N1-Switches, Tumbler, Disconnect, Explosionproof

N1-Switches, Tumbler, Disconnect, Explosionproof

N1-Switches, Tumbler, Disconnect, Explosionproof

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

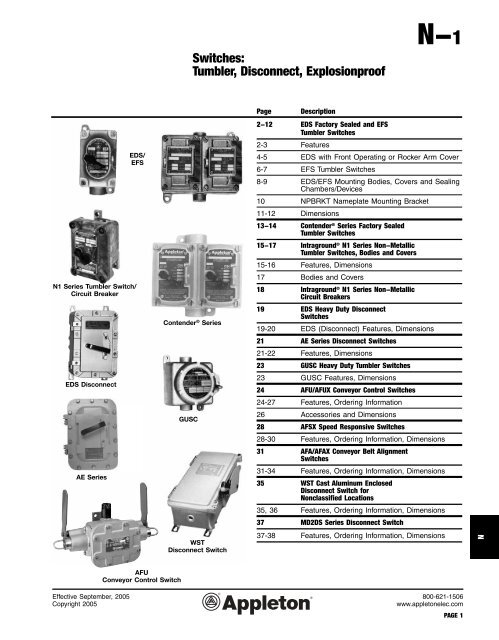

<strong>N1</strong> Series <strong>Tumbler</strong> Switch/<br />

Circuit Breaker<br />

EDS <strong>Disconnect</strong><br />

AE Series<br />

Effective September, 2005<br />

Copyright 2005<br />

EDS/<br />

EFS<br />

AFU<br />

Conveyor Control Switch<br />

<strong>Switches</strong>:<br />

<strong>Tumbler</strong>, <strong>Disconnect</strong>, <strong>Explosionproof</strong><br />

Contender ® Series<br />

GUSC<br />

WST<br />

<strong>Disconnect</strong> Switch<br />

N-1<br />

Page Description<br />

2-12 EDS Factory Sealed and EFS<br />

<strong>Tumbler</strong> <strong>Switches</strong><br />

2-3 Features<br />

4-5 EDS with Front Operating or Rocker Arm Cover<br />

6-7 EFS <strong>Tumbler</strong> <strong>Switches</strong><br />

8-9 EDS/EFS Mounting Bodies, Covers and Sealing<br />

Chambers/Devices<br />

10 NPBRKT Nameplate Mounting Bracket<br />

11-12 Dimensions<br />

13-14 Contender ® Series Factory Sealed<br />

<strong>Tumbler</strong> <strong>Switches</strong><br />

15-17 Intraground ® <strong>N1</strong> Series Non-Metallic<br />

<strong>Tumbler</strong> <strong>Switches</strong>, Bodies and Covers<br />

15-16 Features, Dimensions<br />

17 Bodies and Covers<br />

18 Intraground ® <strong>N1</strong> Series Non-Metallic<br />

Circuit Breakers<br />

19 EDS Heavy Duty <strong>Disconnect</strong><br />

<strong>Switches</strong><br />

19-20 EDS (<strong>Disconnect</strong>) Features, Dimensions<br />

21 AE Series <strong>Disconnect</strong> <strong>Switches</strong><br />

21-22 Features, Dimensions<br />

23 GUSC Heavy Duty <strong>Tumbler</strong> <strong>Switches</strong><br />

23 GUSC Features, Dimensions<br />

24 AFU/AFUX Conveyor Control <strong>Switches</strong><br />

24-27 Features, Ordering Information<br />

26 Accessories and Dimensions<br />

28 AFSX Speed Responsive <strong>Switches</strong><br />

28-30 Features, Ordering Information, Dimensions<br />

31 AFA/AFAX Conveyor Belt Alignment<br />

<strong>Switches</strong><br />

31-34 Features, Ordering Information, Dimensions<br />

35 WST Cast Aluminum Enclosed<br />

<strong>Disconnect</strong> Switch for<br />

Nonclassified Locations<br />

35, 36 Features, Ordering Information, Dimensions<br />

37 MD2DS Series <strong>Disconnect</strong> Switch<br />

37-38 Features, Ordering Information, Dimensions<br />

800-621-1506<br />

www.appletonelec.com<br />

PAGE 1<br />

N

N<br />

N-2<br />

Applications<br />

• Designed to prevent arcing of enclosed<br />

switches in ignitable atmospheres<br />

during connect and disconnect operation<br />

of lighting and light power loads.<br />

• For use in classified areas where<br />

ignitable vapors, gases or highly<br />

combustible dusts are present.<br />

• For installation in chemical and<br />

petrochemical plants, refineries, and<br />

other process industries.<br />

Features:<br />

All <strong>Tumbler</strong> <strong>Switches</strong><br />

• EDS and EFS enclosures have external<br />

mounting lugs for ease of mounting.<br />

• Smooth, rounded integral bushing in<br />

each hub protects conductor insulation.<br />

• Enclosures furnished with internal<br />

ground screw.<br />

• 20-ampere and 30-ampere units<br />

available for use with 120-277 Volt A.C.<br />

Features:<br />

EDS Factory Sealed <strong>Tumbler</strong> <strong>Switches</strong><br />

• Factory sealed switches are<br />

designed to a UL Standard so that<br />

any arcing devices are contained<br />

within an explosionproof lybryinth<br />

switch (standard switch and sealing<br />

chamber on select models). EDS<br />

tumbler switch devices are approved<br />

for installation without additional<br />

external sealing fittings.<br />

• 1/2” and 3/4” single gang units suitable<br />

for Class I, Group B, in addition<br />

to Class I, Groups C and D; Class II,<br />

Groups E, F and G; and Class III.<br />

• 20Amp 4-way and all 30Amp models<br />

utilize a switch enclosed in separate<br />

sealing chamber. Smooth double-face,<br />

accurately ground surfaces on sealing<br />

chamber flange mate with cover and<br />

body to provide positive flame-tight construction.<br />

• Sealing chamber has prewired<br />

factory sealed pigtail leads to switch.<br />

• Corrosion-resistant, strong stainless<br />

steel hex-head cap screws attach<br />

cover/body/sealing chamber assembly<br />

for approved flame-tight construction.<br />

• Threaded stainless steel operating<br />

handle provides positive corrosionresistant<br />

operation.<br />

• Choice of Front-Operating or Side<br />

Rocker Arm Handle—each may be<br />

locked in ON or OFF position.<br />

Effective September, 2005<br />

Copyright 2005<br />

PAGE 2<br />

EDS Factory Sealed and EFS <strong>Tumbler</strong> <strong>Switches</strong>:<br />

<strong>Explosionproof</strong>, Dust-Ignitionproof<br />

UNILETS ® for Use with Threaded Metal Conduit.<br />

EDS Factory Sealed <strong>Tumbler</strong> <strong>Switches</strong><br />

Front Operated Rocker Arm Operated<br />

EFS Non-Sealed <strong>Tumbler</strong> <strong>Switches</strong><br />

Front Operated Rocker Arm Operated<br />

800-621-1506<br />

www.appletonelec.com

Features:<br />

EFS Non-Sealed <strong>Tumbler</strong> <strong>Switches</strong><br />

• Smooth ground mating surfaces assure<br />

flame-tight joint between cover<br />

and mounting enclosure.<br />

• Stainless steel hex-head cap<br />

screws for attaching cover to mounting<br />

enclosure.<br />

• Choice of Front-Operating or Side<br />

Rocker Arm Handle—each may be<br />

locked in ON or OFF position.<br />

• Each handle has close-tolerance<br />

threaded stainless steel shaft to meet<br />

<strong>Explosionproof</strong> requirements.<br />

• Enclosures furnished with internal<br />

ground screw.<br />

Standard Materials<br />

• EDS tumbler switches: malleable<br />

iron body and cover with aluminum<br />

sealing chamber (on select models).<br />

Handle is nylon 6/6.<br />

• EFS tumbler switches: malleable<br />

iron body and cover.<br />

Standard Finishes<br />

• EDS and EFS tumbler switches:<br />

triple-coat—(1) zinc electroplate, (2)<br />

dichromate, and (3) epoxy powder<br />

coat.<br />

Compliances:<br />

• UL Standard 894 - File E10523.<br />

• Class I, Div. 1 and 2; Class II, Div.<br />

1 and 2. See listing pages for specific<br />

groups. Conduit seals are required in<br />

Class I areas unless unit is factory<br />

sealed.<br />

• Appleton malleable iron products<br />

conform to ASTM A47-77, Grade<br />

32510, which has the following properties;<br />

tensile strength, 50,000 psi; yield,<br />

32,000 psi; and elongation, 10%.<br />

• Appleton aluminum products are<br />

produced from a high strength copper-free<br />

(4/10 of 1% max.) alloy.<br />

Product Cross Reference:<br />

• For classified-location push button,<br />

pilot light and selector switch control<br />

stations, see Catalog Section M.<br />

Effective September, 2005<br />

Copyright 2005<br />

N-3<br />

EDS Factory Sealed and EFS <strong>Tumbler</strong> <strong>Switches</strong>:<br />

<strong>Explosionproof</strong>, Dust-Ignitionproof<br />

UNILETS ® for Use with Threaded Metal Conduit.<br />

EDS explosionproof labyrith switch – used<br />

on all 20Amp models excluding 4-way.<br />

EDS factory sealed tumbler switch – shows<br />

seperate sealing chamber and switch construction.<br />

Used on 20Amp 4-pole and and<br />

all 30Amp models.<br />

EDS and EFS choice of handles – front<br />

operated or rocker arm handle.<br />

EDS and EFS handles may be locked in<br />

ON or OFF position.<br />

Ordering Information for “Custom” EDS<br />

and EFS Units<br />

Devices, covers and bodies may be<br />

ordered separately so that a different<br />

EDS Chamber/Switch Assembly<br />

or EFS Switch may be used in each<br />

gang.<br />

Order components separately as<br />

follows: (1) select body catalog<br />

number, (2) select cover catalog number,<br />

and (3) select switch or switch<br />

assembly catalog number (1-pole,<br />

2-pole, 3-way or 4-way available in<br />

listings).<br />

How to Order Hub Arrangements<br />

Simply send sketch indicating sizes<br />

and locations for brazed hubs on<br />

body or bodies selected from catalog<br />

listings. Orient sketch so that cover<br />

opening faces front and mounting lugs<br />

face upward and downward (box wall<br />

opposite cover should be referred to<br />

as the back of box).<br />

See Catalog Section M, Page 23, for additional<br />

ordering information.<br />

Bodies and Hubs Available<br />

• EDS and EFS tumbler switches<br />

may be ordered in single thru five<br />

gang deep malleable iron blank bodies<br />

with brazed hubs as specified at any<br />

location.<br />

• EDS and EFS tumbler switches may<br />

be ordered with tandem malleable iron<br />

boxes with additional brazed hubs as<br />

specified.<br />

• Standard EDS and EFS malleable<br />

iron single and two gang tumbler<br />

switches may be ordered with additional<br />

brazed hubs as specified.<br />

• EDS and EFS single and two gang<br />

tumbler switches may be ordered with<br />

aluminum boxes with additional brazed<br />

hubs as specified.<br />

800-621-1506<br />

www.appletonelec.com<br />

PAGE 3<br />

N

N<br />

N-4<br />

Class I, Div. 1 and 2,<br />

Groups B◊,C,D<br />

Class II, Div. 1 and 2,<br />

Groups E,F,G<br />

Class III<br />

NEMA 7 B CD,9EFG<br />

Effective September, 2005<br />

Copyright 2005<br />

PAGE 4<br />

EDS Factory Sealed <strong>Tumbler</strong> <strong>Switches</strong>:<br />

Front Operated;<br />

<strong>Explosionproof</strong>, Dust-Ignitionproof<br />

Malleable Iron Body and Cover.<br />

UNILETS ® for Use with Threaded Metal Conduit.<br />

Furnished with Internal Ground Screw.<br />

Hub<br />

Size,<br />

Catalog Number†<br />

Inches<br />

Single Gang<br />

Switch Dead-End Feed-Thru<br />

20-Ampere—120-277 Volt A.C.*<br />

1/2 1-Pole EDS150-F1 EDSC150-F1<br />

1/2 2-Pole EDS150-F2 EDSC150-F2<br />

1/2 3-Way EDS150-F3W EDSC150-F3W<br />

1/2 4-Way EDS150-F4W EDSC150-F4W<br />

3/4 1-Pole EDS175-F1 EDSC175-F1<br />

3/4 2-Pole EDS175-F2 EDSC175-F2<br />

3/4 3-Way EDS175-F3W EDSC175F3W<br />

3/4 4-Way EDS175-F4W EDSC175F4W<br />

1 1-Pole EDS110-F1 EDSC110-F1<br />

1 2-Pole EDS110-F2 EDSC110-F2<br />

1 3-Way EDS110-F3W EDSC110-F3W<br />

1 4-Way EDS110-F4W‡ EDSC110-F4W‡<br />

30-Ampere—120-277 Volt A.C.**<br />

3/4 1-Pole EDS175-F13‡ EDSC175-F13‡<br />

3/4 2-Pole EDS175-F23‡ EDSC175-F23‡<br />

3/4 3-Way EDS175-F3W3‡ EDSC175-F3W3‡<br />

1 1-Pole EDS110-F13‡ EDSC110-F13‡<br />

1 2-Pole EDS110-F23‡ EDSC110-F23‡<br />

1 3-Way EDS110-F3W3‡ EDSC110-F3W3‡<br />

Two Gang<br />

20-Ampere—120-277 Volt A.C.*<br />

1/2 1-Pole EDS250-F1 EDSC250-F1<br />

1/2 2-Pole ———— EDSC250-F2<br />

1/2 3-Way ———— EDSC250-F3W<br />

1/2 4-Way ———— EDSC250-F4W‡<br />

3/4 1-Pole EDS275-F1 EDSC275-F1<br />

3/4 2-Pole ———— EDSC275-F2<br />

3/4 3-Way EDS275-F3W EDSC275-F3W<br />

3/4 4-Way ———— EDSC275-F4W‡<br />

1 1-Pole EDS210-F1 EDSC210-F1<br />

1 2-Pole EDS210-F2 EDSC210-F2<br />

1 3-Way EDS210-F3W EDSC210-F3W<br />

1 4-Way EDS210-F4W EDSC210-F4W‡<br />

† For Aluminum Backbox and Cover, add Suffix - A.<br />

* 20 Amp—1 HP at 120 Volt A.C. and 2 HP at 240 Volt A.C. **30 Amp—2 HP at 120 Volt A.C. or 240 Volt A.C.<br />

◊Shaded area indicates items suitable for Class I, Group B, as well as Class I, Groups C and D; Class II, Groups E,F,G; and Class III.<br />

‡ Contains standard switch and sealing chamber.<br />

800-621-1506<br />

www.appletonelec.com

Class I, Div. 1 and 2,<br />

Groups B◊,C,D<br />

Class II, Div. 1 and 2,<br />

Groups E,F,G<br />

Class III<br />

NEMA 7 B CD,9EFG<br />

Dead-End<br />

Feed-Thru<br />

Dead-End<br />

Feed-Thru<br />

Effective September, 2005<br />

Copyright 2005<br />

EDS Factory Sealed <strong>Tumbler</strong> <strong>Switches</strong>:<br />

Rocker Arm Operated;<br />

<strong>Explosionproof</strong>, Dust-Ignitionproof<br />

Malleable Iron Body and Cover.<br />

UNILETS ® for Use with Threaded Metal Conduit.<br />

Furnished with Internal Ground Screw.<br />

N-5<br />

Hub Catalog Number<br />

Size,<br />

Inches Switch Dead-End Feed-Thru<br />

Single Gang<br />

20-Ampere—120-277 Volt A.C.*<br />

1/2 1-Pole EDS150-R1 EDSC150-R1<br />

1/2 2-Pole EDS150-R2 EDSC150-R2<br />

1/2 3-Way EDS150-R3W EDSC150-R3W<br />

1/2 4-Way EDS150-R4W‡ EDSC150-R4W‡<br />

3/4 1-Pole EDS175-R1 EDSC175-R1<br />

3/4 2-Pole EDS175-R2 EDSC175-R2<br />

3/4 3-Way EDS175-R3W EDSC175-R3W‡<br />

3/4 4-Way EDS175-R4W‡ EDSC175-R4W‡<br />

1 1-Pole EDS110-R1 EDSC110-R1<br />

1 2-Pole EDS110-R2 EDSC110-R2<br />

1 3-Way EDS110-R3W EDSC110-R3W<br />

1 4-Way EDS110-R4W‡ EDSC110-R4W‡<br />

30-Ampere—120-277 Volt A.C.**<br />

3/4 1-Pole EDS175-R13‡ EDSC175-R13‡<br />

3/4 2-Pole EDS175-R23‡ EDSC175-R23‡<br />

3/4 3-Way EDS175-R3W3‡ EDSC175-R3W3‡<br />

1 1-Pole EDS110-R13‡ EDSC110-R13‡<br />

1 2-Pole EDS110-R23‡ EDSC110-R23‡<br />

1 3-Way EDS110-R3W3‡ EDSC110-R3W3‡<br />

Two Gang<br />

20-Ampere—120-277 Volt A.C.*<br />

1/2 1-Pole EDS250-R1 EDSC250-R1<br />

1/2 2-Pole ———— EDSC250-R2<br />

1/2 3-Way ———— EDSC250-R3W<br />

1/2 4-Way ———— EDSC250-R4W<br />

3/4 1-Pole EDS275-R1 EDSC275-R1<br />

3/4 2-Pole ———— EDSC275-R2<br />

3/4 3-Way EDS275-R3W EDSC275-R3W<br />

3/4 4-Way ———— EDSC275-R4W<br />

1 1-Pole EDS210-R1 EDSC210-R1<br />

1 2-Pole EDS210-R2 EDSC210-R2<br />

1 3-Way EDS210-R3W EDSC210-R3W<br />

1 4-Way EDS210-R4W EDSC210-R4W<br />

*20 Amp—1 HP at 120 Volt A.C. and 2 HP at 240 Volt A.C. **30 Amp—2 HP at 120 Volt A.C. or 240 Volt A.C.<br />

◊ Shaded area indicates items suitable for Class I, Group B, as well as Class I, Groups C and D; Class II, Groups E,F,G; and Class III.<br />

‡ Contains standard switch and sealing chamber.<br />

800-621-1506<br />

www.appletonelec.com<br />

PAGE 5<br />

N

N<br />

N-6<br />

Class I, Div. 1 and 2,<br />

Groups C,D<br />

Class II, Div. 1 and 2,<br />

Groups E,F,G<br />

Class III<br />

NEMA 7CD,9EFG<br />

Dead-End<br />

Feed-Thru<br />

Dead-End<br />

Feed-Thru<br />

† For Aluminum Backbox and Cover, add Suffix - A.<br />

*20 Amp—1 HP at 120 Volt A.C. and 2 HP at 240 Volt A.C. **30 Amp—2 HP at 120 Volt A.C. or 240 Volt A.C.<br />

Effective September, 2005<br />

Copyright 2005<br />

PAGE 6<br />

EFS <strong>Tumbler</strong> <strong>Switches</strong>:<br />

Non-Sealed, Front Operated;<br />

<strong>Explosionproof</strong>, Dust-Ignitionproof<br />

Malleable Iron Body and Cover.<br />

UNILETS ® for Use with Threaded Metal Conduit.<br />

Furnished with Internal Ground Screw.<br />

Hub Catalog Number†<br />

Size,<br />

Inches Switch Dead-End Feed-Thru<br />

Single Gang<br />

20-Ampere—120-277 Volt A.C.*<br />

1/2 1-Pole EFS150-F1 EFSC150-F1<br />

1/2 2-Pole ———— EFSC150-F2<br />

1/2 3-Way EFS150-F3W EFSC150-F3W<br />

1/2 4-Way EFS150-F4W EFSC150-F4W<br />

3/4 1-Pole EFS175-F1 EFSC175-F1<br />

3/4 2-Pole EFS175-F2 EFSC175-F2<br />

3/4 3-Way EFS175-F3W EFSC175-F3W<br />

3/4 4-Way EFS175-F4W EFSC175-F4W<br />

30-Ampere—120-277 Volt A.C.**<br />

3/4 1-Pole EFS175-F13 EFSC175-F13<br />

3/4 2-Pole EFS175-F23 EFSC175-F23<br />

Two Gang<br />

20-Ampere—120-277 Volt A.C.*<br />

1/2 1-Pole EFS250-F1 EFSC250-F1<br />

1/2 2-Pole ———— EFSC250-F2<br />

1/2 3-Way ———— EFSC250-F3W<br />

1/2 4-Way ———— EFSC250-F4W<br />

3/4 1-Pole EFS275-F1 EFSC275-F1<br />

3/4 2-Pole ———— EFSC275-F2<br />

3/4 3-Way ———— EFSC275-F3W<br />

3/4 4-Way ———— EFSC275-F4W<br />

1 2-Pole EFS210-F2 EFSC210-F2<br />

1 3-Way EFS210-F3W EFSC210-F3W<br />

1 4-Way EFS210-F4W EFSC210-F4W<br />

30-Ampere—120-277 Volt A.C.**<br />

3/4 1-Pole EFS275-F13 EFSC275-F13<br />

3/4 2-Pole ———— EFSC275-F23<br />

1 2-Pole EFS210-F23 EFSC210-F23<br />

800-621-1506<br />

www.appletonelec.com

Class I, Div. 1 and 2,<br />

Groups C,D<br />

Class II, Div. 1 and 2,<br />

Groups E,F,G<br />

Class III<br />

NEMA 7CD,9EFG<br />

Dead-End<br />

Feed-Thru<br />

Dead-End<br />

Feed-Thru<br />

*1 HP at 120 Volt A.C.; 2 HP at 240 Volt A.C.<br />

Effective September, 2005<br />

Copyright 2005<br />

EFS <strong>Tumbler</strong> <strong>Switches</strong>:<br />

Non-Sealed, Rocker Arm Operated;<br />

<strong>Explosionproof</strong>, Dust-Ignitionproof<br />

Malleable Iron Body and Cover.<br />

UNILETS ® for Use with Threaded Metal Conduit.<br />

Furnished with Internal Ground Screw.<br />

N-7<br />

Hub Catalog Number<br />

Size,<br />

Inches Switch Dead-End Feed-Thru<br />

Single Gang<br />

20-Ampere—120-277 Volt A.C.*<br />

1/2 1-Pole EFS150-R1 EFSC150-R1<br />

1/2 2-Pole ———— EFSC150-R2<br />

1/2 3-Way EFS150-R3W EFSC150-R3W<br />

1/2 4-Way EFS150-R4W EFSC150-R4W<br />

3/4 1-Pole EFS175-R1 EFSC175-R1<br />

3/4 2-Pole EFS175-R2 EFSC175-R2<br />

3/4 3-Way EFS175-R3W EFSC175-R3W<br />

3/4 4-Way EFS175-R4W EFSC175-R4W<br />

Two Gang<br />

20-Ampere—120-277 Volt A.C.*<br />

1/2 1-Pole EFS250-R1 EFSC250-R1<br />

1/2 2-Pole ———— EFSC250-R2<br />

1/2 3-Way ———— EFSC250-R3W<br />

1/2 4-Way ———— EFSC250-R4W<br />

3/4 1-Pole EFS275-R1 EFSC275-R1<br />

3/4 2-Pole ———— EFSC275-R2<br />

3/4 3-Way ———— EFSC275-R3W<br />

3/4 4-Way ———— EFSC275-R4W<br />

1 2-Pole EFS210-R2 EFSC210-R2<br />

1 3-Way EFS210-R3W EFSC210-R3W<br />

1 4-Way EFS210-R4W EFSC210-R4W<br />

800-621-1506<br />

www.appletonelec.com<br />

PAGE 7<br />

N

N<br />

N-8<br />

Class I, Div. 1 and 2<br />

Groups C,D<br />

Class II, Div. 1 and 2<br />

Groups E,F,G<br />

Class III<br />

NEMA 7CD,9EFG<br />

Effective May, 2008<br />

Copyright 2008<br />

PAGE 8<br />

Single<br />

Gang<br />

Tandem<br />

Five Gang<br />

EDS Front Cover/<br />

Switch Assembly<br />

(Factory Assembled)<br />

EDS RockerCover/<br />

Chamber/<br />

Switch Assembly<br />

(Factory Assembled)<br />

Factory Sealed<br />

Switch Only<br />

(Factory Assembled)<br />

Two<br />

Gang<br />

EDS/EFS Mounting Bodies, Covers and Sealing<br />

Chamber/Switch Assemblies<br />

Furnished with Internal Ground Screw.<br />

Hub Size, Dead-End Catalog Numbers Feed-Thru Catalog Numbers<br />

Inches Malleable Iron Aluminum Malleable Iron Aluminum<br />

Single Gang<br />

1/2 EFD150-NL-Q EFD150A-NL-Q EFDC150-NL-Q EFDC150A-NL-Q<br />

3/4 EFD175-NL-Q EFD175A-NL-Q EFDC175-NL-Q EFDC175A-NL-Q<br />

1 EFD110-NL-Q EFD110A-NL-Q EFDC110-NL-Q EFDC110A-NL-Q<br />

Two Gang<br />

1/2 EFD250-NL-Q EFD250A-NL-Q EFDC250-NL-Q EFDC250A-NL-Q<br />

3/4 EFD275-NL-Q EFD275A-NL-Q EFDC275-NL-Q EFDC275A-NL-Q<br />

1 EFD210-NL-Q EFD210A-NL-Q EFDC210-NL-Q EFDC210A-NL-Q<br />

Tandem<br />

1/2 EFDT50-NL-Q ————— EFDCT50-NL-Q —————<br />

3/4 EFDT75-NL-Q ————— EFDCT75-NL-Q —————<br />

1 EFDT10-NL-Q ————— EFDCT10-NL-Q —————<br />

EFD Blank Bodies for Brazed Hubs<br />

Gang Cat. No.<br />

1 Gang EFD-1-NL<br />

2 Gang EFD-2-NL<br />

3 Gang EFD-3-NL<br />

4 Gang EFD-4-NL<br />

5 Gang EFD-5-NL<br />

Construct complete catalog numbers per Cat. Sec. M,<br />

page 23. Hubs will be located in center of walls and<br />

evenly spaced unless otherwise specified. Where spacings<br />

are critical, submit sketch showing exact spacing<br />

requirements.<br />

Catalog Number<br />

20 Amp 30 Amp<br />

Switch 120-277 Volt AC* 120-277 Volt AC**<br />

Type Malleable Iron Aluminum Malleable Iron Aluminum<br />

Factory Sealed Factory Sealed<br />

1-Pole EDKF21-Q† EDKF21-AQ† EDKF31-Q EDKF31-QA<br />

2-Pole EDKF22-Q† EDKF22-AQ† EDKF32-Q EDKF32-QA<br />

3-Way EDKF23W-Q† EDKF23W-AQ† EDKF33W-Q EDKF33W-QA<br />

4-Way EDKF24W-Q‡ EDKF24W-AQ — —<br />

1-Pole EDK-R21-Q† EDK-R31-Q<br />

2-Pole EDK-R22-Q† EDK-R32-Q<br />

3-Way EDK-R23W-Q† EDK-R33W-Q<br />

4-Way EDK-R24W-Q‡ —<br />

1-Pole LAB21 —<br />

2-Pole LAB22 —<br />

3-Way LAB23W —<br />

*20A <strong>Switches</strong> 1 HP at 120 Volt A.C. and 2 HP at 240 Volt A.C. **30A <strong>Switches</strong> 2 HP at 120 Volt A.C. or 240 Volt A.C.<br />

† Contains Factory Sealed Switch; no sealing chamber.<br />

‡ With sealing chamber.<br />

800-621-1506<br />

www.appletonelec.com

Front<br />

Cover<br />

Only<br />

Effective May, 2008<br />

Copyright 2008<br />

Rocker<br />

Cover<br />

Only<br />

Switch<br />

Only<br />

EFS Mounting Covers and <strong>Switches</strong><br />

Non-Factory Sealed Covers.<br />

Furnished with Device Mounting Screws.<br />

Catalog Number<br />

Switch Front Rocker<br />

Type Cover Cover Switch<br />

EFS Covers and <strong>Switches</strong> (Non-Factory Sealed)<br />

20-Ampere—120-277 Volt A.C.*<br />

N-9<br />

1-Pole EFK-F12-Q EFK-R12-Q EFS-FR1-Q<br />

2-Pole EFK-F12-Q EFK-R12-Q EFS-FR2-Q<br />

3-Way EFK-F34W-Q EFK-R34W-Q EFS-FR3W-Q<br />

4-Way EFK-F34W-Q EFK-R34W-Q EFS-FR4W-Q<br />

30-Ampere—120-277 Volt A.C.**<br />

1-Pole EFK-F12-Q EFK-R12-Q EFS-FR13-Q<br />

2-Pole EFK-F12-Q EFK-R12-Q EFS-FR23-Q<br />

3-Way EFK-F34W-Q EFK-R34W-Q EFS-FR3W3-Q<br />

*20A <strong>Switches</strong> 1HP at 120 Volt A.C. and 2 HP at 240 Volt A.C. **30A <strong>Switches</strong> 2 HP at 120 or 240 Volt A.C.<br />

For Aluminum Cover add Suffix -A.<br />

800-621-1506<br />

www.appletonelec.com<br />

PAGE 9<br />

N

N<br />

N-10<br />

Applications<br />

• For mounting on EFDB, EFS,<br />

Contender and Intraground series control<br />

stations to make circuit description/<br />

identification easy.<br />

Features<br />

• Pre-drilled holes in bottom of bracket<br />

allow direct mounting to Appleton EFDB,<br />

EFS, Contender and intraground series<br />

control stations with existing cover bolts<br />

(Intraground series bracket is mounted<br />

using nameplate screws).<br />

• Pre-drilled holes in middle of bracket<br />

allow mounting of customer’s circuit<br />

identification nameplate; epoxy glue<br />

may also be used for mounting (phenolic<br />

nameplate not included).<br />

• Nameplate mounting bracket is<br />

corrosion resistant stainless steel.<br />

• Bracket eliminates costly field installation<br />

of drilling and tapping to accommodate<br />

circuit identification nameplate.<br />

• Brackets fit side-by-side on 2, 3<br />

and 4 gang boxes and 3 Device EFD<br />

Series.<br />

Dimensions (In Inches):<br />

Catalog No. A B C D E<br />

NPBRKT-CONT 2.75 2.50 3.38 2.75 .25<br />

NPBRKT-EFDB 2.38 2.50 3.00 2.75 .25<br />

NPBRKT-<strong>N1</strong>N2 2.13 2.25 2.75 2.69 .16<br />

Effective September, 2005<br />

Copyright 2005<br />

PAGE 10<br />

NPBRKT Nameplate Mounting Bracket<br />

For use with EFDB, EFS, Contender ® and <strong>N1</strong>/N2 Series<br />

Control Stations, <strong>Tumbler</strong> <strong>Switches</strong> and Manual Motor Starters.<br />

Description Catalog Number*<br />

Nameplate Mounting Bracket for EFDB and EFS series NPBRKT-EFDB<br />

Nameplate Mounting Bracket for Contender ® and 3 Device EFD Series NPBRKT-CONT<br />

Nameplate Mounting Bracket for <strong>N1</strong>/N2 series NPBRKT-<strong>N1</strong>N2<br />

* To order bracket with either series control station or manual motor starter, add<br />

suffix–NPBRKT to end of catalog number.<br />

Secure<br />

bracket<br />

under cover<br />

screws of<br />

box.<br />

Torque<br />

cover<br />

screws to<br />

12ft - lbs.<br />

Note: Mount bracket between cover<br />

screws and cover. Do not mount bracket<br />

between ground joint flame path<br />

between cover and back box.<br />

800-621-1506<br />

www.appletonelec.com

EDS Front Operated <strong>Tumbler</strong> <strong>Switches</strong><br />

EDS Rocker Arm Operated <strong>Tumbler</strong> <strong>Switches</strong><br />

Effective September, 2005<br />

Copyright 2005<br />

Dimensions:<br />

EDS Factory Sealed <strong>Tumbler</strong> <strong>Switches</strong><br />

See Catalog Section M for Tandem Body Dimensions.<br />

N-11<br />

Dimensions Dimensions<br />

Hub in Inches In Centimeters<br />

Inches A B C A B C<br />

1/2 & 3/4 5.38 6.13 .78 13.7 15.6 2.0<br />

1 5.50 6.31 .94 14.0 16.0 2.4<br />

Dimensions Dimensions<br />

Hub in Inches In Centimeters<br />

Inches A B C A B C<br />

1/2 & 3/4 5.38 6.13 .78 13.7 15.6 2.0<br />

1 5.50 6.31 .94 14.0 16.0 2.4<br />

800-621-1506<br />

www.appletonelec.com<br />

PAGE 11<br />

N

N<br />

N-12<br />

EFS Front Operated <strong>Tumbler</strong> <strong>Switches</strong><br />

EFS Rocker Arm Operated <strong>Tumbler</strong> <strong>Switches</strong><br />

Effective September, 2005<br />

Copyright 2005<br />

PAGE 12<br />

Dimensions:<br />

EFS <strong>Tumbler</strong> <strong>Switches</strong><br />

See Catalog Section M for Tandem Body Dimensions.<br />

Dimensions Dimensions<br />

Hub in Inches In Centimeters<br />

Inches A B C A B C<br />

1/2 & 3/4 5.38 6.13 .78 13.7 15.6 2.0<br />

1 5.50 6.31 .94 14.0 16.0 2.4<br />

Dimensions Dimensions<br />

Hub in Inches In Centimeters<br />

Inches A B C A B C<br />

1/2 & 3/4 5.38 6.13 .78 13.7 15.6 2.0<br />

1 5.50 6.31 .94 14.0 16.0 2.4<br />

800-621-1506<br />

www.appletonelec.com

Class I, Div. 1 and 2<br />

Groups C,D;<br />

Class II, Div. 1 and 2<br />

Groups E,F,G<br />

Class III<br />

NEMA 3,7CD,9EFG<br />

Dead-End<br />

Feed-Thru<br />

Dead-End<br />

Feed-Thru<br />

† For Aluminum body and cover, add suffix —SA.<br />

‡ Contains Factory Sealed Switch; no sealing chamber.<br />

* 20 Amp. - 1 HP at 120 Volt A.C. and 2 HP at 240 Volt A.C.<br />

** 30 Amp. - 2 HP at 120 Volt A.C. or 240 Volt A.C.<br />

Effective September, 2005<br />

Copyright 2005<br />

N-13<br />

Contender ® Series Factory Sealed <strong>Tumbler</strong><br />

<strong>Switches</strong>, Front Operated:<br />

<strong>Explosionproof</strong>, Dust-Ignitionproof<br />

UNILETS ® for use with Threaded Metal Conduit.<br />

Malleable Iron Body and Cover ✝ . Furnished with Internal Ground.<br />

Hub Size, Catalog Number†<br />

Inches<br />

Single Gang<br />

Switch Dead-End Feed-Thru<br />

20 Ampere - 120-277 Volt A.C. *<br />

1/2 1 Pole EDS1129‡ EDSC1129‡<br />

1/2 2 Pole EDS118‡ EDSC118‡<br />

1/2 3 Way EDS1130‡ EDSC1130‡<br />

1/2 4 Way EDS1140 EDSC1140<br />

3/4 1 Pole EDS2129‡ EDSC2129‡<br />

3/4 2 Pole EDS218‡ EDSC218‡<br />

3/4 3 Way EDS2130‡ EDSC2130‡<br />

3/4 4 Way EDS2140 EDSC2140<br />

1 1 Pole EDS3129‡ EDSC3129‡<br />

1 2 Pole EDS318‡ EDSC318‡<br />

1 3 Way EDS3130‡ EDSC3130‡<br />

1 4 Way EDS3140 EDSC3140<br />

30-Ampere - 120-277 Volt A.C.**<br />

1 1 Pole EDS3591 EDSC3591<br />

1 2 Pole EDS3593 EDSC3593<br />

1 3 Way EDS3594 EDSC3594<br />

Two Gang<br />

20 Ampere - 120-277 Volt A.C. *<br />

1/2 1 Pole EDS1229‡ EDSC1229‡<br />

1/2 2 Pole EDS128‡ EDSC128‡<br />

1/2 3 Way EDS1230‡ EDSC1230‡<br />

1/2 4 Way EDS1240 EDSC1240<br />

3/4 1 Pole EDS2229‡ EDSC2229‡<br />

3/4 2 Pole EDS228‡ EDSC228‡<br />

3/4 3 Way EDS2230‡ EDSC2230‡<br />

3/4 4 Way EDS2240 EDSC2240<br />

1 1 Pole EDS3229‡ EDSC3229‡<br />

1 2 Pole EDS328‡ EDSC328‡<br />

1 3 Way EDS3230‡ EDSC3230‡<br />

1 4 Way EDS3240 EDSC3240<br />

800-621-1506<br />

www.appletonelec.com<br />

PAGE 13<br />

N

N<br />

N-14<br />

Class I, Div. 1 & 2<br />

Groups C,D;<br />

Class II, Div. 1 & 2<br />

Groups E,F,G;<br />

Class III<br />

NEMA 3,7CD,9EFG<br />

Dimensions<br />

Factory Sealed Front Cover/Chamber/Switch Assembly<br />

Cover/Switch<br />

Assembly<br />

Front<br />

Cover<br />

Only<br />

Effective September, 2005<br />

Copyright 2005<br />

PAGE 14<br />

Factory<br />

Sealed<br />

LAB<br />

Switch<br />

EFSFR<br />

Switch<br />

* 20 Amp. - 1 HP at 120 Volt A.C. and 2 HP at 240 Volt A.C.<br />

** 30 Amp. - 2 HP at 120 Volt A.C. or 240 Volt A.C.<br />

† Contains Factory Sealed Switch; no sealing chamber.<br />

Note: For Contender Series mounting boxes see page M-37.<br />

Dimensions:<br />

Contender ® Series Factory Sealed<br />

<strong>Tumbler</strong> <strong>Switches</strong><br />

Dimensions Dimensions<br />

Hub in Inches In Centimeters<br />

Inches A B C A B C<br />

1/2 & 3/4 6.06 6.81 .75 15.40 17.30 1.90<br />

1 6.17 7.03 1.00 15.70 17.90 2.50<br />

Catalog Number<br />

Switch 20 Amp 20 Amp 30 Amp<br />

Type Replacement Switch 120-277 Volt A.C.* 120-277 Volt A.C.**<br />

1 Pole LAB 21 EDSF21Q† EDSF31Q<br />

2 Pole LAB 22 EDSF22Q† EDSF32Q<br />

3 Way LAB 23W EDSF23WQ† EDSF33WQ<br />

4 Way — EDSF24WQ —<br />

Catalog Number (Non-Factory Sealed)<br />

Switch Type Front Cover Only Switch<br />

20 Amp. - 120-277 Volt A.C.*<br />

1 Pole EDSF12 EFSFR1Q<br />

2 Pole EDSF12 EFSFR2Q<br />

3 Way EDSF34W EFSFR3WQ<br />

4 Way EDSF34W EFSFR4WQ<br />

30 Amp. - 120-277 Volt A.C.**<br />

1 Pole EDSF12 EFSFR13Q<br />

2 Pole EDSF12 EFSFR23Q<br />

3 Way EDSF34W EFSFR3W3Q<br />

800-621-1506<br />

www.appletonelec.com

Applications<br />

• Listed for use in Class I, Group C<br />

and D, Division 1 and 2 atmospheres<br />

such as diethyl ether, methyl ethyl<br />

keytone, acetone, toluene, No. 3 fuel<br />

oil, ammonium hydroxide (20%),<br />

benzene, regular unleaded gas, ethyl<br />

acetate, hexane and methanol. Not<br />

suitable for ethylene dichloride and<br />

partially halogenated hydrocarbons.<br />

Sealing fittings must be field installed<br />

adjacent to enclosure on all conduit<br />

runs.†<br />

• <strong>Explosionproof</strong>. With sealing fittings<br />

installed at each conduit entrance,<br />

the <strong>N1</strong> Series enclosures withstood<br />

a hydrostatic test of four times the<br />

maximum internal explosion pressure<br />

that could be developed from a gas or<br />

vapor explosion in actual use.<br />

Features<br />

• First UL listed non-metallic tumbler<br />

switches available for Class I, Div. 1<br />

locations.<br />

• Non-metallic construction with metal<br />

imbedded grounding grid. No need<br />

to install special wires and parts for<br />

grounding. Feed-thru or dead end<br />

grounded 1/2” or 3/4” conduit openings<br />

for threaded conduit.<br />

• Special grounding wire furnished<br />

with each box provides safe grounding<br />

when cover is removed.<br />

• Ideal for use in corrosive environments.<br />

Non-metallic enclosures<br />

with corrosion resistant parts coated<br />

with epoxy, Teflon ® or Mylar ® , these<br />

switches offer unsurpassed resistance<br />

to a wide variety of corrosive<br />

chemicals.<br />

• Unique labyrinth-path construction<br />

assures flame-tight joint between body<br />

and cover.<br />

• Silicone gasket, specially designed<br />

for the labyrinth-path joint, prevents<br />

entrance of moisture without interfering<br />

with the venting of cooled hazardous<br />

gases and vapors.<br />

• Typical mechanical properties of<br />

24,500 psi tensile strength, 3% elongation<br />

at break, 33,000 psi flexural<br />

strength, and 1,200,000 psi flexural<br />

modulus.<br />

Effective September, 2005<br />

Copyright 2005<br />

Intraground ® <strong>N1</strong> Series Non-Metallic<br />

<strong>Tumbler</strong> <strong>Switches</strong>: <strong>Explosionproof</strong><br />

UNILETS ® for use with Threaded Metal Conduit.<br />

Dead-End Feed-Thru<br />

• Electrical properties of sample<br />

specimens: dielectric strength (in air)<br />

of 769 at 1/16”.<br />

• High strength thermoplastic polyetherimide,<br />

together with thick walls<br />

(5/16”) and sound structural design<br />

(rounded corners) provides superior<br />

resistance to impact and crushing.<br />

• Excellent resistance to ulraviolet<br />

light and water. After 336 hours of<br />

immersion in water at 82ûC and 720<br />

hours of exposure to ultraviolet radiation,<br />

there was no appreciable change<br />

in tensile strength.<br />

• Excellent conduit connection strength.<br />

UL pull-out and bending resistance<br />

tests resulted in no effect on conduit<br />

connections.<br />

• Excellent resistance to attack by<br />

fungi and mold.<br />

• Excellent Heat Deflection Temperature.<br />

At 264 psi, in accordance<br />

with ASTM D648 testing procedure,<br />

sample specimens rated at 410°F<br />

(the temperature required to deflect<br />

the material .01”).<br />

N-15<br />

• UL Temperature Index (continuous<br />

use temperature): 338°F electrical<br />

properties, 338°F mechanical properties<br />

with impact.<br />

• Superior flammability resistance.<br />

After five UL gas burner tests, where<br />

flame was applied directly to the box,<br />

there was no dripping of burning parts<br />

and enclosure retained its integrity.<br />

Sample specimens rated V-0 at .03”<br />

and 5V at .075”.<br />

†Sealing fittings not furnished. Order<br />

from Cat. Sec. I.<br />

800-621-1506<br />

www.appletonelec.com<br />

PAGE 15<br />

N

N<br />

N-16<br />

Features<br />

• Enclosures have external mounting<br />

lugs for ease of mounting.<br />

• Smooth, rounded integral bushing in<br />

each hub protects conductor insulation.<br />

• 20-ampere and 30-ampere units available<br />

for use with 120-277 Volt A.C.<br />

• Corrosion-resistant, strong stainless<br />

steel Teflon ® coated hex-head<br />

cap screws attach cover and body for<br />

approved flame-tight construction.<br />

• Operating handle has closetolerance<br />

threaded stainless steel<br />

shaft to meet <strong>Explosionproof</strong> requirements.<br />

Provides positive corrosionresistant<br />

operation.<br />

• Handle may be locked in ON or OFF<br />

position.<br />

Standard Materials<br />

• Body and cover: 30% glassreinforced<br />

thermoplastic polyetherimide—<br />

neutral color.<br />

• Handle: Nylon 6/6.<br />

• Cover bolts: stainless steel.<br />

• Nameplates: aluminum.<br />

Standard Finishes<br />

• Cover bolts: Teflon ® .<br />

• Nameplates: Mylar ® .<br />

Compliances:<br />

• UL Standard 894.<br />

Product Cross Reference:<br />

• For classified-location push button,<br />

pilot light and selector switch control<br />

stations, see Catalog Section M.<br />

Effective September, 2005<br />

Copyright 2005<br />

PAGE 16<br />

Intraground ® <strong>N1</strong> Series Non-Metallic <strong>Tumbler</strong><br />

<strong>Switches</strong>: <strong>Explosionproof</strong><br />

UNILETS ® for use with Threaded Metal Conduit.<br />

Aluminum grounding grid, imbedded<br />

into the non-metallic enclosure during<br />

molding, provides complete ground-<br />

Dimensions of <strong>N1</strong> Series <strong>Tumbler</strong> Switch<br />

ing system. No field work. No extra<br />

grounding wires or parts required.<br />

800-621-1506<br />

www.appletonelec.com

Class I, Div. 1 and 2<br />

Groups C,D<br />

NEMA 3,4X,7CD,12<br />

U.S. Patent 4,260,863<br />

Patented Canada 1980<br />

Cover Switch<br />

Only Only<br />

Effective September, 2005<br />

Copyright 2005<br />

N-17<br />

Intraground ® <strong>N1</strong> Series Non-Metallic<br />

<strong>Tumbler</strong> <strong>Switches</strong>, Bodies and<br />

Covers: <strong>Explosionproof</strong><br />

UNILETS ® for Use with Threaded Metal Conduit.<br />

Enclosures and Covers Have Neutral Color. Non-Factory Sealed.◊<br />

Hub Size, Catalog Number<br />

Inches† Switch Dead-End Feed-Thru<br />

Single Gang <strong>Tumbler</strong> <strong>Switches</strong><br />

20 Ampere - 120-277 Volt A.C. *<br />

1/2 or 3/4 1-Pole <strong>N1</strong>D75-F1 <strong>N1</strong>DC75-F1<br />

1/2 or 3/4 2-Pole <strong>N1</strong>D75-F2 <strong>N1</strong>DC75-F2<br />

1/2 or 3/4 3-Way <strong>N1</strong>D75-F3W <strong>N1</strong>DC75-F3W<br />

1/2 or 3/4 4-Way <strong>N1</strong>D75-F4W <strong>N1</strong>DC75-F4W<br />

30-Ampere–120-277 Volt A.C**<br />

1/2 or 3/4 1-Pole <strong>N1</strong>D75-F13 <strong>N1</strong>DC75-F13<br />

1/2 or 3/4 2-Pole <strong>N1</strong>D75-F23 <strong>N1</strong>DC75-F23<br />

1/2 or 3/4 3-Way <strong>N1</strong>D75-F3W3 <strong>N1</strong>DC75-F3W3<br />

Hub Size,<br />

Type Inches† Catalog Number<br />

Single Gang Non-Metallic Mounting Bodies<br />

For Use with covers below<br />

Dead-End 1/2 or 3/4 <strong>N1</strong>D75Q<br />

Feed-Thru 1/2 or 3/4 <strong>N1</strong>DC75Q<br />

Switch<br />

Type Cover Switch<br />

Single Gang Covers and <strong>Switches</strong><br />

All covers furnished with four bolts and blank nameplate.<br />

20-Ampere–120-277 Volt A.C.*<br />

1-Pole <strong>N1</strong>K-F12 EFS-FR1-Q<br />

2-Pole <strong>N1</strong>K-F12 EFS-FR2-Q<br />

3-Way <strong>N1</strong>K-F34W EFS-FR3W-Q<br />

4-Way <strong>N1</strong>K-F34W EFS-FR4W-Q<br />

30-Ampere–120-277 Volt A.C.**<br />

1-Pole <strong>N1</strong>K-F12 EFS-FR13-Q<br />

2-Pole <strong>N1</strong>K-F12 EFS-FR23-Q<br />

3-Way <strong>N1</strong>K-F34W EFS-FR3W3-Q<br />

◊Sealing fittings must be field installed adjacent to enclosure on all conduit runs. †Furnished with a 3/4” to 1/2” NPT reducer.<br />

*20 Amp— 1 HP at 120 Volt A.C. and 2 HP at 240 Volt A.C. **30 Amp— 2 HP at 120 Volt A.C. or 240 Volt A.C.<br />

800-621-1506<br />

www.appletonelec.com<br />

PAGE 17<br />

N

N<br />

N-18<br />

Class I, Div. 1 and 2<br />

Groups C,D<br />

NEMA 3,4X,7CD,12<br />

Applications<br />

• Short circuit protection and safe disconnect<br />

means.<br />

• Thermal time delay overload protection<br />

for branch circuits for lighting, appliance<br />

and motor circuits.<br />

• Ideal for use in corrosive atmospheres.<br />

• Designed for use in locations made<br />

hazardous by the presence of flammable<br />

gases or vapors, such as those<br />

encountered in refineries, chemical<br />

and petro-chemical plants and other<br />

processing plants.<br />

Features<br />

• 15-, 20-, and 30-ampere single pole<br />

circuit breakers for 120 VAC operation.<br />

• Dead End or Feed Thru hubs– 1/2”<br />

or 3/4”.<br />

• Furnished with lead wires for ease of<br />

connection.<br />

• Breaker mounted on cover.<br />

• Handle may be locked in ON or OFF<br />

position.<br />

• External mounting lugs for ease of<br />

installation.<br />

• Smooth, rounded integral bushing in<br />

each hub protects conductor insulation.<br />

Dimensions of <strong>N1</strong> Series Circuit Breakers<br />

Effective September, 2005<br />

Copyright 2005<br />

PAGE 18<br />

Intraground ® <strong>N1</strong> Series Non-Metallic<br />

Circuit Breakers: <strong>Explosionproof</strong><br />

Enclosures and Covers have Neutral Color. Non-Factory Sealed.◊<br />

• Corrosion-resistant, strong, stainless<br />

steel Teflon ® coated hex-head<br />

cap screws attach cover and body for<br />

approved flame-tight construction.<br />

• Operating handle has close-tolerance<br />

threaded stainless steel shaft to<br />

meet <strong>Explosionproof</strong> requirements.<br />

Standard Materials<br />

• Body and cover: 30% glass-reinforced<br />

thermoplastic polyetherimide.<br />

• Handle: Nylon 6/6<br />

• Cover bolts: stainless steel.<br />

• Nameplates: aluminum.<br />

Enclosures with Square D Type “QOU” Single Pole Breakers<br />

for 120/240 VAC Operation<br />

Standard Finishes<br />

• Cover bolts: Teflon ®<br />

• Nameplates: Mylar ®<br />

Compliances<br />

• UL Standard 698 and 877.<br />

Product Cross Reference<br />

• For full descriptions of non-metallic<br />

enclosures circuit breakers listed<br />

below, see page N-15.<br />

For classified-location push button,<br />

pilot light and selector switch control<br />

stations, see Cat. Sec. M.<br />

Hub Size Catalog Number<br />

Amp Inches† Dead-End Feed-thru<br />

15 Amp 1/2 or 3/4 <strong>N1</strong>D75-15B <strong>N1</strong>DC75-15B<br />

20 Amp 1/2 or 3/4 <strong>N1</strong>D75-20B <strong>N1</strong>DC75-20B<br />

30 Amp 1/2 or 3/4 <strong>N1</strong>D75-30B <strong>N1</strong>DC75-30B<br />

◊ Sealing fittings must be field installed adjacent to enclosure on all conduit runs. Furnished with a 3/4” to 1/2” NPT reducer.<br />

800-621-1506<br />

www.appletonelec.com

Applications<br />

• Functions as load disconnect switch<br />

or as individual motor control switch.<br />

Features<br />

• 600 Volt A.C. three-pole, non-fused<br />

motor circuit switch; available in four<br />

sizes from 30 to 200 amperes.<br />

• Hinged, removable cover provides<br />

instant access for installation and<br />

servicing.<br />

• Self-locating, spring-mounted internal<br />

handle actuator.<br />

• Rugged handle has stainless steel<br />

shaft within a stainless steel bushing;<br />

may be locked in ON or OFF position.<br />

• Removable mounting plate simplifies<br />

installation.<br />

• Top and bottom standard feed-thru<br />

conduit openings. Removable reducer<br />

bushing furnished with each opening.<br />

• Additional top and bottom openings<br />

for drain and breather supplied with<br />

close-up plugs.<br />

• Covers have captive, slotted, stainless<br />

steel screws to prevent “freezing.”<br />

• Grounded neutral lug and insulated<br />

neutral lug supplied as standard.<br />

Standard Materials<br />

• Body and cover: copper free<br />

aluminum.<br />

• Handle shaft, bushing, exposed<br />

hardware: stainless steel.<br />

Standard Finishes<br />

• Exterior surfaces: epoxy powder coat.<br />

Options<br />

• When ordering options for EDS <strong>Disconnect</strong><br />

Switch, add following suffix to<br />

catalog numbers:<br />

(30,60,100)Auxiliary switch.............-AUX<br />

(200) Auxiliary switch....................-AUX2<br />

Drain & breather set.........................-DV<br />

NEMA 4,4X......................................-N4<br />

Compliances<br />

• UL Standard 894.<br />

• Class I, Div. 1 and 2; Class II, Div.<br />

1 and 2. See listing pages for specific<br />

groups. Conduit seals required in Class<br />

I areas.<br />

• Appleton aluminum products are<br />

produced from a high strength copperfree<br />

(4/10 of 1% max.) alloy.<br />

Effective September, 2005<br />

Copyright 2005<br />

N-19<br />

EDS Heavy Duty <strong>Disconnect</strong> Switch:<br />

<strong>Explosionproof</strong>, Dust-Ignitionproof<br />

30-, 60-, 100-, and 200-Ampere Units for 600 Volt A.C. Maximum.<br />

UNILETS ® for Use with Threaded Metal Conduit.<br />

EDS20036<br />

EDS3036<br />

EDS6036<br />

EDS1036<br />

800-621-1506<br />

www.appletonelec.com<br />

PAGE 19<br />

N

N<br />

N-20<br />

Class I, Div. 1 and 2,<br />

Groups B,C,D<br />

Class II, Div. 1 and 2,<br />

Groups E,F,G<br />

Class III<br />

NEMA 3R,4 • ,4X • ,7BCD,9EFG<br />

Bolt-On<br />

Bolt-On Dimensions Electrical Ratings<br />

Max. Motor H.P.<br />

Effective September, 2005<br />

Copyright 2005<br />

PAGE 20<br />

EDS Heavy Duty <strong>Disconnect</strong> Switch:<br />

<strong>Explosionproof</strong>, Dust-Ignitionproof<br />

30-, 60-, 100-, and 200-Ampere Units for 600 Volt A.C. Maximum.<br />

UNILETS ® for Use with Threaded Metal Conduit.<br />

Ampere Conduit Opening, Inches Catalog Number•<br />

30 1-1/2 EDS3036<br />

60 2 EDS6036<br />

100 2 EDS1036<br />

200 3 EDS20036<br />

Note: Supplied with Cutler-Hammer disconnect switch.<br />

EDS Series Dimensions<br />

Maximum Horsepower Rating<br />

Max.<br />

Amp. 120VAC 240VAC 480VAC 600VAC 250VDC<br />

30 5 10 20 25 7-1/2<br />

60 10 20 40 60 15<br />

100 15 30 75 75 25<br />

200 — 60 125 150 40<br />

Dimensions in Inches Dimensions in Centimeters<br />

EDS6036 EDS6036<br />

Dim. EDS3036 EDS1036 EDS20036 EDS3036 EDS1036 EDS20036<br />

A 7.75 9.13 14.38 19.69 23.18 36.50<br />

B 8.25 9.63 15.25 20.96 24.45 38.74<br />

C† 12.13 14.13 20.13 30.80 35.88 51.12<br />

D 14.75 16.75 24.63 37.47 42.55 62.55<br />

E 6.50 7.25 10.63 16.51 18.42 26.99<br />

F 8.88 9.63 13.00 22.54 24.45 33.02<br />

G* 1.5 2. 3. — — —<br />

H 2.38 2.75 4.63 6.03 6.99 11.75<br />

J 3.75 3.75 6.75 9.53 9.53 17.15<br />

K 1.06 2.75 4.13 2.7 6.99 10.48<br />

M 6.13 7.50 12.13 15.56 19.05 30.80<br />

N 13.25 15.13 22.88 33.66 38.38 58.10<br />

P .375 .375 .625 — — —<br />

Q 1.50 1.75 2.25 3.81 4.45 5.72<br />

R 3.88 4.13 4.75 9.84 10.48 12.07<br />

† For Drains and Breathers, add 2” to dimension C. Close-up plugs furnished when enclosures are ordered without drains and breathers.<br />

* Conduit openings are tapped to size shown. A removable reducer bushing is furnished for each opening which, when installed, makes the<br />

conduit opening one size smaller.<br />

• Add suffix N4 for NEMA 4,4X rating (Not suitable for Group B).<br />

800-621-1506<br />

www.appletonelec.com

Application<br />

<strong>Explosionproof</strong> disconnect enclosures<br />

are used where hazardous materials<br />

are handled or stored. These<br />

units are used for overload and short<br />

circuit protection, control of lighting<br />

and power circuits.<br />

Features<br />

• Sand cast copper-free aluminum.<br />

• Precision machined flame path<br />

between box and cover.<br />

• Bolt on stainless steel slotted mounting<br />

feet.<br />

• Stainless steel hinges are standard.<br />

• Stainless steel, captive Quad-Lead<br />

cover bolts are standard (disengaged<br />

in 1-1/2 turns).<br />

• Ground lug package and installation<br />

instructions for termination of ground<br />

wire enclosed.<br />

• External operating handle with stops<br />

for limiting handle travel. External stainless<br />

steel operating handle on 400AF<br />

and above.<br />

• <strong>Disconnect</strong>s and operator shafts are<br />

stainless steel.<br />

• <strong>Disconnect</strong>s operators can be locked<br />

in the “On” or “Off” position (up to 3<br />

padlocks).<br />

• External flange maximizes internal<br />

space.<br />

• Standard outlets top and bottom for<br />

line and load wiring.<br />

• Plugged 1/2” outlets top and bottom<br />

for breather and drain.<br />

• <strong>Disconnect</strong>s mounted on a galvanized<br />

steel removable pan.<br />

• O-ring gasket ensures watertight<br />

integrity.<br />

Standard Materials<br />

• Bodies and covers: copper-free<br />

aluminum.<br />

• Cover bolts: stainless steel.<br />

• Hinges: stainless steel.<br />

• O-Ring: Neoprene<br />

Effective September, 2005<br />

Copyright 2005<br />

AE Series <strong>Disconnect</strong> <strong>Switches</strong>:<br />

<strong>Explosionproof</strong>, Dust-Ignitionproof<br />

Standard Finishes<br />

• Bodies and covers: Grey epoxy powder<br />

coat inside and outside standard to provide<br />

NEMA 4X rating.<br />

Compliances:<br />

• UL Standard 894<br />

• CSA Certified - Standard C22.2 No. 30<br />

N-21<br />

800-621-1506<br />

www.appletonelec.com<br />

PAGE 21<br />

N

N<br />

N-22<br />

Class I, Div. 1 and 2<br />

Groups B,C,D<br />

Class II, Div. 1 and 2<br />

Groups E,F,G<br />

Class III<br />

NEMA 4,4X,7,9<br />

<strong>Disconnect</strong> <strong>Switches</strong><br />

No. of Amp<br />

Standard<br />

Conduit<br />

Outlets<br />

Type Poles Volts Rating (Inches) Catalog Number<br />

Fused 30 1.50 AEAB3036FDS<br />

(fuses 600 Volt AC, 60 2.00 AEBB6036FDS<br />

not 3 125/250 Volt 100 2.50 AECB10036FDS<br />

included) DC 200 3.00 AEEB20036FDS<br />

30 1.50 AEAB3036DS<br />

Non- 600 Volt AC, 60 1.50 AEAB6036DS<br />

Fused 3 125/250 Volt 100 2.00 AEBB10036DS<br />

DC 200 3.00 AEEB20036DS<br />

Note: Supplied with Cutler-Hammer disconnect switch.<br />

Type J Fuses Recommended.<br />

Dimensions:<br />

Dimensions<br />

Effective May, 2008<br />

Copyright 2008<br />

PAGE 22<br />

AE Series <strong>Disconnect</strong> <strong>Switches</strong>:<br />

<strong>Explosionproof</strong>, Dust-Ignitionproof<br />

Modifications & Accessories<br />

Factory Installed Suffix Description<br />

AS1 Auxiliary Switch (1A or 1B)<br />

AS2 Auxiliary Switch (2A or 2B)<br />

BR Breather, NEMA 4X (includes outlets and installation)<br />

DN Drain, NEMA 4X (includes outlets and installation)<br />

EGS External grounding stud<br />

H Hinges stainless steel<br />

AHOF12SS Hinge Kit, 2 light duty ss hinges<br />

AHOF22SS Hinge Kit, 2 heavy duty ss hinges<br />

AHOF23SS Hinge Kit, 3 heavy duty ss hinges<br />

NP Plastic nameplate, 2” x 4”, 1/8” black letters<br />

on white surface, 3 lines max. specify legend.<br />

ST Shunt trip (specify voltage)<br />

UV Under voltage release (specify voltage)<br />

Electrical Ratings Max. Motor H.P.<br />

Maximum Horsepower Rating<br />

Max.<br />

Amp. 120VAC 240VAC 480VAC 600VAC 250VDC<br />

30 5 10 20 25 7-1/2<br />

60 10 20 40 60 15<br />

100 15 30 75 75 25<br />

200 — 60 125 150 40<br />

Enclosure Catalog Mounting Dimensions Inside Dimensions Outside Dimensions Number K Approx.<br />

Size No A B J C D E F G H of Outlets Dim. Wt. (lbs.)<br />

A AEAB 5.50 13.13 14.13 6.13 10.75 5.25 10.63 15.25 8.84 2 2.00 38<br />

B AEBB 6.00 18.00 19.00 6.50 16.00 5.50 11.00 20.50 8.97 2 2.31 57<br />

C AECB 10.25 22.63 n/a 11.38 20.00 6.38 16.38 25.13 9.59 2 3.50 104<br />

E AEEB 8.50 27.13 n/a 11.25 29.88 7.63 16.00 29.50 12.28 2 4.00 145<br />

All dimensions are in inches.<br />

800-621-1506<br />

www.appletonelec.com

Class I, Div. 1 and 2<br />

Group D<br />

Class II, Div. 1 and 2<br />

Groups E,F,G<br />

Class III<br />

NEMA 7D, 9EFG<br />

Applications<br />

• For heavy-duty usage. Units<br />

available for disconnect use up to<br />

20 H.P. at 600 Volt A.C.<br />

• For controlling motors and other<br />

apparatus.<br />

• Confines arcing of switch, if any, to<br />

enclosure interior.<br />

• For use in such classified locations<br />

as paint and varnish plants, grain elevators,<br />

coal or grain processing, gasoline<br />

bulk loading terminals and metal<br />

finishing areas.<br />

Features<br />

• Heavy-duty disconnect use up to<br />

600V A.C.<br />

• Compact design permits use in<br />

cramped quarters as on machinery.<br />

• Threaded cover provides easy<br />

access for wiring and maintenance.<br />

• Provided with mounting lugs.<br />

• Smooth, rounded integral bushing in<br />

each hub protects conductor insulation.<br />

• Accurately tapped, tapered hubs for<br />

tight, rigid joints and ground continuity.<br />

• Threaded stainless steel shaft for<br />

operating handle.<br />

• Lockable operating handle.<br />

Standard Materials<br />

• GUSC body: malleable iron.<br />

• GUSC cover: aluminum.<br />

Standard Finishes<br />

• GUSC body: triple-coat (1) zinc<br />

electroplate, (2) dichromate, and (3)<br />

epoxy powder coat.<br />

• GUSC cover: natural finish.<br />

Compliances<br />

• UL Standard 894.<br />

• Class I, Div. 1 and 2; Class II, Div. 1<br />

and 2. See listings at top of this page<br />

for specific groups. Conduit seals required<br />

in Class I areas.<br />

• Appleton malleable iron products<br />

conform to ASTM A47-77, Grade<br />

32510, which has the following properties:<br />

tensile strength, 50,000 psi: yield,<br />

32,000 psi; and elongation, 10%.<br />

• Appleton aluminum products are<br />

produced from a high strength copperfree<br />

(4/10 of 1% max.) alloy.<br />

Effective September, 2005<br />

Copyright 2005<br />

N-23<br />

GUSC Heavy Duty <strong>Tumbler</strong> <strong>Switches</strong>:<br />

<strong>Explosionproof</strong>, Dust-Ignitionproof<br />

30 Amp, 600V AC UNILETS ® for Use with Rigid Metal Conduit and IMC.<br />

Hub Size, Switch Catalog<br />

Inches Switch Rating Number<br />

3/4 2-Pole 30 Amperes, 600V A.C. GUSC75-2<br />

3 H.P., 240V A.C.<br />

7-1/2 H.P., 480V A.C.<br />

10 H.P., 600V A.C.<br />

3/4 3-Pole 30 Amperes, 600V A.C. GUSC75-3<br />

7-1/2 H.P., 240V A.C.<br />

15 H.P., 480V A.C.<br />

20 H.P., 600V A.C.<br />

Dimensions<br />

GUSC<br />

Feed-Thru Only<br />

Dimensions in Inches Dimensions in Centimeters<br />

Switch A B C D E A B C D E<br />

2- and 3-pole 6.06 5.63 4.19 3.94 4.63 15.4 14.3 10.6 10.0 11.7<br />

800-621-1506<br />

www.appletonelec.com<br />

PAGE 23<br />

N

N<br />

N-24<br />

AFUX Series<br />

Class I, Div. 1 and 2<br />

Groups C,D<br />

Class II, Div. 1 and 2<br />

Groups E,F,G<br />

Class III<br />

NEMA 7CD, 9EFG<br />

AFU Series<br />

NEMA 3,4,4X<br />

Applications<br />

• Emergency stop or normal stop<br />

switch for conveyor lines, cranes,<br />

unloaders and bulk handling systems.<br />

• Where alarm or computer interface<br />

capabilities are needed.<br />

• Used in the control circuit of<br />

magnetic motor starters to shut down<br />

motor-driven conveyors or other<br />

machinery.<br />

• For use in steel mills, mining ore<br />

and coal handling operations; automotive<br />

and other assembly lines;<br />

warehouses, loading docks and other<br />

industrial processes.<br />

• AFUX Series is used in Class I and<br />

II areas where flammable vapors or<br />

highly combustible dusts are present.<br />

• AFU Series has a gasketed cover<br />

rated for NEMA 3, 3R, 4, 4X.<br />

Features<br />

• Rugged Torsion Spring for positive<br />

actuation of Flag Arm.<br />

• Stainless steel bushing may be<br />

easily reversed to increase or decrease<br />

actuation force (15 or 25 lbs.)<br />

• Maximum distance between switches<br />

should not exceed 200 feet.<br />

• Available with two switch types:<br />

A) Two circuit double break switch is<br />

rated 15 Amp, 120, 240, 480, 600 VAC,<br />

0.5 HP 120 VAC, 1 HP 240 VAC, 0.8A<br />

115 VDC, 0.4A 230 VDC.<br />

B) Single pole/double throw switch is<br />

rated 20 Amp, 125, 250, 480VAC, 10<br />

Amp 125 VAC “L” tungsten lamp load,<br />

1 HP 125 VAC, 2 HP 250 VAC, 0.5 A<br />

125 VDC, 0.25 A 250 VDC.<br />

• Switch temperature range -40°F to<br />

150°F (-40°C to 66°C).<br />

• Two 1” conduit openings (top and<br />

bottom).<br />

Standard Materials<br />

• Cast aluminum housing.<br />

• Flag arm is steel with red epoxy paint.<br />

• Stainless steel actuator shaft,<br />

retaining ring, clevis loop and torsion<br />

springs.<br />

Standard Finishes<br />

• Standard enclosure is peened;<br />

epoxy powder coat optional.<br />

Effective May, 2008<br />

Copyright 2008<br />

PAGE 24<br />

AFU, AFUX Conveyor Control <strong>Switches</strong><br />

Pull Cord Type, Left or Right Hand, Single or Double End.<br />

Options<br />

• When using in dimly lit applications,<br />

add suffix -L for red warning light (uses<br />

top conduit opening).<br />

• To order epoxy powder coated<br />

switches add suffix -S752.<br />

Accessories<br />

• AFUTSL, AFUTSR: Replacement<br />

torsion springs- left, right.<br />

• PLG100-S: Conduit plug.<br />

• AFUMB: Pull-cord switch mounting<br />

bracket.<br />

Double End Unit<br />

Right and Left Handed<br />

with Option Warning Light<br />

AFU or AFUX<br />

Left Hand Single Unit Right Hand Single Unit<br />

Compliances<br />

• UL Listed: Files #E164877,<br />

#E10449.<br />

• CSA Certified.<br />

• UL Standards 508,698.<br />

800-621-1506<br />

www.appletonelec.com

AFUX Series<br />

Class I, Div. 1 and 2<br />

Groups C,D<br />

Class II, Div. 1 and 2<br />

Groups E,F,G<br />

Class III<br />

NEMA 7CD, 9EFG<br />

AFU Series<br />

NEMA 3,4,4X<br />

Effective September, 2005<br />

Copyright 2005<br />

AFU, AFUX Conveyor Control <strong>Switches</strong><br />

Pull Cord Type, Left or Right Hand, Single or Double End.<br />

N-25<br />

No. of Two Circuit<br />

Location Type<br />

Left or Right<br />

15 Pound Pull Force- Single End<br />

Double Break<br />

Micro <strong>Switches</strong><br />

Ordinary Hazardous<br />

Left 1 AFU0333-10 AFUX0333-10<br />

Right 1 AFU0333-01 AFUX0333-01<br />

Left 2 AFU0333-50 AFUX0333-50<br />

Right<br />

15 Pound Pull Force- Double End<br />

2 AFU0333-05 AFUX0333-05<br />

Double End 1, each end AFU0333-11 AFUX0333-11<br />

Double End<br />

25 Pound Pull Force- Single End<br />

2, each end AFU0333-55 AFUX0333-55<br />

Left 1 AFU0333-20 AFUX0333-20<br />

Right 1 AFU0333-02 AFUX0333-02<br />

Left 2 AFU0333-60 AFUX0333-60<br />

Right<br />

25 Pound Pull Force- Double End<br />

2 AFU0333-06 AFUX0333-06<br />

Double End 1, each end AFU0333-22 AFUX0333-22<br />

Double End 2, each end AFU0333-66 AFUX0333-66<br />

No. of Single Pole,<br />

Location Type<br />

Left or Right<br />

15 Pound Pull Force- Single End<br />

Double Throw Micro<br />

<strong>Switches</strong><br />

Ordinary Hazardous<br />

Left 1 AFU0333-30 AFUX0333-30<br />

Right 1 AFU0333-03 AFUX0333-03<br />

Left 2 AFU0333-70 AFUX0333-70<br />

Right<br />

15 Pound Pull Force- Double End<br />

2 AFU0333-07 AFUX0333-07<br />

Double End 1, each end AFU0333-33 AFUX0333-33<br />

Double End<br />

25 Pound Pull Force- Single End<br />

2, each end AFU0333-77 AFUX0333-77<br />

Left 1 AFU0333-40 AFUX0333-40<br />

Right 1 AFU0333-04 AFUX0333-04<br />

Left 2 AFU0333-80 AFUX0333-80<br />

Right<br />

25 Pound Pull Force- Double End<br />

2 AFU0333-08 AFUX0333-08<br />

Double End 1, each end AFU0333-44 AFUX0333-44<br />

Double End 2, each end AFU0333-88 AFUX0333-88<br />

800-621-1506<br />

www.appletonelec.com<br />

PAGE 25<br />

N

N<br />

N-26<br />

Accessories<br />

Dimensions<br />

Effective September, 2005<br />

Copyright 2005<br />

PAGE 26<br />

Accessories and Dimensions:<br />

AFU, AFUX Conveyor Control <strong>Switches</strong><br />

Pull Cord Type, Left or Right Hand, Single or Double End.<br />

Description Catalog Number<br />

Mounting Bracket AFUMB<br />

Replacement Torsion Spring — Left AFUTSL<br />

Replacement Torsion Spring — Right AFUTSR<br />

Conduit Plug 1”—11-1/2 N.P.T. PLG100-S<br />

15#<br />

<br />

800-621-1506<br />

www.appletonelec.com

Typical Application<br />

Right End<br />

Unit<br />

Right Hand Single Unit<br />

(with option Warning Lamp)<br />

Wiring Information<br />

Single Pole, Double Throw Micro Switch<br />

Rating: 20 AMPS, 125, 250 or 480 VAC •<br />

10 AMPS, 125 VAC “L” (tungsten lamp load)<br />

• 1 HP, 125 VAC • 2 HP, 250 VAC • 1/2<br />

AMP, 125 VDC • 1/4 AMP, 250 VDC<br />

Two Circuit, Double Break Micro Switch<br />

Rating: 15 AMPS, 120, 240, 480 or 600<br />

VAC • 1/2 HP, 120 VAC • 1 HP, 240 VAC •<br />

0.8 AMPS, 115 VDC • 0.4 AMP, 230 VDC<br />

0.8, 250 VAC • 1/2 AMP, 125 VDC • 1/4 AMP, 250<br />

VDC<br />

Effective September, 2005<br />

Copyright 2005<br />

AFU, AFUX Conveyor Control <strong>Switches</strong><br />

Pull Cord Type, Left or Right Hand, Single or Double End.<br />

Double End Unit<br />

200’ Maximum 200’ Maximum<br />

Double End Unit Right and Left Handed<br />

(with option Warning Lamp)<br />

SINGLE POLE, DOUBLE THROW CIRCUIT<br />

<br />

TWO CIRCUIT, DOUBLE BREAK CIRCUIT<br />

MOTOR CONTROL CIRCUIT WARNING CIRCUIT<br />

N-27<br />

Left End<br />

Unit<br />

Left Hand Single Unit<br />

(with option Warning Lamp)<br />

NOTE: Two circuit double break switches must be wired to equal voltage sources and the same polarity. Loads should be on the same side<br />

of the lines. 1B has the same polarity as 3A.<br />

800-621-1506<br />

www.appletonelec.com<br />

PAGE 27<br />

N

N<br />

N-28<br />

Class I, Div. 1 and 2;<br />

Groups C,D<br />

Class II, Div. 1 and 2;<br />

Groups E,F,G<br />

Class III<br />

NEMA 7CD,9EFG<br />

Applications<br />

• For use in bulk material handling/<br />

processing systems to monitor speeds<br />

of belt conveyors, screw conveyors,<br />

bucket elevators and rotating machinery.<br />

• Used where alarm or computer<br />

interface capabilities are needed.<br />

• For installation in steel mills,<br />

mining (ore and coal) operations,<br />

grain handling, chemical and plastic<br />

industries to protect elevators,<br />

feeders, and conveyors from speed<br />

related damage resulting from broken<br />

belts, overloads or belt slippage.<br />

• For installation in mining and<br />

industrial areas where rugged control<br />

enclosures are needed for protection<br />

from falling ores, other heavy aggregates<br />

and from dripping water or hosedowns.<br />

• Used in Class I and II areas where<br />

flammable vapors or highly combustible<br />

dusts are present.<br />

• Designed to monitor material flow by<br />

sequencing the operation of multiple<br />

conveyors feeding a common bin or<br />

conveyor.<br />

• Used as overspeed switches to<br />

detect motor overrun conditions:<br />

Pick-up speed should be set above<br />

normal operating speeds. The output<br />

relay will energize if operating speed<br />

exceeds the set-point.<br />

• Used as underspeed switches to<br />

detect slipping belts, jammed<br />

conveyors or equipment and stalled<br />

motors: Pick-up speed setting should<br />

be below normal operating speeds.<br />

The output relay will de-energize if<br />

operating speed falls below the setpoint.<br />

• Used as zero speed switch: When<br />

speed approaches zero (0.1 RPM), the<br />

output relay will de-energize.<br />

Features<br />

• Signal range: three settings available.<br />

(0.1-10 RPM; 1-100 RPM; 10-1000<br />

RPM)<br />

•Adjustable time delay. (up to 45 sec)<br />

• Input power is applied to the speed<br />

responsive switch at all times. The<br />

switch then senses input shaft speed<br />

in either direction.<br />

Effective June, 2008<br />

Copyright 2008<br />

PAGE 28<br />

AFSX Speed Responsive Switch<br />

0.1–1000 RPM.<br />

AFSX300<br />

Typical Application<br />

• When input shaft speed exceeds<br />

the pick-up set-point, the output relay<br />

is energized.<br />

• If shaft speed falls below 80-85%<br />

of the pick-up speed the relay will<br />

de-energize.<br />

• Clockwise or counter-clockwise<br />

rotation.<br />

• Senses speed changes as slight<br />

as 1%.<br />

• Operating temperatures are -50°F to<br />

150°F.<br />

• 3/4” NPT standard, two conduit<br />

openings.<br />

• Radial load is 125 lb. maximum at<br />

center of the key.<br />

• Axial thrust load is 100 pound<br />

maximum.<br />

• Driving torque required is one inchpound<br />

maximum.<br />

• Flexible coupling accessory allows<br />

up to 7.5 degree misalignment, high<br />

shock resistance and eliminates transmission<br />

of thrust loads.<br />

800-621-1506<br />

www.appletonelec.com

Class I, Div. 1 and 2;<br />

Groups C,D<br />

Class II, Div. 1 and 2;<br />

Groups E,F,G<br />

Class III<br />

NEMA 7CD,9EFG<br />

Electrical Specifications<br />

• Input voltage is 105-135 VAC,<br />

50-60 Hz.<br />

• Output is a double pole, double<br />

throw relay rated 5 Amp resistive at<br />

120VAC, 5 Amp at 240 VAC, 5 Amp at<br />

30 VDC.<br />

• Repeatability is +/-2% maximum at<br />

constant voltage and temperature.<br />

• Power consumption is 3 watts<br />

maximum.<br />

• Pulse sensor (solid state optoelectric<br />

infrared device) operating life<br />

is 25 years if constant operation is at<br />

maximum speed.<br />

• Pick-up speed is adjustable by<br />

setpoint potentiometer.<br />

Material<br />

Catalog<br />

Number<br />

Copper-free aluminum AFSX300<br />

Optional Flexible Coupling<br />

This coupling will operate at up to a 7-1/2° axial misalignment with no significant life<br />

reduction. This unit features high shock resistance and eliminates transmission of lateral<br />

thrust 3/8"<br />

from one shaft to the other (no<br />

e n d thrust).<br />

Sleeve: With axially molded internal<br />

3” teeth.<br />

1-5/8" rein- 5/8" Bore<br />

Made of neoprene with textile<br />

1-11/16"<br />

forcement.<br />

T w o end fittings grooved to mate with sleeve<br />

teeth. One fitting attached to each shaft.<br />

AFSC1<br />

Effective June, 2008<br />

Copyright 2008<br />

2-3/4"<br />

AFSX Speed Responsive Switch<br />

0.1–1000 RPM.<br />

• Drop-out RPM will be 10-15%<br />

lower than pick-up speed to account<br />

for normal fluctuations in actual operating<br />

RPM.<br />

• If a signal is required within 1-15%<br />

of the normal operating speed, consult<br />

factory for presetting.<br />

Standard Materials<br />

• Cast aluminum housing also<br />

available with corrosion resistant epoxy<br />

powder coat.<br />

• Shaft is stainless steel, 5/8”<br />

diameter, #11 Woodruff Key stainless<br />

steel hardware.<br />

• Flexible coupling is cast zinc.<br />

• Sleeve is neoprene with textile<br />

reinforcement.<br />

N-29<br />

Standard Finishes<br />

• Standard enclosure is shot peened.<br />

Options<br />

• For epoxy powder coated switches,<br />

add suffix -G1.<br />

Accessories<br />

• Mounting Bracket: AFSA1, AFSB1,<br />

AFSB2, AFSB3.<br />

• Flexible coupling: AFSC1.<br />

• Coupling Guard: AFSG1.<br />

• Stub shaft: AFSS1.<br />

Compliances<br />

• UL Standards 508,698.<br />

Stub Shaft<br />

3” threaded one end, keyed other end.<br />

With jam nut and 3/16” key.<br />

AFSS1<br />

3”<br />

with Jam Nut and 3/16” Key<br />

5/8” Dia.<br />

800-621-1506<br />

www.appletonelec.com<br />

PAGE 29<br />

N

N<br />

N-30<br />

Suggested Mounting Arrangement<br />

Bearing All Dimensions are in inches<br />

Bracket<br />

and Shim Shaft<br />

Plate Part # Diameter A B C D E F G H<br />

AFSB1 1-7/16 1-1/4 - 2 1-7/8 - 2-1/8 3-1/8 1-1/8 2-11/16 1-13/16 9/16 W x 1-5/16 Lg.<br />

AFSB2 1-15/16 - 2-7/16 1-1/2 - 2-9/16 2-1/4 - 3 3-3/4 1-5/8 3-11/16 1-15/16 13/32 x 1 Lg. 13/16 W x 2 Lg.<br />

AFSB3 2-15/16 - 3-15/16 3 - 3-3/4 3-1/8 - 4-1/8 4-1/2 2-3/16 4-13/16 2-11/16 1-1/16 W x 2-9/16 Lg.<br />

Mounting Dimensions<br />

4.875<br />

4.750<br />

REAR VIEW<br />

Effective September, 2005<br />

Copyright 2005<br />

PAGE 30<br />

2.000<br />

1.261<br />

Dimensions:<br />

AFSX Speed Responsive Switch<br />

0.1–1000 RPM.<br />

SIDE VIEW<br />

8.980<br />

0.375<br />

.750 NPT PIPE TAP<br />

(BOTH SIDES)<br />

REAR VIEW<br />

0.875<br />

AFSG1<br />

(Coupling Guard)<br />

1.250<br />

1.250<br />

2.250<br />

0.312<br />

dia.<br />

MOUNTING HOLE PLAN<br />

3.500<br />

800-621-1506<br />

www.appletonelec.com

AFAX Series<br />

Class I, Div. 1 and 2<br />

Groups C,D<br />

Class II, Div. 1 and 2<br />

Groups E,F,G<br />

Class III<br />

NEMA 7CD, 9EFG<br />

AFA Series<br />

NEMA 3,4,4X<br />

Applications<br />

• Emergency stop switch for conveyor<br />

lines and bulk handling systems<br />

which become misaligned or run off<br />

their tracks due to excessive speed,<br />

uneven load, leveling, breakage or<br />

other problems.<br />

• Used where alarm or computer interface<br />

capabilities are needed.<br />

• Used in the control circuit of magnetic<br />

motor starters to shut down motordriven<br />

conveyors in case of abnormal<br />

belt misalignment or run-off.<br />

• For installation in steel mills,<br />

mining (ore and coal) handling operations;<br />

automotive and other assembly<br />

lines; and warehouses, loading docks<br />

and other industrial processes.<br />

• AFAX Series is used in Class I and<br />

II areas where flammable vapors or<br />

highly combustible dusts are present.<br />

• AFA Series has a gasketed cover<br />

rated for NEMA 3, 3R, 4 and 4X.<br />

• Unit is used in pairs with one switch<br />

placed on each side of the conveyor<br />

belt. Recommended installation locates<br />

switches near the tail and head pulleys<br />

on conveyors 300 ft. and longer.<br />

Features<br />

AFA10, AFA20, AFAX10, AFAX20:<br />

• Each unit can be equipped with<br />

two micro switches to produce signals<br />

indicating belt misalignment at two<br />

deviation points.<br />

• The first signal point could indicate<br />

small belt deviations by sounding an<br />

alarm.<br />

• The second signal point could guard<br />

against extreme belt runoff by shutting<br />

down the conveyor.<br />

• Operating arm has 9.75’’ high and<br />

1.25’’ diameter roller and moves 90<br />

degrees in both directions.<br />

• 3/4’’ NPT standard conduit opening.<br />

• Spring loaded arm returns to original<br />

position when belt is realigned.<br />

AFA1, AFA2, AFAX1, AFAX2:<br />

• Roller is 3.5’’ high and actuates with<br />

0.25’’ travel.<br />

• Unit should be mounted about 1’’<br />

from belt to eliminate false signals.<br />

• Operating temperatures are -40°F to<br />

150°F.<br />

• 1/2’’ NPT standard, one conduit<br />

opening.<br />

Effective May, 2008<br />

Copyright 2008<br />

N-31<br />

AFA, AFAX Conveyor Belt Alignment <strong>Switches</strong><br />

Post Style or Large Roller Style.<br />

AFA10 AFAX10<br />

AFA20 AFAX20<br />

Post Style<br />

(no accessories)<br />

Standard Materials<br />

AFA10, AFA20, AFAX10, AFAX20:<br />

• Cast aluminum housing.<br />

• Actuating arm contains a red epoxy<br />

coated steel roller with stainless steel<br />

shaft.<br />