hanit® - Hahn Kunststoffe GmbH

hanit® - Hahn Kunststoffe GmbH

hanit® - Hahn Kunststoffe GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2<br />

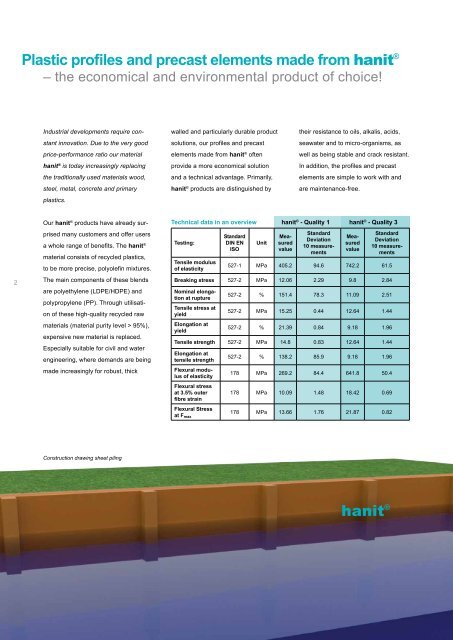

Plastic profiles and precast elements made from hanit ®<br />

– the economical and environmental product of choice!<br />

Industrial developments require constant<br />

innovation. Due to the very good<br />

price-performance ratio our material<br />

hanit ® is today increasingly replacing<br />

the traditionally used materials wood,<br />

steel, metal, concrete and primary<br />

plastics.<br />

Our hanit ® products have already sur-<br />

prised many customers and offer users<br />

a whole range of benefits. The hanit ®<br />

material consists of recycled plastics,<br />

to be more precise, polyolefin mixtures.<br />

The main components of these blends<br />

are polyethylene (LDPE/HDPE) and<br />

polypropylene (PP). Through utilisation<br />

of these high-quality recycled raw<br />

materials (material purity level > 95%),<br />

expensive new material is replaced.<br />

Especially suitable for civil and water<br />

engineering, where demands are being<br />

made increasingly for robust, thick<br />

Construction drawing sheet piling<br />

walled and particularly durable product<br />

solutions, our profiles and precast<br />

elements made from hanit ® often<br />

provide a more economical solution<br />

and a technical advantage. Primarily,<br />

hanit ® products are distinguished by<br />

Testing:<br />

Standard<br />

DIN EN<br />

ISO<br />

Unit<br />

Measured<br />

value<br />

their resistance to oils, alkalis, acids,<br />

seawater and to micro-organisms, as<br />

well as being stable and crack resistant.<br />

In addition, the profiles and precast<br />

elements are simple to work with and<br />

are maintenance-free.<br />

Technical data in an overview hanit ® - Quality 1 hanit ® - Quality 3<br />

Tensile modulus<br />

of elasticity<br />

Standard<br />

Deviation<br />

10 measurements<br />

Measured<br />

value<br />

Standard<br />

Deviation<br />

10 measurements<br />

527-1 MPa 405.2 94.6 742.2 61.5<br />

Breaking stress 527-2 MPa 12.06 2.29 9.8 2.84<br />

Nominal elongation<br />

at rupture<br />

Tensile stress at<br />

yield<br />

Elongation at<br />

yield<br />

527-2 % 151.4 78.3 11.09 2.51<br />

527-2 MPa 15.25 0.44 12.64 1.44<br />

527-2 % 21.39 0.84 9.18 1.96<br />

Tensile strength 527-2 MPa 14.8 0.83 12.64 1.44<br />

Elongation at<br />

tensile strength<br />

Flexural modulus<br />

of elasticity<br />

Flexural stress<br />

at 3.5% outer<br />

fibre strain<br />

Flexural Stress<br />

at Fmax<br />

527-2 % 138.2 85.9 9.18 1.96<br />

178 MPa 269.2 84.4 641.8 50.4<br />

178 MPa 10.09 1.48 18.42 0.69<br />

178 MPa 13.66 1.76 21.87 0.82