Draft - JRC IPTS - Sustainable Production and Consumption - Europa

Draft - JRC IPTS - Sustainable Production and Consumption - Europa

Draft - JRC IPTS - Sustainable Production and Consumption - Europa

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

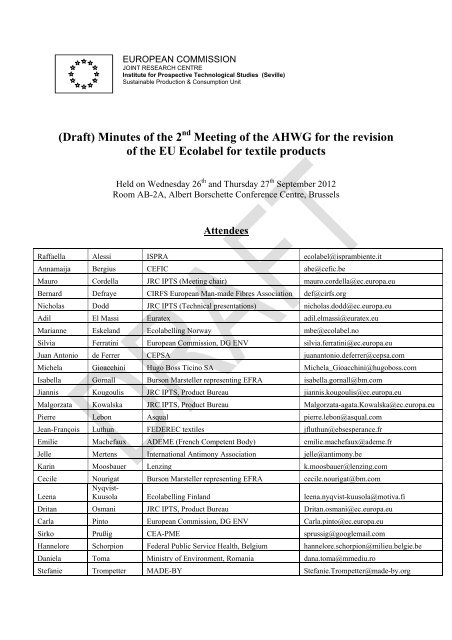

EUROPEAN COMMISSION<br />

JOINT RESEARCH CENTRE<br />

Institute for Prospective Technological Studies (Seville)<br />

<strong>Sustainable</strong> <strong>Production</strong> & <strong>Consumption</strong> Unit<br />

(<strong>Draft</strong>) Minutes of the 2 nd Meeting of the AHWG for the revision<br />

of the EU Ecolabel for textile products<br />

Held on Wednesday 26 th <strong>and</strong> Thursday 27 th September 2012<br />

Room AB-2A, Albert Borschette Conference Centre, Brussels<br />

Attendees<br />

Raffaella Alessi ISPRA ecolabel@isprambiente.it<br />

Annamaija Bergius CEFIC abe@cefic.be<br />

Mauro Cordella <strong>JRC</strong> <strong>IPTS</strong> (Meeting chair) mauro.cordella@ec.europa.eu<br />

Bernard Defraye CIRFS European Man-made Fibres Association def@cirfs.org<br />

Nicholas Dodd <strong>JRC</strong> <strong>IPTS</strong> (Technical presentations) nicholas.dodd@ec.europa.eu<br />

Adil El Massi Euratex adil.elmassi@euratex.eu<br />

Marianne Eskel<strong>and</strong> Ecolabelling Norway mbe@ecolabel.no<br />

Silvia Ferratini European Commission, DG ENV silvia.ferratini@ec.europa.eu<br />

Juan Antonio de Ferrer CEPSA juanantonio.deferrer@cepsa.com<br />

Michela Gioacchini Hugo Boss Ticino SA Michela_Gioacchini@hugoboss.com<br />

Isabella Gornall Burson Marsteller representing EFRA isabella.gornall@bm.com<br />

Jiannis Kougoulis <strong>JRC</strong> <strong>IPTS</strong>, Product Bureau jiannis.kougoulis@ec.europa.eu<br />

Malgorzata Kowalska <strong>JRC</strong> <strong>IPTS</strong>, Product Bureau Malgorzata-agata.Kowalska@ec.europa.eu<br />

Pierre Lebon Asqual pierre.lebon@asqual.com<br />

Jean-François Luthun FEDEREC textiles jfluthun@ebsesperance.fr<br />

Emilie Machefaux ADEME (French Competent Body) emilie.machefaux@ademe.fr<br />

Jelle Mertens International Antimony Association jelle@antimony.be<br />

Karin Moosbauer Lenzing k.moosbauer@lenzing.com<br />

Cecile Nourigat<br />

Nyqvist-<br />

Burson Marsteller representing EFRA cecile.nourigat@bm.com<br />

Leena Kuusola Ecolabelling Finl<strong>and</strong> leena.nyqvist-kuusola@motiva.fi<br />

Dritan Osmani <strong>JRC</strong> <strong>IPTS</strong>, Product Bureau Dritan.osmani@ec.europa.eu<br />

Carla Pinto European Commission, DG ENV Carla.pinto@ec.europa.eu<br />

Sirko Prußig CEA-PME sprussig@googlemail.com<br />

Hannelore Schorpion Federal Public Service Health, Belgium hannelore.schorpion@milieu.belgie.be<br />

Daniela Toma Ministry of Environment, Romania dana.toma@mmediu.ro<br />

Stefanie Trompetter MADE-BY Stefanie.Trompetter@made-by.org

Dirk Van Hessche<br />

Van<br />

Plastics Europe dirk.van.hessche@plasticseurope.org<br />

Martine Schoorisse Bioforum martine.vanschoorisse@bioforum.be<br />

Paul Vaughan UK Ecolabel Delivery paul.vaughan@oakdenehollins.co.uk<br />

Jakob Waidtlöw Ecolabelling Denmark jwa@ecolabel.dk<br />

Oliver Wolf <strong>JRC</strong> <strong>IPTS</strong>, Product Bureau oliver.wolf@ec.europa.eu<br />

2

Agenda<br />

Wednesday 26 th September (14:30 – 18:00)<br />

Start time 14:30<br />

Opening <strong>and</strong> welcome<br />

1. Introduction to revision of the EU Ecolabel <strong>and</strong> Green Public Procurement (GPP)<br />

criteria<br />

Product group scope <strong>and</strong> definition<br />

2.<br />

Product group scope <strong>and</strong> definition revisions<br />

Coffee break<br />

Textile fibre criteria area – presentation <strong>and</strong> discussion<br />

3. The key issues proposed to be addressed by the revision, findings of follow-up<br />

research <strong>and</strong> revised proposals for revisions.<br />

Close of meeting 18:00<br />

Thursday 27 th September (09:30 – 13:30)<br />

Start time 09:30<br />

Processes <strong>and</strong> chemical criteria area – presentation <strong>and</strong> discussion<br />

4. The key issues proposed to be addressed by the revision, findings of follow-up<br />

research <strong>and</strong> revised proposals for revisions.<br />

Coffee break<br />

Fitness for use criteria area – presentation <strong>and</strong> discussion<br />

5. The key issues proposed to be addressed by the revision, findings of follow-up<br />

research <strong>and</strong> revised proposals for revisions.<br />

New criteria areas – presentation <strong>and</strong> discussion<br />

6. Care labelling, end-of-life <strong>and</strong> CSR criteria: findings of follow-up research <strong>and</strong><br />

revised proposals.<br />

Next steps<br />

7.<br />

Resume of AHWG <strong>and</strong> next steps in the EU Ecolabel revision process<br />

Close of meeting 13:30<br />

3

Session 1 – Introduction <strong>and</strong> background<br />

A brief introduction to the EU Ecolabel <strong>and</strong> the revision process for textile products was made by<br />

<strong>JRC</strong>-<strong>IPTS</strong> European Commission. This will be the second of two AHWG meetings designed to obtain<br />

feedback from stakeholders.<br />

Written feedback on the draft Preliminary Report <strong>and</strong> draft Technical Report <strong>and</strong> Criteria Proposals<br />

was requested within four weeks by the 24 th October 2012. The documents can be downloaded from<br />

the <strong>JRC</strong> <strong>IPTS</strong> Product Bureau website from the following link:<br />

http://susproc.jrc.ec.europa.eu/textiles/stakeholders.html<br />

The stakeholder feedback obtained during the AHWG meeting will be used to develop the criteria<br />

proposals which will be presented to the EU Ecolabel Board at the end of November with a view to<br />

Interservices consultation during December-January followed by presentation to the EU Ecolabel<br />

Board for voting in March 2013.<br />

The evidence base for the criteria revision will also be used to develop, in parallel, criteria for Green<br />

Public Procurement (GPP). <strong>JRC</strong>-<strong>IPTS</strong> European Commission then presented a brief overview of:<br />

o the current scope, aim <strong>and</strong> structure of the Ecolabel criteria,<br />

o the market analysis for EU textile products,<br />

o the technical analysis based on LCA evidence,<br />

4

Session 2 – Product group scope <strong>and</strong> verification<br />

Product scope definition<br />

Proposed revisions presented included more specific product definitions for clothing <strong>and</strong> interior<br />

textiles, a list of exclusions <strong>and</strong> lowering of the threshold for definition of a textile product to 85%.<br />

Input from stakeholders<br />

Synthetic material not covered within the scope of the criteria requires further consideration. The<br />

Nordic Swan sets thresholds for membranes <strong>and</strong> coatings of 20%. All of other materials could be set<br />

at a limit of 15%.<br />

The inclusion/exclusion of a number of products requires clarification so that stakeholders can be<br />

consulted e.g. cleaning products, bags, rucksacks. Would it not be better to just have a list of what is<br />

excluded, as what happens if something is not included? This point requires clarification.<br />

It was also suggested that it may be better to introduce the list of products ’such as…’ rather than a<br />

definitive list ’defined as…’<br />

<strong>IPTS</strong> clarified that cleaning products are proposed for exclusion because of the greater complexity of<br />

the associated fitness for use criteria that would be required (with reference to the Nordic Swan).<br />

It was queried as to why products such as tents should not be included if they met all the criteria <strong>and</strong><br />

as to whether the definition of electrical devices should include fibres as an application was not known<br />

to exist.<br />

It was clarified that the Textile Names Directive 121/2008 was repealed in May 2012 <strong>and</strong> a new<br />

definition of 80% introduced.<br />

Actions arising from the discussion:<br />

o Clarify <strong>and</strong> improve wording of inclusions/exclusions, including cleaning products, rucksacks<br />

<strong>and</strong> bags;<br />

o Review potential for a maximum % content for synthetic materials not covered by the criteria<br />

– specifically membranes, coatings <strong>and</strong> fillings – with reference to the Nordic Swan;<br />

o Cross-check the reference to the revised Textile Names Directive;<br />

5

Assessment <strong>and</strong> verification<br />

A proposed new requirement for certification schemes to be operated in line with the ISO Guide 65<br />

was presented.<br />

Input from stakeholders<br />

It was considered challenging <strong>and</strong> difficult for Competent Bodies to verify this requirement to the<br />

level stated in the proposal. A simple declaration would be the best option.<br />

This would require mutual recognition of certification schemes. The only thing that could be possible<br />

is to accept accredited certification bodies, which could be listed in the criteria in order to leave no<br />

doubt, but then this list would need to be maintained.<br />

It was stated that it would be easy to check the status of the certification body as it will be written on<br />

any certification issued by them.<br />

It was stated that the ISO/IEC Guide 65 has been replaced by a new ISO st<strong>and</strong>ard 17065.<br />

Actions arising from the discussion:<br />

o Review the potential for requiring a simple declaration;<br />

o Change the reference from ISO Guide 65 to ISO 17065.<br />

6

Session 3 – Textile fibre criteria area<br />

Criteria pre-amble<br />

Proposals to improve the clarity of how the fibres are presented <strong>and</strong> to lower the threshold for recycled<br />

content to 70% were presented.<br />

Input from stakeholders<br />

It was queried as to why silk does not have criteria. It is becoming more important for high quality<br />

products in combination with other fibres. It was also queried as to why aramid fibre, which typically<br />

has applications such as fire service <strong>and</strong> military, should not be included.<br />

<strong>IPTS</strong> clarified that neither of the fibres were as significant from a market perspective. Silk had not<br />

been raised in previous meetings/stakeholder written feedback. Aramid was being considered within<br />

the scope of GPP, however, further LCA evidence is needed to evaluate the environmental impacts<br />

associated with its manufacture.<br />

It was also clarified that a revised threshold of 70% is proposed for recycled content, above which the<br />

relevant fibre criteria do not apply.<br />

Actions arising from the discussion:<br />

o Scientific evidence for the environmental impacts of silk fibres should be reviewed with a<br />

view to deciding whether to include/exclude silk fibres;<br />

o A further attempt should be made to obtain LCA evidence for aramid fibres;<br />

C2 Cotton <strong>and</strong> other natural cellulosic seed fibres (including kapok)<br />

Revision proposals to increase the minimum organic cotton content to 10%, to introduce a higher<br />

minimum of 50% for specific products, to introduce IPM cotton as an alternative option to IPM cotton<br />

(with same minimum requirements <strong>and</strong> to add two pesticides to the current testing list were presented.<br />

Input from stakeholders<br />

Disappointment was expressed about the potential weakness highlighted in relying on final fibre<br />

pesticide testing. Specific additional pesticides were suggested that are commonly used in conjunction<br />

with GM cotton – Glyphosate <strong>and</strong> Ammonium Sulfamate were cited. Moving to organic <strong>and</strong> IPM<br />

cotton would mean that cotton couldn’t be bought on the spot market.<br />

Concerns were raised that greater minimum requirements for organic cotton would restrict the<br />

Ecolabel to a low market share. The experience with the Nordic Swan is that a high content st<strong>and</strong>ard<br />

7

has not been successful.<br />

The justification for raising the minimum content requirement was queried. In particular the issue of<br />

potential false content claims by manufacturers was raised as a major concern, <strong>and</strong> it was claimed that<br />

there is not enough organic cotton on the market to meet all the content claims being made. The<br />

ethical impact of possible increased l<strong>and</strong> use was also highlighted.<br />

Feedback from some industry stakeholders suggests that a 50% content requirement for organic cotton<br />

is too high.<br />

The method of calculating the content claim to be verified by Competent Bodies requires greater<br />

clarity – is it based on the final product or an annual average?<br />

<strong>IPTS</strong> clarified that very different views had been received from stakeholders in advance of the<br />

meeting, with some Competent Bodies <strong>and</strong> br<strong>and</strong>s/manufacturers proposing a content requirement of<br />

between 50-100%. The proposal is an attempt to bridge the very different opinions, reflect strategies<br />

in the market today <strong>and</strong> to ensure a higher level of environmental improvement.<br />

It was felt that organic cotton <strong>and</strong> IPM cotton should not be considered together or as equal in terms of<br />

minimum requirements. The requirements for IPM were not considered to be at the same level. It was<br />

felt that there are currently not real IPM criteria but guidelines. There are big differences between<br />

them in terms of improvement potential. One view was that IPM minimum requirements should be<br />

higher.<br />

<strong>IPTS</strong> clarified that there is clear evidence from UN/FAO of an improvement potential of between 30-<br />

90% for IPM cotton, the problem is the ability to verify this improvement. Schemes do include specific<br />

criteria. Licenseholders had also fed back the need to have IPM as an alternative option to organic<br />

cotton.<br />

It was also noted by <strong>IPTS</strong> that a Competent Body had suggested that feedback be obtained from the<br />

four IPM schemes on <strong>IPTS</strong>’s evaluation of their strengths <strong>and</strong> weaknesses.<br />

A question was raised as to whether membership of the BCI IPM scheme would be sufficient in terms<br />

of verification.<br />

It was clarified by <strong>IPTS</strong> that this would not be sufficient, the verification requirements in the proposal<br />

would need to be met.<br />

8

Actions arising from the discussion:<br />

o With regard to pesticide tests:<br />

- Check the proposed additional pesticides for relevance to the criteria;<br />

o With regard to organic cotton:<br />

- Review the proposed % minimum requirements <strong>and</strong> the associated justification;<br />

- Obtain further background from Euratex on false content claim concerns;<br />

o With regard to IPM:<br />

- The criteria should be redrafted so that it considers IPM differently from organic<br />

cotton;<br />

- Recommend which IPM scheme would be acceptable at this point in time <strong>and</strong> obtain<br />

feedback from the four schemes.<br />

C3 Elastane<br />

The proposal for an occupational exposure limit for di-isocyanates was presented.<br />

Input from stakeholders<br />

It was stated that the solvent DMAC, which is used to manufacture elastane <strong>and</strong> also acrylic <strong>and</strong><br />

aramid, has been proposed for addition to the ECHA C<strong>and</strong>idate List for Authorisation.<br />

The question was raised as to whether there are alternatives to DMAC as its C<strong>and</strong>idate List status may<br />

rule out the use of acrylic <strong>and</strong> elastane fibres. Further information will be provided by CIRFS.<br />

<strong>IPTS</strong> clarified that this would be addressed under the hazardous substances criteria <strong>and</strong> that there<br />

may be an option for derogation if there are no alternatives.<br />

It was clarified that elastane is generally used in clothing at 20-30% blend <strong>and</strong> that although<br />

alternatives to DMAC exist their toxicology is similar.<br />

Clarification was requested where the proposed occupational health <strong>and</strong> safety limit value for diisocyanates<br />

was derived from. In the EU there are m<strong>and</strong>atory levels – is this stricter than this level?<br />

<strong>IPTS</strong> clarified that it was from the Blue Angel label scheme in Germany.<br />

Actions arising from the discussion:<br />

o CIRFS to provide background information about DMAC, its applications, alternatives <strong>and</strong> the<br />

proposal for Authorisation;<br />

o A comparison is to be made between the proposed di-isocyanate limit value <strong>and</strong> m<strong>and</strong>atory<br />

levels in the EU, with input from CIRFS <strong>and</strong> Blue Angel.<br />

9

C4 Flax <strong>and</strong> other bast fibres (including hemp, jute <strong>and</strong> ramie)<br />

Revision proposals to introduce a requirement for retting at ambient temperature were presented.<br />

Input from stakeholders<br />

It was commented that the COD limit to the receiving waters should be specified with a limit value of<br />

% requirement.<br />

Actions arising from the discussions:<br />

o Review the potential for a COD limit value or a % requirement<br />

C5 Greasy wool <strong>and</strong> other keratin fibres (including wool from sheep, camel, alpaca, goat)<br />

Revisions proposals to link the wool scouring COD limit to the level of grease recovery, to require<br />

value recovery from by-products <strong>and</strong> to improve the approach to sampling for ectoparasiticide testing.<br />

Input from stakeholders<br />

The final COD achieved for the 180 g/kg starting value (= 45 g/kg wool) was felt by one Competent<br />

Body to be too high. A lower COD limit of 24 g/kg should be achieveable in New Zeal<strong>and</strong>.<br />

<strong>IPTS</strong> clarified that it based the proposals on discussions with the two remaining New Zeal<strong>and</strong><br />

scourers as well as a review of BAT technology. Differentiation could be made between fine <strong>and</strong><br />

course wool, as the final COD would be closer to 24 g/kg for coarse wool.<br />

Specific comments had been submitted by Danish Licenseholders, which should be taken into<br />

consideration. The reference to the EU wastewater treatment directive should be replaced with a<br />

specific COD limit value or % COD reduction. A query was raised about the potential for an energy<br />

benchmark, as energy use was mentioned in the presentation.<br />

<strong>IPTS</strong> clarified that research highlighted that wool can require as much energy to scour as to<br />

manufacture synthetic fibres <strong>and</strong> there was good experience in New Zeal<strong>and</strong> operating a benchmark.<br />

However, <strong>IPTS</strong> recognised that most stakeholders were not in favour of energy benchmarks.<br />

Actions arising from the discussions:<br />

o Split the COD criteria into coarse <strong>and</strong> fine wool so that the COD targets better relate to<br />

operational conditions;<br />

o Review comments submitted by Danish licenseholders <strong>and</strong> follow-up on the issues raised;<br />

o Replace reference to Wastewater Treatment Directive with specific COD limit value or %<br />

COD reduction.<br />

10

C6 Man-made cellulose fibres (including viscose, lyocell, acetate, cupro <strong>and</strong> triacetate)<br />

Revision proposals were presented to lower the OX limit, to introduce an energy self-sufficiency<br />

requirement for dissolving pulp production <strong>and</strong> to introduce a requirement for 25% of pulp to be from<br />

certified sustainable sources with the remaining balance from legal sources.<br />

Input from stakeholders<br />

It was stated that Cupro is no longer manufactured in the EU. The need for reference to it in the<br />

criteria was therefore questioned.<br />

The BAT limit values were queried – please check that the VOC levels are correctly quoted for<br />

filament fibre processes.<br />

An annual increment was not considered possible by Competent Bodies because of the need to renew<br />

licenses if conditions change. The % that certified sustainable fibre content requirement could reach<br />

should be clarified if this approach is introduced.<br />

Concern was raised that the energy self-sufficient proposal would only be achieveable for integrated<br />

production sites, of which there are only a limited number in the world, so it would restrict potential<br />

licenses. The criteria should be feasible for suppliers of market pulp. A specific figure would be<br />

needed in the final proposal, if the criteria is shown to be feasible.<br />

<strong>IPTS</strong> clarified that they understood that integrated production was very limited, <strong>and</strong> the criteria was<br />

worded to apply to integrated production <strong>and</strong> market pulp production. BREF has been referred to in<br />

order to identify the BAT technology referred to.<br />

The reference to AOX in the criteria requires clarification as the ISO st<strong>and</strong>ard referred in the<br />

verification conditions measures OX. The criteria could be made simpler by stating that elemental<br />

chlorine gas is excluded, reflecting the use of ECF technology. The current Nordic Swan criteria were<br />

suggested as a reference point.<br />

Actions arising from the discussions:<br />

o Check for the continued relevance of Cupro on the market;<br />

o <strong>IPTS</strong> to liaise with Lenzing, who will put out an enquiry to their market pulp suppliers to find<br />

out how many could meet the criteria;<br />

o Check the Nordic Swan criteria for paper products as they provide a reference to ECF pulp<br />

production;<br />

11

C7 Polyamide<br />

Revision proposals to harmonise the VOC limits with those in the Blue Angel <strong>and</strong> to introduce a<br />

minimum recycled content of 3% were presented.<br />

Input from stakeholders<br />

Concern was raised that the emission limits are not in line with the BREF for Polymers.<br />

Concern was raised that the proposed 3% recycled content minimum was very low <strong>and</strong> would not<br />

justify the modification of production lines to achieve this. Further feedback will be provided from<br />

CIRFS members, but it is possible that a higher % will be recommended.<br />

The recyclability of fibre should also be addressed by the criteria. For example, it is known that<br />

polyamide 6,6 is more difficult technically to recycle.<br />

Recycled content was felt by some stakeholders to be only one possible environmental improvement<br />

<strong>and</strong> that others should be considered.<br />

Actions arising from the discussions:<br />

o Reference <strong>and</strong> justification for the N2O limit value to be checked/reviewed;<br />

o CIRFS to provide feedback <strong>and</strong> % content proposal to <strong>IPTS</strong> within the formal consultation<br />

period;<br />

o Option to consider the recyclability of polyamide 6,6 fibres to be reviewed further;<br />

C8 Polyester<br />

Revision proposals to introduce a minimum recycled content requirement of 50% for staple fibre <strong>and</strong><br />

20% for filament fibre with some specific exemptions were presented.<br />

Input from stakeholders<br />

Recycled content was felt by some stakeholders to be only one possible environmental improvement<br />

<strong>and</strong> other options should be considered.<br />

The market diffusion of recycled content was queried, with fleece being suggested as the only<br />

significant product. CIRFS clarified that 70% of staple fibre manufactured in the EU is made from<br />

100% recycled content.<br />

<strong>IPTS</strong> further clarified based on discussions with industry stakeholders that polyester with a recycled<br />

content is being used in a wide range of clothing <strong>and</strong> interior textile applications.<br />

12

The proposal for various exemptions from the recycled content criteria was welcomed, although they<br />

will need to be more specific <strong>and</strong> may need to be broader, in order to reflect industry feedback relating<br />

to the different end-uses. Problems with controls on the quality of production outside of the EU were<br />

cited as a potential problem.<br />

The proposal to maintain the current limit value of 260 ppm for antimony catalysts was welcomed <strong>and</strong><br />

it was stated evidence shows that the catalyst is bound within the fibre.<br />

Actions arising from the discussions:<br />

o Further refine <strong>and</strong> specify the recycled content exemptions in conjunction with stakeholders;<br />

13

Session 4 – Chemicals <strong>and</strong> process criteria area<br />

New proposals to interpret the st<strong>and</strong>ard legal text for hazardous substances with proposed new criteria<br />

11 <strong>and</strong> 12 were presented. Criteria 11 would bring together <strong>and</strong> update existing substance restrictions<br />

contained within the criteria into a Restricted Substance List (RSL). Criteria 12 would, with a focus<br />

on dyeing, printing <strong>and</strong> finishing processes, restrict the use of substances classified with specific<br />

hazard statements, with the derogation of specific hazard statements for specific groups of substances,<br />

<strong>and</strong> under certain conditions.<br />

Input from stakeholders<br />

C10 Hazardous substances <strong>and</strong> mixtures<br />

The combined proposals for Criteria 10-12 were considered complex <strong>and</strong> so a summary of the<br />

proposals was requested so that it can be circulated to other stakeholders for their comment.<br />

The consistency with REACH <strong>and</strong> the C<strong>and</strong>idate List was welcomed, including the potential for<br />

derogations. Do substances that are restricted need to be specifically listed?<br />

The wording "substitution as far as possible" seemed not to be clear enough. The reference to<br />

substances vs preparations (<strong>and</strong> viceversa) was also not considered clear.<br />

The proposals for testing require greater clarification in terms of how they will minimise potential<br />

costs. It makes no sense to test for everything <strong>and</strong> so a targeted approach should be used. It was<br />

suggested that testing <strong>and</strong> declarations could be combined within the verification requirements.<br />

Declarations could be allowed where good quality information is provided about the substances used.<br />

C11 Restricted Substance List (RSL)<br />

It was noted that some old criteria were restricting some substances that were not present on the final<br />

product, but used in the processes, <strong>and</strong> this is something that should be kept. It was also noted that not<br />

all the substances are restricted or Authorised by REACH or appear on the C<strong>and</strong>idate List e.g. high<br />

molecular weight phthalates.<br />

The focus of the criteria therefore requires clarification. The potential for declarations of non-use<br />

should be left open to complement testing e.g. for azo dyes.<br />

The potential for verification using Oeko-Tex 100 certification was discussed. The overlap between<br />

the criteria requires clarification. The assessment <strong>and</strong> verification was felt difficult for CBs. A<br />

consistent approach is needed.<br />

14

Comments relating to specific substance groups:<br />

The wording for the restriction of APEO’s requires amending in-line with written feedback<br />

provided by various stakeholders.<br />

Blends that may be restricted by the proposed changes to metal complex dyes should be<br />

checked e.g. wool-viscose, wool-polyamide. The limit values should also be reviewed based<br />

on information to be provided by Norwegian Competent Body.<br />

The treatment of biocides <strong>and</strong> flame retardants that are not added as finishes but instead as<br />

additives during fibre manufacturing should be clarified. The reference to existing EU<br />

authorisation procedures should make verification easier.<br />

There are forms of silver biocides other than the nanosilver that should be banned.<br />

C12 Subsitution of hazardous substances used in dyeing, printing <strong>and</strong> finishing<br />

The overall approach was seen as being workable. However, the 2 year phase out period was not seen<br />

as being compatible with the licensing process for the Ecolabel as licenses would need to be re-issued.<br />

The difference approaches being proposed for different product groups was noted <strong>and</strong> the potential for<br />

a special Horizontal Task Force meeting to discuss was also proposed. Concern was raised because of<br />

the limited time for Competent Bodies <strong>and</strong> Licenseholders to become familiar with the proposals,<br />

which could mean that a lot of last minute changes would be needed. Could a 3rd AHWG be a<br />

possibility?<br />

Greater clarity is needed as to how suppliers will report to the applicant. The explanations provided in<br />

the User Manual will be very important to ensure it is clear for the applicant.<br />

REACH Annexes I <strong>and</strong> II provide a framework for providing information on substances, with<br />

consideration of exposure scenarios relating to human health <strong>and</strong> the environment, with human health<br />

including workers <strong>and</strong> consumers.<br />

A request was made in relation to flame retardants for R40 (H351) to be considered as Category B. A<br />

question was posed as to how many substances that fall below the concentration thresholds would<br />

therefore be derogated from within Category B.<br />

<strong>IPTS</strong> confirmed that a sample of substances had been tested, including those submitted for derogation<br />

by stakeholders, however a definitive answer cannot be provided at this stage.<br />

15

Actions arising from the discussion:<br />

o Prepare a summary of criteria 10,11 <strong>and</strong> 12 <strong>and</strong> circulate to stakeholders;<br />

o Consider how the approach may be further refined by reference to the Horizontal Task Force<br />

<strong>and</strong>, potentially, a 3rd AHWG;<br />

o With regards to C11 RSL:<br />

- Wording of APEO restriction to be amended in-line with written feedback;<br />

- Norwegian Competent Body to provide further information in relation to metal<br />

complex dyes, blends that may be restricted <strong>and</strong> metal limit values;<br />

- The biocides wording requires clarification that it applies to all finishes.<br />

- The status of fibre additives as opposed to finishes is to be confirmed;<br />

o With regards to C12 Hazard substitution:<br />

o Consider the Categorisation of R40<br />

C13 Dyeing, printing <strong>and</strong> finishing process efficiency<br />

A new proposal was presented to introduce a criteria addressing process efficiency. The requirements<br />

would be based on BAT improvements identified from the textile BREF <strong>and</strong> industry best practice.<br />

Input from stakeholders<br />

There are an increasing number of checklists for manufacturers covering energy <strong>and</strong> water use e.g.<br />

CPO12 carbon footprinting training tool. These not only suggest technologies but also quantify<br />

possible advantages e.g. energy <strong>and</strong> financial savings. Tools which include this information are more<br />

convincing. The checklist should highlight the savings <strong>and</strong> the benefits.<br />

A general concern was raised about the additional burden of the criteria. It was highlighted that the<br />

application of BAT Techniques under IPPC Directive is limited to certain production capacity<br />

thresholds. This is to minimise the burden for SME’s of investment in expensive BAT techniques.<br />

It was questioned as to why a manufacturer would want to hold both Oeko-Tex 1000 <strong>and</strong> the Ecolabel.<br />

They will choose labels according to their market.<br />

Actions:<br />

o Review potential to allow different tools/checklists to be used to achieve compliance;<br />

o Consider how the checklist could be improved to highlight savings <strong>and</strong> benefits;<br />

o Review IPPC threshold <strong>and</strong> whether this is should be applicable to this criteria;<br />

16

C27 Waste water from discharges from wet-processing<br />

Revision proposals to harmonise the criterion with Oeko-Tex 1000, Bluesign <strong>and</strong> GOTS were<br />

presented. Higher requirements were also outlined as derogation conditions (linked to proposed<br />

Criterion 12).<br />

Input from stakeholders<br />

A possible errata was noted – the COD should be g/kg instead of mg/kg? It was also noted that by<br />

moving from g/kg to g/l the criteria would not treat fairly those making water savings as the specific<br />

value may then be higher.<br />

Actions arising from the discussions:<br />

o Check the units used in the criteria<br />

C26 Formaldehyde<br />

Revision proposals were presented to align the proposals with Oeko-Tex 100, with the exception of<br />

skin contact clothing at 75ppm.<br />

Input from stakeholders<br />

The revised proposals were not seen as being acceptable by a number of Competent Bodies. Why was<br />

it not acceptable at 30ppm?<br />

Actions arising from the discussions:<br />

o Re-review rationale <strong>and</strong> limit values<br />

C15 Detergents, fabric softeners <strong>and</strong> complexing agents<br />

Revision proposals were presented to harmonise the criterion with those in the recently approved<br />

professional laundry detergents criteria, with ionic <strong>and</strong> cationic detergents being required to be<br />

biodegradable under anaerobic conditions.<br />

Input from stakeholders<br />

It was noted that Detergents Regulation 684 bans surfactants that are not biodegradable under aerobic<br />

conditions. Reference to this would simplify the criterion. The ISO st<strong>and</strong>ard 6060 could also help<br />

simplify the approach, refering to mg/l figures.<br />

Actions arising from the discussions:<br />

o Consider potential to reference Regulation 684 <strong>and</strong> ISO st<strong>and</strong>ard for biodegradability;<br />

17

Flame retardants<br />

Revision proposals to restrict the use of flame retardants unless they are required to meet Member<br />

State fire regulations or ISO/EN product safety st<strong>and</strong>ards, <strong>and</strong> to introduce a requirement for them to<br />

meet certain durability requirements were presented.<br />

Input from stakeholders<br />

With regards to durability it was highlighted that a soak test would be more relevant for textiles that<br />

are not removable. It was highlighted that such tests are not designed to test for consumer exposure. A<br />

query was raised as to how derogations would work for flame retardants.<br />

<strong>IPTS</strong> confirmed that these were linked to regulatory need, technical need <strong>and</strong> the proposed new<br />

durability criteria.<br />

Actions arising from the discussions:<br />

o Amend durability tests for non-removable textiles;<br />

18

Session 5 – Fitness for use criteria area<br />

Durability of finishes<br />

A new proposal to introduce durability requirements for flame retardant, water repellent, softener <strong>and</strong><br />

easy care finishes was presented. Fibres <strong>and</strong> fabrics with inherent properties would be exempted.<br />

Input from stakeholders<br />

Fibre additives are incorporated into fibres which have been tested to last more than 50 wash cycles. It<br />

was also noted that not all finishes are intended to remain on the fibre e.g. those applied to enable<br />

efficient spinning. The current wording should distinguish between functions incorporated into a fibre<br />

<strong>and</strong> those added to the surface. Durability therefore not only applies to surface finishes.<br />

It was noted that if the durability of a textile product is high then it will improve its life cycle<br />

performance <strong>and</strong> increase its value <strong>and</strong> potential for re-use.<br />

Actions arising from the discussions:<br />

o Clarify how criteria distinguishes between additive <strong>and</strong> reactive functions, <strong>and</strong> between final<br />

product <strong>and</strong> intermediate product;<br />

19

Session 6 – Proposals for new criteria areas<br />

Corporate Social Responsibility (CSR)<br />

A new proposal was presented to introduce a requirement for compliance of production sites with the<br />

eight ILO core labour st<strong>and</strong>ards.<br />

Input from stakeholders<br />

There was general support for the criteria as proposed. The proposal is pragmatic.<br />

It is important that we don’t discriminate against EU manufacturers. The criteria is concerned more<br />

with manufacturing sites in developing countries.<br />

The risk to the Ecolabel’s reputation of any contraventions occuring should be considered – there are<br />

clearly risks with <strong>and</strong> without the criteria. But with this new criteria expectations would be raised.<br />

The frequency of verification could be an issue. The Nordic Swan, for example, carries out control<br />

visits. An opinion was expressed that it is too early for verification by third party schemes. This<br />

could come later once there is greater experience with the criteria. Discussions with licenseholders in<br />

Denmark highlighted that they tend to have only limited control over their supply chain.<br />

Actions arising from the discussions:<br />

o Review the verification requirements – with regards to frequency <strong>and</strong> third party schemes<br />

Product re-use <strong>and</strong> recycling<br />

A new proposal was presented that would require applicants that produce br<strong>and</strong>ed final products, or<br />

that have a direct interface with textile consumers via retail stores or contractual agreements to provide<br />

consumers or clients with take-back routes for repair, re-use or recycling.<br />

Input from stakeholders<br />

The general view was that although it is recognised as being important the Ecolabel is not the correct<br />

policy instrument to address this issue. For example, it would not be practical if the licenseholder<br />

exports to many EU countries.<br />

The criteria may also require significant risk <strong>and</strong> investment because before applying for the Ecolabel<br />

the applicant may not have a system in place. It was suggested that commercial textile suppliers could<br />

be asked to pilot take-back services.<br />

20

The consensus reached was that the only practical possibility at this stage is to provide information to<br />

consumers on the product or on a website. The consumer should be informed. This could therefore be<br />

the first step.<br />

Actions arising from the discussions:<br />

o Reduce the criteria scope to focus on the provision of information to the consumer;<br />

o Textile service providers could still be required to provide take-back services.<br />

Energy saving advice<br />

A new proposal was presented that would require applicants that produce br<strong>and</strong>ed products to use<br />

marketing, packaging <strong>and</strong> swing tags to communicate energy saving measures to ecolabel consumers.<br />

Input from stakeholders<br />

The proposal was felt to be too prescriptive <strong>and</strong> that instead the applicant should just be asked to<br />

provide information to the consumer on potential energy savings. It should not be a pass/fail criteria<br />

for applicants.<br />

The criterion should not be implemented in a way that imposes disproportional costs. Information<br />

provided via the internet would be acceptable.<br />

It was noted that consumer campaigns have focussed on providing specific information on energy <strong>and</strong><br />

financial savings from specific measures e.g. the benefits of washing at 30 o C.<br />

<strong>IPTS</strong> clarified that this could work but that it is important that the specific three messages that are<br />

highlighted in the Technical Report are the main point of reference.<br />

Actions arising from the discussions:<br />

o Reduce the criteria scope to focus on the provision of information to the consumer;<br />

o The wording/focus of the three energy saving messages is to be finalised;<br />

Certification of B2B processes<br />

A proposal by certain Competent Bodies <strong>and</strong> stakeholders to certify <strong>and</strong>/or maintain a database of<br />

processes that meet the Ecolabel criteria was presented for discussion.<br />

The proposal would make it easier for br<strong>and</strong>s <strong>and</strong> manufacturers to identify suppliers, which would be<br />

particularly beneficial for those that regularly use different/new suppliers in order to deliver new<br />

21

products to the market.<br />

Input from stakeholders<br />

A proposal to label <strong>and</strong>/or maintain a database of production processes that meet the criteria (e.g.<br />

dyehouses, printers, finishers) was briefly discussed. The need for this had been raised by Competent<br />

Bodies <strong>and</strong> industry stakeholders because it would assist in identifying pre-approved suppliers.<br />

This would need to be voluntary as manufacturers may not wish to reveal or share details of their<br />

suppliers as this is intellectual property.<br />

It was felt that the Ecolabel may not yet be mature enough for this proposal <strong>and</strong> that it was unclear<br />

how it would be resourced <strong>and</strong> co-ordinated. However, it is a good objective <strong>and</strong> could help in<br />

seeking to emulate the success of certifications such as GOTS.<br />

Actions arising from the discussions:<br />

o Further discussion of the proposal at the November EUEB <strong>and</strong> invitation for further comment<br />

from stakeholders;<br />

22