- Page 1 and 2:

Source: STANDARD HANDBOOK OF MACHIN

- Page 3 and 4:

EVOLUTION OF A SUCCESSFUL DESIGN EV

- Page 5 and 6:

Flywheels are an important machine

- Page 7 and 8:

EVOLUTION OF A SUCCESSFUL DESIGN sp

- Page 9 and 10:

Source: STANDARD HANDBOOK OF MACHIN

- Page 11 and 12:

GLOSSARY OF SYMBOLS CHAPTER 2 A THE

- Page 13 and 14:

(a) A THESAURUS OF MECHANISMS 2.5 (

- Page 15 and 16:

(c) A THESAURUS OF MECHANISMS A THE

- Page 17 and 18:

(g) (l) (c) (e) A THESAURUS OF MECH

- Page 19 and 20:

(a) (g) (c) A THESAURUS OF MECHANIS

- Page 21 and 22:

(a) (c) (e) A THESAURUS OF MECHANIS

- Page 23 and 24:

(e) (a) (i) A THESAURUS OF MECHANIS

- Page 25 and 26:

(b) A THESAURUS OF MECHANISMS (d) A

- Page 27 and 28:

(a) (f) A THESAURUS OF MECHANISMS A

- Page 29 and 30:

(a) A THESAURUS OF MECHANISMS A THE

- Page 31 and 32:

(c) (a) A THESAURUS OF MECHANISMS A

- Page 33 and 34:

(c) (f) (i) A THESAURUS OF MECHANIS

- Page 35 and 36:

A THESAURUS OF MECHANISMS (a) A THE

- Page 37 and 38:

(a) (d) (j) (g) A THESAURUS OF MECH

- Page 39 and 40:

CHAPTER 3 LINKAGES Richard E. Gusta

- Page 41 and 42:

(a) (c) where l = number of links (

- Page 43 and 44:

(a) (c) LINKAGES LINKAGES 3.5 FIGUR

- Page 45 and 46:

Since both sides of (3.5) can be di

- Page 47 and 48:

The driven link d will be at angle

- Page 49 and 50:

LINKAGES FIGURE 3.8 Two positions o

- Page 51 and 52:

LINKAGES LINKAGES 3.13 FIGURE 3.10

- Page 53 and 54:

LINKAGES FIGURE 3.12 Determining th

- Page 55 and 56:

of motion. Proper care in selection

- Page 57 and 58:

4. With O B as vertex, set off a li

- Page 59 and 60:

3. Determine lines S ab(ab) and S a

- Page 61 and 62:

LINKAGES LINKAGES 3.23 3.13 John J.

- Page 63 and 64:

CHAPTER 4 CAM MECHANISMS Andrzej A.

- Page 65 and 66:

FIGURE 4.3 Plate cams with oscillat

- Page 67 and 68:

FIGURE 4.6 Types of follower motion

- Page 69 and 70:

CAM MECHANISMS CAM MECHANISMS 4.7 F

- Page 71 and 72:

CAM MECHANISMS CAM MECHANISMS 4.9 F

- Page 73 and 74:

the motion specification for the ri

- Page 75 and 76:

CAM MECHANISMS CAM MECHANISMS 4.13

- Page 77 and 78:

CAM MECHANISMS 4.15 This is called

- Page 79 and 80:

CAM MECHANISMS CAM MECHANISMS 4.17

- Page 81 and 82:

It is a common rule of thumb to ass

- Page 83 and 84:

CAM MECHANISMS CAM MECHANISMS 4.21

- Page 85 and 86:

CAM MECHANISMS CAM MECHANISMS 4.23

- Page 87 and 88:

For F23 = 0, roller and cam lose th

- Page 89 and 90:

FIGURE 4.20 Programming of cam syst

- Page 91 and 92:

Source: STANDARD HANDBOOK OF MACHIN

- Page 93 and 94:

n5 = N2N4 n2 (5.5) N3N5 and the t

- Page 95 and 96:

5.3 PLANETARY GEAR TRAINS GEAR TRAI

- Page 97 and 98:

GEAR TRAINS 5.7 termini of the velo

- Page 99 and 100:

GEAR TRAINS TABLE 5.1 Solution by T

- Page 101 and 102:

GEAR TRAINS 5.11 TABLE 5.2 Characte

- Page 103 and 104:

FIGURE 5.9 (a) Planetary train; (b)

- Page 105 and 106:

GEAR TRAINS GEAR TRAINS 5.15 (a) (b

- Page 107 and 108:

Source: STANDARD HANDBOOK OF MACHIN

- Page 109 and 110:

Source: STANDARD HANDBOOK OF MACHIN

- Page 111 and 112:

SPRINGS SPRINGS 6.5 close-wound: wo

- Page 113 and 114:

6.3.2 Heat Treatment of Springs Hea

- Page 115 and 116:

SPRINGS 6.9 Downloaded from Digital

- Page 117 and 118:

SPRINGS 6.11 Downloaded from Digita

- Page 119 and 120:

Helical compression springs are str

- Page 121 and 122:

Types of Ends. Four basic types of

- Page 123 and 124:

TABLE 6.5 Typical Properties of Spr

- Page 125 and 126:

SPRINGS SPRINGS 6.19 The rate equat

- Page 127 and 128:

SPRINGS SPRINGS 6.21 FIGURE 6.9 End

- Page 129 and 130:

The fatigue life estimates in Table

- Page 131 and 132:

The spring rate for a rectangular-w

- Page 133 and 134:

SPRINGS 6.27 FIGURE 6.15 Stress cor

- Page 135 and 136:

6.5 HELICAL EXTENSION SPRINGS 6.5.1

- Page 137 and 138:

6.5.2 Initial Tension Initial tensi

- Page 139 and 140:

SPRINGS FIGURE 6.20 Common end conf

- Page 141 and 142:

Dynamic considerations discussed pr

- Page 143 and 144:

SPRINGS SPRINGS 6.37 TABLE 6.14 Tol

- Page 145 and 146:

The number of coils is equal to the

- Page 147 and 148:

SPRINGS SPRINGS 6.41 TABLE 6.17 Com

- Page 149 and 150:

6.7.1 Nomenclature a OD/2, mm (in)

- Page 151 and 152:

Ef Sc = C1 h − 2 2 (1 −µ )Ma

- Page 153 and 154:

SPRINGS SPRINGS 6.47 FIGURE 6.31 Lo

- Page 155 and 156:

Because of production variations in

- Page 157 and 158:

7. h = 1.41t = 1.41(0.054) = 0.076

- Page 159 and 160:

and Design equations are SPRINGS SP

- Page 161 and 162:

6.9 FLAT SPRINGS 6.9.1 Introduction

- Page 163 and 164:

SPRINGS fEb P = ot (6.52) where K =

- Page 165 and 166:

SPRINGS SPRINGS 6.59 TABLE 6.25 Max

- Page 167 and 168:

If unknown, let b/t = 100/1, D2 = 1

- Page 169 and 170:

6.11.2 Design Equations: Rectangula

- Page 171 and 172:

SPRINGS SPRINGS 6.65 FIGURE 6.50 Ty

- Page 173 and 174:

SPRINGS SPRINGS 6.67 FIGURE 6.51 Av

- Page 175 and 176:

used only for centerless ground all

- Page 177 and 178:

CHAPTER 7 FLYWHEELS Daniel M. Curti

- Page 179 and 180:

The energy-storage capacity of a fl

- Page 181 and 182:

FLYWHEELS Since the torque-angle cu

- Page 183 and 184:

7.2.3 Coefficient of Energy Variati

- Page 185 and 186:

7.2.5 Speed-Dependent Torques FLYWH

- Page 187 and 188:

FLYWHEELS FLYWHEELS 7.11 range [7.7

- Page 189 and 190:

and 205 rpm = 2π(205)/60 = 21.468

- Page 191 and 192:

Example 6. An alloy of density 26.6

- Page 193 and 194:

cos (π/8) f4 = =0.340 (7.42) 7.11

- Page 195 and 196:

For a constant-thickness disk witho

- Page 197 and 198:

factor F s = 1.0 for the fully stre

- Page 199 and 200:

FLYWHEELS FLYWHEELS 7.23 (g) (h) (i

- Page 201 and 202:

many composite flywheels shred, for

- Page 203 and 204:

Source: STANDARD HANDBOOK OF MACHIN

- Page 205 and 206:

CLUTCHES AND BRAKES CLUTCHES AND BR

- Page 207 and 208:

CLUTCHES AND BRAKES CLUTCHES AND BR

- Page 209 and 210:

shaft begins to rotate.At the desig

- Page 211 and 212:

CLUTCHES AND BRAKES CLUTCHES AND BR

- Page 213 and 214:

FIGURE 8.7 Classification of brakes

- Page 215 and 216:

8.1.4 Selecting a Brake CLUTCHES AN

- Page 217 and 218:

TABLE 8.2 Selecting the Right Brake

- Page 219 and 220:

Similarly, In general, CLUTCHES AND

- Page 221 and 222:

IPIL(ΩP −ΩL) tS = (8.10) T(I

- Page 223 and 224:

The rate at which heat is generated

- Page 225 and 226:

Here ωo = 2π 60 (315) = 33 rad/

- Page 227 and 228:

for preliminary design estimates on

- Page 229 and 230:

CLUTCHES AND BRAKES FIGURE 8.16 Equ

- Page 231 and 232:

drum’s rotation, use the positive

- Page 233 and 234:

pmax Px = (θ2 −θ1 + sin θ1 cos

- Page 235 and 236:

8.5.2 Centrifugal Clutches CLUTCHES

- Page 237 and 238:

CLUTCHES AND BRAKES FIGURE 8.19 For

- Page 239 and 240:

3. Next the moment arm length for

- Page 241 and 242:

CLUTCHES AND BRAKES CLUTCHES AND BR

- Page 243 and 244:

CLUTCHES AND BRAKES 8.41 to the dis

- Page 245 and 246:

CLUTCHES AND BRAKES Torque Capacity

- Page 247 and 248:

For finding the average contact pre

- Page 249 and 250:

CLUTCHES AND BRAKES (a) (b) (c) FIG

- Page 251 and 252:

CLUTCHES AND BRAKES CLUTCHES AND BR

- Page 253 and 254:

Source: STANDARD HANDBOOK OF MACHIN

- Page 255 and 256:

CHAPTER 9 SPUR GEARS Joseph E. Shig

- Page 257 and 258:

SPUR GEARS SPUR GEARS 9.5 FIGURE 9.

- Page 259 and 260:

9.3 FORCE ANALYSIS In Fig. 9.3 a ge

- Page 261 and 262:

SPUR GEARS SPUR GEARS 9.9 TABLE 9.5

- Page 263 and 264:

Allowable Bending Stress Number. Th

- Page 265 and 266:

10.1 INTRODUCTION / 10.1 10.2 TYPES

- Page 267 and 268:

HELICAL GEARS HELICAL GEARS 10.3 (a

- Page 269 and 270:

helical gears are employed, a limit

- Page 271 and 272:

contact ratio and the axial overlap

- Page 273 and 274:

10.5.1 Strength and Durability HELI

- Page 275 and 276:

HELICAL GEARS FIGURE 10.4 Dynamic f

- Page 277 and 278:

HELICAL GEARS HELICAL GEARS 10.13 (

- Page 279 and 280:

HELICAL GEARS housing which support

- Page 281 and 282:

If the tooth contact pattern at nor

- Page 283 and 284:

for external gears; for internal ge

- Page 285 and 286:

HELICAL GEARS HELICAL GEARS 10.21 G

- Page 287 and 288:

HELICAL GEARS HELICAL GEARS 10.23 F

- Page 289 and 290:

HELICAL GEARS HELICAL GEARS 10.25 F

- Page 291 and 292:

HELICAL GEARS HELICAL GEARS 10.27 F

- Page 293 and 294:

HELICAL GEARS HELICAL GEARS 10.29 F

- Page 295 and 296:

HELICAL GEARS HELICAL GEARS 10.31 F

- Page 297 and 298:

HELICAL GEARS HELICAL GEARS 10.33 F

- Page 299 and 300:

HELICAL GEARS HELICAL GEARS 10.35 F

- Page 301 and 302:

Letting Ze = distance on line of ac

- Page 303 and 304:

HELICAL GEARS HELICAL GEARS 10.39 H

- Page 305 and 306:

HELICAL GEARS 10.41 Downloaded from

- Page 307 and 308:

HELICAL GEARS HELICAL GEARS 10.43 F

- Page 309 and 310:

HELICAL GEARS HELICAL GEARS 10.45 F

- Page 311 and 312:

HELICAL GEARS HELICAL GEARS 10.47 F

- Page 313 and 314:

HELICAL GEARS HELICAL GEARS 10.49 F

- Page 315 and 316:

HELICAL GEARS HELICAL GEARS 10.51 p

- Page 317 and 318:

HELICAL GEARS HELICAL GEARS 10.53 W

- Page 319 and 320:

HELICAL GEARS HELICAL GEARS 10.55 E

- Page 321 and 322:

In most cases the blank temperature

- Page 323 and 324:

CHAPTER 11 BEVEL AND HYPOID GEARS T

- Page 325 and 326:

FIGURE 11.3 Zerol bevel set. (Gleas

- Page 327 and 328:

FIGURE 11.7 Hypoid gear nomenclatur

- Page 329 and 330:

The taper you select depends in som

- Page 331 and 332:

BEVEL AND HYPOID GEARS BEVEL AND HY

- Page 333 and 334:

Hypoid gears are recommended where

- Page 335 and 336:

TABLE 11.1 Material Factors C M BEV

- Page 337 and 338:

11.4.7 Hypoid Offset BEVEL AND HYPO

- Page 339 and 340:

FIGURE 11.16 Selection of spiral an

- Page 341 and 342:

should be hardened and tempered abo

- Page 343 and 344:

BEVEL AND HYPOID GEARS BEVEL AND HY

- Page 345 and 346:

TABLE 11.7 Mean Addendum Factor BEV

- Page 347 and 348:

11.5.4 AGMA References † The foll

- Page 349 and 350:

BEVEL AND HYPOID GEARS TABLE 11.10

- Page 351 and 352:

BEVEL AND HYPOID GEARS TABLE 11.10

- Page 353 and 354:

BEVEL AND HYPOID GEARS area.The rec

- Page 355 and 356:

TABLE 11.12 Load-Distribution Facto

- Page 357 and 358:

BEVEL AND HYPOID GEARS FIGURE 11.21

- Page 359 and 360:

BEVEL AND HYPOID GEARS FIGURE 11.25

- Page 361 and 362:

BEVEL AND HYPOID GEARS FIGURE 11.29

- Page 363 and 364:

BEVEL AND HYPOID GEARS FIGURE 11.33

- Page 365 and 366:

BEVEL AND HYPOID GEARS 11.43 Downlo

- Page 367 and 368:

BEVEL AND HYPOID GEARS FIGURE 11.39

- Page 369 and 370:

BEVEL AND HYPOID GEARS FIGURE 11.43

- Page 371 and 372:

BEVEL AND HYPOID GEARS FIGURE 11.47

- Page 373 and 374:

TABLE 11.15 Allowable Bending Stres

- Page 375 and 376:

BEVEL AND HYPOID GEARS 11.7.3 Axial

- Page 377 and 378:

Pressure lubrication is recommended

- Page 379 and 380:

CHAPTER 12 WORM GEARING K. S. Edwar

- Page 381 and 382:

FIGURE 12.2 Photograph of a worm-ge

- Page 383 and 384:

12.3 VELOCITY AND FRICTION Figure 1

- Page 385 and 386:

where the subscripts are t for the

- Page 387 and 388:

This force is the negative x direct

- Page 389 and 390:

24, from Table 12.3, K m = 0.823 by

- Page 391 and 392:

12.7 DESIGN STANDARDS The American

- Page 393 and 394:

TABLE 12.6 Dimensions of the Gear a

- Page 395 and 396:

Table 12.9 presents a system for st

- Page 397 and 398:

12.8.3 Gear Ratio The gear ratio is

- Page 399 and 400:

12.8.10 Worm Length The effective l

- Page 401 and 402:

CHAPTER 13 POWER SCREWS Rudolph J.

- Page 403 and 404:

FIGURE 13.1 Power screw assembly us

- Page 405 and 406:

POWER SCREWS POWER SCREWS 13.5 TABL

- Page 407 and 408:

POWER SCREWS POWER SCREWS 13.7 The

- Page 409 and 410:

which can be solved for a circular

- Page 411 and 412:

TABLE 13.3 Sizes and Capacities of

- Page 413 and 414:

REFERENCES POWER SCREWS POWER SCREW

- Page 415 and 416:

Source: STANDARD HANDBOOK OF MACHIN

- Page 417 and 418:

CHAPTER 14 BELT DRIVES Wolfram Funk

- Page 419 and 420:

Disadvantages: ● Limited power tr

- Page 421 and 422:

FIGURE 14.2 Multiple-pulley drives.

- Page 423 and 424:

Because µβwπ Fu = F2′(m − 1)

- Page 425 and 426:

The maximum power transmission capa

- Page 427 and 428:

(a) (c) BELT DRIVES BELT DRIVES 14.

- Page 429 and 430:

BELT DRIVES FIGURE 14.11 Pretension

- Page 431 and 432:

BELT DRIVES 14.17 Taking into consi

- Page 433 and 434:

FIGURE 14.15 Multiple-ply belt. BEL

- Page 435 and 436:

4. The manufacturer can supply belt

- Page 437 and 438:

BELT DRIVES FIGURE 14.18 Section of

- Page 439 and 440:

The calculation of belt velocity (p

- Page 441 and 442:

BELT DRIVES The flexibility of the

- Page 443 and 444:

BELT DRIVES BELT DRIVES 14.29 FIGUR

- Page 445 and 446:

transmissible power P is determined

- Page 447 and 448:

BELT DRIVES BELT DRIVES 14.33 The a

- Page 449 and 450:

BELT DRIVES BELT DRIVES 14.35 (a) (

- Page 451 and 452:

(twisting of tension member and its

- Page 453 and 454:

The power transmission capacity of

- Page 455 and 456:

FIGURE 14.33 Comparison of system c

- Page 457 and 458:

CHAPTER 15 CHAIN DRIVES John L. Wri

- Page 459 and 460:

esponding chains in Ref. [15.1], bu

- Page 461 and 462:

TABLE 15.1 Roller-Chain Dimensions

- Page 463 and 464:

CHAIN DRIVES 15.3 SELECTION OF ROLL

- Page 465 and 466:

sprockets may be required. Idler sp

- Page 467 and 468:

CHAIN DRIVES TABLE 15.2 Service Fac

- Page 469 and 470:

Determine Lubrication Type. The typ

- Page 471 and 472:

CHAIN DRIVES CHAIN DRIVES 15.15 TAB

- Page 473 and 474:

CHAIN DRIVES inexpensive, but they

- Page 475 and 476:

TABLE 15.9 Offset Sidebar Chain Dim

- Page 477 and 478:

CHAIN DRIVES CHAIN DRIVES 15.21 Cha

- Page 479 and 480:

CHAIN DRIVES CHAIN DRIVES 15.23 TAB

- Page 481 and 482:

15.6.3 Horsepower Ratings of Offset

- Page 483 and 484:

15.7.3 Silent-Chain Sprockets CHAIN

- Page 485 and 486:

In a drive where the shaft centers

- Page 487 and 488:

CHAIN DRIVES silent-chain size when

- Page 489 and 490:

Source: STANDARD HANDBOOK OF MACHIN

- Page 491 and 492:

7. Misalignment Amount and type of

- Page 493 and 494:

COUPLINGS COUPLINGS 16.5 TABLE 16.1

- Page 495 and 496:

alignment up to 45°. The maximum a

- Page 497 and 498:

FIGURE 16.4 Portion of shaft showin

- Page 499 and 500:

COUPLINGS 16.3.2 Chain, Grid, and B

- Page 501 and 502:

COUPLINGS 16.13 FIGURE 16.11 (a) Si

- Page 503 and 504:

COUPLINGS 16.15 FIGURE 16.16 Hydrau

- Page 505 and 506:

operating radius corresponding to a

- Page 507 and 508:

FIGURE 16.24 A bellows coupling. (S

- Page 509 and 510:

COUPLINGS COUPLINGS 16.21 pression

- Page 511 and 512:

FIGURE 16.30 Bonded type of a shear

- Page 513 and 514:

16.5 UNIVERSAL JOINTS AND ROTATING-

- Page 515 and 516:

COUPLINGS COUPLINGS 16.27 FIGURE 16

- Page 517 and 518:

COUPLINGS The correction factor Ks

- Page 519 and 520: COUPLINGS COUPLINGS 16.31 Rzeppa Un

- Page 521 and 522: method of attachment allows a much

- Page 523 and 524: CHAPTER 17 SHAFTS Charles R. Mischk

- Page 525 and 526: Geometric fidelity is important to

- Page 527 and 528: Solution. Equation (17.1) is used.

- Page 529 and 530: SHAFTS Based on this, the designer

- Page 531 and 532: SHAFTS 17.9 The dual-entry slope dy

- Page 533 and 534: SHAFTS SHAFTS 17.11 The prediction

- Page 535 and 536: 17.4 DISTORTION DUE TO TORSION Angu

- Page 537 and 538: A press fit induces a surface press

- Page 539 and 540: factor corrected for notch sensitiv

- Page 541 and 542: The methods of Secs. 17.2 and 17.3

- Page 543 and 544: REFERENCES 17.1 Joseph E. Shigley a

- Page 545 and 546: Source: STANDARD HANDBOOK OF MACHIN

- Page 547 and 548: Source: STANDARD HANDBOOK OF MACHIN

- Page 549 and 550: ROLLING-CONTACT BEARINGS 18.5 FIGUR

- Page 551 and 552: FIGURE 18.9 Tapered-roller thrust b

- Page 553 and 554: ROLLING-CONTACT BEARINGS where C s

- Page 555 and 556: ROLLING-CONTACT BEARINGS For exampl

- Page 557 and 558: ROLLING-CONTACT BEARINGS ROLLING-CO

- Page 559 and 560: age on the bearing per revolution a

- Page 561 and 562: ROLLING-CONTACT BEARINGS TABLE 18.5

- Page 563 and 564: deep-groove ball bearings. Self-ali

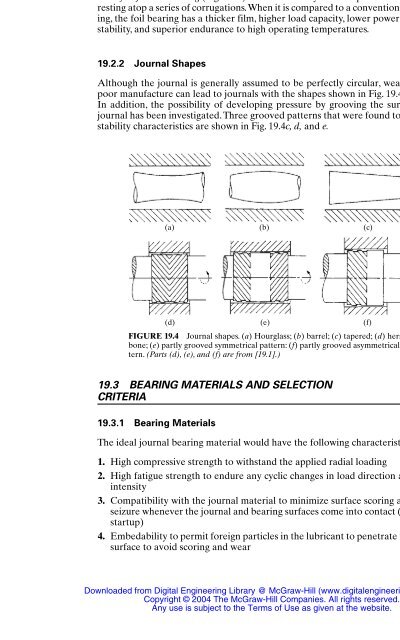

- Page 565 and 566: CHAPTER 19 JOURNAL BEARINGS Theo G.

- Page 567 and 568: Λ Bearing number = (6µω/p a)(R/C

- Page 569: TABLE 19.1 Characteristics of Lubri

- Page 573 and 574: TABLE 19.2 Physical Properties of J

- Page 575 and 576: TABLE 19.4 Performance Ratings from

- Page 577 and 578: Next the candidate materials are gi

- Page 579 and 580: This equation can be interpreted as

- Page 581 and 582: JOURNAL BEARINGS where θ 1 and θ

- Page 583 and 584: In general, volume flow rate per un

- Page 585 and 586: JOURNAL BEARINGS JOURNAL BEARINGS 1

- Page 587 and 588: It was proposed that the film press

- Page 589 and 590: JOURNAL BEARINGS JOURNAL BEARINGS 1

- Page 591 and 592: JOURNAL BEARINGS JOURNAL BEARINGS 1

- Page 593 and 594: JOURNAL BEARINGS JOURNAL BEARINGS 1

- Page 595 and 596: JOURNAL BEARINGS JOURNAL BEARINGS 1

- Page 597 and 598: L b 1 Sb2 + b3 (L/D) TABLE 19.15 S

- Page 599 and 600: JOURNAL BEARINGS JOURNAL BEARINGS 1