Solubility of Hydrogen, Oxygen, Nitrogen, and Helium in Water

Solubility of Hydrogen, Oxygen, Nitrogen, and Helium in Water

Solubility of Hydrogen, Oxygen, Nitrogen, and Helium in Water

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

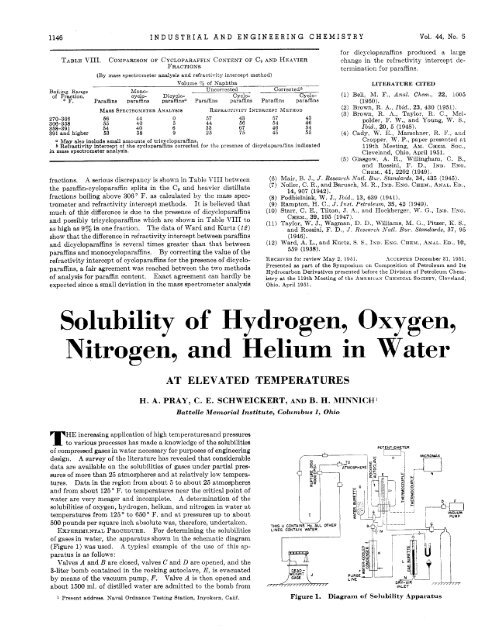

1146 INDUSTRIAL AND ENGINEERING CHEMISTRY Vol. 44, No. 5<br />

TABLE lTIII. COMPARISON OF CYCLOP.4RAFFIN CONTENT OF cs AND HEAVIER<br />

FRACTIONS<br />

fractions. -4 serious discrepancy is shown <strong>in</strong> Table VI11 between<br />

the paraff<strong>in</strong>-cycloparaff<strong>in</strong> splits <strong>in</strong> the CQ <strong>and</strong> heavier distillate<br />

fractions boil<strong>in</strong>g above 306" F. as calculated by the mass spec-<br />

trometer <strong>and</strong> refractivity <strong>in</strong>tercept methods. It is believed that<br />

much <strong>of</strong> this difference is due to the presence <strong>of</strong> dicycloparaff<strong>in</strong>s<br />

<strong>and</strong> possibly tricycloparaff<strong>in</strong>s which are shown <strong>in</strong> Table VI11 to<br />

as high as 9% <strong>in</strong> one fraction. The data <strong>of</strong> Ward <strong>and</strong> Kurta (12)<br />

show that the difference <strong>in</strong> refractivity <strong>in</strong>tercept between paraff<strong>in</strong>s<br />

<strong>and</strong> dicycloparaff<strong>in</strong>s is several times greater than that between<br />

paraff<strong>in</strong>s <strong>and</strong> monocycloparaff<strong>in</strong>s. By correct<strong>in</strong>g the value <strong>of</strong> the<br />

refractivity <strong>in</strong>tercept <strong>of</strong> cycloparaff<strong>in</strong>s for the presence <strong>of</strong> dicyclo-<br />

paraff<strong>in</strong>s, a fair agreement was reached between the two methods<br />

<strong>of</strong> analysis for paraff<strong>in</strong> content. Exact agreement can hardly be<br />

expected s<strong>in</strong>ce a small deviation <strong>in</strong> the mass spectrometer analysis<br />

for dicycloparaff<strong>in</strong>s produced a laigc<br />

change <strong>in</strong> the refractivity <strong>in</strong>terccpt de-<br />

term<strong>in</strong>ation for paraff<strong>in</strong>s.<br />

(By mass spectrometer analysis <strong>and</strong> refractivity <strong>in</strong>tercept method)<br />

Volume % <strong>of</strong> Saphtha<br />

LITERATURE CITED<br />

Boil<strong>in</strong>g Range Mono-<br />

Uncorrected Corrected6<br />

<strong>of</strong> Fraction, cyolo- Dicyclo- Cyclo- Cyclo-<br />

(1) Bell, M. F., Anal. Chem., 22, 1005<br />

F. Paraff<strong>in</strong>s paraff<strong>in</strong>s paraff<strong>in</strong>sa Paraff<strong>in</strong>s paraff<strong>in</strong>s Paraff<strong>in</strong>s paraff<strong>in</strong>s<br />

(1950).<br />

MAE^ SPECTROYETER ANALYSIS REFRACTIVITY INTERCEPT hf ETHOD<br />

(2) Brown, R. A,, Zbid., 23, 430 (1951).<br />

(3) Brown, R. A,, Taylor, R. C., Mel-<br />

270-306<br />

56 44 0 57 43 57 43<br />

306-358 55 40 5 44 56 54<br />

46<br />

polder, F. W., <strong>and</strong> Young, W. S.,<br />

358-391<br />

54 40 6 33 67 46 54<br />

Zbid., 20, 5 (1948).<br />

391 <strong>and</strong> higher 53 38 9 25 75 45 55 14) Cady, W. E., AIarschner, R. F., <strong>and</strong><br />

a May also <strong>in</strong>clude small amounts <strong>of</strong> tricycloparaff<strong>in</strong>s.<br />

Cropper, W. P., payer presented at<br />

b Refractivity <strong>in</strong>tercept <strong>of</strong> the cycloparaff<strong>in</strong>s corrected for the presence <strong>of</strong> dicycloparaff<strong>in</strong>s <strong>in</strong>dicated<br />

119th Meet<strong>in</strong>g, AM. CHEM. SOC.,<br />

<strong>in</strong> mass spectrometer analysis.<br />

Clevel<strong>and</strong>, Ohio, April 1951.<br />

(5) Glaspow. A. 11.. Will<strong>in</strong>pham. C. B..<br />

<strong>and</strong> Ross<strong>in</strong>i, F. D.; IND. ENG.<br />

CHEM., 41, 2282 (1949).<br />

(6) Whir, B. J., J. Reseaich Natl. Bur. St<strong>and</strong>ards, 34, 435 (1945).<br />

(7) Noller, C. R., <strong>and</strong> Barusch, h.1. R., IND. ENG. CHmf., API'AL. ED.,<br />

14, 907 (1942).<br />

(8) Podbielniak, W. J., Zbid., 13, 639 (1941).<br />

(9) Rampton, H. C., J. Znst. Petroleum, 35, 42 (1949).<br />

(10) Starr, C. E., Tilton, J. A,, <strong>and</strong> Hockberger, W. G., END. KNG.<br />

CREM., 39, 195 (1947).<br />

(11) Taylor, W. J., Wagman, D. D., Williams, M. G., Pitzer, K. S.,<br />

<strong>and</strong> Ross<strong>in</strong>i, F. D., J. Rrseurch Natl. Bur. Stadwds, 37, 95<br />

(1946).<br />

(12) Ward, A. L., <strong>and</strong> Kurts. 8. S., IND. ENG. CHEY., .ANAL. ED., 20,<br />

559 (1938).<br />

RECEIVED for review May 2, 1951. -4CCEPTED December 31, 1961.<br />

Presented as part <strong>of</strong> the Symposium cn Composition <strong>of</strong> Petroleum <strong>and</strong> Its<br />

Hydrocarbon Derivatives presented before the Division <strong>of</strong> Petroleum Cliern-<br />

istry at the 119th Meet<strong>in</strong>g <strong>of</strong> the .4~E~lc.43 CHEYICAI. EOCIETY, Clevel<strong>and</strong>,<br />

Ohio, April 1951.<br />

<strong>Solubility</strong> <strong>of</strong> <strong>Hydrogen</strong>, <strong>Oxygen</strong>,<br />

<strong>Nitrogen</strong>, <strong>and</strong> <strong>Helium</strong> <strong>in</strong> <strong>Water</strong><br />

THE<br />

AT ELEVATED TEMPERATURES<br />

H. A. PRAY, C. E. SCHWEICKERT, AND B. H. R/IIYVIvICH1<br />

Battelle iMemorial Institute, Columbus 1, Ohio<br />

1 <strong>in</strong>cidng application <strong>of</strong> high temperatures<strong>and</strong> pressures<br />

to various processes has made a knowledge <strong>of</strong> the solubilities<br />

<strong>of</strong> compressed gases <strong>in</strong> water necessary for purpoises <strong>of</strong> eng<strong>in</strong>eer<strong>in</strong>g<br />

design. A survey <strong>of</strong> the literature has revealed that considerable<br />

data are available on the solubilities <strong>of</strong> gases under partial pressures<br />

<strong>of</strong> more than 25 atmospheres <strong>and</strong> at relatively low temperatures.<br />

Data <strong>in</strong> the region from about 5 to about 25 atmospheres<br />

<strong>and</strong> from about 125' F. to temperatures near the critical po<strong>in</strong>t <strong>of</strong><br />

water are very meager <strong>and</strong> <strong>in</strong>complete. A determ<strong>in</strong>ation <strong>of</strong> the<br />

solubilities <strong>of</strong> oxygen, hydrogen, helium, <strong>and</strong> nitrogen <strong>in</strong> water at<br />

temperatures from 128" to 650" F. <strong>and</strong> at presmres up to about<br />

500 pounds per square <strong>in</strong>ch absolute was, therefore, undertaken.<br />

EXPERIMENTAL PROCEDURE. For determ<strong>in</strong><strong>in</strong>g the solubilities<br />

<strong>of</strong> gases <strong>in</strong> water, the apparatus shown <strong>in</strong> the schematic diagram<br />

(Figure 1) was used. A typical example <strong>of</strong> the use <strong>of</strong> this apparatus<br />

is as follows:<br />

Valves A <strong>and</strong> B are closed, valves C <strong>and</strong> D are opened, <strong>and</strong> the<br />

3-liter bomb conta<strong>in</strong>ed <strong>in</strong> the rock<strong>in</strong>g autoclave, E, is evacuated<br />

by means <strong>of</strong> the vamum pump, F. Valve A is then opened <strong>and</strong><br />

about 1500 ml. <strong>of</strong> distilled water are admitted to the bomb from<br />

1 Present address, Naval Ordnance Test<strong>in</strong>g Station, Inyokern, Calif.<br />

INLET<br />

Figure 1. Diagram <strong>of</strong> Solrability Apparatus

May 1952 INDUSTRIAL AND ENGINEERING CHEMISTRY 1147<br />

Figure 2. <strong>Solubility</strong> <strong>of</strong> <strong>Oxygen</strong> <strong>in</strong> <strong>Water</strong> with Vary<strong>in</strong>g<br />

Pressure<br />

0. Authors<br />

A. Froblioh et 01. (I)<br />

Figure 3. <strong>Solubility</strong> <strong>of</strong> <strong>Oxygen</strong> <strong>in</strong> <strong>Water</strong> with Vary<strong>in</strong>g<br />

Temperature<br />

MRTIAL PRESSURE, PS I A<br />

Figure 4. <strong>Solubility</strong> <strong>of</strong> <strong>Hydrogen</strong> <strong>in</strong> <strong>Water</strong> with Vary<strong>in</strong>g<br />

Pressure<br />

A. Ipatieff <strong>and</strong> Teodorovish (2)<br />

B. Authom<br />

C. Wiebe <strong>and</strong> Gaddy (3)<br />

TEMPERATURE, OF.<br />

Figure 5. <strong>Solubility</strong> <strong>of</strong> <strong>Hydrogen</strong> <strong>in</strong> <strong>Water</strong> with Vary<strong>in</strong>g<br />

Temperature

1143 INDUSTRIAL AND ENGINEERING CHEMISTRY Vol. 44, No. 5<br />

PARTIAL PRESSURE, PS.1 A<br />

Figure 6. <strong>Solubility</strong> <strong>of</strong> <strong>Helium</strong> <strong>in</strong> <strong>Water</strong> with Vary<strong>in</strong>g<br />

Pressure<br />

A. Wiebe <strong>and</strong> Gaddy (4)<br />

0. Authors<br />

Figure 7. <strong>Solubility</strong> <strong>of</strong> <strong>Helium</strong> <strong>in</strong> <strong>Water</strong> with Vary<strong>in</strong>g<br />

Temperature<br />

the water buret, G. Valve A is then closed <strong>and</strong> the system is<br />

evacuated to a pressure correspond<strong>in</strong>g to the saturated vapor pres-<br />

sure <strong>of</strong> water at room temperature. Valve C is then closed <strong>and</strong><br />

the rock<strong>in</strong>g autoclave, which is heated electrically, is set <strong>in</strong><br />

motion <strong>and</strong> brought to some predeterm<strong>in</strong>ed temperature. The<br />

Figure 8. <strong>Solubility</strong> <strong>of</strong> <strong>Nitrogen</strong> <strong>in</strong> <strong>Water</strong> with Vary<strong>in</strong>g<br />

Pressure<br />

A. Frohlich et QZ. (I)<br />

R. Wiebe <strong>and</strong> Gaddr (5)<br />

Figure 9. <strong>Solubility</strong> <strong>of</strong> <strong>Nitrogen</strong> <strong>in</strong> <strong>Water</strong> with Vary<strong>in</strong>g<br />

Temperature<br />

temperature <strong>of</strong> the autoclave is controlled by a Leeds & Northrup<br />

Micromax temperature controller <strong>and</strong> recorder, N. The telu-<br />

perature <strong>in</strong>side <strong>of</strong> the bomb is determ<strong>in</strong>ed by means <strong>of</strong> a chromel-<br />

alumel thermocouple <strong>in</strong>serted <strong>in</strong> a sta<strong>in</strong>less steel well <strong>in</strong>side <strong>of</strong> the<br />

bomb. The electromotive force <strong>of</strong> the thermocouple is deter-

May 1952 INDUSTRIAL AND ENGINEERING CHEMISTRY 1149<br />

TABLE I. SOLUBILITY OF OXYGEN IN WATER<br />

OZ Partid<br />

Pressure<br />

Lb./'Sq. In.' Abs. Souroe Cc. OP/G. <strong>of</strong> <strong>Water</strong> Average<br />

140 (1) . ,<br />

295 ..<br />

370 ..<br />

77' F.<br />

..<br />

..<br />

..<br />

325' F.<br />

200 loo<br />

300<br />

Authors<br />

Authors<br />

Authors<br />

0. 14 0.16 0. 16<br />

0.31 0.31 0.31<br />

0.47 0.47 0.45<br />

. ..<br />

..<br />

..<br />

400' F.<br />

100<br />

150<br />

Authors<br />

Authors<br />

0.19 0.18 0.17<br />

0.30 0.28 0.27<br />

. .<br />

..<br />

100<br />

200<br />

300<br />

400<br />

Authors<br />

Authors<br />

Authors<br />

Authors<br />

5000 P.<br />

0.68 0.63 0.62 0.51<br />

0.47 0.99 0.69 0.56<br />

0.92 0.89 0 91<br />

1.52 1.68 1.18 1:OQ<br />

1.37 1.24<br />

t .<br />

1.80 1.63 1:70 ..<br />

600' P.<br />

..<br />

. .<br />

..<br />

,.<br />

..<br />

loo<br />

Authors 0.63 0.60 0.69 0.62 . ,<br />

Authors 1.39 1 45 1.43<br />

300 Authors 2.22 2:14 2.34 2:02 2:24<br />

650' F.<br />

104 Authors 1.17 1.26 . . . , . .<br />

175 Authors 1.85 .. ..<br />

205 Authors 2.39 2128 2:19 ..<br />

2 80 Authors 2.96 ,. .. .<br />

2 89 Authors 2.51 2:61 , , ..<br />

309 Authors 2.99 . . . . , . . .<br />

a At st<strong>and</strong>rsrd temperature <strong>and</strong> pressure.<br />

m<strong>in</strong>ed with the aid <strong>of</strong> a Leeds & Northrup<br />

Semi-Precision potentiometer, H. The<br />

thermocouple was calibrated aga<strong>in</strong>st the<br />

melt<strong>in</strong>g po<strong>in</strong>ts <strong>of</strong> metals obta<strong>in</strong>ed from<br />

the Bureau <strong>of</strong> St<strong>and</strong>ards for that purpose.<br />

The temperature dur<strong>in</strong>g any one run is<br />

held constant to with<strong>in</strong> 2" F. After the<br />

temperature <strong>in</strong>side <strong>of</strong> the bomb reaches<br />

the deRired temperature, the outlet valve,<br />

A, lead<strong>in</strong>g to the mercury U-tube is<br />

opened <strong>and</strong> the saturated vapor pressure<br />

<strong>of</strong> water is determ<strong>in</strong>ed with the dead-<br />

weight gage, J. The mercury U-tube<br />

isolates the material <strong>in</strong> the bomb from the<br />

oil <strong>in</strong> the dead-weight gage. The pres-<br />

sure, as determ<strong>in</strong>ed by the dead-weight<br />

gage, is checked aga<strong>in</strong>st the vapor pres-<br />

sure <strong>of</strong> water given <strong>in</strong> the steam tables.<br />

The gas under <strong>in</strong>vestigation is then ad-<br />

mitted to the bomb by open<strong>in</strong>g one side<br />

<strong>of</strong> valve C. The pressure is allowed to<br />

build up to slightly over the desired<br />

partial preseure at which the solubility<br />

<strong>of</strong> the gaa is to be determ<strong>in</strong>ed. Valve C<br />

is then closed <strong>and</strong> the system is allowed<br />

to come to equilibrium. This is done by<br />

keep<strong>in</strong>g the autoclave <strong>in</strong> motion over-<br />

night at the desired temperature. The<br />

temperature is then readjusted, if neces-<br />

sary, <strong>and</strong> the pressure <strong>of</strong> the gas is re-<br />

adjusted to ita desired partial preasure.<br />

When the temperature <strong>and</strong> pressure have<br />

rema<strong>in</strong>ed constant for about 2 hours, a<br />

sample is taken. This is done by circu-<br />

lat<strong>in</strong>g ice water through the condenser, K,<br />

<strong>and</strong> then open<strong>in</strong>g the purg<strong>in</strong>g l<strong>in</strong>e side <strong>of</strong><br />

valve B. After about 25 ml. <strong>of</strong> water<br />

have been taken <strong>of</strong>f, the purg<strong>in</strong>g l<strong>in</strong>e valve<br />

0.28<br />

0.56<br />

0.70<br />

0.15<br />

0.31<br />

0.46<br />

0.18<br />

0.28<br />

0.64<br />

0.91<br />

1.35<br />

1 71<br />

0.63<br />

1.42<br />

2.19<br />

1.22<br />

1.85<br />

2.29<br />

2.96<br />

2.56<br />

2.99<br />

Probable<br />

Error<br />

,.<br />

..<br />

..<br />

0.01<br />

0.00<br />

0.01<br />

0.01<br />

0.01<br />

0.04<br />

0.02<br />

0.06<br />

0.03<br />

0.01<br />

0.02<br />

0.04<br />

0.01<br />

0:03<br />

0:03<br />

..<br />

Maximum<br />

Deviation<br />

...<br />

...<br />

...<br />

t0.01 to -0.01<br />

fO.OO to -0.00<br />

t0.01 to -0.01<br />

fO.O1 to -0.01<br />

$0.02 to -0.01<br />

f0.35 to -0.17<br />

+0.01 to -0.02<br />

t0.33 to -0.26<br />

+0.09 to -0.17<br />

-I-0.06 to -0.03<br />

f0.03 to -0.03<br />

+0.15 to -0.17<br />

+0.04to -0.05<br />

+o. lo'to' -0.10<br />

+O.O5'to' -0.05<br />

...<br />

is closed <strong>and</strong> the sampl<strong>in</strong>g l<strong>in</strong>e side <strong>of</strong><br />

valve B is opened. About 25 ml. <strong>of</strong> water<br />

conta<strong>in</strong><strong>in</strong>g an amount <strong>of</strong> gas which depends<br />

on the partial pressure <strong>and</strong> water<br />

temperature are then collected over mercury<br />

<strong>in</strong> the measur<strong>in</strong>g buret, L, which is<br />

surrounded by a water thermostat. The<br />

gas <strong>and</strong> water volumes are then measured<br />

<strong>and</strong> the needle valve, M, is opened. This<br />

allows the water that rema<strong>in</strong>ed <strong>in</strong> the<br />

sample l<strong>in</strong>e, because <strong>of</strong> capillary action,<br />

to dra<strong>in</strong> <strong>in</strong>to the buret. After the total<br />

amount <strong>of</strong> gas <strong>and</strong> water have been determ<strong>in</strong>ed,<br />

dry air is blown <strong>in</strong> through the<br />

<strong>in</strong>let at N <strong>and</strong> allowed to escape through<br />

M. This procedure dries all <strong>of</strong> the sampl<strong>in</strong>g<br />

l<strong>in</strong>es <strong>in</strong> preparation for the next<br />

sample. The solubility <strong>of</strong> the gas <strong>in</strong> water<br />

is then determ<strong>in</strong>ed by reduc<strong>in</strong>g the gas<br />

<strong>and</strong> water volumes, as found <strong>in</strong> the<br />

measur<strong>in</strong>g buret, to cubic centimeters <strong>of</strong><br />

gas at normal temperature <strong>and</strong> pressure<br />

per gram <strong>of</strong> water,<br />

EXPERIMENTAL RESULTS<br />

The present experimental results <strong>and</strong><br />

certa<strong>in</strong> previously reported data for the<br />

solubility <strong>of</strong> hydrogen, oxygen, helium,<br />

TABLE 11. SOLUBILITY OF HYDROGEN IN WATER<br />

Ha Partial<br />

Pressure Probable Maximum<br />

Lb./Sq. In: Abs. Source CO. Hia/G. <strong>of</strong> <strong>Water</strong> - Average Error Deviation<br />

300<br />

367<br />

200<br />

300<br />

350<br />

100<br />

200<br />

300<br />

375<br />

500<br />

100<br />

200<br />

300<br />

375<br />

500<br />

100<br />

200<br />

300<br />

376<br />

100<br />

200<br />

300<br />

375<br />

500<br />

100<br />

200<br />

300<br />

100<br />

200<br />

300<br />

100<br />

115<br />

120<br />

125<br />

75' F.<br />

. . , . . . . . . . . ,<br />

(8)<br />

Authors<br />

Authors<br />

Authors<br />

. . . . . . . .<br />

125°F. ''<br />

0.38 0.32 0.32 0.31 0.37 0.30<br />

0.41 0.42 0.40 0.41<br />

0.47 0.44 0.44 0.44 0.'46 .:'<br />

(3 h ::<br />

. .<br />

(8) . .<br />

(8) . .<br />

::<br />

. .<br />

. .<br />

, .<br />

::<br />

. .<br />

, .<br />

, ,<br />

300' F.<br />

:: ::<br />

. . ,<br />

. . , ,<br />

. , . ,<br />

345' F.<br />

:'<br />

, ,<br />

, ,<br />

,<br />

390" F.<br />

435O F.<br />

(8) , . . . . . . , . . . ,<br />

(a) , , . , . . . . . . , ,<br />

yj . . . . . . . . . . ,<br />

. . . . .<br />

(8) , . . . , , . . , . , .<br />

. . . . . . ,<br />

500' F.<br />

Authors 0.45 0.38 0.31 0.32 ..<br />

Authors 0.98 0.91 0.84 0.92 , ,<br />

Authors 1.24 1.23 1.28 . . , ,<br />

600" F.<br />

Authors 0.68 0.61 0.68 0.62 . . , .<br />

Authors 1.24 1.31 1.34 1.41 . . . ,<br />

Authors 2.05 2.06 1.98 1.94 . . . ,<br />

650' F.<br />

Authors . . . . . , . . . . , ,<br />

Authors . . . . . . . . . . . .<br />

Authors , . . . . , . . , . ,<br />

Authors . . . . . . , . . . , .<br />

At st<strong>and</strong>ard temperature <strong>and</strong> pressnre.<br />

0.32<br />

0.44<br />

0.33<br />

0.41<br />

0.45<br />

0.13<br />

0.28<br />

0.40<br />

0.52<br />

0.70<br />

0.15<br />

0.30<br />

0.43<br />

0.66<br />

0.75<br />

0.18<br />

0.34<br />

0.52<br />

0.68<br />

0.22<br />

0.49<br />

0.75<br />

0 94<br />

1.26<br />

0.39<br />

0.91<br />

1.25<br />

0.65<br />

1.32<br />

2.01<br />

1.40<br />

1.63<br />

1.68<br />

1.74<br />

0.01 +0.05 to -0.03<br />

0.00 +O.Ol to -0.01<br />

0.01 +0.02 to -0.01<br />

. .<br />

..<br />

..<br />

..<br />

..<br />

..<br />

..<br />

0.02 +0.06 to -0.08<br />

0.10 4-0.07 to -0.09<br />

0.01 +0.03t0 -0.02<br />

0.01 +0.03 to -0.04<br />

0.02 +0.09 to -0.08<br />

0.02 t0.05 to -0.03

11.50 INDUSTRIAL AND ENGINEERING CHEMISTRY Vol. 44, No, 5<br />

Figure 10. <strong>Solubility</strong>- Constant versus<br />

Temperature near the Critical Po<strong>in</strong>t<br />

<strong>and</strong> nitrogen are listed <strong>in</strong> Tables I, 11, 111, <strong>and</strong> IV, <strong>and</strong> are also<br />

shown graphically <strong>in</strong> Figures 1 to 9. The probable error shown<br />

<strong>in</strong> column 5 <strong>of</strong> tjhe tables was calculated from the usual formula<br />

I .-."<br />

probable error = 0.6745 LA'<br />

-\<strong>in</strong>(n. - 1)<br />

, TABLE IT'. SOL~BILITY OF NITROGEN xii WATER<br />

h'l Partial<br />

Pressure,<br />

Lb./Sq. In.<br />

Abs. Source Cc. Nna/G. <strong>of</strong> <strong>Water</strong> dverage<br />

77' F.<br />

Probable<br />

Error<br />

Maximum<br />

Deviation<br />

294<br />

367<br />

588<br />

(1)<br />

(6)<br />

(1)<br />

. .<br />

. .<br />

. ,<br />

. .<br />

. .<br />

. ,<br />

. .<br />

. .<br />

. .<br />

0.28<br />

0.35<br />

0.55<br />

..<br />

..<br />

..<br />

...<br />

.,.<br />

..<br />

1220 F.<br />

367 (6) . . . . . . 0.27<br />

167" F.<br />

367 (6) . . . . . . 0.25<br />

...<br />

2120 F.<br />

3 67<br />

(6) . . . . . . 0.26 ,.<br />

5000 F.<br />

150 Authors 0.47 0.43 0.41 0.44 0.01 50 03 to -0.03<br />

400 -4uthors 1.21 1.34 1.18 1.24 0.02 +O.lO to -0.06<br />

600' F.<br />

150 Authors 0.56 0.54 0.56 0.55 0.00 +O 01 to -0 01<br />

300 Authors 1.56<br />

400 Authors 2.40 2:29 2:26 2:32 0.'02 +0,08'tb'-0,06<br />

6 st<strong>and</strong>ard temperature <strong>and</strong> pressure.<br />

TABLE 1x1. SOLUBILITY OF HELIUM IX WATER<br />

He Partial<br />

Pressure, Lh./<br />

Sq. In. Abs. Source Cc. He"/G. <strong>of</strong> <strong>Water</strong>- Average<br />

Probable<br />

Error<br />

;\laximum<br />

Deviation<br />

TABLE v. HENRY'S LAW COSSTANT, x, FOR VARIOUS Gas~sa<br />

Temp.,<br />

E". <strong>Oxygen</strong><br />

Gas, K X 10-6<br />

<strong>Hydrogen</strong> <strong>Helium</strong> <strong>Nitrogen</strong><br />

32<br />

75<br />

77<br />

122<br />

125<br />

,.<br />

6:56<br />

..<br />

11:o<br />

..<br />

8: 72<br />

20.40<br />

2i : 75<br />

,..<br />

...<br />

13:io<br />

16.M<br />

167 ,. .. IS: io lS:&<br />

212 .. .. ... 18.00<br />

300 9.30 ...<br />

325 8:oO 8.04<br />

I . Si34<br />

346<br />

390<br />

32' F.<br />

(4) .. ...<br />

367 . . . . . . . . . . 0.23<br />

367<br />

77' F.<br />

(4) . . . . . . . . . . 0.22 I . ...<br />

167' F.<br />

367 (4) . . . . . . . . . . 0.24<br />

325' F.<br />

100 Authors 0.20 0.20 0.19 , , . , . 0.20 0.00 iO.00 to -0.01<br />

200 Authors 0.31 0.31 0.30 .. , , 0.31 0.00 io.00 to -0.01<br />

300 huthors 0.39 0.37 0.37 . . , . 0.38 0.00 -0.01 to -0.01<br />

600' F.<br />

100 Authors 0.42 0.38 0.42 0.38 0.40 0.40 0.01 +0.02 to -0.02<br />

200 Authors 0.58 0.60 0.64 0.59 0.60 0.01 iO.04 to -0.03<br />

300 Authors 1.36 0.13 0.82 0.81 0:87<br />

1.15 1.07 0.87 1.03 1.03 0:99 0:05 +0.37 tb'10.37<br />

400 Authors 1.31 1 41 1 32 1.47 1.38 0.03 +0.09 to -0.07<br />

500 Author8 1.74 1:64 1:86 1.70 1:85 1.76 0.03 +0.10to -0.12<br />

600' F.<br />

200<br />

300<br />

400<br />

500<br />

Authors<br />

Authors<br />

'Authors<br />

Authors<br />

0.92 0.95 0.89 0.93<br />

1.64 1.61 1.70 1.66<br />

2.44 2.37 2.59 2.31<br />

2.84 2.37<br />

2.72 3 12 8:07 3:i3<br />

, ,<br />

,.<br />

2:82<br />

0.92<br />

1.66<br />

2.'49<br />

2.99<br />

0.01<br />

0.01<br />

0:05<br />

0 06<br />

LO.03 to -0 04<br />

+O.O4to -0 05<br />

+0.35'tb'-0.18<br />

+0.23to -0.27<br />

.Z .kt st<strong>and</strong>ard temperature <strong>and</strong> preeaure.<br />

6.98 ...<br />

400 6: ... ...<br />

435<br />

4:98<br />

500 2177 2.90 3:56 4: 18<br />

GOO 1.74 1.86 2.20 2.38<br />

650 1.22 0.885 ... ...<br />

a K = 2, where PA = partial Pressure <strong>of</strong> gas, A, <strong>in</strong> pounds per 3~uar0<br />

NA<br />

<strong>in</strong>ch <strong>and</strong> NA = mole fraction <strong>of</strong> gas, A, <strong>in</strong> solution.<br />

which gives an <strong>in</strong>dication <strong>of</strong> the preci-<br />

sion <strong>of</strong> the data, where ZA = the<br />

arithmetical sum <strong>of</strong> the deviations <strong>and</strong><br />

n = the number <strong>of</strong> measurements.<br />

It is <strong>in</strong>terest<strong>in</strong>g to observe from the<br />

tables <strong>and</strong> graphs that the solubilities <strong>of</strong><br />

these gases <strong>in</strong> water <strong>in</strong>crease Kith <strong>in</strong>-<br />

creas<strong>in</strong>g temperature, <strong>in</strong> the high tem-<br />

perature range, where= it has been estah-<br />

lished that at temperatures <strong>in</strong> the<br />

region from about 20" to ZOO" F. the<br />

solubilities decrease with <strong>in</strong>creas<strong>in</strong>g tem-<br />

perature.<br />

With<strong>in</strong> experimental accuracy, the<br />

solubilities <strong>of</strong> hydrogen, oxygen, helium,<br />

<strong>and</strong> nitrogen appear to be l<strong>in</strong>ear func-<br />

tions <strong>of</strong> pressure over the range <strong>in</strong>vesti-<br />

gated. The result<strong>in</strong>g straight l<strong>in</strong>es<br />

(Figures 2, 4, 6, <strong>and</strong> 8) show that the<br />

solubilities <strong>in</strong> question follow Henry's<br />

law <strong>and</strong> may be predicted with<strong>in</strong> the<br />

limits <strong>of</strong> eng<strong>in</strong>eer<strong>in</strong>g accuracy over B<br />

fairly wide range <strong>of</strong> temperatures <strong>and</strong><br />

pressures from the Henry's law con-<br />

stants, which are listed io Table V.

May 1952 INDUSTRIAL AND ENGINEERING CHEMISTRY 11.51<br />

At <strong>and</strong> above the critical temperature <strong>of</strong> water (705" F.), the<br />

gases must be <strong>in</strong>f<strong>in</strong>itely soluble <strong>and</strong> the Henry's law constant<br />

must become relatively very small. The constants for the four<br />

gases <strong>in</strong> the region <strong>of</strong> the critical temperature are plotted <strong>in</strong><br />

Figure 10. It is apparent that <strong>in</strong> this region the solubility con-<br />

stants tend to converge <strong>and</strong> approach very low values at 705" F.,<br />

thus <strong>in</strong>dicat<strong>in</strong>g that the data are consistent with the fact that the<br />

gases are miscible <strong>in</strong> all proportions at the critical po<strong>in</strong>t for water.<br />

LITERATURE CITED<br />

(1) Frolich et al., IND. ENG. CHEM., 23, 548 (1931).<br />

(2) Ipatieff <strong>and</strong> Teodorovish, J. Gem. Chem. (U.S.S.R.), 4, No. 3, 396<br />

(1934).<br />

(3) Wiebe <strong>and</strong> Gaddy, J. Am. Chem. SOC., 55, 947 11933).<br />

(4) Ibid., 56, 76 (1934).<br />

(5) Ibid., 57, 847 (1935).<br />

RECEIVED for review July 14, 1960. ACCEPTED December 31, 1951.<br />

This work was csrried out under contract with the Atomic Energy Ccmmission,<br />

Contract 7405-eng-92.<br />

Selection <strong>of</strong> Surface Active Agents<br />

for Detergent Applications<br />

SUSPENDING POWEK AND MICELLAR SOLUBILIZATION<br />

A. M. MANKOWICH<br />

Pa<strong>in</strong>t & Chemical Laboratory, Aberdeen Prov<strong>in</strong>g Ground, Aberdeen, Md.<br />

ELECTION <strong>of</strong> surface active agents (sirfactants) for specific<br />

S metal clean<strong>in</strong>g applications is usually made on a trial <strong>and</strong><br />

error basis, us<strong>in</strong>g laboratory detergency tests which have been<br />

correlated with field test results. Experience plus the fragmentary<br />

available <strong>in</strong>formation on such properties as molecular structure,<br />

type <strong>and</strong> chemical stability <strong>of</strong> surfactant, surface <strong>and</strong> <strong>in</strong>terfacial<br />

tensions, <strong>and</strong> Draves <strong>and</strong> Clarkson s<strong>in</strong>k<strong>in</strong>g times (a)<br />

may be used &s empirical screen<strong>in</strong>g media. It is imperative that<br />

all possible comb<strong>in</strong>ations <strong>of</strong> compatible types <strong>of</strong> surfactants be<br />

studied, s<strong>in</strong>ce it is not possible at present to predict synergistic<br />

comb<strong>in</strong>ations. Builder action varies with type <strong>of</strong> agent <strong>and</strong> soil,<br />

which necessitates <strong>in</strong>vestigation <strong>of</strong> additional comb<strong>in</strong>ations, The<br />

development <strong>of</strong> B laboratory detergency test that can be correlated<br />

with field results is a problem. An obviously considerable<br />

amount <strong>of</strong> research must be performed even when only a limited<br />

number <strong>of</strong> surfactants are tested. This process has to be repeated<br />

for every detergent application <strong>in</strong> which the soil <strong>and</strong>/or substratum<br />

is varied.<br />

The time-consum<strong>in</strong>g, trial <strong>and</strong> error approach <strong>in</strong> determ<strong>in</strong><strong>in</strong>g<br />

the suitability <strong>of</strong> various surfactants for use <strong>in</strong> clean<strong>in</strong>g co<strong>in</strong>pounds<br />

<strong>in</strong>tended for the removal <strong>of</strong> specific soils from specific<br />

substrata is viewed unfavorably <strong>in</strong> this laboratory. It is believed<br />

that the selection <strong>of</strong> surfactants for specific detergent applications<br />

can be accomplished more scientifically <strong>and</strong> economically by determ<strong>in</strong><strong>in</strong>g<br />

the fundamental or prime factors <strong>in</strong> the detergency<br />

process; study<strong>in</strong>g each factor to establish numerical criteria for<br />

the various types <strong>of</strong> surfactants <strong>and</strong> builders under vary<strong>in</strong>g pH,<br />

concentration, <strong>and</strong> temperature conditions; <strong>and</strong> classify<strong>in</strong>g soils<br />

with reference to the numerical values <strong>of</strong> the prime factors, obta<strong>in</strong><strong>in</strong>g<br />

c<strong>of</strong>actors (m<strong>in</strong>imum numerical criteria for each prime factor<br />

necessary to accomplish soil removal <strong>in</strong> specific soil-surface<br />

comb<strong>in</strong>ations).<br />

Once the prime factors for various types <strong>of</strong> surfactants <strong>and</strong> the<br />

c<strong>of</strong>actors for the soils are determ<strong>in</strong>ed, an <strong>in</strong>spection <strong>of</strong> the data<br />

will <strong>in</strong>dicate appropriate surfactants or comb<strong>in</strong>ations <strong>of</strong> surfactants,<br />

as well as suitable temperature, pH, concentration, <strong>and</strong><br />

builder data. This is done by select<strong>in</strong>g the surfactant, or comb<strong>in</strong>ation<br />

<strong>of</strong> surfactants, whose prime factors have equal or greater<br />

numerical rat<strong>in</strong>gs than the correspond<strong>in</strong>g c<strong>of</strong>actors. The pr<strong>in</strong>ciple<br />

advanced is that detergency <strong>in</strong> a specific soil-surface application<br />

is accomplished only if the numerical rat<strong>in</strong>gs <strong>of</strong> all the c<strong>of</strong>actors<br />

are equaled or exceeded by the prime factors <strong>of</strong> the clean<strong>in</strong>g<br />

solution. The need for utiliz<strong>in</strong>g more than one surfactant for a specific<br />

detergency application will be readily apparent <strong>in</strong> those<br />

cases where an otherwise! satisfactory agent is deficient <strong>in</strong> one or<br />

more prime factors. When it is necessary to select two or more<br />

surfactants, the maximum numerical rat<strong>in</strong>g for each prime factor<br />

<strong>of</strong> the comb<strong>in</strong>ation is estimated by add<strong>in</strong>g the respective rat<strong>in</strong>gs<br />

<strong>of</strong> the <strong>in</strong>dividual surfactants <strong>in</strong>volved. Prelim<strong>in</strong>ary work <strong>in</strong>di-<br />

cates that the numerical rat<strong>in</strong>g <strong>of</strong> a prime factor approaches a de&-<br />

nite maximum which is not exceeded, regardless <strong>of</strong> the number <strong>of</strong><br />

surfactants comb<strong>in</strong>ed for a specific detergent application. This<br />

maximum is usually the highest value atta<strong>in</strong>ed by any <strong>of</strong> the <strong>in</strong>-<br />

dividual surfactants <strong>in</strong>vestigated. However, Bdditiveness <strong>of</strong><br />

numerical rat<strong>in</strong>gs <strong>of</strong> a comb<strong>in</strong>ation <strong>of</strong> surfactants is obta<strong>in</strong>ed un-<br />

til the maximum for the prime factors is reached. It is <strong>in</strong>tended<br />

to cover the determ<strong>in</strong>ation <strong>of</strong> c<strong>of</strong>actors <strong>and</strong> classification <strong>of</strong> soils<br />

<strong>and</strong> substrata <strong>in</strong> a later paper.<br />

An advantage <strong>of</strong> the proposed method <strong>of</strong> selection is that it will<br />

<strong>in</strong>dicate a number <strong>of</strong> surfactants or comb<strong>in</strong>ations <strong>of</strong> surfactanta<br />

for each soil-surface application, thus permitt<strong>in</strong>g a f<strong>in</strong>al selection<br />

on an economic basis. No attempt is made to evaluate the rela-<br />

tive importance <strong>of</strong> the various prime factors, <strong>and</strong> the method does<br />

not depend on such evaluation. The proposed method is not to<br />

be confused with the speculations ($1) that detergency will even-<br />

tually be calculated from a formula conta<strong>in</strong><strong>in</strong>g weighted physico-<br />

chemical factors. Assum<strong>in</strong>g that these speculations are realized<br />

eventually, they will not aid <strong>in</strong> the selection <strong>of</strong> surfactants for spe-<br />

cific detergent applications. The formula will only give an <strong>in</strong>dex<br />

<strong>of</strong> detergency. The proposed method <strong>in</strong>dicates the m<strong>in</strong>imum<br />

physicochemical requirements for a detergent application, to-<br />

gether with a number <strong>of</strong> surfactants or comb<strong>in</strong>ations <strong>of</strong> surfac-<br />

tants capable <strong>of</strong> meet<strong>in</strong>g the requirements. It is important to<br />

realize that the proposed method <strong>in</strong>dicates synergistic comb<strong>in</strong>a-<br />

tions <strong>of</strong> surfactants.<br />

PHYSICOCHEMICAL FACTORS OF DETERGENCY<br />

Present-day knowledge <strong>in</strong>dicates that detergency is the result-<br />

ant <strong>of</strong> many factors (I, 22, 20, $2). It is underst<strong>and</strong>able, there-<br />

fore, that attempts to correlate detergency with one factor only<br />

have been unsuccessful. Reich <strong>and</strong> Snell (18) emphasize a fur-<br />

ther error made <strong>in</strong> attempt<strong>in</strong>g to evaluate detergency with one<br />

factor. Detergency is dependent on three groups <strong>of</strong> variables<br />

(13): those orig<strong>in</strong>at<strong>in</strong>g <strong>in</strong> the soil, <strong>in</strong> the surfactant, <strong>and</strong> <strong>in</strong> the<br />

surface. A factor <strong>in</strong>volv<strong>in</strong>g only one <strong>of</strong> the groups, such as sur-<br />

face tension, or two <strong>of</strong> the groups, such as micellar solubilization,<br />

is basically not <strong>in</strong> correlation with detergency.