Wear-resistant steels - voestalpine

Wear-resistant steels - voestalpine

Wear-resistant steels - voestalpine

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

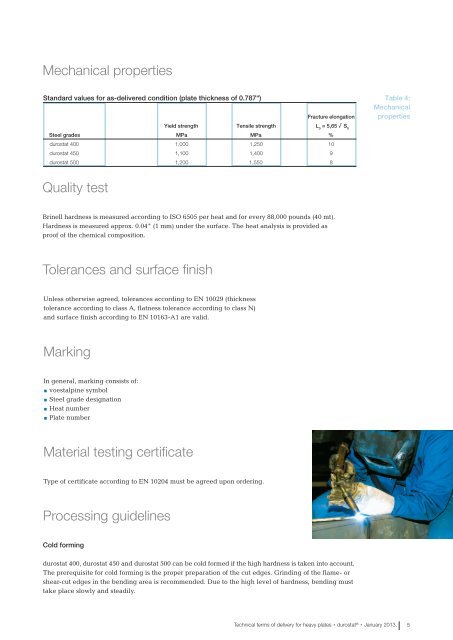

Mechanical properties<br />

Standard values for as-delivered condition (plate thickness of 0.787")<br />

Quality test<br />

Brinell hardness is measured according to ISO 6505 per heat and for every 88,000 pounds (40 mt).<br />

Hardness is measured approx. 0.04" (1 mm) under the surface. The heat analysis is provided as<br />

proof of the chemical composition.<br />

Tolerances and surface finish<br />

Unless otherwise agreed, tolerances according to EN 10029 (thickness<br />

tolerance according to class A, flatness tolerance according to class N)<br />

and surface finish according to EN 10163-A1 are valid.<br />

Marking<br />

In general, marking consists of:<br />

<strong>voestalpine</strong> symbol<br />

Steel grade designation<br />

Heat number<br />

Plate number<br />

Material testing certificate<br />

Type of certificate according to EN 10204 must be agreed upon ordering.<br />

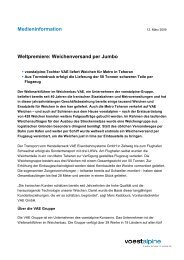

Processing guidelines<br />

Cold forming<br />

Fracture elongation<br />

Yield strength Tensile strength L 0 = 5,65 √ S 0<br />

Steel grades MPa MPa %<br />

durostat 400 1,000 1,250 10<br />

durostat 450 1,100 1,400 9<br />

durostat 500 1,200 1,550 8<br />

durostat 400, durostat 450 and durostat 500 can be cold formed if the high hardness is taken into account.<br />

The prerequisite for cold forming is the proper preparation of the cut edges. Grinding of the flame- or<br />

shear-cut edges in the bending area is recommended. Due to the high level of hardness, bending must<br />

take place slowly and steadily.<br />

Table 4:<br />

Mechanical<br />

properties<br />

Technical terms of delivery for heavy plates durostat ® January 2013.<br />

5