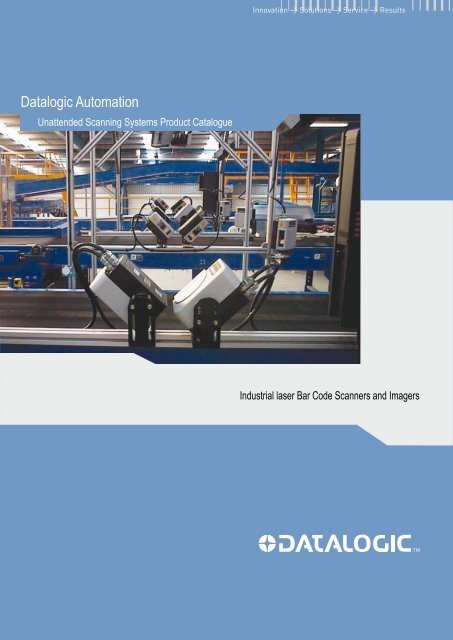

Inside discov Datalo For a s this lea Datalogic Automation

Inside discov Datalo For a s this lea Datalogic Automation

Inside discov Datalo For a s this lea Datalogic Automation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Datalo</strong>gic <strong>Automation</strong><br />

Unattended Scanning Systems Product Catalogue<br />

Innovation > Solutions > Service > Results<br />

Industrial laser Bar Code Scanners and Imagers

Unattended Scanning Systems Product Catalogue

Contents<br />

> <strong>Datalo</strong>gic Profile 4<br />

> <strong>Datalo</strong>gic <strong>Automation</strong> Profile 6<br />

> <strong>Datalo</strong>gic <strong>Automation</strong> Main Markets 8<br />

> <strong>Datalo</strong>gic <strong>Automation</strong> Main Applications 8<br />

> <strong>Datalo</strong>gic <strong>Automation</strong> Service & Support 10<br />

> Automatic Products & Solutions 12<br />

> Industrial linear and 2D scanners 14<br />

> Technologies 20<br />

> DS1100 22<br />

> DS1500 26<br />

> DS2200 30<br />

> DS2100N & DS2400N 34<br />

> DS4800 40<br />

> DS6300 44<br />

Innovation > Solutions > Service > Results<br />

> DS6400 50<br />

> DS8100A 58<br />

> DX8200A 64<br />

> SC6000 68<br />

> MATRIX-2000 72<br />

> MATRIX 400 76<br />

> MATRIX 200 84<br />

> DV9500 88<br />

> CBX SERIES 92<br />

> <strong>Datalo</strong>gic WebSentinel 96<br />

> Logistic Performances 98<br />

> <strong>Datalo</strong>gic <strong>Automation</strong><br />

Sales & Service Network 99

4<br />

<strong>Datalo</strong>gic Profile<br />

Mission<br />

To “Promote and provide business solutions for data management<br />

by offering high value systems, products and services, to mark,<br />

capture, compute and communicate (M&3C) information<br />

anywhere and anytime, and to generate a high ROI for our<br />

Customers”.<br />

Company vision: “To be Top of Mind when thinking about needs in<br />

the item identification value chain”.

<strong>Datalo</strong>gic Group is the third largest world producer * and <strong>lea</strong>der in Europe for bar code readers, data collection mobile computers, and<br />

RFID systems. Over the past 30 years <strong>Datalo</strong>gic has established an undisputed world <strong>lea</strong>dership position in Automatic Identification<br />

and Data Capture (AIDC), as a result of high quality products, extreme flexibility, and meticulous design. <strong>Datalo</strong>gic offers outstanding<br />

and innovative business solutions in numerous markets, including retail, manufacturing, transport and logistics. The Group has<br />

been quoted on the techSTAR segment of the Italian stock exchange since 2001 as DAL.MI, with headquarters located in Calderara<br />

di Reno (Bologna). <strong>Datalo</strong>gic has over 1880 employees world-wide, in over 40 countries in Europe, Asia, the United States and<br />

the Pacific Rim. In 2007 <strong>Datalo</strong>gic completed a significant structural transformation programme <strong>lea</strong>ding to a business model with<br />

increased focus on products and market, increasing the company’s competitive edge and optimizing future investments.<br />

* VDC 2007 service<br />

Innovation > Solutions > Service > Results<br />

This development will be supported by three autonomous operative divisions:<br />

<strong>Datalo</strong>gic <strong>Automation</strong> - headquartered in Bologna, Italy, including three<br />

Business Units:<br />

• Unattended Scanning Systems (fixed scanners for the industrial market)<br />

• Marking (laser marking system) - Laservall<br />

• RFID (radiofrequency system) - EMS<br />

<strong>Datalo</strong>gic Scanning - headquartered in the US, including two Business<br />

Units:<br />

• High-Performance Retail POS Scanners (fixed scanners for the retail<br />

market)<br />

• General Purpose and Ruggedized Handheld Scanners<br />

<strong>Datalo</strong>gic Mobile - headquartered in Bologna, Italy, including the Business<br />

Unit:<br />

• Mobile Computers<br />

Additionally, there is a “Business Development” unit (currently consisting in<br />

Informatics and Shop-Evolution), which oversees organizational development<br />

of new business platforms within the Group, and assesses new merger and<br />

acquisition opportunities. Within <strong>this</strong> new organization, <strong>Datalo</strong>gic Spa of<br />

Bologna (Italy), maintains responsibility not only for company vision, strategy<br />

and values, and company policy, but also the coordination and control of the<br />

group and its companies.<br />

5

6<br />

<strong>Datalo</strong>gic <strong>Automation</strong> Profile<br />

<strong>Datalo</strong>gic <strong>Automation</strong> is one of the major producers of automatic identification systems for the industrial sector<br />

in the world. The company was the result of a business union stemming from the shared beliefs with regard to<br />

market and client typology, in the automation industry world: <strong>Datalo</strong>gic Unattended Scanning Systems (fixed<br />

readers for the industrial market), RFID technology solution by EMS, and Laservall laser marking systems.<br />

<strong>Datalo</strong>gic first entered the factory automation industry in 1972, and the fusion of the above mentioned business<br />

units drive its current market value.

Innovation > Solutions > Service > Results<br />

The single business units themselves act as the driving force<br />

behind <strong>Datalo</strong>gic <strong>Automation</strong>’s success, enabling <strong>lea</strong>dership in<br />

each of their respective fields.<br />

• Unattended Scanning Systems (fixed scanners for the<br />

industrial market) - range of fixed bar code readers, laser and<br />

imaging technology - is the first in the EMEA industrial sector,<br />

and third in the world<br />

• Marking (Laservall) - marking solutions which use the most<br />

innovative laser marking technologies - <strong>lea</strong>der in Italy<br />

• RFID (EMS) - radio frequency identification system - <strong>lea</strong>der in<br />

the United States automotive industry, electronic-manufacturers<br />

and warehouse management system (WMS)<br />

<strong>Datalo</strong>gic <strong>Automation</strong>, with a long tradition of quality behind it,<br />

now meets the performance criteria of BNP Associates, Inc., for<br />

laser scanner array.<br />

<strong>Datalo</strong>gic <strong>Automation</strong> is headquartered in Bologna. The<br />

manufacturing plant for Unattended Scanning Systems is located<br />

in Teramo (southern Italy); Laservall manufacturing plants are<br />

located in northern Italy (Donnas and Sesto Calende) and in<br />

Asia; and RFID solutions by EMS.<br />

7

8<br />

<strong>Datalo</strong>gic <strong>Automation</strong> Main Markets<br />

Identifying objects of any kind is an activity that presents an enormous application potential, and<br />

the only limitations lie in the creative capacity of whoever realises solutions. In its thirty years of life,<br />

<strong>Datalo</strong>gic has solved identification and data capture problems for any number of industries, and<br />

today its technology governs many processes which we encounter in our day to day life without even<br />

noticing them, guaranteeing the highest precision and control, enabling us to improve the quality of<br />

our lives. <strong>For</strong> <strong>this</strong> reason <strong>Datalo</strong>gic <strong>Automation</strong> offers a wide range of solutions to various industry<br />

segments: from electronics to the more complex aerospace technology, automotive, and scientific<br />

industries.<br />

<strong>Datalo</strong>gic <strong>Automation</strong> Main Applications<br />

Parcel Sorting<br />

Today, <strong>Datalo</strong>gic <strong>Automation</strong> products and solutions reliably address the growing need for goods<br />

identification and traceability. Thanks to their a modular and flexible design, <strong>Datalo</strong>gic solutions<br />

can be easily installed in specific process applications controlling work-in-progress in factories,<br />

automatic baggage handling, parcels in postal sorting centres and packages in distribution centres.<br />

Furthermore, <strong>Datalo</strong>gic offers warehouse management system and scan & DIM solutions (parcel<br />

identification and dimensioning). <strong>Datalo</strong>gic also proposes specifically designed products for OEM<br />

integration for various uses, such as retail kiosks, lottery tickets, vending machines, parking tickets,<br />

access control and medical analysis machines.<br />

Scan&DIM Application<br />

Automatic Baggage<br />

Handling

Transport/Logistics Manufacturing OEM<br />

Work in progress Product Traceability Warehousing<br />

OEM Application<br />

Innovation > Solutions > Service > Results<br />

9

10<br />

<strong>Datalo</strong>gic <strong>Automation</strong> Service & Support<br />

Selling a product has implications that go beyond the sale itself. Indeed, it entails assuring customers fast and efficient service also<br />

after the sale. <strong>Datalo</strong>gic <strong>Automation</strong> therefore offers its customers a wide range of formulas for care of its products. The proposed<br />

solutions are based on the specific needs of our customers, while balancing service level and costs. Use our know how to be sure of<br />

the complete efficiency of your <strong>Datalo</strong>gic product, in order to protect your investment (maintaining the read rate) and assure maximum<br />

performance.<br />

Service Repair service & Support<br />

<strong>Datalo</strong>gic <strong>Automation</strong> has revised and empowered the repair process to ensure a fast, easy and reliable repair service.<br />

• Fast and effective repairs inside the factory by qualified <strong>Datalo</strong>gic personnel<br />

• A network of six authorized repair centres all over the world<br />

• A simple, automatic repair process through a new on-line management system (EASEOFCARE) *.<br />

This new service offers:<br />

• Full on-line management of repair operations<br />

• Service availability 24/7/365. Customers can enter repair orders at any time<br />

• 3% discount on the repair charge by using the on-line MRA request<br />

• On-line visibility of repair status<br />

• Repair process is sped up thanks to a (flat rate) repair charge and on-line acceptance. No lengthy estimate<br />

approval needed<br />

• On line visibility of the repair status<br />

• Availability of the repair history of the products<br />

Maintenance contract available after 24 months warranty provided, with service level tailored to customer’s needs.<br />

* Contact your local subsidiary for <strong>this</strong> service

Technical Support<br />

A team of highly qualified professionals plan and then implement the barcode reading station. Our support includes:<br />

• Pinpointing the best solution for customer requirements and application needs.<br />

• Feasibility study and delivery of a detailed proposal: solution description, device description, drawings<br />

• Installation and commissioning<br />

• Support to the system integrator during system handover to end user.<br />

• Telephone and remote support<br />

• Service call and on site support<br />

Furthermore, a set of after sale maintenance contracts is available to maintain the performance of your system at a known cost.<br />

Service includes preventive maintenance and emergency calls, and processing of customer needs.<br />

And if you want, you can rely on the best local service. <strong>Datalo</strong>gic<br />

<strong>Automation</strong> has a network of over 100 certified Partners assuring<br />

pre and post sales support worldwide.<br />

Education<br />

<strong>Datalo</strong>gic’s objective is to create and develop the professional<br />

knowledge and competence of its partners and customers to support<br />

the evolution of their business in the short, medium and long term.<br />

Innovation > Solutions > Service > Results<br />

QUALITY<br />

PARTNER<br />

DATALOGIC AUTOMATION<br />

11

12<br />

<strong>Automation</strong> Products & Solutions<br />

<strong>Datalo</strong>gic <strong>Automation</strong> has the most comprehensive range of Industrial Bar code readers on the market today.<br />

Wide:<br />

To cover all applications, whatever the conditions (reading distance and speed, code orientation and type,<br />

connectivity). Two main technologies, Laser and Vision are available to meet all application needs with the best<br />

performance and highest flexibility.<br />

Deep:<br />

Each product is offered in several versions or, in the newest product lines, with a great deal of flexibility of use<br />

for the single model, to suit even the most specific Customer demands.<br />

LASERS<br />

IMAGERS<br />

PRODUCTS<br />

1000 Family:<br />

Small and economic. The perfect scanner for OEM applications. A real industrial scanner in one of the<br />

smallest size formats on the market.<br />

2000 Family:<br />

The Perfect scanner for the world of Manufacturing. From OEM to Shop Floor, small and powerful.<br />

Strong and flexible.<br />

4000 Family:<br />

The new King of Manufacturing – a new scanner concept. Combines the newest design methodology<br />

and the most advanced production technology for the best price/performance ratio on the market. One<br />

model only for all needs. Easy to buy, to stock, to use.<br />

6000 Family:<br />

Top performance for the most demanding Shop Floor applications and the best price performance for<br />

omnidirectional stations.<br />

Matrix Family:<br />

From the consolidated 2000 to the newest Matrix 400, simply the best in bar code reading<br />

for Manufacturing. The most reliable and performing imager, when using a laser is no longer<br />

possible or just to have your first simple and cost effective omnidirectional reading point.

SYSTEMS<br />

8000 Family:<br />

The King of Logistics. Thousands working hard day and night to ensure correct sorting in<br />

hundreds of Airports and Logistics centres worldwide. Strong and reliable, <strong>this</strong> product embodies<br />

some of the most important technology creations from <strong>Datalo</strong>gic <strong>Automation</strong>.<br />

A set of accessories and software applications is available to improve the performance of your<br />

systems.<br />

9000 Family:<br />

When reading is almost impossible, vision becomes the answer. Small codes, image capture, 2D<br />

codes. Our cameras are the answer to extreme reading conditions in distribution and logistics.<br />

Supervisory software, remote control tools and video-coding are available to complete your<br />

vision system.<br />

Innovation > Solutions > Service > Results<br />

Simple:<br />

Easy to install, easy to set up, easy to maintain. <strong>Datalo</strong>gic <strong>Automation</strong> range of scanners from the 1000 to 4000<br />

family represents the best in terms of industrial Bar Code reading components. Matrix Family of Vision Technology<br />

scanners are the most performing 2D readers on the market today.<br />

Performing:<br />

<strong>Datalo</strong>gic <strong>Automation</strong> Solutions for multi-side omnidirectional reading points contain the best technology for Logistic<br />

applications. Family 8000 and 9000 are used in hundreds of applications worldwide at Airports, Distribution Centres<br />

and Logistic hubs, and for Postal applications etc. Our Reading Stations offer their unique patented Astra and<br />

Packtrack technology to grant the highest throughput. A full set of pre and post sales services are available to<br />

accompany the Customer project during in all stages from concept to delivery. Laser scanners and Cameras are<br />

available for all application needs.<br />

LASERS<br />

IMAGERS<br />

13

14<br />

Industrial linear and 2D scanners<br />

DS1100<br />

DS1500<br />

DS2200<br />

DS2100<br />

DS2400<br />

READING DISTANCE AND DEPTH OF FIELD<br />

in<br />

DS1100-2XXX<br />

High resolution<br />

DS1100-1XXX<br />

Standard resolution<br />

DS1100-1XXX<br />

Standard resolution<br />

mm<br />

in<br />

DS1500-2100<br />

High resolution<br />

DS1500-1100<br />

Standard resolution<br />

DS1500-1100<br />

Standard resolution<br />

mm<br />

DS2200-2XXX<br />

High resolution<br />

DS2200-1XXX<br />

Standard resolution<br />

DS2200-1XXX<br />

Standard resolution<br />

mm<br />

mm<br />

0 2<br />

4<br />

6 8 10 12 14<br />

0.20 mm / 8 mils<br />

0.30 mm / 12 mils<br />

0.50 mm / 20 mils<br />

CONDITIONS<br />

• On code 39<br />

• Scan rate= 500 scan/s<br />

0 50 100 150 200 250 300 350<br />

0 2 4<br />

6 8 10 12 14<br />

0.20 mm / 8 mils<br />

0.30 mm / 12 mils<br />

0.50 mm / 20 mils<br />

CONDITIONS<br />

• On code 39<br />

• Scan rate=1200 scans/s<br />

0 50 100 150 200 250 300 350<br />

in 0 2 4 6 8 10 12 14<br />

in<br />

DS2100N-2XX4<br />

High resolution<br />

DS2100N-1XX4<br />

Standard resolution<br />

DS2100N-1XX4<br />

Standard resolution<br />

DS2400N-0200<br />

Short reading range<br />

DS2400N-1200<br />

Medium reading range<br />

DS2400N-2200<br />

Long reading range<br />

0.20 mm / 8 mils<br />

0.30 mm / 12 mils<br />

0.50 mm / 20 mils<br />

CONDITIONS<br />

• On code 39<br />

• Scan rate= 500 scans/s<br />

0 50 100 150 200 250 300 350<br />

0<br />

2<br />

4<br />

6<br />

0.20 mm / 8 mils<br />

<strong>For</strong> the real sizes of the products shown here, p<strong>lea</strong>se check the section<br />

“Dimensions” on the following pages.<br />

in<br />

mm<br />

12 14<br />

0 50 100 150 200 250 300 350<br />

0<br />

8<br />

10<br />

0.30 mm / 12 mils<br />

CONDITIONS<br />

• On code 39<br />

• Scan rate=1000 scans/s<br />

0.50 mm / 20 mils<br />

4 8 12 16 20 24<br />

0.30 mm / 12 mils<br />

0.50 mm / 20 mils<br />

CONDITIONS<br />

• On code 39<br />

• Scan rate=1000 scans/s<br />

0.50 mm / 20 mils<br />

0 100 200 300 400 500 600

• Two digital inputs<br />

• Two digital outputs<br />

• Dual serial interface<br />

• One digital input<br />

• Two digital outputs<br />

• Dual serial RS232<br />

interface or single<br />

serial RS485 interface<br />

• One digital input<br />

• Two digital outputs<br />

• Dual serial interface<br />

• Two digital inputs<br />

• Two digital outputs<br />

• Dual serial interface<br />

• ID-NET Interface<br />

• Two digital inputs<br />

• Two digital outputs<br />

• Dual serial interface<br />

• ID-NET Interface<br />

Standard • Dimensions:<br />

80x50x24 mm<br />

(3.15x1.9x1 in)<br />

• Weight without cable:<br />

Solutions > Service > Results<br />

Communication I/O Decoding Features Mechanical Output scan pattern Application<br />

• Chemical and blood analysis<br />

machines<br />

• Automatic Teller Machines (ATMs)<br />

• Video rental machines<br />

• Film processing machines<br />

• Print & Apply systems<br />

• Assembly lines, document<br />

and library tracking<br />

• Linear • OEM integration in automatic<br />

machines<br />

• Chemical and biomedical analysis<br />

machines<br />

• Document handling machines<br />

• Print & Apply systems<br />

• Packaging machines<br />

• ATL (Automated Tape Library)<br />

• OEM integration in automatic<br />

machines<br />

• Chemical and biomedical analysis<br />

machines<br />

• Document handling machines<br />

• Print & Apply systems<br />

• Packaging machines<br />

• ATL (Automated Tape Library)<br />

• Small conveyor sorting<br />

• Picking systems<br />

• Items and parts tracking<br />

• Process control and packaging<br />

• Document handling<br />

• Print & apply systems<br />

• Small conveyor sorting<br />

• Picking systems<br />

• Items and parts tracking<br />

• Process control and packaging<br />

• Document handling<br />

• Print & apply systems<br />

15

16<br />

Industrial linear and 2D scanners<br />

DS4800<br />

DS6300<br />

DS6400<br />

DS8100A<br />

DX8200A<br />

READING DISTANCE AND DEPTH OF FIELD<br />

in<br />

Near focusing<br />

Medium focusing<br />

Far focusing<br />

mm<br />

in<br />

Near focusing<br />

Medium focusing<br />

Far focusing<br />

mm<br />

Focus = 550 mm<br />

Focus = 800 mm<br />

Focus = 1200 mm<br />

Focus = 1800 mm<br />

0 10 20 30<br />

40<br />

50 60<br />

CONDITIONS<br />

•On code 128<br />

• Scan rate = Up to 1000<br />

scans/s<br />

• Resolution = 0.50 mm<br />

0 250 500 750 1000 1250 1500<br />

0 10 20 30<br />

40<br />

50 60<br />

CONDITIONS<br />

• On code 39<br />

• Scan rate = 1200 scans/s<br />

• Resolution = 0.50 mm<br />

0 250 500 750 1000 1250 1500<br />

in 0 10 20 30<br />

40 50<br />

60 70<br />

80 90<br />

mm<br />

DS8100A-2X10 (2 laser)<br />

Medium resolution<br />

DS8100A-2X10 (2 laser)<br />

Low resolution<br />

DS8100A-3X10 (3 laser)<br />

Medium resolution<br />

DS8100A-3X00 (3laser)<br />

Low resolution<br />

CONDITIONS<br />

• On code 39<br />

• Scan rate = 1200 scans/s<br />

• Resolution = 0.50 mm<br />

0 250 500 750 1000 1250 1500 1750 2000 2250<br />

in 0 10 20 30<br />

40 50<br />

60 70<br />

80 90<br />

mm<br />

DX8200A-3X3X<br />

High resolution<br />

DX8200A-3X2X<br />

Medium resolution<br />

DX8200A-3X1X<br />

Low resolution<br />

0.38 mm / 15 mils<br />

0.50 mm / 20 mils<br />

0.38 mm / 15 mils<br />

0.50 mm / 20 mils<br />

CONDITIONS<br />

• On code 39<br />

• Scan rate = 1000 scans/s<br />

0 250 500 750 1000 1250 1500 1750 2000 2250<br />

in 0 10 20 30<br />

40 50<br />

60 70<br />

80 90<br />

mm<br />

0.25 mm / 10 mils<br />

0.30 mm / 12 mils<br />

0.50 mm / 20 mils<br />

CONDITIONS<br />

• On code 39<br />

• Scan rate = ≤ 1000 scans/s<br />

(500 per leg)<br />

0 250 500 750 1000 1250 1500 1750 2000 2250<br />

<strong>For</strong> the real sizes of the products shown here, p<strong>lea</strong>se check the in “Dimensions”<br />

section on in the following pages.

• Two digital inputs<br />

• Two digital outputs<br />

• Dual serial interface<br />

• ID-NET Interface<br />

• Four digital inputs<br />

• Three digital outputs<br />

• Dual serial interface<br />

• Lonworks interface<br />

• Ethernet/Devicenet/<br />

Profibus interfaces<br />

(optional)<br />

• Four digital inputs<br />

• Three digital outputs<br />

• Dual serial interface<br />

• Lonworks interface<br />

• Ethernet/Devicenet/<br />

Profibus interfaces<br />

(optional)<br />

• Five digital inputs<br />

• Four digital outputs<br />

• Dual serial interface<br />

• Lonworks interface<br />

• Ethernet interface<br />

(optional)<br />

• Four digital inputs<br />

• Three digital outputs<br />

ACR4<br />

ACR4<br />

ACR4<br />

ACR4<br />

ACR4<br />

• Dimensions:<br />

85 x 101 x 42 mm<br />

(3.3 x 4 x 1.7 in)<br />

• Weight:<br />

570 g (20.1 oz.)<br />

• Case material:<br />

Aluminium<br />

• Dimensions:<br />

110x113x99 mm<br />

(4.33x4.45x3.9 in)<br />

• Weight:<br />

1.5 kg (3.3 lb)<br />

• Case material:<br />

Aluminium<br />

• Dimensions:<br />

110x113x99 mm<br />

(4.33x4.45x3.9 in)<br />

• Weight:<br />

1.5 kg (3.3 lb)<br />

• Case material:<br />

Aluminium<br />

• Dimensions:<br />

217 x 172.5 x 126.6 mm<br />

(8.54 x 6.79 x 4.98 in)<br />

• Weight:<br />

5 kg (11 lbs)<br />

• Case material:<br />

Aluminium<br />

• Dimensions:<br />

470 x 300 x 141 mm<br />

18.50 x 11.81 x 5.55 in)<br />

• Weight:<br />

11 kg (24 lbs. 3 oz.)<br />

• Case material:<br />

Steel<br />

• Linear<br />

• Linear<br />

• Oscillating mirror<br />

• Linear<br />

• Oscillating mirror<br />

• X-pattern<br />

Innovation > Solutions > Service > Results<br />

Communication I/O Decoding Features Mechanical Output scan pattern Application<br />

• Linear<br />

• Oscillating mirror<br />

• Automated warehousing<br />

• Medium / small conveyor sorting<br />

• Reading on pallets<br />

• Picking system<br />

• Automated shop floor<br />

• Items and parts tracking<br />

• Process control systems<br />

• Automated warehousing<br />

• Medium conveyor sorting<br />

• Reading on pallets<br />

• Picking systems<br />

• Automated shop floor<br />

• Tracking and sorting of goods<br />

• Process control systems<br />

• Automated warehousing<br />

• Medium conveyor sorting<br />

• Reading on forklift trucks<br />

• Picking systems<br />

• Automated shop floor<br />

• Tracking and sorting of goods<br />

• Process control systems<br />

• Postal/Courier parcel sorting<br />

and tracking<br />

• Automated warehousing<br />

identification systems<br />

• Airport baggage sorting systems<br />

• Cargo applications<br />

• Loading/unloading systems<br />

• Postal/Courier parcel sorting<br />

and tracking<br />

• Automated warehousing<br />

identification systems<br />

• Airport baggage sorting systems<br />

• Cargo applications<br />

• Loading/unloading systems<br />

17

18<br />

Industrial linear and 2D scanners<br />

MATRIX-2000<br />

MATRIX 400<br />

400-0X0<br />

MATRIX 400<br />

600-0X0<br />

MATRIX 200<br />

DV9500<br />

The Horizontal Field of View refers to the<br />

longest side of the image.<br />

The Horizontal Field of View refers to the<br />

longest side of the image.<br />

The Horizontal Field of View refers to the<br />

longest side of the image.<br />

HORIZONTAL FIELD OF VIEW<br />

in<br />

mm<br />

in<br />

mm<br />

in<br />

mm<br />

in<br />

mm<br />

* Field of View long side<br />

0 0,8 1,6 2,4 3,2 4 4,8 5,5 6,3 7,1 8 8,7 9,5<br />

0.13 mm (5 mils)<br />

0.19 mm (7.5 mils)<br />

0.25 mm (10 mils)<br />

0.38 mm (15 mils)<br />

0,50 mm (20 mils)<br />

0.60 mm (24 mils)<br />

VGA 0,3 MP (640x480)<br />

0 20 40 60 80 100 120 140 160 180 200 220 240<br />

0 0,8 1,6 2,4 3,2 4 4,8 5,5 6,3 7,1 8 8,7 9,5<br />

0.15 mm (6 mils)<br />

0.20 mm (8 mils)<br />

0.25 mm (10 mils)<br />

0.38 mm (15 mils)<br />

SXGA 1,3 MP (1280X1024)<br />

0,50 mm (20 mils)<br />

0 20 40 60 80 100 120 140 160 180 200 220 240<br />

0 0,8 1,6 2,4 3,2 4 4,8 5,5 6,3 7,1 8 8,7 9,5<br />

0.10 mm (4 mils)<br />

0.12 mm (5 mils)<br />

0.15 mm (6 mils)<br />

0.20 mm (8 mils)<br />

0.25 mm (10 mils)<br />

0,50 mm (20 mils)<br />

0.38 mm (15 mils)<br />

UXGA 2,0 MP (1600X1200)<br />

0 20 40 60 80 100 120 140 160 180 200 220 240<br />

0 0,8 1,6 2,4 3,2 4 4,8 5,5 6,3 7,1 8 8,7 9,5<br />

0.13 mm (5 mils)<br />

0.25 mm (10 mils)<br />

0.38 mm (15 mils)<br />

0.50 mm (20 mils)<br />

0,60 mm (24 mils)<br />

0 20 40 60 80 100 120 140 160 180 200 220 240<br />

Reading performance depends on application requirements<br />

(i.e. code resolution, conveyor speed, etc.).<br />

<strong>For</strong> further information and feasibility analysis p<strong>lea</strong>se contact<br />

your local <strong>Datalo</strong>gic office.<br />

<strong>For</strong> the real sizes of the products shown here, p<strong>lea</strong>se check the “Dimensions”<br />

section on the following pages.<br />

Horizontal FOV*<br />

Horizontal FOV*<br />

Horizontal FOV*

• Two digital inputs<br />

• Three digital outputs<br />

• Dual serial interface<br />

• Ethernet interface<br />

(optional)<br />

• Two digital inputs<br />

• Two digital outputs<br />

• Dual serial interface<br />

• ID-NET port up to<br />

1 Mbps<br />

• USB Serial (supports<br />

USB 2.0)<br />

• Two digital inputs<br />

• Two digital outputs<br />

• Dual serial interface<br />

• ID-NET port up to<br />

1 Mbps<br />

• USB Serial (supports<br />

USB 2.0)<br />

• Two digital inputs<br />

• Two digital outputs<br />

• Dual serial interface<br />

• ID-NET port up to<br />

1 Mbps<br />

• USB Serial (supports<br />

USB 2.0)<br />

• Two digital inputs<br />

• Three serial interfaces<br />

• 2D, 1D, Stacked and<br />

Postal symbologies<br />

• Symbol verification<br />

• DPM reading<br />

• Omnidirectional<br />

reading<br />

• 2D, 1D, Stacked and<br />

Postal symbologies<br />

• Symbol verification<br />

• DPM reading<br />

• Omnidirectional<br />

reading<br />

• 2D, 1D, Stacked and<br />

Postal symbologies<br />

• Symbol verification<br />

• DPM reading<br />

• Omnidirectional<br />

reading<br />

• 2D, 1D, Stacked and<br />

Postal symbologies<br />

• Symbol verification<br />

• DPM reading<br />

• Omnidirectional<br />

reading<br />

• 2D, 1D, Stacked and<br />

Postal symbologies<br />

• Omnidirectional<br />

reading<br />

• Dimensions:<br />

121 x 73 x 57 mm<br />

(4.76 x 2.87 x 2.24 in.)<br />

• Weight:<br />

380 g. (13.4 oz.)<br />

• Case Material:<br />

Magnesium alloy<br />

• Dimensions:<br />

123 x 60.5 x 87 mm<br />

(4.85 x 2.38 x 3.43 in.)<br />

with lens cover<br />

• Weight:<br />

482 g. (17 oz.) with lens<br />

and internal illuminator<br />

• Case Material:<br />

Aluminium<br />

• Dimensions:<br />

123 x 60.5 x 87 mm<br />

(4.85 x 2.38 x 3.43 in.)<br />

with lens cover<br />

• Weight:<br />

482 g. (17 oz.) with lens<br />

and internal illuminator<br />

• Case Material:<br />

Aluminium<br />

• MATRIX 200 21x-1x0<br />

dimensions:<br />

50 x 25 x 45 mm<br />

(1.97 x 0.98 x 1.77 in)<br />

• MATRIX 200 21x-0x0<br />

dimensions:<br />

50 x 31 x 45 mm<br />

(1.97 x 1.22 x 1.77 in)<br />

• Weight:<br />

60g. (2.1 oz.)<br />

without cable<br />

• Case material:<br />

Aluminium<br />

• Dimension:<br />

500x198x160 mm<br />

(19.68x7.79x6.29 in)<br />

• Weight:<br />

13 Kg / 28.7 lb<br />

• Case material:<br />

galvanized iron<br />

• Area imager<br />

• Area imager<br />

• Area imager<br />

• Area imager<br />

• Linear imager<br />

Innovation > Solutions > Service > Results<br />

Communication I/O Decoding Features Mechanical Output scan pattern Application<br />

Automotive Industry<br />

• Work-in-Progress Traceability<br />

• DPM Reading and Verification<br />

• Tire Sorting<br />

Electronic Industry<br />

• PCB Handling Systems<br />

• Semi-conductor Assembly<br />

Medical & Pharmaceutical Industry<br />

• Medical Devices Traceability<br />

• Pharmaceutical Manufacturing<br />

• Chemical & Biomedical Analysis Machines<br />

Postal & Distribution Industry<br />

• Document and Mail Processing<br />

• Small Parcel Sorting<br />

• CD/DVD Identification<br />

Food & Beverage Industry<br />

• Work-in-Progress Traceability<br />

• Reverse Vending Machines<br />

Automotive Industry<br />

• DPM Reading and Verification<br />

• Work-in-Progress Traceability<br />

• Tire Sorting<br />

Electronics<br />

• Large PCB Board Tracking<br />

• Electronics Product Tracking<br />

Distribution & Retail Industry<br />

• Presentation Scanner<br />

• Small Objects Sorting<br />

• Warehouse application<br />

Medical & Pharmaceutical Industry<br />

• Medical Devices Traceability<br />

• Pharmaceutical and Medicine Manufacturing<br />

• Chemical & Biomedical Analysis Machines<br />

Food & Beverage Industry<br />

• Work in Progress Traceability<br />

• Code Quality Control<br />

• Automotive Industry<br />

• Electronic Industry<br />

• Medical & Pharmaceutical<br />

• Postal & Distribution Industry<br />

• Food & Beverage Industry<br />

• Automotive Industry<br />

• Electronics Industry<br />

• Medical & Pharmaceutical<br />

• Postal & Distribution Industry<br />

• Food & Beverage Industry<br />

• Postal and logistics applications<br />

• Distribution applications<br />

• Garment and Multimedia sorting<br />

• Reverse Logistic Processes<br />

• Suitable for OCR and Video-coding<br />

19

20<br />

Technologies<br />

GENIUS<br />

ACB<br />

ACR4<br />

PACKTRAK<br />

ASTRA<br />

GENIUS<br />

Windows-based configuration program providing an easy way to set up the barcode<br />

scanner and perform functions such as remote control, SW updates or any kind of scanner<br />

check-up. Defined configuration directly stored in the reader and communication protocol<br />

independent from the physical interface means the reader can be considered a remote<br />

object to be configured and monitored.<br />

ACB (Advanced Code Builder)<br />

Advanced Code Builder (ACB) enables code reading by ‘stitching’ together two partial code<br />

reads. ACB is effective in reading codes positioned close-to-linear, small height codes,<br />

damaged codes, or poor print quality codes.<br />

ACR4 (Advanced Code Reconstruction - 4th Generation)<br />

The traditional method for barcode reading could be called “Linear Reading”. In <strong>this</strong> case,<br />

the laser beam crosses the barcode symbol from beginning to end. Thanks to ACR4 it is<br />

no longer necessary for the laser beam to cross the label from beginning to end. With just<br />

a set of partial scans on the label (obtained using the motion of the label itself), the barcode<br />

reader is able to ‘reconstruct’ the barcode.<br />

PackTrack<br />

<strong>Datalo</strong>gic patented parcel tracking system which improves the reading features in<br />

omnidirectional stations. Packtrack is used to read and correctly assign codes read on<br />

different packs when placed in the scanner Reading Area at the same time.<br />

Astra (Automatically SwiTched Reading Area)<br />

The new <strong>Datalo</strong>gic technology based on a multi-laser architecture and a fixed mounted optic<br />

system which concentrates the multiple laser emissions in a single laser beam. As each<br />

laser emitter is focused on a specific range of the reading area, a sophisticated electronic<br />

controller selects the best focused laser emitter with respect to the code to read.<br />

This enables reading medium-high density codes in a large reading area on very fast<br />

conveyors.

ID-NET<br />

X-PRESS<br />

VISISET<br />

BLUE DIAMOND<br />

FLASH<br />

Innovation > Solutions > Service > Results<br />

ID-NET<br />

The ID-NET network is a high-speed, built-in, up to 1 Mbit/s reader interconnectiondedicated<br />

interface ID-NET can be used in addition to the standard Main and Auxiliary<br />

serial interfaces. ID-NET can be configured as a Single station/Multiple readers: <strong>this</strong><br />

enables local connection of up to 16 readers reading different sides of the same target.<br />

In addition, ID-NET can be configured as a Multiple stations/Single reader: <strong>this</strong> enables<br />

connection of up to 32 readers reading objects placed on independent conveyors.<br />

X-PRESS<br />

The intuitive X-PRESS Human Machine Interface designed to improve ease of<br />

installation and maintenance. Status and diagnostic information are c<strong>lea</strong>rly presented by<br />

a five LED bar-graph and the multi-function key providing immediate access to relevant<br />

functions: Test Mode (for bar code verification), AutoLearn (for automatic code setting)<br />

and AutoSetup (for self optimization of reading performance).<br />

VisiSet<br />

Windows-based configuration SW providing an immediate path to properly setting up the<br />

imager. It is suitable for parameter setting, code analysis, general service operation and<br />

firmware upgrade.<br />

Blue Diamonds<br />

Patented optical technology which enables easy focusing and positioning of the reader.<br />

The Blue Diamonds are accessed through the X-PRESS Interface.<br />

FLASH<br />

The new dynamic focusing system implemented in the DS6400, FLASH, is able to<br />

move the focus position rail to rail, from the minimum position to the maximum position,<br />

in less than 10 msec. In typical applications, where a DOF

22<br />

DS1100<br />

Main Applications<br />

Applications<br />

• Chemical and blood analysis machines<br />

• Automatic Teller Machines (ATMs)<br />

• Video rental machines<br />

• Film processing machines<br />

• Print & Apply systems<br />

• Assembly lines, document and library tracking<br />

Lightweight<br />

Benefits<br />

Compact<br />

Dimensions<br />

Direct and 90°<br />

reading<br />

• Extended product applicability in high throughput<br />

processes thanks to an improved scanning speed of<br />

500 scans/s<br />

• Grants excellent performance on high resolution<br />

codes with reduced min reading distance<br />

• The motor can be switched on and off via software<br />

commands depending on application needs<br />

• Enables flexible installation thanks to compact<br />

dimensions

Features<br />

• Cost effective<br />

• Very compact dimensions for both<br />

direct/90° reading window models<br />

• Wide reading width at a short reading<br />

distance<br />

• Lightweight Service > Results<br />

DS1100 is specifically designed to be easily integrated in OEM<br />

equipment as it is compact in dimensions and lightweight. It has two<br />

high speed serial interfaces simplifying connectivity with host control<br />

systems. DS1100 is ideal for use in chemical and biomedical analysis,<br />

pharmaceutical code analysers, automatic teller machines, printing<br />

systems, and video rental and film processing machines. It can also be<br />

used on assembly lines, as well as light work in progress and quality<br />

control.<br />

23

24<br />

DS1100 Reading Diagrams<br />

DS1100-1XXX (Standard Resolution)<br />

CONDITIONS<br />

0 1 2 3 4 5 6 7 8 9 10 (in)<br />

0 20 40 60 80 100 120 140 160 180 200 220 240 260 (mm)<br />

5<br />

120<br />

4 100<br />

3<br />

2<br />

80<br />

60<br />

40<br />

1<br />

20<br />

0 0<br />

0.20 mm<br />

(8 mils)<br />

0.30 mm<br />

(12 mils)<br />

≥ 0.50 mm<br />

(20 mils)<br />

1<br />

20<br />

40<br />

2<br />

60<br />

3 80<br />

4 100<br />

5<br />

(in)<br />

120<br />

(mm)<br />

Code = Inter<strong>lea</strong>ved 2/5 or Code 39<br />

PCS = 0.90<br />

Pitch angle = 0°<br />

Skew angle = 15°<br />

Tilt angle = 0°<br />

Dimensions<br />

DS1100-2XXX (High Resolution)<br />

2<br />

1<br />

0<br />

1<br />

2<br />

60<br />

(in) (mm)<br />

CONDITIONS<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

10<br />

20<br />

30<br />

40<br />

50<br />

0 1 2<br />

3<br />

4<br />

5 (in)<br />

0 10 20 30 40 50 60 70 80 90 100 110 120 130 (mm)<br />

0.12 mm<br />

(5 mils)<br />

Code = Inter<strong>lea</strong>ved 2/5 or Code 39<br />

PCS = 0.90<br />

Pitch angle = 0°<br />

Skew angle = 15°<br />

Tilt angle = 0°<br />

0.20 mm<br />

(8 mils)<br />

≥ 0.30 mm<br />

(12 mils)

Specifications<br />

OPERATING TEMPERATURE 0 to 45 °C (32 to 113 °F)<br />

STORAGE TEMPERATURE -20 to 70 °C (-4 to 158 °F)<br />

HUMIDITY 90% non condensing<br />

VIBRATION RESISTANCE IEC 68-2-6 test FC 1.5 mm; 10 to 55 Hz; 2 hours on each axis<br />

SHOCK RESISTANCE IEC 68-2-27 test EA 30 G; 11 ms; 3 shocks on each axis<br />

PROTECTION CLASS IP65<br />

LIGHT SOURCE Visible laser diode (650 nm)<br />

SCANNING SPEED 500 scans/s<br />

MAX. RESOLUTION<br />

1xxx models 0.20 mm (8 mils)<br />

2xxx models 0.12 mm (5 mils)<br />

MAX. READING DISTANCE<br />

1xxx models 220 mm (8.7 in) on 0.50 mm (20 mils) code res.<br />

2xxx models 110 mm (4.3 in) on 0.30 mm (12 mils) code res.<br />

MAX. DEPTH OF FIELD<br />

1xxx models 190 mm (7.5 in) on 0.50 mm (20 mils) code res.<br />

2xxx models 100 mm (3.7 in) on 0.30 mm (12 mils) code res.<br />

APERTURE ANGLE 70 degrees<br />

RASTER APERTURE 15 mm (0.6 in) at 220 mm (8.7 in)<br />

READABLE CODES Code 2/5, Code 39, Code 93, Code 128, EAN/UPC, EAN 128,<br />

Codabar, Plessey, Pharmacode<br />

MULTILABEL READING Up to 6 different codes in the same reading phase<br />

COMM. INTERFACES RS232+RS485 half duplex<br />

BAUD RATE Up to 115,200 bauds<br />

INPUT SIGNALS One programmable digital input and One External Trigger digital input<br />

OUTPUT SIGNALS Two programmable digital outputs<br />

PROGRAMMING METHOD Via serial port (WINHOST)<br />

OPERATING MODES ‘On-line’, ‘Serial On-line’, ‘Automatic’, ‘Test’<br />

MOTOR CONTROL Motor on/off software commands<br />

LED INDICATORS ‘Power On’, ‘Ext Trigger’, ‘Laser On’, ‘Good Read’, ‘Tx Data’<br />

LASER CLASSIFICATION IEC 825-1 Class 2; CDRH Class II<br />

LASER CONTROL Safety system to turn laser off in cases of motor slowdown or failure<br />

POWER SUPPLY 5 VDC ±5% (4 to 30 VDC with converter)<br />

POWER CONSUMPTION 1.5 W<br />

WEIGHT (without cable) Service > Results<br />

25-pin female connector<br />

25

26<br />

DS1500<br />

Main Applications<br />

Applications<br />

• OEM integration in automatic machines<br />

• Chemical and biomedical analysis machines<br />

• Document handling machines<br />

• Print & Apply systems<br />

• Packaging machines<br />

• ATL (Automated Tape Library)<br />

Lightweight<br />

Compact<br />

Dimensions<br />

1200 scan/s<br />

Benefits<br />

Test Mode with<br />

Bar-graph<br />

ACB<br />

Technology<br />

• Improves reading effectiveness in difficult and fast<br />

reading conditions thanks to an increased number of<br />

scans on the same moving code (1200 scans/s)<br />

• Consistent decoding of damaged or low contrast labels<br />

due to the embedded connectivity ACB (Advanced<br />

Code Builder) reconstruction software algorithm<br />

• Offers double serial option (RS232/485 SW sw<br />

selectable) which keeps the number of models to a<br />

minimum

Features<br />

• Extremely compact dimensions<br />

(40 x 30 x 22mm)<br />

• Ease of use - Test mode with bar-graph<br />

• Up to 1200 scan/s<br />

• ACB (Advanced Code Builder)<br />

reconstruction algorithm<br />

• Motor ON/OFF SW control<br />

• Selectable RS232/485 serial link<br />

• IP65 rugged industrial housing<br />

• Lightweight 44 g (1.55 oz.)<br />

General description<br />

Innovation > Solutions > Service > Results<br />

The combination of extremely compact dimensions and powerful high<br />

speed reading capabilities makes <strong>this</strong> scanner particularly suitable for<br />

integration in automatic machinery, such as in chemical and biomedical<br />

analysis machines, automated tape libraries, and pharmaceutical<br />

packaging and document handling machines. In conformity with the<br />

needs of automatic machinery, the scanner includes IP65 rugged<br />

industrial housing.<br />

DS1500 ease of installation and configuration is guaranteed by compact<br />

size, and a new operating test mode with bar-graph. This test mode is<br />

activated by means of a push button on the outer case of the scanner,<br />

and the LED bar-graph shows the reading percentage in real-time.<br />

Hence, there is no need for an external PC connected to monitor reading<br />

performance. This feature also simplifies re-positioning of the scanner<br />

during product changeovers in automated machinery.<br />

27

28<br />

DS1500 Reading Diagrams<br />

DS1500-1100 DS1500-2100<br />

0 1 2 3 4 5 6 7 8 9 10 (in)<br />

0 20 40 60 80 100 120 140 160 180 200 220 240 260 (mm)<br />

5<br />

120<br />

4 100<br />

3<br />

2<br />

80<br />

60<br />

40<br />

1<br />

20<br />

0 0<br />

1 20<br />

2<br />

40<br />

3<br />

60<br />

80<br />

0.15 mm<br />

(6 mils)<br />

4 100<br />

120<br />

5<br />

(mm)<br />

(in)<br />

0.20 mm<br />

(8 mils)<br />

0.30 mm<br />

(12 mils)<br />

0.50 mm<br />

(20 mils)<br />

NOTE: (0,0) is the center of the laser beam output window. NOTE: (0,0) is the center of the laser beam output window.<br />

CONDITIONS<br />

CONDITIONS<br />

Code = Inter<strong>lea</strong>ved 2/5 or Code 39<br />

PCS = 0.90<br />

“Pitch” angle = 0°<br />

“Skew” angle = 15°<br />

“Tilt” angle = 0°<br />

*Motor Control = Speed_3 (800 scans/s) for 0.15mm codes, Speed_4<br />

(1200 scans/s) for 0.20mm codes and greater<br />

* Parameter selectable in Winhost<br />

Dimensions<br />

2.5<br />

2<br />

1.5<br />

1<br />

0.5<br />

0<br />

0.5<br />

1<br />

1.5<br />

2<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

10<br />

20<br />

30<br />

40<br />

50<br />

60<br />

2.5<br />

(mm)<br />

(in)<br />

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 (in)<br />

0 20 40 60 80 100 120 140 160 180 200 220 240 260 (mm)<br />

0.10 mm<br />

(4 mils )<br />

Code = Inter<strong>lea</strong>ved 2/5 or Code 39<br />

PCS = 0.90<br />

“Pitch” angle = 0°<br />

“Skew” angle = 15°<br />

“Tilt” angle = 0°<br />

*Motor Control = Speed_3 (800 scans/s)<br />

• Parameter selectable in Winhost<br />

0.12 mm<br />

(5 mils )<br />

0.15 mm<br />

(6 mils )<br />

0.20 mm<br />

(8 mils )

Specifications<br />

OPERATING TEMPERATURE 0 to 45°C (32 to 113 °F)<br />

STORAGE TEMPERATURE -20 to 70 °C (-4 to 158 °F)<br />

HUMIDITY 90% non condensing<br />

VIBRATION RESISTANCE IEC 68-2-6 test FC 1.5 mm; 10 to 55 Hz; 2 hours on each axis<br />

SHOCK RESISTANCE IEC 68-2-27 test EA 30 G; 11 ms; 3 shocks on each axis<br />

PROTECTION CLASS IP65<br />

LIGHT SOURCE Visible laser diode (658 nm)<br />

MAX. RESOLUTION 0.15 mm (6 mils)<br />

SCANNING SPEED 1200 scans/s or 800 scan/s (SW selectable)<br />

MAX. READING DISTANCE 240 mm / 9.45 in (on codes with 0.50 mm/20 mils resolution)<br />

MAX. DEPTH OF FIELD 200 mm / 7.87 in (on codes with 0.50 mm/20 mils resolution)<br />

APERTURE ANGLE 60°<br />

READABLE CODES All main linear bar code symbologies<br />

MULTILABEL READING Up to 6 different codes readable in the same phase<br />

RECONSTRUCTION SOFTWARE ACB (Advanced Code Builder) embedded<br />

USER INTERFACE Push Button, 5 LEDs (scanner status/performance monitor)<br />

LED INDICATORS ‘Power on/100%’, ‘Good Read/80%’, ‘Ext. Trig./60%’,<br />

‘TX Data/40%’, ‘Laser On/20%’<br />

INPUT/OUTPUT SIGNALS 1 digital Input + 2 programmable digital outputs<br />

PROGRAMMING METHOD Via serial port (Winhost)<br />

OPERATING MODES On-line, Serial On-line, Automatic, Continuous, Test<br />

CONNECTIVITY 2 x RS232 or 1 x RS485 (full or half duplex) SW selectable<br />

BAUD RATE Up to 115.2 KBaud<br />

LASER CLASSIFICATION Class 2 - EN 60825-1, Class II - CDRH<br />

LASER CONTROL Laser auto shut-off in cases of motor failure<br />

MOTOR CONTROL On/Off via SW command<br />

POWER SUPPLY 5 VDC<br />

POWER CONSUMPTION 2 W max.<br />

DIMENSIONS 40 x 30 x 22 mm (1.6 x 1.2 x 0.9 in)<br />

WEIGHT 44 g (1.55 oz.) without cable<br />

CASE MATERIAL ZAMA (zinc, aluminium, magnesium alloy)<br />

Electrical Connections<br />

Connector pins details are indicated in the following table:<br />

15-pin male high density D-sub connector pinout<br />

Pin Name Function<br />

1 VS Power supply input voltage +<br />

5 GND Power supply input voltage -<br />

8 PE Protective Earth Ground<br />

13 SHIELD Cable Shield<br />

9 EXT TRIG - External Trigger -<br />

7 OUT1 + Output 1 +<br />

14 OUT2 + Output 2 +<br />

11, 12, 15 NC Not Connected<br />

Pin RS232 RS485 RS485<br />

Full-Duplex Half-Duplex<br />

2 TX232 Main TX485- RTX485-<br />

3 RX232 Main RX485+<br />

6 TXAUX TX485+ RTX485+<br />

10 RXAUX RX485-<br />

4 SGND SGND SGND<br />

Innovation > Solutions > Service > Results<br />

15-pin D-sub High-Density Male Connector<br />

29

30<br />

DS2200<br />

Main Applications<br />

Applications<br />

• OEM integration in automatic machines<br />

• Chemical and biomedical analysis machines<br />

• Document handling machines<br />

• Print & Apply systems<br />

• Packaging machines<br />

• ATL (Automated Tape Library)<br />

Benefits<br />

Lightweight<br />

Compact<br />

Dimensions<br />

• Impressive performance and reliability on all main bar<br />

code symbologies are provided thanks to high scan<br />

speed, excellent optical quality, new generation real<br />

time decoder and flexible decoding software<br />

• High reading performance is ensured on damaged or<br />

poorly printed bar codes<br />

• Easy integration into automated equipment<br />

• The dual serial interface increases device connectivity,<br />

enabling multi-point scanning configurations through<br />

Master-Slave or Multiplexer connections<br />

• WINHOST configuration software enables easy and<br />

user friendly device setup

Features<br />

• Ultra compact dimensions 50 x 40 x 28 mm<br />

(1.97x1.57x1.10 in)<br />

• Lightweight 150 g (5.29 oz.)<br />

• Very high density code reading<br />

(up to 0.076 mm / 3mils)<br />

• Scanning speed of 500 scans/s<br />

• Dual serial interface<br />

• IP65 rugged industrial housing<br />

General description<br />

Innovation > Solutions > Service > Results<br />

DS2200 is the ideal component for OEM and other applications requiring<br />

easy integration, high reliability and cost effectiveness. <strong>Datalo</strong>gic’s<br />

advanced technology and experience in miniaturized laser components<br />

enables development of a compact industrial laser scanner without<br />

compromising reading performance and industrial quality standards.<br />

Thanks to <strong>Datalo</strong>gic’s recognized high quality standards, system<br />

manufacturers can be confident that the scanners installed in their<br />

machines will improve overall system performance and reliability.<br />

31

32<br />

DS2200 Reading Diagrams<br />

DS2200-1XXX (Standard Resolution)<br />

CONDITIONS<br />

0 1 2 3 4 5 6 7 8 9 10 (in)<br />

0 20 40 60 80 100 120 140 160 180 200 220 240 260 (mm)<br />

5<br />

120<br />

4 100<br />

3<br />

2<br />

80<br />

60<br />

40<br />

1<br />

20<br />

0 0<br />

1<br />

20<br />

40<br />

2<br />

60<br />

3 80<br />

4 100<br />

0.15 mm 0.20 mm 0.30 mm 0.50 mm<br />

0.60 mm<br />

120<br />

5<br />

(mm)<br />

(in)<br />

(6 mils) (8 mils) (12 mils) (20 mils) (24 mils)<br />

Code = Inter<strong>lea</strong>ved 2/5 or Code 39<br />

PCS = 0.90<br />

Pitch angle = 0°<br />

Skew angle = 15°<br />

Tilt angle = 0°<br />

Dimensions<br />

DS2200-2XXX (High Resolution)<br />

2<br />

1<br />

0<br />

1<br />

2<br />

60<br />

(mm)<br />

(in)<br />

CONDITIONS<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

10<br />

20<br />

30<br />

40<br />

50<br />

0 1 2 3 4 5 (in)<br />

0 10 20 30 40 50 60 70 80 90 100 110 120 130 (mm)<br />

0.10 mm<br />

(4 mils)<br />

0.12 mm<br />

(5 mils)<br />

Code = Inter<strong>lea</strong>ved 2/5 or Code 39<br />

PCS = 0.90<br />

Pitch angle = 0°<br />

Skew angle = 15°<br />

Tilt angle = 0°<br />

0.15 mm<br />

(6 mils)<br />

0.20 mm<br />

(8 mils)

Specifications<br />

OPERATING TEMPERATURE 0 to 40 °C (32 to 104 °F)<br />

STORAGE TEMPERATURE -20 to 70 °C (-4 to 158 °F)<br />

HUMIDITY 90% non condensing<br />

VIBRATION RESISTANCE IEC 68-2-6 test FC 1.5 mm; 10 to 55 Hz; 2 hours on each axis<br />

SHOCK RESISTANCE IEC 68-2-27 test EA 30 G; 11 ms; 3 shocks on each axis<br />

PROTECTION CLASS IP65<br />

LIGHT SOURCE Visible laser diode (650 nm)<br />

MAX. RESOLUTION 0.15 mm (6 mils) for standard resolution models<br />

0.076 mm (3 mils) for high resolution models<br />

SCANNING SPEED 500 scans/sec<br />

MAX. READING DISTANCE 220 mm (on 0.60 mm/24 mils codes) for standard resolution models<br />

125mm (on 0.20 mm/8 mils codes) for high resolution models<br />

MAX. DEPTH OF FIELD 170 mm (on 0.60 mm/24 mils codes) for standard resolution models<br />

85 mm (on 0.20 mm/8 mils codes) for high resolution models<br />

APERTURE ANGLE 52 degrees for standard resolution models<br />

62 degrees for high resolution models<br />

RASTER APERTURE 15 mm (0.6 in) at 220 mm (8.7 in) for raster models<br />

READABLE CODES Code 2/5, Code 39, Code 93, Code 128, EAN/UPC, EAN128, Codabar, Pharmacode<br />

MULTILABEL READING Up to 6 different codes in the same presence sensor phase<br />

COMMUNICATION INTERFACE Dual serial interface (RS232+RS485 half duplex)<br />

BAUD RATE Up to 115.2 Kbauds<br />

INPUT SIGNALS One external trigger digital input<br />

OUTPUT SIGNALS Two programmable digital outputs<br />

PROGRAMMING METHOD Via serial port (WINHOST)<br />

OPERATING MODES ‘ ‘On-line’, ‘Serial On-line,’ ‘Automatic,’ ‘Test,’ ‘Verifier’<br />

LED INDICATORS ‘Power On,’ ‘External Trigger,’ ‘Good Read,’ ‘TX Data’<br />

LASER CLASSIFICATION IEC 825 Class 2<br />

LASER CONTROL Safety system to turn laser off in cases of motor slowdown or failure<br />

POWER SUPPLY 5 VDC ±5% (4 to 30 VDC with converter)<br />

POWER CONSUMPTION 2 W<br />

DIMENSIONS 50 x 40 x 28 mm (1.97 x 1.57 x 1.10 in)<br />

WEIGHT (without cable) 150 g (5.29 oz.)<br />

CASE MATERIAL Die-cast zinc<br />

Electrical Connections<br />

Connector pins details are indicated in the following table:<br />

25-pin D-sub female connector pinout<br />

Pin Name Function<br />

9, 13 VS Power supply input voltage +<br />

25* GND Power supply input voltage -<br />

1* CHASSIS Chassis ground<br />

2, 21 TXAUX TX RS232 Aux. Interface<br />

3, 20 RXAUX RX RS232 Aux. Interface<br />

4 RTX485- RTX- RS485 Main Interface<br />

5 RTX485+ RTX+ RS485 Main Interface<br />

7 SGND Signal Ground<br />

8 OUT 1+ Output 1+<br />

11 OUT 2+ Output 2+<br />

18 IN 1- Input 1-<br />

19 EXT TRIG - External Trigger -<br />

12, 22 GND Input/Output reference<br />

23, 24 N.U. Not Used<br />

6, 10, 14, 15, 16, 17 N.C. Not Connected<br />

* Pins 1 and 25 are connected internally.<br />

Innovation > Solutions > Service > Results<br />

25-pin female connector<br />

33

34<br />

DS2100N & DS2400N<br />

Main Applications<br />

Applications<br />

• Small conveyor sorting<br />

• Picking systems<br />

• Items and parts tracking<br />

• Process control and packaging<br />

• Document handling<br />

• Print & apply systems<br />

Enhanced<br />

Connectivity<br />

Ease of use<br />

Benefits<br />

Configuration<br />

SW Tool<br />

ACB<br />

Technology<br />

• Overall cost reduction and simple system wiring thanks<br />

to ID-NET high-speed connectivity system (no need<br />

for external multiplexer)<br />

• Easily and rapidly configured thanks to <strong>Datalo</strong>gic<br />

GENIUS (intuitive and multilanguage configuration<br />

program)<br />

• Decoding of partially damaged or normally unreadable<br />

bar codes due to high tilt angle, enabled by embedded<br />

ACB (Advanced Code Builder) software

Features<br />

• Increased read rate on low contrast<br />

and dirty bar codes<br />

• Embedded ID-NET high speed<br />

connectivity to simplify data collection<br />

and cluster wiring<br />

• Intuitive X-PRESS interface for quick<br />

scanner installation and troubleshooting<br />

• Easy setup through multilanguage<br />

Genius SW tool<br />

• ACB advanced code builder technology<br />

improves the read rate on damaged<br />

bar codes<br />

• Motor on/off and motor speed SW<br />

programmable for higher reliability<br />

• IP65 rugged industrial housing<br />

General description<br />

Innovation > Solutions > Service > Results<br />

DS2100N and DS2400N are designed to offer ease of use. Typical<br />

applications in automated warehousing (conveyor sorting and picking<br />

systems), automated shop floor (for items and parts tracking), process<br />

control and packaging. In OEM integration these scanners are suitable<br />

for integration into automatic machinery (chemical and biomedical<br />

analysis machines) and in packaging and document handling machines.<br />

The scanners guarantee reliability in achieving very good read rates.<br />

DS2100N and DS2400N scanners are equipped with the innovative<br />

X-PRESS Human Machine Interface granting ease of use and<br />

quick scanner installation. This technology c<strong>lea</strong>rly presents status and<br />

diagnostic information by means of a five LED bar-graph, and the single<br />

multi-function key gives immediate access to relevant functions such as<br />

Test Mode, Auto Learn and Auto Setup.<br />

35

36<br />

DS2100N & DS2400N Reading Diagrams<br />

DS2100N-1200 (Standard Resolution, 500 scans/s)<br />

4 100<br />

120<br />

5<br />

(mm)<br />

(in)<br />

CONDITIONS<br />

Optic Version = Linear<br />

Code = Inter<strong>lea</strong>ved 2/5 or Code 39<br />

PCS = 0.90<br />

Pitch angle = 0°<br />

Skew angle = 15°<br />

Tilt angle = 0°<br />

* Reading Conditions = Standard<br />

* Parameter selectable in Genius<br />

DS2100N-1204 High Performance (Standard Resolution, 1000 scan/s)<br />

CONDITIONS<br />

0 1 2 3 4 5 6 7 8 9 10 11 12(in)<br />

0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 (mm)<br />

5<br />

120<br />

4 100<br />

3<br />

2<br />

80<br />

60<br />

40<br />

0.35 mm<br />

1<br />

20<br />

0.20 mm<br />

(8 mils)<br />

0.30 mm<br />

(12 mils)<br />

(14 mils) ≥ 0.50 mm<br />

(20 mils)<br />

0 0<br />

1 20<br />

2<br />

40<br />

60<br />

3<br />

80<br />

0 1 2 3 4 5 6 7 8 9 10 11 12 (in)<br />

0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 (mm)<br />

5<br />

120<br />

4 100<br />

3<br />

2<br />

80<br />

60<br />

40<br />

1<br />

0<br />

1<br />

20<br />

0<br />

20<br />

0.15 mm<br />

(6 mils)<br />

0.20 mm<br />

(8 mils)<br />

0.30 mm<br />

(12 mils)<br />

≥ 0.50 mm<br />

(20 mils)<br />

2<br />

40<br />

60<br />

3<br />

80<br />

4 100<br />

120<br />

5<br />

(mm)<br />

(in)<br />

Optic Version = Linear<br />

Code = Inter<strong>lea</strong>ved 2/5 or Code 39<br />

PCS = 0.90<br />

Pitch angle = 0°<br />

Skew angle = 15°<br />

Tilt angle = 0°<br />

*Code Resolution:<br />

High - for 0.30 mm (12 mils) codes and smaller<br />

Standard - for 0.50 mm (20 mils) codes and greater<br />

*Reading Conditions = Standard<br />

* Parameter selectable in Genius<br />

DS2100N-2200 (High Resolution, 500 scans/s)<br />

2<br />

1<br />

0<br />

1<br />

2<br />

CONDITIONS<br />

Optic Version = Linear<br />

Code = Inter<strong>lea</strong>ved 2/5 or Code 39<br />

PCS = 0.90<br />

Pitch angle = 0°<br />

Skew angle = 15°<br />

Tilt angle = 0°<br />

* Reading Conditions = Standard<br />

* Parameter selectable in Genius<br />

DS2100N-2204 High Performance - (High Resolution, 1000 scans/s)<br />

2<br />

1<br />

0<br />

1<br />

CONDITIONS<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

10<br />

20<br />

30<br />

40<br />

50<br />

60<br />

(mm)<br />

(in)<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

10<br />

20<br />

30<br />

40<br />

2 50<br />

60<br />

(mm)<br />

(in)<br />

0 1 2<br />

3 4 5 (in)<br />

0 10 20 30 40 50 60 7080<br />

90 100 110 120 130 (mm)<br />

Optic Version = Linear<br />

Code = Inter<strong>lea</strong>ved 2/5 or Code 39<br />

PCS = 0.90<br />

Pitch angle = 0°<br />

Skew angle = 15°<br />

Tilt angle = 0°<br />

*Code Resolution:<br />

High - for 0.15 mm (6 mils) codes and smaller<br />

Standard - for 0.20 mm (8 mils) codes<br />

*Reading Conditions = Standard<br />

* Parameter selectable in Genius<br />

0.15 mm<br />

(6 mils)<br />

≥ 0.30 mm<br />

(12 mils)<br />

0.20 mm<br />

(8 mils)<br />

0 1 2<br />

3<br />

4<br />

5 (in)<br />

0 10 20 30 40 50 60 7080<br />

90 100 110 120 130 (mm)<br />

0.12 mm<br />

(5 mils)<br />

≥ 0.20 mm<br />

(8 mils )<br />

0.15 mm<br />

(6 mils)

DS2400N-0200 (Short Reading Range)<br />

4<br />

3<br />

2<br />

1<br />

0<br />

1<br />

2<br />

3<br />

4<br />

10<br />

7,5<br />

5<br />

2,5<br />

0<br />

2,5<br />

5<br />

7,5<br />

10<br />

(in) (cm)<br />

CONDITIONS<br />

Optic Version = Linear<br />

Code = Inter<strong>lea</strong>ved 2/5 or Code 39<br />

PCS = 0.90<br />

Pitch angle = 0°<br />

Skew angle = 10°<br />

Tilt angle = 0°<br />

* Code Resolution = High<br />

* Reading Conditions = Standard<br />

* Scan Speed = Speed_3 (800 scans/s)<br />

* Parameter selectable in Genius<br />

DS2400N-2200 (Long Reading Range)<br />

8<br />

6<br />

4<br />

2<br />

0<br />

2<br />

4<br />

6<br />

8<br />

20<br />

15<br />

10<br />

5<br />

0<br />

5<br />

10<br />

15<br />

20<br />

(in) (cm)<br />

CONDITIONS<br />

Optic Version = Linear<br />

Code = Inter<strong>lea</strong>ved 2/5 or Code 39<br />

PCS = 0.90<br />

Pitch angle = 0°<br />

Skew angle = 10°<br />

Tilt angle = 0°<br />

* Code Resolution:<br />

High – for 0.35 mm (14 mils) codes<br />

Std – for 0.50 mm (20 mils) codes and greater<br />

* Reading Conditions = Standard<br />

* Scan Speed = Speed_3 (800 scans/s)<br />

* Parameters selectable in Genius.<br />

2 4 6 8 10 12<br />

14<br />

5 10 15 20 25 30 35<br />

0.20 mm<br />

(8 mils)<br />

0.25 mm<br />

(10 mils)<br />

≥0.35 mm<br />

(14 mils)<br />

(in)<br />

(cm)<br />

4 8 12 16 20 24<br />

28 (in)<br />

10 20 30 40 50 60 70 (cm)<br />

0.35 mm ≥ 0.50 mm<br />

(14 mils) (20 mils)<br />

DS2400N-1200 (Medium Reading Range)<br />

8<br />

6<br />

4<br />

2<br />

0<br />

2<br />

4<br />

6<br />

8<br />

CONDITIONS<br />

Innovation > Solutions > Service > Results<br />

20<br />

15<br />

10<br />

5<br />

0<br />

5<br />

10<br />

15<br />

20<br />

(in) (cm)<br />

0.35 mm<br />

(14 mils)<br />

Optic Version = Linear<br />

Code = Inter<strong>lea</strong>ved 2/5 or Code 39<br />

PCS = 0.90<br />

Pitch angle = 0°<br />

Skew angle = 10°<br />

Tilt angle = 0°<br />

* Code Resolution:<br />

High – for 0.25 mm (10 mils) codes<br />

Std – for 0.35 mm (14 mils) codes and greater<br />

* Reading Conditions = Standard<br />

* Scan Speed = Speed_3 (800 scans/s)<br />

* Parameters selectable in Genius.<br />

4 8 121620<br />

(in)<br />

10 20 35 40 50 (cm)<br />

0.25 mm<br />

(10 mils)<br />

≥0.50 mm<br />

(20 mils)<br />

37

38<br />

DS2100N & DS2400N Dimensions

Specifications<br />

OPERATING TEMPERATURE 0 to 40 °C (32 to 104 °F)<br />

STORAGE TEMPERATURE -20 to 70 °C (-4 to 158 °F)<br />

HUMIDITY 90% non condensing<br />

VIBRATION RESISTANCE IEC 68-2-6 test FC 1.5 mm; 10 to 55 Hz; 2 hours on each axis<br />

SHOCK RESISTANCE IEC 68-2-27 test EA 30 G; 11 ms; 3 shocks on each axis<br />

PROTECTION CLASS IP65<br />

LIGHT SOURCE Visible laser diode (650 nm)<br />

MAX. RESOLUTION 0.15 mm (6 mils) for standard resolution models<br />

0.076 mm (3 mils) for high resolution models<br />

SCANNING SPEED 500 scans/sec<br />

MAX. READING DISTANCE 220 mm (on 0.60 mm/24 mils codes) for standard resolution models<br />

125mm (on 0.20 mm/8 mils codes) for high resolution models<br />

MAX. DEPTH OF FIELD 170 mm (on 0.60 mm/24 mils codes) for standard resolution models<br />

85 mm (on 0.20 mm/8 mils codes) for high resolution models<br />

APERTURE ANGLE 52 degrees for standard resolution models<br />

62 degrees for high resolution models<br />

RASTER APERTURE 15 mm (0.6 in) at 220 mm (8.7 in) for raster models<br />

READABLE CODES Code 2/5, Code 39, Code 93, Code 128, EAN/UPC, EAN128, Codabar, Pharmacode<br />

MULTILABEL READING Up to 6 different codes in the same presence sensor phase<br />

COMMUNICATION INTERFACE Dual serial interface (RS232+RS485 half duplex)<br />

BAUD RATE Up to 115.2 Kbauds<br />

INPUT SIGNALS One external trigger digital input<br />

OUTPUT SIGNALS Two programmable digital outputs<br />

PROGRAMMING METHOD Via serial port (WINHOST)<br />

OPERATING MODES ‘On-line’, ‘Serial On-line,’ ‘Automatic,’ ‘Test,’ ‘Verifier’<br />

LED INDICATORS ‘Power On,’ ‘External Trigger,’ ‘Good Read,’ ‘TX Data’<br />

LASER CLASSIFICATION IEC 825 Class 2<br />

LASER CONTROL Safety system to turn laser off in cases of motor slowdown or failure<br />

POWER SUPPLY 5 VDC ±5% (4 to 30 VDC with converter)<br />

POWER CONSUMPTION 2 W<br />

DIMENSIONS 50 x 40 x 28 mm (1.97 x 1.57 x 1.10 in)<br />

WEIGHT (without cable) 150 g (5.29 oz.)<br />

CASE MATERIAL Die-cast zinc<br />

Electrical Connections<br />

Pin Name<br />

25-pin D-sub female connector pinout<br />

Function<br />

13, (9) VS Power supply input voltage +<br />

25 GND Power supply input voltage -<br />

1 CHASSIS Cable shield connected to chassis<br />

18 EXT TRIG A External Trigger A (polarity insensitive)<br />

19 EXT TRIG B External Trigger B (polarity insensitive)<br />

10 IN2 - Input 2 -<br />

8 OUT1 + Output 1 +<br />

22 OUT1 - Output 1 -<br />

11 OUT2 + Output 2 +<br />

12 OUT2 - Output 2 -<br />

20 RXAUX Auxiliary RS232<br />

21<br />

23<br />

TXAUX<br />

ID-NET +<br />

Auxiliary RS232<br />

High speed internal network +<br />

25-pin Female D-sub Connector<br />

24 ID-NET - High speed interconnection network -<br />

6, 14, 15, 16, 17 NC Not Connected<br />

Pin Name RS232 RS485 RS485<br />

Full-Duplex Half-Duplex<br />

2 TX232 TX485+ RTX485+<br />

3<br />

4<br />

5<br />

MAIN INTERFACE<br />

(SW SELECTABLE)<br />

RX232<br />

RTS232<br />

CTS232<br />

*RX485+<br />

TX485-<br />

*RX485-<br />

RTX485-<br />

7 SGND SGND S GND<br />

* Do not <strong>lea</strong>ve floating, see par. “RS485 Full-Duplex Interface” for connection details.<br />

Innovation > Solutions > Service > Results<br />

39

40<br />

DS4800<br />

Main Applications<br />

Applications<br />

• Automated warehousing<br />

• Medium / small conveyor sorting<br />

• Reading on pallets<br />

• Picking systems<br />

• Automated shop floor<br />

• Items and parts tracking<br />

• Process control systems<br />

Enhanced<br />

Connectivity<br />

Ease of use<br />

Configuration<br />

SW Tool<br />

Benefits<br />

ACR4<br />

technology<br />

Smart focus<br />

adjustment<br />

• Performance optimization based on actual reading<br />

distance, and extended reading area through smart<br />

focus adjustment<br />

• DIGITECH Digitech technology permits full SW control<br />

over signal processing parameters. Scanner setup can<br />

therefore be optimized quite simply by simply loading the<br />

right SW recipe, thus enabling excellent performance in<br />

all reading conditions<br />

• Improved reading rate on low contrast barcodes while<br />

granting excellent performance at high skew angles<br />

• ACR4 reconstruction technology increases the max<br />

tilt angle and overall read rate of damaged barcodes<br />

• Overall cost reduction and simple system wiring thanks<br />

to ID-NET high-speed connectivity system (no need<br />

for external multiplexer)

Features<br />

• Smart Focus adjustment for flexible<br />

reading area selection<br />

• DIGITECH technology enables excellent<br />

reading performance<br />

• Intuitive X-PRESS interface provides<br />

easy scanner setup<br />

• ACR4 reconstruction technology<br />

improves reading of damaged barcodes<br />

• Multilanguage Genius SW tool enables<br />

rapid scanner configuration<br />

• ID-NET embedded interface for<br />

high-speed communication network<br />

• Multilanguage display improves scanner<br />

monitoring and diagnostics<br />

• Total ambient light immunity thanks to high<br />

frequency laser modulation<br />

• IP65 rugged industrial housing<br />

General description<br />

Innovation > Solutions > Service > Results<br />

DS4800 features excellent reading performance satisfying all main<br />

identification needs of manufacturing plants, especially in Shop Floor<br />

and Warehousing applications. With the innovative X-PRESS<br />

interface, installation and maintenance are easier than ever. Status<br />

and diagnostic information is are c<strong>lea</strong>rly shown in the 5-LED bar-graph,<br />

while a multi-function push button enables all relevant activities such as<br />

bar code verification (Test mode), automatic code setting (Auto Learn)<br />

and self optimization of reading performance (Auto Setup). Through<br />

smart focus adjustment, DS4800 optimizes the performance based<br />

on reading distance. This extends the reading area and improves the<br />

overall read rate. Thanks to DIGITECH technology, DS4800 provides<br />

excellent reading performance on demanding barcodes. By means<br />

of optimized reading recipes, DS4800 improves reading rate on low<br />

contrast barcodes while granting excellent performance at high skew<br />

angles. DS4800 is equipped with an embedded high-speed ID-NET<br />

communication interface. ID-NET enables efficient data collection<br />

without requiring an external multiplexer, thus providing overall cost<br />

reduction and simplifying network wiring. Extended field bus connectivity<br />

is available through a complete range of modular connection boxes.<br />

DS4800 is also easily programmed through the multilanguage Genius<br />

configuration SW. Thanks to the Wizard approach and graphic add-ons,<br />

scanner SW setup is rapidly accomplished.<br />

41

42<br />

DS4800 Reading Diagrams<br />

DS4800 DS4800<br />

in<br />

80<br />

40<br />

mm<br />

300<br />

200<br />

100<br />

0<br />

-40 -100<br />

-80<br />

-200<br />

-300<br />