Predict Mechanical, Electrical, Thermal,<br />

Electromagnetic Properties of Nano-Platelet Rein<strong>for</strong>ced Polymer Composites.<br />

Failure Models <strong>for</strong> Nano-Platelet Rein<strong>for</strong>ced Polymer Composites.<br />

Fatigue Failure Models <strong>for</strong> Various <strong>Wind</strong> <strong>Turbine</strong> Components.<br />

Computationally <strong>Efficient</strong> Fluid-Solid Interaction Strategies/Model <strong>for</strong> Blade<br />

Aerodynamics Simulation.<br />

Integration of Simulink with Aerodynamics, Gear Train, CVT, and Generator<br />

Models.<br />

Robust Controls Strategies <strong>for</strong> Optimization of <strong>Wind</strong> <strong>Turbine</strong>s System.<br />

Etc.<br />

Sensor Development <strong>for</strong> Real-Time Health Monitoring of <strong>Wind</strong> <strong>Turbine</strong> System.<br />

Land Policy and Supply Chain Management Issues in India.

Thank You!<br />

Questions?

U.S. <strong>Wind</strong> Map

4. Fabrication of Flat Laminated Composites<br />

(a)<br />

(a)<br />

50 wt % PLA /50 wt % Kenaf fiber mat laminated composite: (a) be<strong>for</strong>e and<br />

(b) after the Compression Molding.<br />

Hybrid laminated composite (PLA/Glass mat/PLA/Kenaf fiber /PLA/Kenaf fiber<br />

/PLA/Glass mat/PLA) : (a) be<strong>for</strong>e and (b) after the Compression Molding.<br />

(b)<br />

(b)