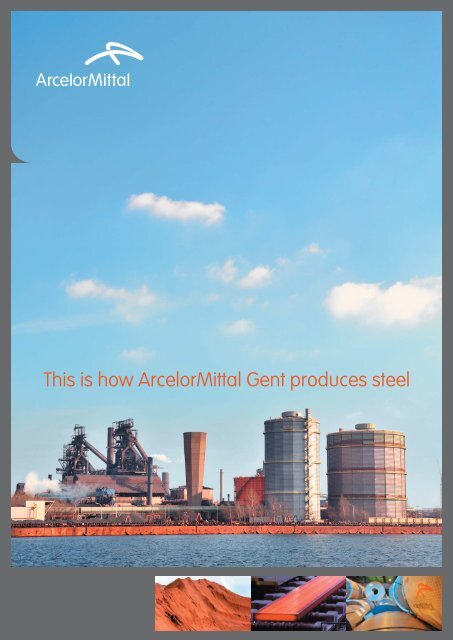

This is how ArcelorMittal Gent produces steel

This is how ArcelorMittal Gent produces steel

This is how ArcelorMittal Gent produces steel

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Th<strong>is</strong></strong> <strong>is</strong> <strong>how</strong> <strong>ArcelorMittal</strong> <strong>Gent</strong> <strong>produces</strong> <strong>steel</strong>

<strong>Th<strong>is</strong></strong> <strong>is</strong> <strong>how</strong> <strong>ArcelorMittal</strong> <strong>Gent</strong> <strong>produces</strong> <strong>steel</strong>

5<br />

8<br />

10<br />

12<br />

13<br />

14<br />

16<br />

20<br />

25<br />

35<br />

38<br />

40<br />

42<br />

44<br />

Contents<br />

Introduction<br />

Production scheme<br />

Coking plant<br />

Raw material handling<br />

Sinter plants<br />

Blast furnaces<br />

Steel shop<br />

Wide hot strip mill<br />

Cold rolling mills<br />

Hot dip galvan<strong>is</strong>ing lines<br />

Organic coating lines<br />

Electrolytic galvan<strong>is</strong>ing line<br />

Production of tailor-welded blanks<br />

<strong>ArcelorMittal</strong> <strong>Gent</strong>, Geel and Genk in figures<br />

Publ<strong>is</strong>hed by<br />

B. De Lembre<br />

John Kennedylaan 51<br />

9042 <strong>Gent</strong><br />

Compilation<br />

Internal & External Communications<br />

Photography<br />

J. Op de Beeck<br />

J. Van den Berghe<br />

Concept & real<strong>is</strong>ation<br />

B. Van Eyken

4 <strong>Th<strong>is</strong></strong> <strong>is</strong> <strong>how</strong> <strong>ArcelorMittal</strong> <strong>Gent</strong> <strong>produces</strong> <strong>steel</strong>

Introduction<br />

<strong>ArcelorMittal</strong> <strong>Gent</strong> <strong>is</strong> part of <strong>ArcelorMittal</strong>, the new <strong>steel</strong> group that was<br />

founded in 2006 as a result of the merger of Arcelor and Mittal Steel.<br />

Arcelor itself was founded in 2002 grouping Arbed, Aceralia and Usinor.<br />

<strong>ArcelorMittal</strong> counts 61 companies in<br />

27 countries and employs 310,000<br />

people worldwide. The group <strong>produces</strong><br />

about 110 million tonnes of crude <strong>steel</strong><br />

a year, 5 million tonnes being produced<br />

in <strong>Gent</strong>. Its production capacity and its<br />

maritime location make <strong>ArcelorMittal</strong><br />

<strong>Gent</strong> one of the most important <strong>steel</strong><br />

production sites in Europe.<br />

The development of modern procedures<br />

to produce <strong>steel</strong>, the d<strong>is</strong>covery of<br />

high-grade ore reserves in overseas<br />

areas, the tremendous evolution in<br />

exploitation techniques and the<br />

construction of giant ships – reducing<br />

transport costs significantly – must be<br />

the main reasons why <strong>steel</strong> groups<br />

decided to create new <strong>steel</strong> companies<br />

in coastal areas after World War II. There<br />

they would find themselves with many<br />

more opportunities than the traditional<br />

<strong>steel</strong> industry inland.<br />

<strong>Th<strong>is</strong></strong> <strong>is</strong> the context in which the<br />

<strong>ArcelorMittal</strong> <strong>Gent</strong> production site was<br />

founded. In 1959, the Luxembourgian<br />

<strong>steel</strong> giant Arbed together with some<br />

other Belgian and European <strong>steel</strong><br />

companies and financial groups took the<br />

initiative to found a “modern” <strong>steel</strong><br />

company at the <strong>Gent</strong>-Terneuzen canal.<br />

The city of <strong>Gent</strong> helped in acquiring a<br />

624 hectares territory on the east bank<br />

of the canal. On 27 April 1962, the<br />

project was approved by the ECSC and a<br />

few months later, on 10 July 1962,<br />

Sidmar NV/SA was founded. A maritime<br />

<strong>steel</strong>works in Flanders that could be<br />

accessed by big vessels had now<br />

become reality. It instantly reassured<br />

anyone who had concerns about our<br />

country’s economic expansion.<br />

However, the idea of founding a<br />

<strong>steel</strong>works alongside the<br />

<strong>Gent</strong>-Terneuzen canal had been playing<br />

in people’s heads a lot longer. Indeed, on<br />

5 March 1928, Emile Mayr<strong>is</strong>ch, who<br />

was the director-general of Arbed<br />

Luxembourg at that time, assigned h<strong>is</strong><br />

immediate staff to buy a plot of land<br />

along the <strong>Gent</strong>-Terneuzen canal on<br />

behalf of Arbed. Even then, Emile<br />

Mayr<strong>is</strong>ch had a feeling that rich<br />

overseas iron ore would soon play an<br />

important role in European hot metal<br />

production. He wanted Arbed to be<br />

prepared. As a result, in 1932, Arbed<br />

became the owner of 211 hectares of<br />

land at the right bank of the canal.<br />

Because of World War II and post-war<br />

difficulties, these grounds would not be<br />

exploited until 1962. The construction<br />

of Sidmar – as the site was called at the<br />

time - began in December 1963,<br />

involving driving tens of thousands of<br />

piles into the ground, pouring thousands<br />

of cubic metres of concrete, assembling<br />

thousands of tonnes of <strong>steel</strong> trusses,<br />

drawing kilometres of cable and laying<br />

just as many pipes, building roads and<br />

railways.<br />

It <strong>is</strong> worth mentioning that the various<br />

installations were built in reverse order<br />

to the production process. <strong>Th<strong>is</strong></strong> <strong>is</strong> when<br />

the production units were first used:<br />

<strong>Th<strong>is</strong></strong> <strong>is</strong> <strong>how</strong> <strong>ArcelorMittal</strong> <strong>Gent</strong> <strong>produces</strong> <strong>steel</strong> 5

Introduction<br />

<strong>ArcelorMittal</strong> <strong>Gent</strong> <strong>is</strong> part of <strong>ArcelorMittal</strong>, the new <strong>steel</strong> group that was<br />

founded in 2006 as a result of the merger of Arcelor and Mittal Steel.<br />

Arcelor itself was founded in 2002 grouping Arbed, Aceralia and Usinor.<br />

<strong>ArcelorMittal</strong> counts 61 companies in<br />

27 countries and employs 310,000<br />

people worldwide. The group <strong>produces</strong><br />

about 110 million tonnes of crude <strong>steel</strong><br />

a year, 5 million tonnes being produced<br />

in <strong>Gent</strong>. Its production capacity and its<br />

maritime location make <strong>ArcelorMittal</strong><br />

<strong>Gent</strong> one of the most important <strong>steel</strong><br />

production sites in Europe.<br />

The development of modern procedures<br />

to produce <strong>steel</strong>, the d<strong>is</strong>covery of<br />

high-grade ore reserves in overseas<br />

areas, the tremendous evolution in<br />

exploitation techniques and the<br />

construction of giant ships – reducing<br />

transport costs significantly – must be<br />

the main reasons why <strong>steel</strong> groups<br />

decided to create new <strong>steel</strong> companies<br />

in coastal areas after World War II. There<br />

they would find themselves with many<br />

more opportunities than the traditional<br />

<strong>steel</strong> industry inland.<br />

<strong>Th<strong>is</strong></strong> <strong>is</strong> the context in which the<br />

<strong>ArcelorMittal</strong> <strong>Gent</strong> production site was<br />

founded. In 1959, the Luxembourgian<br />

<strong>steel</strong> giant Arbed together with some<br />

other Belgian and European <strong>steel</strong><br />

companies and financial groups took the<br />

initiative to found a “modern” <strong>steel</strong><br />

company at the <strong>Gent</strong>-Terneuzen canal.<br />

The city of <strong>Gent</strong> helped in acquiring a<br />

624 hectares territory on the east bank<br />

of the canal. On 27 April 1962, the<br />

project was approved by the ECSC and a<br />

few months later, on 10 July 1962,<br />

Sidmar NV/SA was founded. A maritime<br />

<strong>steel</strong>works in Flanders that could be<br />

accessed by big vessels had now<br />

become reality. It instantly reassured<br />

anyone who had concerns about our<br />

country’s economic expansion.<br />

However, the idea of founding a<br />

<strong>steel</strong>works alongside the<br />

<strong>Gent</strong>-Terneuzen canal had been playing<br />

in people’s heads a lot longer. Indeed, on<br />

5 March 1928, Emile Mayr<strong>is</strong>ch, who<br />

was the director-general of Arbed<br />

Luxembourg at that time, assigned h<strong>is</strong><br />

immediate staff to buy a plot of land<br />

along the <strong>Gent</strong>-Terneuzen canal on<br />

behalf of Arbed. Even then, Emile<br />

Mayr<strong>is</strong>ch had a feeling that rich<br />

overseas iron ore would soon play an<br />

important role in European hot metal<br />

production. He wanted Arbed to be<br />

prepared. As a result, in 1932, Arbed<br />

became the owner of 211 hectares of<br />

land at the right bank of the canal.<br />

Because of World War II and post-war<br />

difficulties, these grounds would not be<br />

exploited until 1962. The construction<br />

of Sidmar – as the site was called at the<br />

time - began in December 1963,<br />

involving driving tens of thousands of<br />

piles into the ground, pouring thousands<br />

of cubic metres of concrete, assembling<br />

thousands of tonnes of <strong>steel</strong> trusses,<br />

drawing kilometres of cable and laying<br />

just as many pipes, building roads and<br />

railways.<br />

It <strong>is</strong> worth mentioning that the various<br />

installations were built in reverse order<br />

to the production process. <strong>Th<strong>is</strong></strong> <strong>is</strong> when<br />

the production units were first used:<br />

<strong>Th<strong>is</strong></strong> <strong>is</strong> <strong>how</strong> <strong>ArcelorMittal</strong> <strong>Gent</strong> <strong>produces</strong> <strong>steel</strong> 5

MARITIME STEELWORKS<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

INTEGRATED<br />

STEELWORKS<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

0 100 200 300 400 500

FLAT STEEL PRODUCTS

SUSTAINABLE<br />

DEVELOPMENT<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

HIGHTECH COMPANY

COKING PLANT

COKING PLANT

RAW MATERIAL HANDLING

SINTER PLANTS

BLAST FURNACES

BLAST FURNACES

STEEL SHOP

STEEL SHOP

STEEL SHOP

STEEL SHOP

WIDE HOT STRIP MILL

WIDE HOT STRIP MILL

WIDE HOT STRIP MILL

WIDE HOT STRIP MILL

WIDE HOT STRIP MILL

COLD ROLLING MILL

COLD ROLLING MILL

COLD ROLLING MILL

COLD ROLLING MILL

COLD ROLLING MILL

COLD ROLLING MILL

COLD ROLLING MILL

COLD ROLLING MILL

COLD ROLLING MILL

COLD ROLLING MILL

HOT DIP GALVANISING LINE

HOT DIP GALVANISING LINE

HOT DIP GALVANISING LINE

ORGANIC COATING LINES

ORGANIC COATING LINES

ELECTROLYTIC<br />

GALVANISING LINE

ELECTROLYTIC<br />

GALVANISING LINE

PRODUCTION LINE OF<br />

TAILOR-WELDED BLANKS

PRODUCTION LINE OF<br />

TAILOR-WELDED BLANKS

<strong>ArcelorMittal</strong><br />

<strong>Gent</strong>, Geel and<br />

Genk in figures

<strong>ArcelorMittal</strong><br />

<strong>Gent</strong>, Geel and<br />

Genk in figures

<strong>ArcelorMittal</strong><br />

<strong>Gent</strong>, Geel and<br />

Genk in figures