HAND-FED CHIPPERS - Bandit Tree Equipment

HAND-FED CHIPPERS - Bandit Tree Equipment

HAND-FED CHIPPERS - Bandit Tree Equipment

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

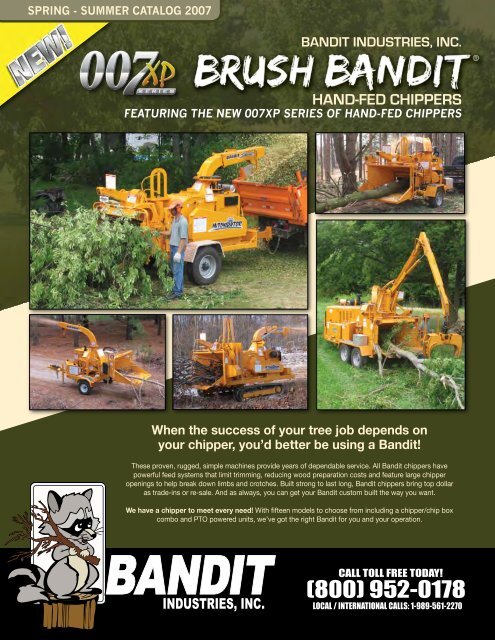

SPRING - SUMMER CATALOG 2007<br />

BANDIT INDUSTRIES, INC.<br />

<strong>HAND</strong>-<strong>FED</strong> <strong>CHIPPERS</strong><br />

FEATURING THE NEW 007XP SERIES OF <strong>HAND</strong>-<strong>FED</strong> <strong>CHIPPERS</strong><br />

When the success of your tree job depends on<br />

your chipper, you’d better be using a <strong>Bandit</strong>!<br />

These proven, rugged, simple machines provide years of dependable service. All <strong>Bandit</strong> chippers have<br />

powerful feed systems that limit trimming, reducing wood preparation costs and feature large chipper<br />

openings to help break down limbs and crotches. Built strong to last long, <strong>Bandit</strong> chippers bring top dollar<br />

as trade-ins or re-sale. And as always, you can get your <strong>Bandit</strong> custom built the way you want.<br />

We have a chipper to meet every need! With fifteen models to choose from including a chipper/chip box<br />

combo and PTO powered units, we’ve got the right <strong>Bandit</strong> for you and your operation.<br />

LOCAL / INTERNATIONAL CALLS: 1-989-561-2270

TABLE OF<br />

CONTENTS<br />

ABOUT US<br />

Pages 1 - 7<br />

007XP SERIES <strong>CHIPPERS</strong><br />

Features of our newest line of hand-fed<br />

chippers, the 007XP Series.<br />

Pages 8 - 9<br />

FEATURES AND OPTIONS<br />

Check out all the available features and<br />

options found on our brush chippers.<br />

Pages 10 - 23<br />

<strong>HAND</strong> <strong>FED</strong> <strong>CHIPPERS</strong><br />

Disc-style Chippers<br />

Pages 26 - 35<br />

Drum-style Chippers<br />

Pages 36 - 41<br />

Conventional / PTO /<br />

Chip Box Combo Chippers<br />

Pages 42 - 45<br />

CHIPPER SAFETY<br />

A brief overview of safety features found<br />

on all <strong>Bandit</strong> hand-fed chippers.<br />

Pages 46 - 47<br />

QUESTIONS? COMMENTS?<br />

<strong>Bandit</strong> Industries, Inc. attributes<br />

much of its success from listening to<br />

the suggestions of those who use their<br />

equipment on a daily basis.<br />

Visit our web site to locate an<br />

authorized <strong>Bandit</strong> dealer in your area!<br />

Have a question or comment for<br />

<strong>Bandit</strong>? Contact us by mail, telephone, or<br />

via the Internet at any time.<br />

BANDIT INDUSTRIES, INC.<br />

6750 Millbrook Road<br />

Remus, MI 49430<br />

TOLL FREE TELEPHONE<br />

(800) 952-0178<br />

LOCAL / INTERNATIONAL<br />

(989) 561-2270<br />

EMAIL: sales@banditchippers.com<br />

ONLINE: www.banditchippers.com<br />

Thank you for your interest<br />

in <strong>Bandit</strong> equipment.<br />

We are excited to have the opportunity to introduce you to our<br />

expansive line of hand-fed brush chippers! We’ve made great strides<br />

towards becoming the industry leader in more than just the tree<br />

care industry. We now supply a complete line of quality, dependable<br />

whole tree chippers, stump grinders and waste reduction units that<br />

are every bit as popular as our hand-fed chippers.<br />

All of our products are built according to customer specifications and<br />

with the highest quality and craftsmanship. For this reason, <strong>Bandit</strong><br />

equipment yields one of the highest re-sale values in the market.<br />

Our hand-fed brochure outlines the basic features and functions of<br />

our innovative chipper line, and highlights our latest line of chippers,<br />

the 007XP Series. For more detailed information on any model,<br />

please contact us or your local <strong>Bandit</strong> dealer. We have a vast library of<br />

video footage and other information should you need specifications<br />

or more detailed information on features and available options.<br />

<strong>Bandit</strong> has over 170 dealer locations worldwide in order to better<br />

serve our customers. You can be sure that our dealers are highly<br />

trained in servicing <strong>Bandit</strong> equipment. Should you need assistance in<br />

locating the nearest <strong>Bandit</strong> dealer, feel free to contact us at anytime.<br />

You can also visit our web site at www.banditchippers.com for daily<br />

updates on used equipment for sale, customer service, or to view our<br />

entire product line video library.<br />

We look forward to continuing to serve you!<br />

Sincerely,<br />

BANDIT INDUSTRIES, INC.<br />

The <strong>Bandit</strong> Promise.<br />

<strong>Bandit</strong> Industries, Inc. is a company dedicated to the success of<br />

our customers. We take the time to listen to those who use our<br />

equipment on a daily basis, garnering many of our innovations<br />

directly from the suggestions of our customers.<br />

Industry professionals trust <strong>Bandit</strong> products to be of the highest<br />

quality on the market, and we strive to build and maintain that<br />

trust with every product improvement.<br />

And that’s a promise.

Modern rebuild facilities allow us to re-sell<br />

used equipment almost as good as new:<br />

Let us rebuild your<br />

chipper, stump<br />

grinder or waste<br />

reduction machine!<br />

CHIPPER / STUMP GRINDING REBUILD FACILITY<br />

WHOLE TREE / WASTE REDUCTION MACHINE REBUILD FACILITY<br />

NEW REBUILD FACILITY - NOW OPEN!<br />

Nearly all of the used equipment that we<br />

re-sell is totally rebuilt. Most used equipment<br />

is sold with a warranty. Looking for a good start-up<br />

or back-up piece of equipment? We are likely to have<br />

something to meet your needs. Send us your used<br />

or damaged chippers, stumpers or waste reduction<br />

machines to be rebuilt.<br />

You will be pleased with the results!<br />

Visit our web site at www.banditchippers.<br />

com for a complete listing of the used<br />

equipment available for sale.<br />

MODEL 1590XP<br />

Over 100 qualified dealers to serve you worldwide!<br />

All of <strong>Bandit</strong>’s products are backed by a dedicated service and support network of over 340 employees and more than<br />

170 dealer locations worldwide. All authorized <strong>Bandit</strong> dealers are stocked with highly qualified employees trained in<br />

servicing <strong>Bandit</strong> equipment and an inventory of new machines to provide quick delivery and to demonstrate the <strong>Bandit</strong><br />

machine that best meets your needs.<br />

DEALERS ALSO LOCATED:<br />

Hawaii, USA<br />

Alaska, USA<br />

WE HAVE DEALERS ACROSS THE WORLD AVAILABLE TO SERVE ALL 50 STATES, AND THE FOLLOWING COUNTRIES AND CANADIAN PROVINCES:<br />

Alberta<br />

Algeria<br />

Australia<br />

Bahrain<br />

British Columbia<br />

Chile<br />

Columbia<br />

Egypt<br />

England<br />

France<br />

Germany<br />

Hong Kong<br />

Hungary<br />

Indonesia<br />

Iraq<br />

BEFORE<br />

AFTER<br />

Ireland<br />

Israel<br />

Italy<br />

Japan<br />

Jordan<br />

Kuwait<br />

Lebanon<br />

Maderia<br />

Malaysia<br />

Malta<br />

Manitoba<br />

Mexico<br />

Morocco<br />

New Zealand<br />

Oman<br />

Ontario<br />

Peru<br />

Poland<br />

Portugal<br />

Puerto Rico<br />

Qatar<br />

Quebec<br />

Russia<br />

Saskatchewan<br />

Saudi Arabia<br />

Scotland<br />

South Africa<br />

South Korea<br />

Spain<br />

Taiwan<br />

Tunisia<br />

Turkey<br />

United Arab<br />

Emirates<br />

United States<br />

of America<br />

<strong>Bandit</strong> specializes in<br />

reconditioning and<br />

servicing customer units.<br />

Is your chipper sending the wrong message to your customers?<br />

Whether your chipper or stump grinder needs routine maintenance or completely<br />

refurbished, <strong>Bandit</strong> can handle any size job and will service all makes and models.<br />

The <strong>Bandit</strong> rebuild department will do it right the first time and on schedule.<br />

The <strong>Bandit</strong> rebuild department will provide a detailed estimate that will<br />

allow you to decide the amount of work you would like to have performed.<br />

Call Gary at 989-866-6230 or the sales office at 1-800-952-0178<br />

for offers on our new and reconditioned units.<br />

Uruguay<br />

Wales<br />

Yemen<br />

PLUS MANY MORE!

6<br />

DID YOU KNOW...<br />

Three <strong>Bandit</strong> hand-fed<br />

chippers are available<br />

with the optional loader<br />

attachment, shown<br />

here. Contact a <strong>Bandit</strong><br />

representative for details.<br />

WHY CHOOSE A BRUSH BANDIT?<br />

The choice is simple! More industry<br />

professionals prefer <strong>Bandit</strong>.<br />

Large chipper openings and powerful feed systems collapse<br />

limbs allowing multiple stems and rough material to flow<br />

smoothly through the chipper. These feed systems have the<br />

power to pull whole trees into the chipper with ease.<br />

These high-performance chippers have the ability to<br />

dispose more of the tree at take down, reducing trimming<br />

and chain saw work.<br />

Give a <strong>Bandit</strong> a try. You will experience lower labor costs,<br />

shortened removal time, reduced operator fatigue, as well<br />

as the benefits of all the safety features designed to protect<br />

the operator. That’s the <strong>Bandit</strong> difference!<br />

Dependable, trouble-free performance<br />

starts with the disc or drum.<br />

The chipper housing, whether it is a disc or a drum, is solidly<br />

built of welded construction to handle the pounding that<br />

results from the chipping of larger materials. The knives<br />

are set at a precise angle so that they pull wood into the<br />

chipper, while limiting or eliminating kick back: key to our<br />

chippers’ high production and dependability.<br />

All of our disc and drum chippers are equipped with<br />

oversized chipper shafts and bearings. A smooth chipping<br />

action limits vibration and reduces maintenance.<br />

Learn more about the differences between disc- and drum-style<br />

chippers on pages 14 and 15.<br />

7

8<br />

INTRODUCING:<br />

007XP SERIES<br />

Just when you thought<br />

they couldn’t possibly get<br />

any better.<br />

Introducing the 007XP series of brush chippers<br />

from <strong>Bandit</strong>. We’ve listened to the comments,<br />

needs and suggestions of our customers and of<br />

industry professionals in order to bring you the<br />

next generation of chippers from <strong>Bandit</strong>. From<br />

enlarged chipper openings to improved paint<br />

processes and decals, these new chippers will get<br />

the job done quicker and more efficiently than<br />

ever before.<br />

New! Model 255XP.<br />

This brand new model from <strong>Bandit</strong> is a 15”<br />

capacity machine.<br />

Larger chipper openings.<br />

MODEL 1290XP-The Model 1290XP is now<br />

a 15” capacity machine with an enlarged<br />

throat opening.<br />

MODEL 1590XP-The Model 1590XP is now<br />

a 17” capacity machine with an enlarged<br />

throat opening.<br />

MODEL 1890XP-The Model 1890XP is an<br />

18” capacity machine with an enlarged<br />

throat opening.<br />

MODEL 1990XP-The Model 1990XP is now<br />

a 19” capacity machine with an enlarged<br />

throat opening.<br />

Durable drum construction.<br />

The baffled construction is key to the strength<br />

of our drum chippers. Having a strong drum is<br />

essential due to the larger volumes and larger<br />

diameters that these chippers will process. The<br />

drum in your <strong>Bandit</strong> 007XP chipper will not fail.<br />

Easy-climb tensioning springs.<br />

Now more durable, with heavier gussets for added<br />

durability.<br />

Enlarged chipper openings.<br />

Many of the 007XP chippers feature larger<br />

openings, meaning greater capacity and increased<br />

efficiency.<br />

Durable folding in-feed pans.<br />

Now constructed out of heavier material with<br />

added structural support.<br />

Don’t forget about the options! <strong>Bandit</strong> chippers<br />

can be outfitted with any number of options to<br />

help make your operation as efficient as possible.<br />

Turn to pages 22 & 23 for a complete listing.<br />

New paint system, better than a powder<br />

coat.<br />

Highly-durable Dupont® Imron polyurethane paint adds life to<br />

your chipper.<br />

Contact your <strong>Bandit</strong> representative for<br />

more details on all the 007XP Series<br />

DID YOU KNOW...<br />

<strong>Bandit</strong> 007XP chippers<br />

have over 28 new features<br />

and improvements.<br />

Contact your <strong>Bandit</strong><br />

representative for details!<br />

9

10<br />

EFFICIENCY IS #1.<br />

Super-sized feed systems make it easier to process limby materials.<br />

The super-sized infeed options allow limby material to be pulled into the chipper by increasing the width of the<br />

feed wheels. The larger throat opening and feed wheels then taper down to the same opening at the disc or<br />

drum as a standard machine.<br />

AUTO-FEED PlUS<br />

LIKE NO OTHER: <strong>Bandit</strong>’s patented Auto-Feed Plus System<br />

Our patented Auto-Feed Plus governs the feed system. If the engine lugs to the point of stalling, Auto-Feed<br />

Plus automatically stops the feed system and reverses the feed wheels to pull the wood out of the cut. Backing<br />

the material from the cut saves fuel, extends knife life, and provides faster engine recovery. When the engine<br />

regains full RPM, Auto-Feed Plus resumes the feed system.<br />

Auto-Feed Plus minimizes plugging, improves chip quality, improves fuel economy, and improves knife life by<br />

backing the wood out of the cut and reducing the heating of knives caused by stopping wood at the knives.<br />

FEATURES & OPTIONS<br />

7 WHY CHOOSE A BRUSH BANDIT?<br />

8 INTRODUCINg 007XP SERIES<br />

10 AUTO-FEED PlUS SYSTEm<br />

12 PAINT & FENDERS<br />

14 DISC vS. DRUm<br />

16 DISCHARgE & FEED SYSTEmS<br />

19 SElF-PROPEllED UNITS<br />

21 INFEED SYSTEmS<br />

22 FEATURES & OPTIONS<br />

25 BRUSH <strong>CHIPPERS</strong> (TABlE OF CONTENTS)<br />

46 CHIPPER SAFETY<br />

EACH CHIPPER IS UNIQUE.<br />

Custom built chippers with every possible option<br />

<strong>Bandit</strong> offers a wide variety of options, which allows you to customize your unit to fit your individual needs. We<br />

do not manufacture “cookie cutter” machines. Our assembly teams take pride in producing the highest quality<br />

chipper possible, and we maintain a high level of quality control during construction. All this allows you to<br />

custom order a machine with features and options that best fit your needs and your budget.<br />

11

12<br />

NEED A CUSTOM PAINT JOB? NO PROBLEM!<br />

<strong>Bandit</strong> offers custom paint jobs on all of their equipment, as well as custom decal application.<br />

Contact your dealer or in-house <strong>Bandit</strong> representative at 800-952-0178 to learn more!<br />

<strong>Bandit</strong><br />

Yellow<br />

CAT<br />

Yellow<br />

Green<br />

Alert<br />

Orange<br />

Black<br />

White<br />

A POlYURETHANE PAINT FINISH<br />

Better than a powder coat.<br />

Unlike many of our competitors, our chipper<br />

components are welded together rather than<br />

bolted. This method of construction makes a<br />

powder coat finish impractical. Instead, <strong>Bandit</strong><br />

utilizes top-of-the-line Dupont Imron® paint for a<br />

professional look that will stand the test of time.<br />

Our process begins when the chippers come off<br />

the line. Welding slag is removed and the chippers<br />

are put through a phosphoric bath to remove<br />

debris, grease and oil. They are then primed with<br />

a primer specifically designed for Imron® paint,<br />

and receive a coat of Imron® polyurethane paint.<br />

The finish is cured in a drying room before going<br />

to final check-out, where decals are applied. Your<br />

chipper receives a finish that will hold up well and<br />

resist chipping to provide the strongest machine<br />

possible.<br />

Six standard colors are offered: <strong>Bandit</strong> yellow, CAT<br />

yellow, green, alert orange, black and white. We<br />

also offer custom colors for a nominal fee.<br />

* Colors shown are printed references. Actual color may vary slightly.<br />

REPlACEABlE AlUmINUm FENDERS<br />

Dress up the appearance of your chipper.<br />

Replaceable aluminum fenders cover the tires<br />

and are standard on the 12” machines, the Model<br />

255XP, Model 1290XP and Model 1590XP. They are<br />

available as an option on the Models 65XP, 90XP<br />

and all 18” hand-fed chippers without loaders.<br />

A machine’s fenders absorb more abuse from<br />

road salt, dirt, sand and debris thrown by the<br />

towing vehicle than any other part of the machine.<br />

Aluminum fenders look sharp, resist chipping and<br />

corrosion, and are easily replaced should they be<br />

damaged.<br />

13

14<br />

DISC vS. DRUm?<br />

We offer two distinct styles of hand-fed chippers: discs<br />

and drums. Each have their advantages. We also offer<br />

conventional drum-style self-feeding chippers.<br />

The conventional drum is a good machine for brush and<br />

trimmings. It is simple and economical to own and operate,<br />

but does not have the capabilities of processing larger<br />

diameter and limby materials that a chipper with a hydraulicfeed<br />

system can process.<br />

Disc-style advantages:<br />

Disc-style chippers are set on an approximate angle of 45°<br />

and chip larger diameter materials better than a drum.<br />

This angle allows the wood to be chipped with the grain,<br />

creating less vibration and consuming less energy.<br />

Drum-style advantages:<br />

Drum-style chippers have larger openings with feed<br />

systems more closely coupled to the chipper. They<br />

collapse limbs easier and can chip more material at one<br />

time. They also process fibrous materials common in<br />

warmer climates easier than a disc-style chipper.<br />

DRUm-STYlE <strong>CHIPPERS</strong><br />

Our drum chippers feature oversized 37” drums, allowing<br />

most of the material to be chipped on the bottom half<br />

of the drum on an angle with the grain of the wood,<br />

similar to a disc, thus operating more efficiently. Typical<br />

drums consume more fuel, create more vibration and<br />

require more horsepower due to the cutting action<br />

of the drum. Many of our competitors’ drum chippers<br />

have 20 or 22-1/2” diameter drums. The arc of the<br />

smaller drums chip into, across and with the grain<br />

when chipping large diameter materials. Because of our<br />

oversized drums, <strong>Bandit</strong>’s hydraulic-feed drum chippers<br />

consume less fuel and chip with less vibration.<br />

DISC-STYlE <strong>CHIPPERS</strong><br />

Similar to whittling, cutting with the knives at a fixed<br />

angle requires less energy to chip, which reduces fuel<br />

consumption. By cutting on a 45º angle, a disc will chip<br />

larger material with less horsepower and less vibration.<br />

STILL NOT SURE WHAT IS BEST FOR YOU?<br />

That’s what we’re here for. Call us today to speak with a representative. They will be happy to<br />

help you decide what equipment is best for your unique operation.<br />

15

16<br />

CHIPPER DISCHARgE CHUTES<br />

These discharge features and options will<br />

save time and money.<br />

Discharge chips in any direction<br />

All but the conventional drum chippers are equipped with<br />

270° swivel discharge spouts that are easy to swing. A<br />

hand-adjustable flipper at the end of the discharge can be<br />

adjusted to direct chip flow downward. Discharge options<br />

make it easier to swivel and raise the height of the discharge<br />

without tools, ensuring fully loaded chip boxes and fewer<br />

trips to the dump site.<br />

Discharge Transitions<br />

Both our drum- and disc-style chippers are equipped with<br />

smooth transitions where chips flow from the chipper hood<br />

to the discharge. The transitions deposit chips in the center<br />

of the discharge without creating any edges or rough spots<br />

that might inhibit the flow of chips. Smooth transitions<br />

mean that the chips throw harder, fully loading chip trucks<br />

and making the chipper less likely to plug.<br />

ADJUSTABlE EASY-ClImB SPRINg TENSIONINg SYSTEm<br />

Our patented system provides down pressure on the top feed wheel, adding crushing power to the feed<br />

wheels. The springs are designed so that they provide little down pressure when the top wheel is in the down<br />

position. They also make it easy for the top wheel to open up to accommodate larger materials, adding pressure<br />

as the opening between the wheels expands.<br />

SlIDE BOX FEED SYSTEm: A trouble-free guide for feed wheels.<br />

The top movable feed wheel in most of our hand-fed chippers runs in a trouble-free slide box and on hardened<br />

plastic wear slides which should provide years of service before needing to be replaced. This slide box allows<br />

the top feed wheel to move straight up and down with the flow and diameter of material passing through<br />

the feed system into the chipper. This trouble-free system for carrying the top feed wheel allows direct down<br />

pressure for crushing material and the amount of pressure can be increased with the optional hydraulic<br />

lift cylinder. There are no pivot arms where wood can collect and bind the feed system. All feed wheels are<br />

supported with heavy-duty bearings on both ends. The feed wheel drive motors attach to the feed wheel shafts<br />

with dependable tapered couplers. Should a feed wheel motor or feed wheel need to be changed, it is easy to<br />

do by removing the coupler.<br />

DEPENDABlE FEED SYSTEmS<br />

All <strong>Bandit</strong> chippers, with the exception of the 65XP, 95XP, 1290<br />

and 1690 have two horizontal feed wheels with knife-edge<br />

teeth that climb the wood being fed and pull material into the<br />

chipper. All have extremely powerful hydraulic motors. The<br />

feed systems are so powerful that they will pull whole trees into<br />

the chipper.<br />

17

We believe our chippers will make<br />

you more money than any other<br />

chipper on the market!<br />

They are more productive and will convert your<br />

wood waste to chips faster.<br />

They are rugged machines that will operate day in<br />

and day out with limited downtime.<br />

They are the most dependable chippers on the<br />

market.<br />

The throwing action will load more material into<br />

your chip trucks, reducing trips to the dump site.<br />

They consume less fuel.<br />

They are available with options and features that<br />

will make you more productive and efficient.<br />

Because of the quality and popularity of <strong>Bandit</strong><br />

chippers, you will receive more at trade or resale.<br />

<strong>Bandit</strong> chippers are simple and easy to maintain.<br />

INNOvATION AND DEDICATION<br />

The little things and attention to detail set us apart from the competition.<br />

Our anvils are easy to change and adjust. <strong>Bandit</strong>’s drum chippers have a two-sided anvil, while the disc<br />

chippers have four-sided anvils. This means there are either two or four surfaces to dull before they need<br />

to be replaced. Two patented cushioned springs make it easier to raise and lower the larger infeed trays.<br />

A torflex axle with a rubber cushion provides a smooth, dependable ride. The axles are backed by a<br />

manufacturer’s warranty (contact your authorized <strong>Bandit</strong> dealer or sales representative for details).<br />

<strong>Bandit</strong> also offers a<br />

complete range of<br />

towable and selfpropelled<br />

whole tree<br />

chippers with up to<br />

860 horsepower.<br />

18 19<br />

(SHOWN AT RIGHT)<br />

TAKE THE CHIPPER TO THE TREES<br />

<strong>Bandit</strong> offers a self-propelled undercarriage option for all chippers, including<br />

those up to 213-horsepower.<br />

The self-propelled undercarriage option eliminates the need to carry and forward trees and brush. Caterpillar<br />

rubber-tracked undercarriages provide our self-propelled chippers with the power, clearance and stability for<br />

off-highway road work. These self-propelled chippers are ideal for land clearing as well as right-of-way and rail<br />

line maintenance. Adding a winch option enhances the machine’s ability to process whole trees. A radio remote<br />

control with tether remote backup is provided.

20<br />

WHERE CAN I GET A WINCH LIKE THAT?<br />

Turn to the next page! most <strong>Bandit</strong> chippers are available with winch options that can easily be<br />

installed by an authorized <strong>Bandit</strong> dealer. Call your representative for details.<br />

INFEED SYSTEmS<br />

<strong>Bandit</strong>’s sloping infeed pans<br />

make feeding piles of brush<br />

and big materials into the<br />

chipper a breeze.<br />

The sloping infeed tray enables the<br />

operator to slide materials into the<br />

feed system as opposed to the flat style<br />

infeed tray, which requires material to be<br />

elevated horizontally to be processed.<br />

The folding trays that are standard on<br />

all <strong>Bandit</strong> hand-fed chippers provide a<br />

great area to advertise your company’s<br />

business and reduce the overall traveling<br />

length of the machine. Optional weld-on<br />

trays are also available. Contact a <strong>Bandit</strong><br />

representative for details.<br />

Clean Out Door<br />

An easy-to-open trap door is located under<br />

the bottom feed wheel and allows the<br />

operator to remove materials that might<br />

hang up in the bottom feed wheel.<br />

21

22<br />

FEATURES AND OPTIONS<br />

[for <strong>Bandit</strong> chippers]<br />

Knife Saver<br />

(OPTION)<br />

The Knife Saver is a unique and inexpensive hand-held knife sharpening<br />

device that easily touches up chipper knives while they are still in the<br />

machine. The Knife Saver reduces knife sharpening costs and increases<br />

chipper performance, chipper productivity and chip uniformity. Severely<br />

nicked or damaged knives must be replaced.<br />

loader Attachment<br />

(OPTION)<br />

Loader options are a must for handling big wood and for high volume<br />

applications. Ease the task of feeding larger diameter material and piles<br />

of brush into these units with the loader option. These unique loaders<br />

offer either a 45º swing in two directions or a 90° swing with a 70° swing<br />

towards the curb, depending on model. Call for details.<br />

Engine Filter Pre-Cleaner<br />

(OPTION)<br />

An engine filter pre cleaner is a must-have option for extending the life of<br />

the engine’s air filter.<br />

gear-Type Hydraulic Pumps<br />

(STANDARD ON MOST MODELS)<br />

This pump provides live hydraulic oil flow to the feed system and some<br />

of the hydraulic options that might be added to the chipper, such as a<br />

hydraulic swivel discharge spout or hydraulic winch.<br />

Self-Propelled Track Undercarriage<br />

(OPTIONAL)<br />

Eliminate the need to forward trees and brush with the self-propelled<br />

track undercarriage option, available on all hand-fed chippers - including<br />

those up to 213-horsepower. Caterpillar rubber-tracked undercarriages<br />

provide our self-propelled chippers with the power, clearance and<br />

stability for off-highway road work. Self-propelled chippers are ideal for<br />

land clearing as well as right-of-way and rail line maintenance.<br />

Debris Screen<br />

(STANDARD)<br />

Liquid-cooled engines are equipped with corrugated radiator debris<br />

screens that provide a convenient means to clean debris from the<br />

machine that might otherwise plug the radiator. Clean radiators are<br />

important for maximizing the performance of the power unit.<br />

Operator Safety Control Bar<br />

(STANDARD)<br />

Available on hand-fed chippers. A control bar that wraps around three<br />

sides of the infeed chute controls the direction of the feed wheels. Push<br />

forward to reverse the material out of the chipper, pull to make the feed<br />

wheels pull material into the chipper.<br />

Hydraulic lift Cylinder<br />

(OPTION)<br />

To apply additional pressure on the top feed wheel to crush and compress<br />

limbs, select the hydraulic lift cylinder option. The lift cylinder makes it<br />

easier to feed larger materials into the chipper and allows for the top<br />

feed wheel to be raised and locked in the ‘up’ position to make it easy to<br />

inspect. If the hydraulic lift cylinder is not ordered, the tongue jack can<br />

also be used to lock the top feed wheel to inspect the disc/drum, make<br />

anvil adjustments, and check anvil clearance.<br />

Hydraulic Winch<br />

(OPTION)<br />

A great labor saving tool is the hydraulic winch option. The winch<br />

greatly reduces hand carrying of material while reducing the need to cut<br />

and trim. The winch is a great tool for dragging material from tight or<br />

restricted areas that are not accessible to the chipper. The winch is also<br />

available with a remote control. A heavy duty valve plate “cover”, mounted<br />

above the infeed chute, also serves as a winch mount, making it easy to<br />

add a winch at a later time.<br />

Remote Control (patented)<br />

(FOR WINCH OPTION, ABOVE)<br />

This allows full control of the winch. The person setting chokers or ties<br />

for the material being winched into the machine can also control the<br />

functions of the winch, making it easier to drag material to the chipper<br />

and feed system.<br />

Hydraulic Tongue Jack<br />

(OPTION)<br />

A hydraulic tongue jack is offered for many of our hand-fed chippers and<br />

are especially popular with larger models with heavier tongue weights.<br />

Hydraulic Pressure Check Kit<br />

(OPTION)<br />

This recommended option provides an easy way to check hydraulic<br />

pressures to make sure the hydraulic system is operating at the correct<br />

relief pressure. This will ensure your chipper feed system is operating at<br />

peak performance.<br />

23

24<br />

BRUSH <strong>CHIPPERS</strong><br />

<strong>Bandit</strong> has a chipper that can maximize the<br />

efficiency of your operation. If we don’t have<br />

exactly what you are looking for, we’ll build it!<br />

26 6” CAPACITY DISC-STYlE<br />

28 9” CAPACITY DISC-STYlE<br />

30 12” CAPACITY DISC-STYlE<br />

32 15” CAPACITY DISC-STYlE<br />

35 18” CAPACITY DISC-STYlE<br />

37 15” CAPACITY DRUm-STYlE <strong>CHIPPERS</strong><br />

39 17” CAPACITY DRUm-STYlE <strong>CHIPPERS</strong><br />

41 18” CAPACITY DRUm-STYlE <strong>CHIPPERS</strong><br />

42 CONvENTIONAl DRUm <strong>CHIPPERS</strong><br />

44 CHIP BOX COmBO / PTO <strong>CHIPPERS</strong><br />

46 CHIPPER SAFETY<br />

25

6” Capacity Disc-Style Chippers<br />

A rugged, compact 6” capacity hydraulic-feed disc-style chipper<br />

is the primary chipper for many tree and landscape contractors.<br />

A great rental machine!<br />

Popular Money Making Options:<br />

• Auto feed system<br />

• Hand-Crank Swivel Discharge<br />

• Height Adjustable Discharge<br />

(See options section for a complete listing)<br />

Hydraulic Feed Disc-Style Chippers<br />

CapaCity opening engine options<br />

MoDeL 65Xp 6” 6” x 12” 25 - 37 Hp<br />

CoMpetition’s<br />

6” CHippeR*<br />

6” 6” x 6” -<br />

*BASED ON THE COMPETITION’S CHIPPER OPENINGS IN THE SAME CLASS.<br />

An optional dual-feed wheel system improves the<br />

performance of the Model 65XP when chipping limby<br />

materials (shown below, center).<br />

Model 65XP. Extremely productive:<br />

this machine will easily keep two<br />

people busy feeding it. The 6” x 12”<br />

chipper opening is twice as big as<br />

competitive 6” chippers. Limbs and<br />

branches feed easier, and twice as<br />

much material can be fed into the<br />

chipper at one time.<br />

The feed wheel is twice as long<br />

and larger in diameter than the<br />

competition. The wheel climbs and<br />

effectively pulls big material into<br />

the chipper. The 12” wide chipper<br />

opening and powerful single feed<br />

pulls and crushes forked and crotched<br />

materials, forcing it into the chipper,<br />

reducing the need to trim.<br />

The Model 65XP easily converts brush,<br />

tree limbs and prunings, including<br />

fibrous materials such as pine boughs<br />

and palm fronds, into dimensional<br />

chips. The low-profile slanting infeed<br />

tray is easy to feed.<br />

Ideal for...the everyday rental user, the light tree removal<br />

contractor, and the medium-capacity landscape contractor<br />

looking for a light-weight, high production brush chipper.<br />

26 5<br />

27

28<br />

9” Capacity Disc-Style Chippers<br />

These rugged, compact 9” diameter capacity chippers meet<br />

the needs of most tree services, contractors and government<br />

agencies, while delivering years of dependable performance.<br />

Model 90XP. Built tough like our<br />

popular 12” Model 150 and with<br />

the same powerful dual feed wheel<br />

system. This machine is built for<br />

heavy-duty production. The wide<br />

17” chipper opening, coupled with<br />

the powerful feed system, allows<br />

this chipper to process material with<br />

multiple limbs as well as large pieces<br />

up to 9” diameter. The Model 90XP<br />

has the power to pull whole trees into<br />

the chipper. Like all <strong>Bandit</strong> chippers,<br />

the 90XP will limit trimming as well<br />

as trips to the dump site. If you are<br />

looking for a high production chipper<br />

that is easy to tow give the Model<br />

90XP a look.<br />

Model 95XP. This unique disc-style<br />

chipper is designed to excel in<br />

chipping fibrous and leafy materials.<br />

The powerful single feed wheel is<br />

parallel to the chipper disc, and<br />

material feeds at a right angle into<br />

the chipper. The feed wheel is<br />

close coupled to the chipper disc,<br />

improving the machine’s ability to<br />

chip fibrous materials. The 95XP is<br />

built much like the 90XP as far as size<br />

and ruggedness and features a 45”wide<br />

infeed chute.<br />

The Model 95XP is designed to excel in chipping fibrous and<br />

leafy materials, available with features and options such as<br />

remote hydraulic winch and rubber-tracked undercarriage.<br />

Hydraulic Feed Disc-Style Chippers<br />

CapaCity opening engine options<br />

MoDeL 90Xp 9” 9.5” x 17” 46 - 90 HP<br />

MoDeL 95Xp 9” 9” x 17” 46 - 90 HP<br />

Popular Money Making Options:<br />

• Auto-Feed Plus<br />

• Hand-Crank Swivel Discharge<br />

• Hydraulic Lift Cylinder<br />

• Height Adjustable Discharge<br />

• Expanded 45”-wide in-feed hopper<br />

(standard on Model 95XP)<br />

29

53<br />

30<br />

12” Capacity Disc-Style Chippers<br />

<strong>Bandit</strong>’s 12” capacity hydraulic-feed disc-style chippers are the<br />

chippers that all others are compared to. With three models<br />

to choose from, these chippers have become the standard in<br />

the tree care industry. These proven, dependable, user-friendly<br />

chippers are known for their ability to efficiently process limby<br />

materials, logs and trees up to their 12” capacity.<br />

Model 150XP. The Model 150XP is<br />

an industry standard, economical<br />

and compact. This basic 12” chipper<br />

features a 14” x 17” chipper opening<br />

and a 90 FPM chipping feed speed.<br />

Model 200XP. The Model 200XP is<br />

built like the 150XP with the same 14”<br />

x 17” chipper opening but has a faster<br />

chipping speed (120 FPM). The 200XP<br />

is the most popular chipper of utility<br />

line maintenance contractors because<br />

of its ability to quickly dispose of<br />

brush and to handle larger stems and<br />

branches.<br />

Model 250XP. The Model 250XP<br />

is the most popular chipper of the<br />

commercial tree contractor. Pound<br />

for pound and dollar for dollar there<br />

is not a tougher, more productive<br />

chipper available in this size range.<br />

The 250XP features a wide 12 1/2”<br />

x 19” opening and a 120 FPM feed<br />

speed.<br />

When given the choice, tree care professionals have chosen<br />

the 12” model chippers as their primary on-site chipping<br />

machine. The features and options allow you to convert as<br />

much of the tree to chips as quickly and efficiently as possible,<br />

thus lowering your tree and brush removal costs.<br />

Hydraulic Feed Disc-Style Chippers<br />

CapaCity opening engine options<br />

MoDeL 150Xp 12” 14” x 17” 65 - 140 Hp<br />

MoDeL 200Xp 12” 14” x 17” 65 - 140 Hp<br />

MoDeL 250Xp 12” 12.5” x 19” 65 - 140 Hp<br />

Popular Money Making Options:<br />

• Auto feed system<br />

• Hand-Crank Swivel Discharge<br />

• Hydraulic Lift Cylinder<br />

• Hydraulic Winch<br />

31

15” Capacity Disc-Style Chippers<br />

NEW FOR 2007! If you are looking for a compact disc-style<br />

chipper with the ability to efficiently chip large material, the all<br />

new model 255XP is for you.<br />

The 255XP is also available as self-propelled<br />

with a Caterpillar rubber tracked undercarriage.<br />

A loader is also offered to assist in feeding larger<br />

pieces into the chipper. Diesel engine options<br />

from all the major engine suppliers from 115 to<br />

213 horsepower are available.<br />

NEW! Model 255XP. This rugged<br />

chipper with a 15.5” x 25” chipper<br />

opening is a dependable work horse.<br />

The 255XP is available with engine<br />

options to 213 horsepower and is built<br />

like our popular Model 250XP chipper.<br />

The Model 255XP is equipped with a number<br />

of features associated with the 007 Chipper<br />

Series from <strong>Bandit</strong>. Advancements to the<br />

infeed hopper have been made, as well as<br />

improvements to the chipper chute and the<br />

wheel bearings. See pages 8 - 9 for details.<br />

Ideal for...the high-production tree service contractor looking<br />

for a disc-style chipper to quickly and efficiently dispose of<br />

brush, limbs and other large diameter materials with ease.<br />

Hydraulic Feed Disc-Style Chippers<br />

CapaCity opening engine options<br />

MoDeL 255Xp 15” 15.5” x 25” 115 - 213 Hp<br />

Popular Money Making Options:<br />

• Auto-Feed Plus<br />

• Hand-crank Swivel Discharge<br />

• Hand-crank Height Adjustable Discharge<br />

• Hydraulic Lift Cylinder<br />

• Hydraulic Winch<br />

• Hydraulic Tongue Jack<br />

32 33

5<br />

34<br />

18” Capacity Disc-Style Chippers<br />

<strong>Bandit</strong> 18” capacity disc-style chippers are perfect for whole<br />

tree take downs. These hydraulic-feed machines are more than<br />

just hand-fed chippers: the feed system is powerful enough to<br />

pull whole trees into the chipper.<br />

Model 280XP. This unit has the throwing capacity to load a 45’ trailer. This rugged machine<br />

is a favorite of those involved in full tree take downs and light land clearing. This unit is<br />

often fed with an optional knuckle boom loader (as shown).<br />

STANDARD MODEL 280XP<br />

The standard 280XP unit features power<br />

options to 140-hp and is also available<br />

towable or self-propelled.<br />

HEAVY-DUTY MODEL 280XP<br />

The heavy-duty 280XP features power options<br />

to 213-hp and is equipped with the same<br />

hydraulic-feed system found on our popular<br />

1850 whole tree chipper.<br />

The most efficient way to chip...The Model 280XP chips<br />

on an angle, thus consuming less fuel, vibrating less and<br />

therefore providing the unit with extended knife-life.<br />

Hydraulic Feed Disc-Style Chippers<br />

MoDeL 280Xp<br />

(stanDaRD)<br />

MoDeL 280Xp<br />

(HeaVy DUty)<br />

CapaCity opening engine options<br />

18” 18” x 20.5” 110 - 140 Hp<br />

18” 18” x 20.5” 160 - 213 Hp<br />

Popular Money Making Options:<br />

• Auto-Feed Plus<br />

• Hand-crank Swivel Discharge<br />

• Hand-crank Height Adjustable Discharge<br />

• Hydraulic Winch<br />

• Hydraulic Tongue Jack<br />

35

36<br />

15” Capacity Drum-Style Chippers<br />

<strong>Bandit</strong>’s model 1290XP is a drum chipper that chips like a<br />

disc. This compact chipper with an oversized drum delivers<br />

dependable service and high performance.<br />

Model 1290XP. Large 17.25” x 20-1/2”<br />

chipper opening and powerful feed system<br />

collapse limbs and branches and limit the<br />

need to trim. With the large 37” drum, most<br />

of the material is chipped on the bottom<br />

half of the drum on an angle, like a disc.<br />

The 1290XP chips with limited vibration,<br />

consumes less fuel and requires less<br />

horsepower than other drums in its class.<br />

<strong>Bandit</strong> drum-style chippers are designed to...chip fibrous<br />

materials with ease, because material enters the drum at a<br />

right angle with the feed wheels positioned close to the drum.<br />

Hydraulic Feed Drum-Style Chippers<br />

CapaCity opening engine options<br />

MoDeL 1290Xp 15” 17.25” x 20.5” 65 - 140 Hp<br />

Popular Money Making Options:<br />

• Auto-Feed Plus<br />

• Hand-crank Swivel Discharge<br />

• Hand-crank Height Adjustable Discharge<br />

• Hydraulic Lift Cylinder<br />

• Hydraulic Tongue Jack<br />

Take the time to compare...<br />

THE COMPETITION’S 22 1/2” DRUM<br />

Cuts primarily across the grain<br />

BANDIT’S 37” DRUM<br />

Cuts primarily with the grain<br />

The 1290XP features a 37” diameter drum compared to the 22” drum that is used in comparable<br />

competitive drum chippers. With the 1290XP, most of the material is chipped on an angle with<br />

the grain of the wood. With a chipper with a 22” drum, the material is chipped against/across<br />

and with the grain, which takes more power and puts more strain on the drum.<br />

37

53<br />

38<br />

17” Capacity Drum-Style Chippers<br />

Featuring 18” x 20-1/2” chipper openings, these machines<br />

are great for breaking down limby and crotched materials.<br />

<strong>Bandit</strong>’s rugged 17” drum chippers are among the most popular<br />

hydraulic-feed chippers on the market.<br />

Just a great all-around chipper. Great for fibrous materials,<br />

like palm waste, because materials enters the drum at a right<br />

angle with the feed wheels positioned close to the drum.<br />

Hydraulic Feed Drum-Style Chippers<br />

Popular Money Making Options:<br />

• Auto-Feed Plus<br />

• Hand-crank Swivel Discharge<br />

• Hand-crank Height Adjustable Discharge<br />

• Hydraulic Lift Cylinder<br />

• Hydraulic Tongue Jack<br />

Take the time to compare...<br />

THE COMPETITION’S 22 1/2” DRUM<br />

Cuts primarily across the grain<br />

CapaCity opening engine options<br />

MoDeL 1590Xp 17” 18” x 20.5” 65 - 140 Hp<br />

Model 1590XP. Like the 1290XP, the<br />

1590XP features a 37” diameter drum<br />

which is about 15” larger in diameter<br />

than the drums in our competitor’s<br />

machines.<br />

Like all <strong>Bandit</strong> hand-fed chippers, the 1590XP<br />

is available towable or self-propelled.<br />

BANDIT’S 37” DRUM<br />

Cuts primarily with the grain<br />

The 1590XP features a 37” diameter drum compared to the 22” drum that is used in comparable<br />

competitive drum chippers. With the 1590XP, most of the material is chipped on an angle with<br />

the grain of the wood. With a chipper with a 22” drum, the material is chipped against/across<br />

and with the grain, which takes more power and puts more strain on the drum.<br />

239

WANT TO SEE THESE <strong>CHIPPERS</strong> IN ACTION?<br />

log on to our web site for video footage of all our chippers in action! While you are<br />

checking out our video library, be sure to take a look at our brochure downloads<br />

used equipment listings. lOg ON >> HTTP://WWW.BANDIT<strong>CHIPPERS</strong>.COm<br />

18” & 19” Capacity Drum-Style Chippers<br />

<strong>Bandit</strong>’s rugged 18” and 19” capacity machines are the ultimate<br />

hand-fed chippers. These machines feature the most powerful<br />

feed systems ever offered on a hand-fed chipper.<br />

Model 1890XP. A rugged, high<br />

production machine with a large 26” x<br />

20 1⁄2” opening to handle big, rough<br />

trees. This hydraulic 18” capacity<br />

machine is more than a hand-fed<br />

chipper. The feed system is powerful<br />

enough to pull whole trees into the<br />

chipper. Although the 1890 is often<br />

fed by a knuckle boom or skid steer<br />

loader, it is not designed to be force<br />

fed. This rugged machine is a favorite<br />

of those involved in full tree take<br />

downs and light land clearing.<br />

Designed to dispose of amazing quantities of tough<br />

material while providing years of dependable service. The<br />

same powerful feed system as our Model 1850 whole tree<br />

chipper can be found on the Models 1890HD and 1990XP.<br />

Hydraulic Feed Drum-Style Chippers<br />

CapaCity opening engine options<br />

Popular Money Making Options:<br />

• Auto-Feed Plus<br />

• Hand-crank Swivel Discharge<br />

• Hand-crank Height Adjustable Discharge<br />

• Hydraulic Winch<br />

• Hydraulic Tongue Jack<br />

40 41<br />

MoDeL 1890Xp<br />

(stanDaRD)<br />

MoDeL 1890Xp<br />

(HeaVy DUty)<br />

18” 26” x 20.5” 110 - 140 HP<br />

18” 26” x 20.5” 140 - 250 HP<br />

MoDeL 1990Xp 19” 26” x 24.5” 160 - 250 HP<br />

Model 1990XP. Built like our popular<br />

Model 1890XP, the 1990XP features a<br />

very large 26” x 24 1/2” wide chipper<br />

opening and is extremely efficient at<br />

processing limby & forked material as<br />

well as large diameter material.<br />

The 1990XP features a powerful whole<br />

tree-type feed system that includes a<br />

15-3/4” diameter top wheel and engine<br />

options up to 250-hp.

42<br />

Conventional Drum-Style Chippers<br />

With drum-style chippers from <strong>Bandit</strong>, you get the quality of a<br />

<strong>Bandit</strong> chipper with unique features that enhance performance,<br />

reduce operational costs and lower your chipping costs.<br />

Model 1290. Heavy duty, greasable pillowblock<br />

chipper bearings with a rated life<br />

of 50,000 hours. The bearings have a split<br />

housing for easy cutterhead removal.<br />

Rotor operating speed of 2400 RPM, more<br />

chipping torque, operator friendly feed<br />

speed. Chipper housing and discharge with<br />

covers that provide easy access to the knives<br />

and anvil.<br />

Model 1690. Similar to our Model 1290<br />

conventional drum, the Model 1690 is<br />

equipped with engine options up to 115-hp<br />

and a chipper opening of 16” x 10”. High<br />

velocity blower with 440 pound flywheel<br />

and 11” x 11” discharge chute with chip<br />

deflector, optional side discharge, and<br />

optional side-to-side discharge assists in full<br />

van loading.<br />

Conventional chippers...<strong>Bandit</strong>’s original Model 1290 and<br />

1690 conventional drum chippers are dependable and reliable.<br />

Conventional Drum-Style Chippers<br />

CapaCity opening engine options<br />

MoDeL 1290 6” 12” x 10” 65 - 115 Hp<br />

MoDeL 1690 6” 16” x 10” 65 - 115 Hp<br />

Popular Money Making Options:<br />

• Side chip discharge<br />

• Lockable filler caps<br />

• 3/16” weld-on steel fenders<br />

• Cone holders<br />

43

44<br />

Chipper/Chip Box Combo<br />

A chipper and chip box on a single trailer can save you money.<br />

It eliminates the need for a chip box truck and related costs like<br />

insurance and license.<br />

Utilizing a chipper/chip box combo frees<br />

the towing vehicle for other uses. <strong>Bandit</strong><br />

offers combo units on 6” and 9” capacity<br />

chippers. With the combo unit, you can<br />

chip from either side with a seven-position,<br />

PTO Chippers<br />

The same high quality standards that have<br />

made over 35,000 <strong>Bandit</strong> chippers the most<br />

popular chippers in the tree care and tree<br />

disposal markets are incorporated into our<br />

“PTO” drive chippers. Other than the main<br />

quick-release turntable. Change chipping<br />

positions in seconds with the 360º swivel<br />

discharge. The eight cubic-yard vented chip<br />

box is powered by hydraulics and has sideopening<br />

rear doors.<br />

With disc-style chippers from <strong>Bandit</strong>, you get the quality of a<br />

<strong>Bandit</strong> chipper with unique features that enhance performance,<br />

reduce operational costs and lower your chipping costs.<br />

power source being supplied by the tractor,<br />

the chipper is completely self-contained<br />

and offered for 540- or 1000-RPM tractor<br />

drives. They can be purchased as a 3-point<br />

hitch unit or a pull-behind, trailerized unit.<br />

3 POINT HITCH:<br />

STANDARD FEATURES:<br />

Model 65 Category I (3/4” top, 7/8” bottom pins) • All other models Category II<br />

(top pins 1”, bottom 1-1/8” diameter pins) unless otherwise specified • All 30” = 40”<br />

models have adjustable hitch height mount plate • Self-contained hydraulic system<br />

• Drive for 540 RPM Tractor PTO (For maximum up to 75-HP tractor PTO, depending<br />

on model.) • Forward - Off - Reverse safety control handle<br />

TRAILERIZED MODELS:<br />

STANDARD FEATURES:<br />

Drive for 540-RPM tractor PTO (For max. up to 75-HP tractor PTO, depending on<br />

model) • Axle, tires and wheels • 2” ball hitch • Tongue jack • Forward - off - reverse<br />

safety control handle<br />

FOR ADDITIONAL INFORMATION ON PTO <strong>CHIPPERS</strong>,<br />

CONTACT YOUR BANDIT REPRESENTATIVE AT 800-952-0178.<br />

Chipping alternatives...<strong>Bandit</strong> offers a number of chippers that work with your unique<br />

operation’s needs, ranging from conventional drum chippers to convenient PTO chippers.<br />

45

46<br />

Chipper Safety<br />

We would like to thank all the tree services who have instituted regular chipper safety<br />

training programs. We also applaud the efforts of the various industry trade associations<br />

who are working hard to make worker safety a top priority.<br />

Guards: Cover the hydraulic pump belt<br />

drive, chipper drive belts, feed wheel drive<br />

couplers and bearing retainer. They reduce<br />

the potential for injury by preventing the<br />

operator from getting caught in the<br />

moving parts.<br />

Wooden pusher paddle: Helps the<br />

operator feed small wood debris.<br />

Safety decals: Prominently displayed and<br />

available in multiple languages. Spanish/<br />

English combination now standard.<br />

Mechanical spring lock pin (patented):<br />

Prevents the disc’s hood pin from being<br />

removed when the disc is turning. (The<br />

disc’s hood won’t open until the disc has<br />

come to a complete stop).<br />

Last chance pull cable (patented): The<br />

last chance pull cable is located inside the<br />

infeed hopper and used to stop and reverse<br />

the feed system.<br />

Chipper disc/drum hood pin with pad<br />

lock: Prevents unauthorized persons from<br />

accessing the disc or drum.<br />

Patented fold-down infeed tray<br />

cushioning springs: Reduces the effort<br />

required to raise and lower the infeed pan.<br />

Standard on larger, heavier <strong>Bandit</strong> chippers<br />

from Model 250XP on up.<br />

Safety colors available: <strong>Bandit</strong> yellow, alert<br />

orange<br />

We continue to stress proper safety training and operation as the best way to avoid<br />

accidents. Always follow ANSI and OSHA standards. We are proud to be doing our part<br />

as well, by offering the above safety features on all <strong>Bandit</strong> chippers.<br />

Electronic limit switch on disc & drum<br />

hood pin lock out: Prevents engine from<br />

being started without the hood pin in<br />

place. Someone turning the key cannot<br />

inadvertently start the engine, disc or drum.<br />

Manuals and videos: supplied with each<br />

unit (operations, service, parts).<br />

Ergonomic design:<br />

• Low risk positions for any operator<br />

• Low force, low stress operation<br />

• No repetitive motion functions required<br />

for operation<br />

• Easy to read gauges<br />

styLe CapaCity opening engine options<br />

MoDeL 65Xp DISC 6” 6” x 12” 25 - 37 HP<br />

MoDeL 90Xp DISC 9” 9.5” x 17” 46 - 90 HP<br />

MoDeL 95Xp DISC 9” 9” x 17” 46 - 90 HP<br />

MoDeL 150Xp DISC 12” 14” x 17” 65 - 140 HP<br />

MoDeL 200Xp DISC 12” 14” x 17” 65 - 140 HP<br />

MoDeL 250Xp DISC 12” 12.5” x 19” 65 - 140 HP<br />

MoDeL 255Xp DISC 15” 15.5” x 25” 110 - 213 HP<br />

MoDeL 280Xp DISC - STANDARD 18” 18” x 20.5” 110 - 140 HP<br />

MoDeL 280Xp DISC - HEAVY DUTY 18” 18” x 20.5” 160 - 213 HP<br />

MoDeL 1290Xp DRUM 15” 17.25” x 25.5” 65 - 140 HP<br />

MoDeL 1590Xp DRUM 17” 18” x 20.5” 65 - 140 HP<br />

MoDeL 1890Xp DRUM - STANDARD 18” 26” x 20.5” 115 - 140 HP<br />

MoDeL 1890Xp DRUM - HEAVY DUTY 18” 26” x 20.5” 140 - 250 HP<br />

MoDeL 1990Xp DRUM 19” 26” x 24.5” 160 - 250 HP<br />

MoDeL 1290 CONVENTIONAL 6” 12” x 10” 65 - 115 HP<br />

MoDeL 1690 CONVENTIONAL 6” 16” x 10” 65 - 115 HP<br />

Brush <strong>Bandit</strong> Hand-Fed Chipper Specifications<br />

ViDeo aVaiLaBLe<br />

(onLine oR DVD)<br />

LoaDeR option<br />

aVaiLaBLe<br />

seLF-pRopeLLeD<br />

option aVaiLaBLe<br />

HyDRaULiC LiFt<br />

CyLinDeR option<br />

DeLUXe option<br />

paCKage aVaiLaBLe<br />

pto option<br />

aVaiLaBLe<br />

ALL SPECIFICATIONS, DIMENSIONS, STANDARDS AND OPTIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE. • BANDIT INDUSTRIES INC. • ALL SPECIFICATIONS, DIMENSIONS, STANDARDS AND OPTIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.<br />

For additional information, ask for any of these <strong>Bandit</strong> catalogs!<br />

In the market for a stump grinder, whole tree chipper, or waste reduction unit?<br />

Call, write or email for additional brochures.<br />

<strong>Bandit</strong> stump<br />

grinders<br />

Featuring eleven highproduction<br />

stumpers,<br />

available both as towable<br />

and self-propelled<br />

models.<br />

<strong>Bandit</strong> Industries, Inc.<br />

6750 millbrook Road<br />

Remus, mI 49340<br />

Phone: 800-952-0178 / 989-561-2270<br />

Fax: 989-561-2273<br />

sales@banditchippers.com<br />

www.banditchippers.com<br />

<strong>Bandit</strong> Whole tree<br />

Chippers<br />

Unique machines that<br />

quickly and efficiently<br />

convert whole trees into<br />

dimensional chips.<br />

<strong>Bandit</strong> Waste<br />

Recyclers<br />

The most practical<br />

machines for turning<br />

unwanted waste into<br />

valuable products.<br />

<strong>Bandit</strong> product Line<br />

Featuring our entire line<br />

of chippers, grinders and<br />

waste recyclers.<br />

Thank you for your interest in <strong>Bandit</strong> equipment. If you would like to learn more<br />

about our company or the products we manufacture, you can log on to our web<br />

site or request additional literature and DvDs.<br />

Our web site features video footage of all our equipment in action, as well as<br />

used equipment listings, a dealer locator, and specification charts. Content is<br />

updated daily, so check back often.<br />

For additional information at any time, please contact your local <strong>Bandit</strong> dealer or<br />

call 800-952-0178 to speak with your regional sales representative.<br />

47

<strong>Bandit</strong> chippers: Built strong to last long.<br />

<strong>Bandit</strong> Industries, Inc. currently employs approximately 340<br />

dedicated employees who help us produce more than 2,500 units per<br />

year. The key to our success and rapid growth continues to be our<br />

employees who share our philosophy of producing a quality product and<br />

providing excellent customer service.<br />

<strong>Bandit</strong> products are manufactured in a modern 240,000 squarefoot<br />

manufacturing facility located at their corporate headquarters in<br />

Remus, Michigan.<br />

We use the latest technology to cut, machine, weld and assemble<br />

our machines. We use a teamwork approach when putting together our<br />

machines. A two-man team can put a 12” chipper together in a day.<br />

We stock an abundant supply of components to ensure quick<br />

delivery, and we and our dealers also stock a supply of new equipment<br />

for those that need immediate delivery.<br />

When quality counts, industry professionals count on <strong>Bandit</strong>.<br />

YOUR AUTHORIZED BANDIT DEALER<br />

BANDIT INDUSTRIES, INC.<br />

6750 Millbrook Road • Remus, MI 49340<br />

Phone: (800) 952-0178 or (989) 561-2270<br />

Email: sales@banditchippers.com<br />

Online: http://www.banditchippers.com<br />

We are a company dedicated to creating quality, innovative<br />

products that help our customers do more for less. As an industry<br />

leader, we strive to meet and exceed our customer’s expectations.<br />

Find out how <strong>Bandit</strong> can maximize the efficiency of your operation.<br />

Call today for a product demonstration.<br />

1-800-952-0178<br />

05.007.HF.20,000.R1