ThermoplasticPultrusions Process using Twintex Roving

ThermoplasticPultrusions Process using Twintex Roving

ThermoplasticPultrusions Process using Twintex Roving

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

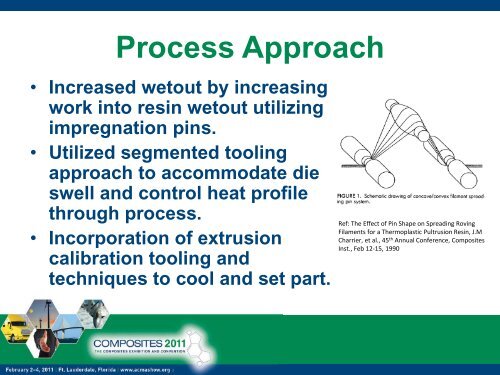

<strong>Process</strong> Approach<br />

• Increased wetout by increasing<br />

work into resin wetout utilizing<br />

impregnation pins.<br />

• Utilized segmented tooling<br />

approach to accommodate die<br />

swell and control heat profile<br />

through process.<br />

• Incorporation of extrusion<br />

calibration tooling and<br />

techniques to cool and set part.<br />

Ref: The Effect of Pin Shape on Spreading <strong>Roving</strong><br />

Filaments for a Thermoplastic Pultrusion Resin, J.M<br />

Charrier, et al., 45 th Annual Conference, Composites<br />

Inst., Feb 12-15, 1990