2009 Greenhouse Gas Savings Study Report - Alberta Used Oil ...

2009 Greenhouse Gas Savings Study Report - Alberta Used Oil ...

2009 Greenhouse Gas Savings Study Report - Alberta Used Oil ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

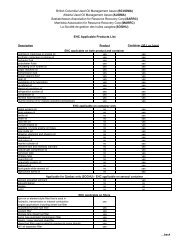

It should be noted that significant data gaps exist in the amounts (percentages) of<br />

materials going to each facility. Only collection data from M&R Environmental, Merlin<br />

Plastics, and Safety-Kleen were received, with the remaining percentages having been<br />

calculated/assumed, applying the assumptions stated above. With more complete data<br />

from other Processors, better estimates of where the materials were actually transported<br />

during the year could be calculated.<br />

<strong>Used</strong> <strong>Oil</strong><br />

It was assumed that all used oil going from Collector to Processor was transported in<br />

large tank trucks with 8,000 gallon capacities (Seneca Tank, 2010). For large tank trucks,<br />

a fuel consumption value of 0.395 L/km was used (NRCan, <strong>2009</strong>). The only exception to<br />

this concerns the railway transportation for used oil that occurs from Safety-Kleen's<br />

facility in Delta, BC to their re-refinery in Breslau, ON. The transportation distances<br />

from Collectors to the Delta facility were separated from the distance of rail transport<br />

from the Delta facility to the Breslau re-refinery, in order to account for the difference in<br />

fuel consumption between trucks and rail locomotives. For rail transport, a fuel<br />

consumption value of 0.828 L/km was calculated, based on a value of<br />

525 gallons/24 hours (Vantuono, 2002, p. 4) and an average speed of 100 km/hour (Via<br />

Rail, 2010). Due to the variable and large capacity that freight rail can offer, it was<br />

assumed that all the used oil that went to the Breslau facility in <strong>2009</strong> was accommodated<br />

in one trip, making the total capacity of the train on this trip equal to 2,450,030 L. With<br />

tank cars having an average capacity of over 113,563 L (30,000 gallons) (UTLX, 2008),<br />

this is equivalent to a train with 22 cars.<br />

<strong>Oil</strong> Filters<br />

It was assumed that all oil filters traveling from Collector to Processor and subsequent<br />

end users were transported in 42 US-gallon oil barrels (barrel height assumed to be<br />

twice its diameter) in large trailer trucks with 107 m3 (3,800 ft3) capacities<br />

(ShipNorthAmerica Transportation, 2007).<br />

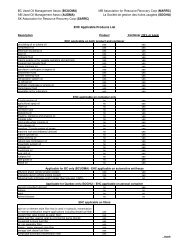

For oil filters traveling to Processors, the number of filters that can fit into this volume<br />

was based on a weight of unprocessed filter per barrel ratio calculated by M&R<br />

Environmental based on their <strong>2009</strong> collection data. With the ratio between weight and<br />

number of filters from the BCUOMA <strong>2009</strong> collection data known (Table 2.1), the truck's<br />

capacity for filters in this arrangement was calculated. Filters are crushed/stripped at<br />

the Processors, thus allowing increased capacity for filters traveling to the metal brokers<br />

and steel mills. A percentage reduction in volume of 20 percent was assumed to<br />

accommodate this fact.<br />

071620 (2) 14 CONESTOGA-ROVERS & ASSOCIATES