2013 formula SaE

2013 formula SaE

2013 formula SaE

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

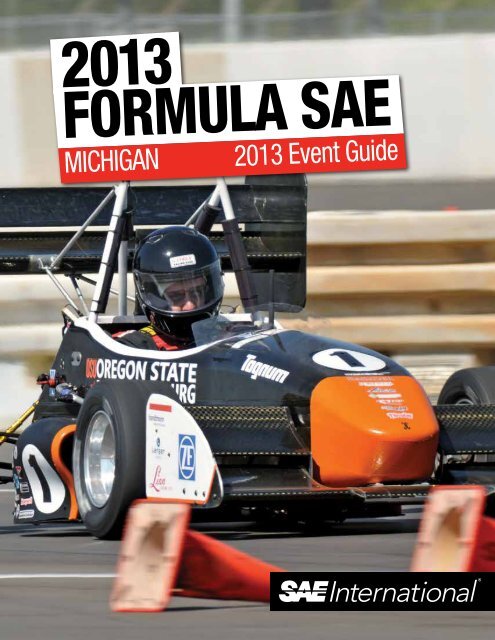

<strong>2013</strong><br />

<strong>formula</strong> <strong>SaE</strong><br />

michigan <strong>2013</strong> Event guide

<strong>2013</strong> Formula SAE Series<br />

Official Events<br />

Formula Hybrid<br />

organized by Dartmouth College<br />

April 29th – May 3rd<br />

New Hampshire, United States<br />

Formula <strong>SaE</strong> micHigan<br />

organized by SAE International<br />

May 8th – 11th<br />

Michigan, United States<br />

Formula <strong>SaE</strong> lincoln<br />

organized by SAE International<br />

June 19th – 22nd<br />

Nebraska, United States<br />

Formula <strong>SaE</strong>-auStralaSia<br />

organized by SAE Australia<br />

Australia<br />

www.saea.com.au/<strong>formula</strong>-sae-a<br />

Formula StudEnt auStria<br />

organized by FSA<br />

Austria<br />

www.fsaustria.at<br />

Formula <strong>SaE</strong> – braSil<br />

organized by SAE Brasil<br />

Brasil<br />

www.saebrasil.org.br<br />

Formula <strong>SaE</strong> – italy<br />

organized by ATA<br />

Italy<br />

www.ata.it/<strong>formula</strong>ata/<strong>formula</strong>saeit<br />

Formula StudEnt<br />

organized by IMeche<br />

United Kingdom<br />

www.<strong>formula</strong>student.com<br />

Formula StudEnt gErmany<br />

organized by FSG e.V.<br />

Germany<br />

www.<strong>formula</strong>student.de<br />

Formula StudEnt Japan<br />

organized by JSAE<br />

Japan<br />

www.jsae.or.jp/<strong>formula</strong>/en<br />

students.sae.org/competitions/<strong>formula</strong>series<br />

page 2 Information published as supplied by teams on or before April 10, <strong>2013</strong>

Formula SAE Michigan<br />

<strong>2013</strong> SAE President’s Message<br />

Information published as supplied by teams on or before April 10, <strong>2013</strong><br />

Dear Formula SAE® Participants and Organizers:<br />

Welcome to the Formula SAE competition at Michigan International Speedway in<br />

Brooklyn, Michigan.<br />

Formula SAE is steeped in tradition and competition. Now in its 35th year,<br />

Formula SAE provides the real-world challenges of systems engineering, design<br />

and problem solving, along with the teaming challenges of collaboration and<br />

cooperation. In short, Formula SAE, along with all of the SAE Collegiate Design<br />

Series competitions, provides the skills and experiences needed for a wellrounded<br />

engineering education.<br />

In addition to learning, Formula SAE also provides a unique form of competition. This week, collegiate engineering<br />

students from many different nations will compete in a series of static and dynamic events designed to challenge<br />

their engineering, problem-solving and teamwork skills. The students will work hard and compete to win. Some will<br />

win first place, others will not. But all will leave here a winner because they will be better engineering students.<br />

Good luck to all who are competing in this event. Also, I want to thank everyone for their hard work, support,<br />

volunteerism and participation. The experiences and learning you gain this weekend will last throughout your lives.<br />

Sincerely,<br />

Donald G. Hillebrand<br />

President, SAE International<br />

page 1<br />

page 1

tablE oF contEntS:<br />

Concept of the<br />

Competition ..................... 2<br />

Schedule ......................... 4<br />

Awards ............................ 7<br />

MIS Teams listed<br />

by Country ....................... 8<br />

Team Information ........... 10<br />

MIS Site Map ................. 69<br />

Key Players .................... 70<br />

Sponsors .......................c4<br />

Concept of the Competition<br />

The Formula SAE ® Series competitions challenge teams of university undergraduate<br />

and graduate students to conceive, design, fabricate and compete with small, <strong>formula</strong><br />

style, competition vehicle. To give teams the maximum design flexibility and the<br />

freedom to express their creativity and imaginations there are very few restrictions on<br />

the overall vehicle design. Teams typically spend eight to twelve months designing,<br />

building, testing and preparing their vehicles before a competition. The competitions<br />

themselves give teams the chance to demonstrate and prove both their creation<br />

and their engineering skills in comparison to teams from other universities around the world.<br />

Registered for this event are 120 teams from colleges and universities. The end result is a great<br />

experience for young engineers in a meaningful engineering project as well as the opportunity of<br />

working in a dedicated team effort.<br />

For the purpose of this competition, the students are to assume that a manufacturing firm has<br />

engaged them to produce a prototype car for evaluation as a production item. The intended<br />

sales market is the nonprofessional weekend competitor. Therefore, the car must have very<br />

high performance in terms of its acceleration, braking, and handling qualities. The car must be<br />

low in cost, easy to maintain, and reliable. In addition, the car’s marketability is enhanced by<br />

other factors such as aesthetics, comfort and use of common parts. The manufacturing firm<br />

is planning to produce four (4) cars per day for a limited production run. The challenge to the<br />

design team is to design and fabricate a prototype car that best meets these goals and intents.<br />

Each design will be compared and judged with other competing designs to determine the best<br />

overall car.<br />

Over the course of three days, the cars are judged in a series of static and dynamic events<br />

including: technical inspection, cost, presentation, and engineering design, solo performance<br />

trials, and high performance track endurance. These events are scored to determine how well<br />

the car performs. In each event, the manufacturing firm has specified minimum acceptable<br />

performance levels that are reflected in the scoring equations.<br />

page 2<br />

page 2 Information published as supplied by teams on or before April 10, <strong>2013</strong>

Static EvEntS:<br />

design report: The students explain their constructive solutions to a jury of experts from the automotive and<br />

motorsport industries in report and discussion. The concept of the design is to evaluate the engineering effort that<br />

went into the design of the car and how the engineering meets the intent of the market. The car that illustrates the<br />

best use of engineering to meet the design goals and the best understanding of the design by the team members will<br />

win the design event.<br />

cost report: The students are to assume that a serial production of 1000 cars a year will follow the prototype. The<br />

cost calculation is discussed with a jury based on a report. The objective of the event is for the participants to learn<br />

and understand the manufacturing techniques and processes of some of the components that they have chosen to<br />

purchase rather than fabricate themselves.<br />

presentation: The objective is to evaluate the team’s ability to develop and<br />

deliver a comprehensive business case that will convince the executives of<br />

a fake manufacturing firm that the team’s design best meets the demands<br />

of the amateur weekend competition market and that it can be profitably<br />

manufactured and marketed.<br />

dynamic EvEntS:<br />

acceleration: The cars are evaluated on their accelerating abilities from a<br />

standing start over a distance of 75 meters.<br />

autocross: The objective is to evaluate the car’s maneuverability and<br />

handling qualities on a tight course without the hindrance of competing cars.<br />

The course will combine the performance features of acceleration, braking<br />

and cornering into one event. The results of the Autocross scores determine<br />

the starting order for endurance.<br />

Skid-pad: The objective is to measure the car’s cornering ability on a flat surface while making a constant-radius<br />

turn. The course will be a pair of concentric circles in shape of the number 8; the cars demonstrate how good lateral<br />

forces can be absorbed (up to 1.4g).<br />

Endurance: Over a distance of 22 km the cars have to prove their durability under long-term conditions. Acceleration,<br />

speed, handling, dynamics, fuel efficiency, reliability – the cars have to prove it all.<br />

Information published as supplied by teams on or before April 10, <strong>2013</strong><br />

tHE Following pointS arE poSSiblE:<br />

Static Events 75 Presentation<br />

(Thursday) 150 Design<br />

100 Cost Analysis<br />

dynamic Events 75 Acceleration<br />

(Friday & Saturday) 50 Skid-Pad<br />

150 Autocross<br />

100 Fuel Efficiency<br />

300 Endurance<br />

total pointS 1000<br />

page 3<br />

page 3

<strong>2013</strong> Formula SAE ® Michigan<br />

Schedule of Events<br />

(Subject to change)<br />

wEdnESday, may 8<br />

10:00 a.m. ........................... Tech Inspection “Take-a-Number” Opens in Garage 2<br />

5:30 p.m. ........................... Welcome Ceremony – Sponsored by Honda R&D Americas in<br />

Main Tent<br />

6:00 p.m. – 6:20 p.m. ......... Captains & Advisors Meeting in Main Tent<br />

6:00 p.m. – 8:00 p.m. ......... Maplesoft Invitation-Only Reception in Champions’ Club<br />

6:20 p.m. – 7:20 p.m. ......... Ford Powertrain Career Discussion – Students Welcome in Main Tent<br />

7:30 p.m. ........................... Official Closing of the Site<br />

8:00 p.m. ........................... EVERYONE MUST BE OFF-SITE<br />

tHurSday, may 9 (All TIMES PRECEDED BY “~” ARE APPROxIMATE)<br />

8:00 a.m. ............................ Drivers Meeting (Brake & Practice) - MANDATORY in Main Tent<br />

8:30 a.m. – 5:30 p.m.. ........ Design Event – Sponsored by Bosch – 1st Round Judging Open in<br />

Garage 3<br />

9:00 a.m. – 5:00 p.m.. ........ Cost Judging Open in Main Tent<br />

9:00 a.m. – 5:00 p.m. ......... Presentation Judging Open in MIS Suites<br />

12:00 p.m. – 1:00 p.m. ......... lUNCH BREAK in Main Tent<br />

~2:00 p.m. – 3:30 p.m. ........ First Autocross Course Walk (weather permitting) – Track<br />

5:00 p.m. ........................... Push Bar Finalist Teams announced (up to 5 teams) in Main Tent<br />

5:00 p.m. .......................... Staging for Panoramic Photo (weather permitting) West of Garage 3<br />

6:00 p.m. ........................... Drivers Meeting (All Dynamic Events) in Main Tent (MANDATORY)<br />

5:30 p.m. – 8:30 p.m. ........ Design Judges Meeting – Judges only – Off Site<br />

7:30 p.m. ........................... Official Closing of the Site<br />

8:00 p.m. ........................... EVERYONE MUST BE OFF-SITE<br />

~9:00 p.m. ........................... Design Finalists announced online - www.sae.org and www.fsae.com<br />

Friday, may 10 (All TIMES PRECEDED BY “~” ARE APPROxIMATE)<br />

8:30 a.m. ........................... Course Crew Briefing – Acceleration and Skid Pad on Track<br />

9:00 a.m. – 12:30 a.m ........ Acceleration and Skid Pad Event Events Open on Track<br />

9:00 a.m. – 4:00 p.m.. ........ Design Feedback for Non-finalists (by appt. only) in Garage 3<br />

9:30 a.m. ............................ Presentation Seminar in Main Tent<br />

12:30 p.m. ........................... lunch Break in Main Tent<br />

~1:30 p.m. – 1:50 p.m ......... First Autocross Course Walk (course set-up depending) on Track<br />

1:35 p.m. ........................... Course Crew Briefing – Autocross on Track<br />

2:00 p.m. – 5:00 p.m. ......... Autocross Event Open on Track<br />

~5:30 p.m. – 8:30 p.m.. ....... Design Finals – Sponsored by Bosch in Garage 3<br />

~7:00 p.m. ........................... Award Ceremony 1 – Sponsored by General Motors in Main Tent<br />

7:30 p.m. ........................... Official Closing of the Site<br />

9:00 p.m. ........................... EVERYONE MUST BE OFF-SITE<br />

page 4<br />

page 4 Information published as supplied by teams on or before April 10, <strong>2013</strong>

Saturday, may 11 (All TIMES PRECEDED BY “~” ARE APPROxIMATE)<br />

7:00 – 8:00 a.m. ..............Endurance Course Walk on Track<br />

8:30 a.m. .........................Endurance Course Crew Briefing on Track<br />

~8:30 a.m. .........................Top 3 Teams Design Finalists Announced<br />

~9:00 a.m. – 2:00 p.m. ......Design Feedback for Finalists not Top 3, by appointment in Garage 3<br />

9:00 a.m. ..........................Ford Endurance/Fuel Efficiency Event Open – Group 1 Only on Track<br />

~12:00 p.m. .........................Ford Endurance/Fuel Efficiency Gate Closes for Group 1 on Track<br />

~12:30 p.m.– 1:00 p.m. .......Endurance Course Walk on Track<br />

~12:30 p.m. .........................lUNCH BREAK (Main Tent)<br />

1:30 p.m. .........................Course Crew back on Track<br />

~1:35 p.m.. ........................Ford Endurance/Fuel Efficiency Event Open – Group 2 Only onn Track<br />

~4:00 p.m. .........................Ford Endurance/Fuel Efficiency Gate Closes for Group 2 on Track<br />

~6:00 p.m ..........................Public Design Review of Top 3 Finalists in Garage 3<br />

~7:00 p.m. .........................Presentation Highlights in Main Tent<br />

~ 8:00 p.m. ........................Final Awards Ceremony – Sponsored by General Motors in Main Tent<br />

10:30 p.m. ..........................Official Closing of the Site<br />

11:00 p.m. ..........................EVERYONE MUST BE OFF-SITE; All Teams and Transporters Must Exit<br />

Sunday, may 12<br />

9:00 a.m. – 2:00 p.m. .........Site Open ONlY for Pick-Up of Transporters<br />

daily opErationS:<br />

n miS Site open:<br />

• wednesday – thursday 7:30 a.m. – 7:30 p.m.<br />

• Friday 7:30 a.m. – 8:30 p.m.<br />

• Saturday 7:00 a.m. – 10:30 p.m.<br />

n Student registration (garage 1):<br />

• Wednesday – Friday 8:00 a.m. – 4:30 p.m.<br />

Saturday All students will be registered as spectators<br />

n tech inspection (garage 2):<br />

• wednesday 10:00 a.m. tech “take-a-number” opens<br />

• Wednesday Noon – 7 p.m. (no new cars after 6 p.m.)<br />

• Thursday 9 a.m. – 5 p.m.<br />

• Friday By appointment 9 a.m. until 5:30 p.m.<br />

• Saturday By appointment 9 a.m. until 1 p.m. (Re-tech only)<br />

n Scales (garage 1 drive thru):<br />

• Wednesday 3 p.m. – 7 p.m.<br />

• Thursday 8 a.m. – 4 p.m.<br />

• Friday 7:30 a.m. – Noon (for “cornering”)<br />

n tilt/noise/brake sponsored by continental:<br />

• Thursday 9 a.m. – 5 p.m.(Staggered opening times by<br />

30 min. per event)<br />

• Friday<br />

n Fuel Station:<br />

9 a.m. – 5:30 p.m.<br />

• Thursday 8:30 a.m. – 5 p.m.<br />

• Friday 8 a.m. – 5 p.m.<br />

• Saturday 7:30 a.m. – 5:00 p.m.<br />

n practice area sponsored by continental:<br />

• Thursday 10 a.m. – 5 p.m.<br />

• Friday 9 a.m. – 5:30 p.m.<br />

• Saturday 8:00 a.m. – 3 p.m.<br />

NOTE: Cars must complete all 4 parts of tech by 5:30 p.m. Friday to qualify for<br />

Endurance.<br />

30 minutes’ notice is required for all appointments, which can be booked through<br />

the announcer in Main Tent.<br />

page 5<br />

page 5

page 6<br />

notES<br />

2012 Formula SAE ® Michigan<br />

Schedule of Events<br />

n No Access Monday - Site closed to all teams Monday, May 13,<br />

<strong>2013</strong>.<br />

n No Access During Dynamic Events - Teams may enter the site<br />

with their rigs/trailers/panel trucks ONlY when there are no<br />

Dynamic Events running.<br />

n Push Bar Comp. - Judging in scale bay as cars are weighed.<br />

Winner announced at Friday Award Ceremony.<br />

n Medical Services - There will not be a First Aid Station on site.<br />

EMS will provide any/all medical attention.<br />

n Overnight Removal - Overnight removal of vehicles is allowed,<br />

but tech must first pull Part 1 of your tech sticker.<br />

n Removing Cars - All teams not shipping cars must remove<br />

vehicles, etc. from the site not later than 2:00 p.m. Sun., May<br />

12, <strong>2013</strong>.<br />

n Shipping Cars - Teams shipping cars must have them picked<br />

up and removed from MIS by 10:00 a.m. Monday, May 13,<br />

<strong>2013</strong>.<br />

n FM Audio - Announcements can be heard via FM radio<br />

(Frequency will be posted in G1 at event).<br />

n Event Closing Times - Acceleration, Skid-Pad and Autocross<br />

close exactly at the scheduled time. Your car must cross the<br />

starting line before the event closing time in order to be<br />

allowed to complete that run.<br />

n F1 in Schools High School Engineering Competition - Event<br />

will be held Fri. & Sat., May 10 & 11 in the Michigan Room,<br />

ground level of South Suites. FSAE participants are invited to<br />

observe this competition from 11 a.m.-12:30 p.m. & 1-5 p.m.<br />

Friday; and 9-11 a.m. Saturday.<br />

Support SErvicES<br />

n gm machine trailer:<br />

• Wed. – Fri. 9 a.m. - 5 p.m.<br />

n lincoln Electric welding:<br />

• Wed. Noon – 5 p.m.<br />

• Th. – Fri. 8 a.m. – 5 p.m.<br />

• Sat. 8 a.m. – Noon<br />

n Hoosier:<br />

• Wed. – Fri. 7 a.m. – 5 p.m.<br />

• Sat. 7 a.m. – 3 p.m.<br />

n land & Sea dyno:<br />

• Th. – Fri. 9 a.m. – 5 p.m.<br />

n Kaz technologies Shock dyno:<br />

• Wed. 9 a.m. – 3 p.m.<br />

• Th. – Sat. 9 a.m. – 5 p.m.<br />

n miS Fire trucks on site:<br />

• Wed. – Sat. 7 a.m. – ~8 p.m.<br />

n ambulance on site:<br />

• Wed. – Sat.7 a.m. – ~8 p.m.<br />

additional SErvicES<br />

n concessions:<br />

• Wed. – Sat 8 a.m. – 6 p.m.*<br />

n <strong>SaE</strong> bookstore:<br />

• Wed. 2 p.m. – 6 p.m.<br />

• Th – Fri. 8 a.m. – 5 p.m.<br />

• Sat. 8 a.m. – Noon<br />

* As business dictates. May close earlier if deemed appropriate<br />

page 6 Information published as supplied by teams on or before April 10, <strong>2013</strong>

STATIC EVENTS<br />

EnginEEring dESign<br />

award SponSorEd by<br />

boScH<br />

Top 3 team scores in Design –<br />

Trophies plus $2000, $1500,<br />

$1000<br />

<strong>SaE</strong> coSt award<br />

Top 3 team scores in Cost -<br />

Trophies<br />

<strong>SaE</strong> prESEntation<br />

award<br />

Top 3 team scores in<br />

Presentation - Trophies<br />

<strong>2013</strong> Formula SAE ®<br />

Competition Awards<br />

DYNAMIC EVENTS<br />

<strong>SaE</strong> accElEration award<br />

Top 3 team scores in<br />

Acceleration - Trophies<br />

EndurancE award<br />

SponSorEd by Ford<br />

Top 3 team scores in Endurance<br />

- Trophies plus $2000, $1500,<br />

$1000<br />

FuEl EFFiciEncy award<br />

SponSorEd by Ford<br />

Top 3 teams that receive best<br />

Fuel Efficiency Score - Trophies<br />

<strong>SaE</strong> SKid pad award<br />

Top 3 team scores in Skid Pad -<br />

Trophies<br />

<strong>SaE</strong> autocroSS award<br />

Top 3 team scores in Autocross.<br />

Trophies plus 8 free tires, 6 free<br />

tires, 4 free tires sponsored by<br />

Hoosier Tire.<br />

OVERAll<br />

<strong>SaE</strong> Spirit oF<br />

ExcEllEncE award<br />

This award recognizes the top<br />

ten (10) finishers overall. –<br />

Trophies plus $3000, $2000,<br />

$1000<br />

SPECIAlITY AWARDS<br />

altair EnginEEring’S<br />

william r. adam<br />

EnginEEring award<br />

Awarded to the teams for<br />

development of new and<br />

innovative design concepts for<br />

the FSAE racing competition. -<br />

$1000, $500<br />

continEntal braKE<br />

award<br />

This award is intended to reward<br />

the Best in Class Brake design<br />

by a team. - $1000<br />

tHE FEv powErtrain<br />

dEvElopmEnt award<br />

This award is intended to reward<br />

the top three Formula SAE<br />

teams for overall excellence<br />

in Powertrain development. -<br />

$2000, $1000, $500<br />

bESt tHrEE viEw<br />

drawing award<br />

Best execution of three view<br />

drawings submitted with a<br />

Design Report – Engineering<br />

handbooks<br />

page 7

<strong>2013</strong> Formula SAE Michigan Registered<br />

Teams<br />

auStria<br />

006 Graz University of Technology<br />

braZil<br />

13 Centro Universitario Da FEI<br />

canada<br />

125 Carleton University<br />

72 Cegep du Vieux - Montreal<br />

21 Dalhousie University<br />

8 Ecole De Technologie Superieure<br />

24 Ecole Polytechnique De Montreal<br />

69 lakehead University<br />

91 McGill University<br />

26 Queen’s University - Ontario Canada<br />

62 Ryerson University<br />

68 Universite Du Quebec a Trois-Rivieres<br />

30 Universite Du Quebec-Chicoutimi<br />

73 Universite laval<br />

86 University of Manitoba<br />

115 University of Ontario Institute of<br />

Technology<br />

61 University of Toronto<br />

106 University of Waterloo<br />

99 University of Western Ontario<br />

78 University of Windsor<br />

EStonia<br />

118 Tallinn University of Technology<br />

gErmany<br />

9 Friedrich Alexander University of<br />

Erlangen<br />

121 RWTH Aachen Tech University<br />

3 Universitat Stuttgart<br />

mExico<br />

124 Universidad Autonoma Estado Mexico<br />

SingaporE<br />

085 National University of Singapore<br />

SoutH KorEa<br />

93 Kookmin University<br />

110 Kumoh National Institute of Technology<br />

122 Seoul National University of Science &<br />

Tech<br />

page 8<br />

unitEd StatES<br />

alabama<br />

79 Auburn University<br />

98 University of Alabama – Tuscaloosa<br />

arizona<br />

90 Arizona State University – Tempe<br />

california<br />

35 San Jose State University<br />

colorado<br />

83 Colorado State University<br />

18 US Air Force Academy<br />

connecticut<br />

107 University of Connecticut<br />

59 University of Hartford<br />

Florida<br />

89 Florida Atlantic University<br />

52 Florida Institute of Technology<br />

20 Florida International University<br />

23 University of Central Florida<br />

103 University of Florida<br />

47 University of North Florida<br />

12 University of South Florida<br />

georgia<br />

48 Georgia Institute of Technology<br />

81 Georgia Southern University<br />

41 Southern Polytechnic State University<br />

illinois<br />

111 Bradley University<br />

102 Northern Illinois University<br />

43 Northwestern University<br />

57 University of Illinois - Chicago<br />

74 University of Illinois - Urbana Champaign<br />

indiana<br />

29 Purdue University - W lafayette<br />

120 Rose Hulman Institute of Technology<br />

126 University of Evansville<br />

Kansas<br />

40 Kansas State University<br />

11 University of Kansas - lawrence<br />

70 Wichita State University<br />

louisiana<br />

64 louisiana State University<br />

maine<br />

54 University of Maine<br />

maryland<br />

42 University of Maryland - College Park<br />

16 US Naval Academy<br />

massachusetts<br />

34 Worcester Polytechnic Institute<br />

michigan<br />

75 Ferris State University<br />

101 Kettering University<br />

119 lawrence Technological University<br />

15 Michigan State University<br />

38 Oakland University<br />

71 Saginaw Valley State University<br />

5 University of Michigan - Ann Arbor<br />

76 University of Michigan - Dearborn<br />

44 Wayne State University<br />

55 Western Michigan University<br />

minnesota<br />

36 University of Minnesota - Twin Cities<br />

123 University of Minnesota-Duluth<br />

56 University of St Thomas<br />

mississippi<br />

108 Mississippi State University<br />

missouri<br />

14 Missouri University of Science and<br />

Technology<br />

33 University of Missouri<br />

53 Washington University - St louis<br />

new Hampshire<br />

49 University of New Hampshire<br />

new Jersey<br />

77 Rutgers University<br />

104 Stevens Institute of Technology<br />

new york<br />

19 Columbia University<br />

63 Cooper Union<br />

84 Cornell University<br />

65 Rensselaer Polytechnic Institute<br />

97 Rochester Institute of Technology<br />

north carolina<br />

113 Duke University<br />

22 North Carolina State University - Raleigh<br />

105 University of North Carolina – Charlotte

north dakota<br />

112 North Dakota State University<br />

ohio<br />

39 Ohio State University<br />

50 University of Akron<br />

58 University of Cincinnati<br />

31 University of Toledo<br />

oklahoma<br />

128 Oklahoma State University<br />

oregon<br />

1 Oregon State University<br />

94 Portland State University<br />

pennsylvania<br />

67 Carnegie Mellon University<br />

37 lafayette College<br />

114 lehigh University<br />

95 Penn State University - University Park<br />

96 Temple University<br />

25 University of Pittsburgh - Pittsburgh<br />

88 Villanova University<br />

27 York College of Pennsylvania<br />

rhode island<br />

32 Brown University<br />

South carolina<br />

100 Clemson University<br />

South dakota<br />

66 South Dakota School of Mines &<br />

Technology<br />

tennessee<br />

87 Tennessee Tech University<br />

60 Vanderbilt University<br />

Bringing Theory to Life<br />

Maplesoft technology helps bridge the gap between education and real<br />

life in an engaging, interactive and visual manner. MapleSim prepares<br />

students for the challenges in industry by giving them experience with<br />

modern techniques and tools for system-level modeling. It is an essential<br />

tool for the toolkit of every graduating engineer.<br />

www.maplesim.com<br />

Formula SAE teams are eligible to get complimentary<br />

copies of Maplesoft products. To apply please visit<br />

www.maplesoft.com/FormulaSAEproduct<br />

A Cybernet Group Company<br />

texas<br />

80 Texas Tech University<br />

virginia<br />

109 Old Dominion University<br />

92 Virginia Tech<br />

washington<br />

116 Washington State University<br />

51 Western Washington University<br />

west virginia<br />

46 West Virginia University<br />

wisconsin<br />

10 University of Wisconsin Madison<br />

© Maplesoft, a division of Waterloo Maple Inc., <strong>2013</strong>. Maplesoft, Maple, and MapleSim are<br />

trademarks of Waterloo Maple Inc. All other trademarks are the property of their respective owners.<br />

vEnEZuEla<br />

82 Universidad Central de Venezuela<br />

117 Universidad Nacional Experimental Polite<br />

17 Universidad Simon Bolivar<br />

6<br />

Advanced System-Level Modeling<br />

page 9

1<br />

oregon State university<br />

Global Formula Racing is the first internationally collaborative FSAE team. Students<br />

from Oregon State University and Duale Hochschule Baden Wurttemberg<br />

Ravensburg work together to design, build, test and race two cars every year, one<br />

combustion one electric.<br />

Stop by our pits to see our <strong>2013</strong> entry and say hi!<br />

braKE : Tilton, Brembo, AP<br />

bScd : 96mm/62mm/1/450cc<br />

cooling : Oil and water coolers<br />

drivE : Chain<br />

ElEctronicS : Motec<br />

EnginE : Honda CRF450x<br />

Fr/rr tracK : 1125mm<br />

FramE : Carbon monocoque, steel hoops<br />

FuEl SyStEm : Honda fuel pump, bosch injector<br />

FuEl typE : 92 octane<br />

matErial : Steel, Al, carbon, plastic, none<br />

mpd : 9100<br />

mpt : 9100<br />

olwH : 3100/1300/1327 mm<br />

SuSpEnSion : SlA pullrod front, pushrod rear<br />

tirE : Hoosier lC0<br />

uniQuE : Heritage<br />

wEigHt : 493<br />

wHEElbaSE : 1555<br />

3<br />

universitat Stuttgart<br />

global racing rennteam uni Stuttgart<br />

United States Germany<br />

Since 2006 the Rennteam Uni Stuttgart has built very successful cars. The<br />

F0711-7 follows in this streak of success as the seventh car built by the<br />

Rennteam.<br />

The frame consists of a full body CFRP safety cell in the front and a tubular steel<br />

space frame at the rear. In comparison to the big tire tracks of the F0711-6, last<br />

year’s car, we changed to 10’’ wheels for the 11-7. This new chassis concept allows<br />

improved driving dynamics, greater agility and faster lap times at a reduced<br />

overall weight. It was tried to reduce weight in order to get better handling and<br />

faster acceleration of the car. less rotating mass in the engine and optimized application<br />

result in improved rev up of the engine and better drivability for the driver<br />

than the car’s predecessors possessed. Thereby we stick to our reliable and well<br />

known Honda CBR600rr engine.<br />

The Rennteam DNA is obvious in the design. The typical Stuttgart nose, the black<br />

and white appearance and the similarities with its predecessor in point of shape<br />

are clearly visible.<br />

We are looking forward to an exciting competition!<br />

braKE : floating rotors, 4 pistons front, 2 pistons rear<br />

bScd : 67.0mm/ 42.5mm/ 4 cylinder/ 599ccm<br />

cooling : student built, separate cooling cycles<br />

drivE : chain drive<br />

ElEctronicS : data acquisition system, telemetry,<br />

adjustable anti roll bar + intake syst<br />

EnginE : Honda CBR 600 RR<br />

Fr/rr tracK : 1170mm/1150mm<br />

FramE : Hybrid Frame, monocoque + tubular steel<br />

space frame<br />

FuEl SyStEm : 2 stage fuel injection system<br />

FuEl typE : E85<br />

matErial : aluminum tank<br />

mpd : 85hp<br />

mpt : 65Nm<br />

olwH : 2651mm long, 1357mm wide, 1059mm high<br />

SuSpEnSion : pullrods T-type anti roll bar front. pushrods,<br />

U-type anti roll bar rear<br />

tirE : 10" Hoosier Tire<br />

uniQuE : modified camshafts + crankshaft, narrowed<br />

inlet ports pipes + outlet ports<br />

wEigHt : 542lbs<br />

wHEElbaSE : 1620mm<br />

page 10 Information published as supplied by teams on or before April 10, <strong>2013</strong>

• Powertrain Controls & Calibration<br />

• Electrified Powertrain Engineering<br />

• Transmission and Driveline<br />

• Vehicle Engineering<br />

• Electrical & Electronics Systems Engineering<br />

• Powertrain NVH<br />

Ford Engineer Mazen Hammoud and<br />

Ford NASCAR driver Carl Edwards<br />

test drive the new Ford Taurus<br />

<strong>2013</strong> Fusion Energi Plug-In<br />

<strong>2013</strong> Mustang BOSS 302 Engine<br />

For a complete list of opportunities and to apply online, please go to www.careers.ford.com

6<br />

The TANKIA2012 is the most revolutionary development in the history of the<br />

TUG-Racing team. In recent years, we used an engine that was amongst the<br />

most powerful on the track. This year, we made a turn regarding this concept.<br />

The focus is now on lightweight and agility rather than merely power. The chassis<br />

has become slimmer, the tires smaller and we shortened the track as well as the<br />

wheelbase. And we even went one step further: we switched the engine from a<br />

heavy 4-cylinder to a 1-cylinder KTM. As a result of our changes, we estimate a<br />

much better fuel consumption and more agility. These improvements will provide<br />

the driver with enough confidence to stick it into the bends and prove our point.<br />

Our car comes with a carbon fiber monocoque and a carbon fiber space frame<br />

rear end, which is stiffer and makes it possible to remove the engine very quickly.<br />

The self-developed multifunctional steering wheel enables the driver to adjust<br />

vehicle parameters easily during the race.<br />

Austria<br />

graz university of technology<br />

tu graz racing<br />

braKE : 4 disc system, self designed steel rotors,<br />

adjustable brake balance,<br />

bScd : 95mm/72mm/1 cylinders/510cc<br />

cooling : side pod mounted radiators with thermostatic<br />

controlled electric fans<br />

drivE : Chain, 520<br />

ElEctronicS : multifunctional steering wheel, traction<br />

and launch control,<br />

EnginE : 2012 KTM ExC 500<br />

Fr/rr tracK : 1386mm/1028<br />

FramE : Carbon fibre monocoque and carbon fibre rear<br />

end<br />

FuEl SyStEm : student designed and built, fuel injection,<br />

2-spray preparation,<br />

FuEl typE : gasoline, 100 octane<br />

matErial : carbon fiber prepregs, Nomex and Aluminum<br />

honeycombs, carbon-inserts<br />

mpd : 10000<br />

mpt : 65000<br />

olwH : 2869mm/1386mm/1028mm<br />

SuSpEnSion : unequal length a-arms, front pull, rear<br />

push rod<br />

tirE : 18x6,0-10 Hoosier lC0<br />

uniQuE : CFRP rims, multifunctional steering wheel,<br />

wEigHt : 476 lb<br />

wHEElbaSE : 1550mm<br />

8Ecole de technologie Superieure<br />

Formula <strong>SaE</strong> EtS<br />

The AxF13 design is based on ambitious competition objectives. The result is a<br />

compact, lightweight, efficient, fast race car. Using a numerical approach, backed<br />

by extensive experimental validation the team is able to always push the limits<br />

further and further.<br />

The AxF<strong>2013</strong> marks a new era in the ETS history, being the first car with aerodynamics<br />

devices. Using extensive Computational fluid dynamics (CFD) the team<br />

managed to design a well balanced and lightweight package.<br />

braKE : Outboard disk, 2 and 4 pistons calipers<br />

bScd : 95mm / 62.4mm / 1 / 449cc<br />

cooling : Sidepods mounted aluminium radiator<br />

drivE : Chain<br />

ElEctronicS : Smoke tube and magic readers<br />

EnginE : 2011 Yamaha WR450F<br />

Fr/rr tracK : 1162mm / 1111mm<br />

FramE : Single piece carbon fiber monocoque<br />

FuEl SyStEm : EFI, port injected<br />

FuEl typE : unleaded 93<br />

matErial : Carbon Fiber, Aluminium, Steel, Titanium,<br />

Balsa,Nylon, Blood, Sweat and Tears<br />

mpd : 8500 rpm<br />

mpt : 8000 rpm<br />

olwH : 2827mm (11.3in) / 1321mm (52po) / 1193.8mm<br />

(47in)<br />

SuSpEnSion : Double Wishbone, pushrod actuated<br />

Horizontal Springs & Dampers, Anti-Roll Bar<br />

tirE : 10 in Hoosier lC3<br />

uniQuE : Fabriquée en français<br />

wEigHt : 483 lbs<br />

wHEElbaSE : 1530 mm<br />

page 12 Information published as supplied by teams on or before April 10, <strong>2013</strong><br />

Canada

Success stories don ‚ t just happen. They are made.<br />

Take your fi rst step on a management career path. Our Professional Development Programs put you<br />

on the fast track for professional and leadership opportunities throughout Bosch. Within 24 months<br />

you will complete four rotations, one of which is international. You will be partnered with an executive<br />

mentor for professional coaching and gain leadership exposure through structured networking events.<br />

You’ll get to know the company inside and out, make independent contributions and cultivate your<br />

skill set. Start your career with Bosch’s Professional Development Training Program for Bachelor’s<br />

level candidates or the Junior Managers Program for Master’s graduates.<br />

What should you bring to the table? An innovative mindset, fl exibility, results-oriented spirit and, of<br />

course, leadership potential. Think you’ve got it? Join Bosch and begin your exciting career today.<br />

Apply now. Discover your potential with our Professional Development Programs.<br />

www.boschcampus.com

10<br />

Wisconsin Racing would like to give special thanks to our sponsors:<br />

Diamond: The United Wisconsin Grain Producers<br />

Platinum: The Wisconsin Corn Promotion Board, Midwest Composite Technologies,<br />

Eric Gorr’s Forward Motion, Engineered Metal Products, Mercury Marine, QMI<br />

Gold: Baum Machine, Wisconsin Metal Parts, Trim-Tex Drywall Products, Isthmus<br />

Engineering, Bosch, Ricardo<br />

As well as our Silver and Bronze sponsors listed at www.uwracing.com<br />

United States<br />

university of wisconsin - madison<br />

wisconsin racing<br />

braKE : Wilwood Front Calipers, AP Racing Rear Calipers,<br />

Custom Rotors<br />

bScd : 100mm / 77mm / 1 / 605cc<br />

cooling : Parallel dual pass with right side fan<br />

drivE : 520 Chain, Drexler Differential<br />

ElEctronicS : Mototron ECU, AiM EVO3 Pro DAQ, lCD<br />

Steering Wheel Display<br />

EnginE : KTM 525-xC, Turbocharged, Single-Cylinder<br />

Fr/rr tracK : 47"/45"<br />

FramE : 4130 Chromoly Spaceframe<br />

FuEl SyStEm : Student-designed fuel injection<br />

FuEl typE : E85<br />

matErial :<br />

mpd : 8100<br />

mpt : 5000<br />

olwH : 116" / 54" / 43.1"<br />

SuSpEnSion : Double unequal length A-Arm, Push rod<br />

tirE : Hoosier 18x6-10 lC0<br />

uniQuE : Feed forward wastegate and feedback ignition<br />

traction control<br />

wEigHt : 505 lbs<br />

wHEElbaSE : 62.0<br />

The team was founded in 1994 by a group of six mechanical engineers, and is<br />

now a team of 36 undergraduate seniors and several volunteers. Team members<br />

represent several disciplines including mechanical and electrical engineering,<br />

computer science, industrial design, and business.<br />

Jayhawk Motorsports has a long history of success in FSAE competitions with 7<br />

top ten finishes over the past 6 years including 1st place overall at both the 2012<br />

FSAE lincoln and Formula Hybrid (Electric division) events. For <strong>2013</strong>, JMS has<br />

designed two new and highly improved racecars, the JMS13c (combustion) and<br />

JMS13e (electric), to be top contenders at FSAE competitions.<br />

United States<br />

of Kansas - lawrence<br />

11university<br />

Jayhawks motorsports<br />

braKE : 2-piston Brembo calipers, ductile iron rotors,<br />

bespoke master cylinders<br />

bScd : 67mm bore / 42.5mm stroke / 4 cyl / 599cc<br />

cooling : Single side-mounted radiator and PWM fan<br />

drivE : Chain-drive<br />

ElEctronicS : life Racing ECU<br />

EnginE : Honda CBR600RR<br />

Fr/rr tracK : Front: 48in (1219.2mm), Rear: 46in<br />

(1168.4mm)<br />

FramE : Carbon fiber monocoque with stressed engine<br />

FuEl SyStEm : Student manufactured, return system<br />

FuEl typE : E-85<br />

matErial : Carbon fiber, aluminum, steel<br />

mpd : 10000<br />

mpt : 8250<br />

olwH : l: 125in (3185mm), W: 56.25in (1428.75mm), H:<br />

40in (1016mm)<br />

SuSpEnSion : Double unequal A-arm pull/push rod actuated<br />

spring and damper<br />

tirE : F: 20.5x7-13, R: 20x7.5-13, R25B Hoosier<br />

uniQuE : Aero package, carbon a-arms<br />

wEigHt : 585lbs<br />

wHEElbaSE : 65in. (1651mm)<br />

page 14 Information published as supplied by teams on or before April 10, <strong>2013</strong>

Information published as supplied by teams on or before April 10, <strong>2013</strong><br />

SOLIDWORKS EDUCATION PROGRAM<br />

3D Design, Simulation, Documentation,<br />

Engineering Analysis Software<br />

Designed in SolidWorks by Aldebaran Robotics.<br />

www.solidworks.com/education<br />

page 15

12<br />

USF Racing is a team of seventeen mechanical engineering students that includes<br />

graduate students through freshmen. F<strong>2013</strong> represents the eighth Formula SAE<br />

vehicle produced by USF Racing since 2005 and the third iteration of our current<br />

design concept.<br />

United States<br />

university of South Florida<br />

uSF racing<br />

braKE : Four Wheel Disc<br />

bScd : 95.5mm/62.8mm/1 Cylinder/449.5cc<br />

cooling : Water Cooled w/Fan<br />

drivE : 520 Chain Drive<br />

ElEctronicS : DTA S80, AIM DAQ<br />

EnginE : Suzuki lT-R450<br />

Fr/rr tracK : 1270/1270 mm<br />

FramE : Steel Spaceframe<br />

FuEl SyStEm : Electronic Fuel Injection<br />

FuEl typE : 100 Octane<br />

matErial : 4130<br />

mpd : 9500<br />

mpt : 6500<br />

olwH : 2405mm l, 1386mm W, 1205mm H<br />

SuSpEnSion : Front Pullrod, Rear Pushrod<br />

tirE : 18x6-10 Hoosier<br />

uniQuE :<br />

wEigHt : 485lb<br />

wHEElbaSE : 1574mm<br />

universitario da FEi<br />

13centro<br />

Formula FEi<br />

The Formula FEI RS7 is the 7th Formula SAE prototype from FEI and the 3rd<br />

vehicle with the lightweight concept, in which 10” wheels and a single cylinder<br />

engine were used.<br />

The RS7 stands for an evolution among the RS generation vehicles. This is accomplished<br />

without losing the main design objective: To suit the non-professional,<br />

weekend, competition racer market, allying the best compromises in performance,<br />

aesthetics, cost, ergonomics, maintainability, manufacturability and reliability.<br />

The yellow, green and blue stripes painting is a tribute to Ayrton Senna and identifies<br />

the Formula FEI during international competitions.<br />

braKE : FEI Calipers and Floating Rotors / Tilton Master<br />

Cylinders w/ Adj. Balance<br />

bScd : 95 mm / 63.4 mm / 1 cyl / 449 cc<br />

cooling : Custom Aluminum Radiator / Side pod<br />

mounted<br />

drivE : 520 Chain and Custom Torsen T-1<br />

ElEctronicS : MoTeC EDl3, FEI Telemetry, CAN bus and<br />

Dashboard<br />

EnginE : Yamaha WR450FEI<br />

Fr/rr tracK : 1165 mm (45,87in) / 1185 mm (46,65in)<br />

FramE : Tubular Space Frame<br />

FuEl SyStEm : FuelTech FT400, Custom Bosch Fuel<br />

Pump and Siemens Racing Injector<br />

FuEl typE : E85 or E100 Ethanol<br />

matErial : 1020 Steel, Nomex Honeycomb and Carbon<br />

Fibe<br />

mpd : 40 kW @ 8000 rpm<br />

mpt : 50 Nm @ 6000 rpm<br />

olwH : 2704mm (106.46in), 1405mm (55,31in),<br />

1005mm (39,57in)<br />

SuSpEnSion : Double A-Arms, Pull rods, Penske Dampers<br />

and Adj. Anti-Roll Bars<br />

tirE : 18x6-10 lC0 Hoosier<br />

uniQuE : FEI Telemetry, CAN bus and Dashboard<br />

wEigHt : 238 kg (525 lb) w/ driver<br />

wHEElbaSE : 1570mm (61.8in)<br />

page 16 Information published as supplied by teams on or before April 10, <strong>2013</strong><br />

Brazil

14<br />

S&T Racing’s <strong>2013</strong> car, “lily” is a high horsepower and high downforce platform<br />

that delivers exceptional lateral and longitudinal performance. A low drag aerodynamic<br />

package produces 510lbs of downforce, elevating lily’s lateral acceleration<br />

to 2.8g. lily sits on four 20.5x7x13 Hoosier R25B tires, mounted on 3 piece<br />

wheels to lightweight, three lug, steel welded uprights. loads are transferred<br />

to the chassis through double A-arms with a pull rod front and push rod rear<br />

suspension. She is powered by a Yamaha R6 that delivers 96Hp and 42ft-lbs to<br />

the wheels through a limited slip, salisbury style differential.<br />

We would like to extend our sincere gratitude to our loyal and generous sponsors<br />

and alumni that helped make this build and test season a success. We would not<br />

be able to produce such a formidable vehicle without your continued support.<br />

United States<br />

missouri university of Science and technology<br />

missouri S&t racing<br />

braKE : Inboard floating rotors with custom masters<br />

bScd : 65.5 mm bore / 44.5 mm stroke / 4 cyl / 599 cc<br />

cooling : Rear mounted radiator with inlet duct<br />

drivE : Drexler limited Slip Differential<br />

ElEctronicS : Motec M600 ECU<br />

EnginE : 1999-2002 Yamaha YZF-R6<br />

Fr/rr tracK : 48 inches/46 inches<br />

FramE : 4130 steel round tubing<br />

FuEl SyStEm : Direct port injection<br />

FuEl typE : 100 Octane<br />

matErial : 4130 Steel<br />

mpd : 12,000 RPM<br />

mpt : 10,700 RPM<br />

olwH : 123" x 52" x 50"<br />

SuSpEnSion : Double A-Arm; Front pull rods; Rear<br />

push rods<br />

tirE : 13" Hoosier R25B<br />

uniQuE : Custom Masters, steering rack, and 450lbs<br />

downforce at 60mph<br />

wEigHt : 580lbs<br />

wHEElbaSE : 64.5 inches<br />

Information published as supplied by teams on or before April 10, <strong>2013</strong><br />

VISIONARIES<br />

WELCOME<br />

CHALLENGING SPIRIT REQUIRED<br />

INDIVIDUALITY RESPECTED<br />

ACCOMPLISHMENTS ROUTINE<br />

Honda is an equal opportunity employer<br />

and we are accepting applications now!<br />

For more information about career<br />

opportunities with Honda please visit:<br />

www.corporate.honda.com<br />

page 17

State university<br />

15michigan<br />

State racing<br />

Michigan State University’s <strong>2013</strong> Formula SAE entry, the SR-13, is an iteration<br />

on the team’s previous carbon fiber monocoque chassis. The SR-13 is designed<br />

to provide a reliable and tunable race car with a simple human machine interface<br />

that inspires driver confidence, and promises to be an exceptional challenger in<br />

this year’s competition. The SR-13’s well-developed powertrain, built around the<br />

Honda F4i, provides more power than ever over a broad torque curve. The electrical<br />

system features over 90 sensors to monitor car and driver performance and<br />

a dash display to relay the information while driving. The SR-13 also features an<br />

electro-pneumatic paddle shifting system, traction and launch control, and MSU’s<br />

first-ever aerodynamics package.<br />

We would like to thank Michigan State University and all of our sponsors, friends,<br />

and family for their kind contributions and support!<br />

United States<br />

braKE : Wilwood PS-1 dual piston, Sintered metallic<br />

compound pads. Tilton 77 MC<br />

bScd : 67 mm / 42.5 mm / Inline 4 cyl / 599 cc<br />

cooling : Single front-ducted, sidepod mounted radiator<br />

25.4 cm shroud-mounted fans<br />

drivE : Chain-driven Drexler Differential<br />

ElEctronicS : Motec M400 with DDU7 Dash Display<br />

EnginE : Honda CBR600F4i<br />

Fr/rr tracK : 1194 mm / 1194 mm<br />

FramE : Full carbon fiber monocoque with rear steel<br />

sub-frame<br />

FuEl SyStEm : Sequential fuel injection<br />

FuEl typE : 93 Octane<br />

matErial : Carbon Fiber<br />

mpd : 10500 RPM<br />

mpt : 9000 RPM<br />

olwH : 2747.3 mm long, 1390.1 mm wide, 1098.3 mm<br />

high<br />

SuSpEnSion : Double unequal length A-Arm. Push-rod<br />

actuated spring and damper<br />

tirE : Continental 205 / 510 R13 M34<br />

uniQuE : Front and rear wing, electro-pneumatic paddle<br />

shifting system<br />

wEigHt : 640 lbs / 290 kg<br />

wHEElbaSE : 1588 mm<br />

16<br />

The <strong>2013</strong> Navy FSAE team leaders, Nick Gfeller and Tyler Faris, are excited to<br />

introduce several significant design features that are new to our team and ground<br />

breaking for our program. Working from the ground up, we are driving on ten<br />

inch center locking wheels for the first time ever thanks to Dan Deland, Wynn<br />

Van Norman, Ryan Pangborn, and Josh Pangborn. Keeping the car pulled to the<br />

ground, Eric More has provided a first time diffuser that weighs just 4.3 lbs. Zach<br />

Basich, James Rocha, and Ethan English have finely tuned a two cylinder Aprilia<br />

SxV 550 to get us off of the drag strip starting line in record time. Cradling this<br />

new power plant is an all-time light weight Hybrid CFRP Monocoque with a 4130<br />

Chromoly Steel Rear Space Frame designed by Ryan Benroth and Katrina lintz.<br />

Inside the cockpit, Andy Musselwhite and Mark Rintz have installed a custom built<br />

Inertial Measurement Unit, 3-Axis Accelerometer, and an Aim Motorsports Solo Dl<br />

dashboard with a speedometer and tachometer. Many parts of the car are custom<br />

fabricated and finished with the N Star, representing the service of all Navy personnel.<br />

We thank them for providing freedom and enabling us to complete this project.<br />

United States<br />

uS naval academy<br />

navy motorsports<br />

braKE : Tilton 77 Series Master Cylinder, AP Racing<br />

Calipers, Custom Rotors<br />

bScd : 80mm Bore/55mm Stroke/2 Cylinders/553cc<br />

Displacement<br />

cooling : Side Pods, 1 Core Aluminum Radiator,<br />

254cfm Fan<br />

drivE : Chain Driven, 5 Speed Aprilia Sequential Transmission,<br />

Drexler Differential<br />

ElEctronicS : Inertial Measurement Unit, 3-Axis Accelerometers,<br />

Slip Control<br />

EnginE : Aprilia SxV 550<br />

Fr/rr tracK : 1219.2 mm/1168.4mm<br />

FramE : Hybrid CFRP Monocoque with 4130 Chromoly<br />

Steel Rear Spaceframe<br />

FuEl SyStEm : Microsquirt ECU<br />

FuEl typE : 93 Octane<br />

matErial : Preimpregnated Carbon Fiber, 4130 Chromoly<br />

Steel, 7075/6061 Aluminum<br />

mpd : 10000<br />

mpt : 4200<br />

olwH : 2616mm long, 1473mm Wide, 1074mm high<br />

SuSpEnSion : Double Unequal length A-Arm, Push<br />

Rod Actuated Spring/Damper, Anti-Roll Bar<br />

tirE : 18x7.5-10 R25B Hoosier<br />

uniQuE : Diffuser, Fighter Jet Inspired Side Pods, Custom<br />

Molded Foam Seats<br />

wEigHt : 550 lbs<br />

wHEElbaSE : 1524mm<br />

page 18 Information published as supplied by teams on or before April 10, <strong>2013</strong>

Simon bolivar<br />

17universidad<br />

Formula <strong>SaE</strong> uSb<br />

Based on the previous year experience and to keep improving our results, this<br />

year F-SAE USB team has set to design and build a Functional, Achievable,<br />

Simple, Tested and Economic car. We want to keep Go FASTER to continue being<br />

the best latin American team.<br />

This year, the team established two main goals, which along with our decision<br />

matrix set the guidelines to the overall design.<br />

I. Increase testing time by optimizing the design and manufacture processes.<br />

II. Reduce weight through an improved design and construction process, maintaining<br />

reliability and performance.<br />

We want thank our sponsors for their support through this year.<br />

Venezuela<br />

braKE : Outboard, Floating, gray cast iron, hub mounted,<br />

215 mm OD. Drilled.<br />

bScd : 67 mm / 42,5 mm / 4cyl / 599 cc<br />

cooling : Two single pass, aluminum radiators with inlet/<br />

outlet duct and no cooling<br />

drivE : Torsen T1<br />

ElEctronicS : PE ECU-3 (EDGE) EFI<br />

EnginE : HONDA CBR600 F4i cylinders<br />

Fr/rr tracK : 1344 mm / 1294 mm<br />

FramE : Tubular frame<br />

FuEl SyStEm :<br />

FuEl typE : Sunoco Ultra 93<br />

matErial : 4130 Round Steel Tubing<br />

mpd : 11.500 rpm<br />

mpt : 7800 rpm<br />

olwH : 2987 mm, 1510 mm, 1664 mm<br />

SuSpEnSion : Double Unequal length A-Arms. Push rod<br />

actuated<br />

tirE : front 7.0 in and rear 7.5 in<br />

uniQuE : Brakes calipers and rotors are design and build<br />

by the team<br />

wEigHt : 470 lb<br />

wHEElbaSE : 1585 mm<br />

Information published as supplied by teams on or before April 10, <strong>2013</strong><br />

NO ROOM fOR<br />

Standing Still.<br />

There’s a movement happening at GM.<br />

One that requires more than hard work and<br />

sheer determination, but a unified vision that<br />

embraces ideas and works collaboratively.<br />

And we need your engineering talent to be<br />

an integral part of this progression. This is<br />

your chance to experience the momentum<br />

of an international company during the day,<br />

and be charged by a city brimming with<br />

electricity at night. Here, your ideas can<br />

contribute to what’s next, now. And your<br />

ambition can propel us toward the future.<br />

Test your talent at GM and discover what our<br />

employees already know — that together,<br />

there’s no stopping us.<br />

W E A R E T H E D R I V I N G F O R C E<br />

w w w . c a r e e r s . G M . c o M<br />

GM <strong>2013</strong>. The policy of General Motors is to extend opportunities to qualified applicants<br />

and employees on an equal basis regardless of an individual’s age, race, color, sex, religion,<br />

national origin, disability, sexual orientation, gender identity expression or veteran status.<br />

page 19

18<br />

The United States Air Force Academy is a four year undergraduate military<br />

institution that develops leaders of character for the US Air Force. Part of this<br />

development involves capstone projects such as Formula SAE. The goal of the<br />

<strong>2013</strong> FSAE team was to design the smallest, lightest, most responsive racecar<br />

ever developed by the Academy. This goal was achieved by maximizing lateral and<br />

longitudinal acceleration. To improve longitudinal and lateral acceleration, a main<br />

focus in design was to reduce weight to less than 400 lbs, dropping 33 pounds<br />

from the baseline 2012 FSAE vehicle. To facilitate this, the decision was made to<br />

switch to 10” wheels, which decreased the overall weight and center of gravity<br />

height, also contributing to increasing the acceleration capabilities. This change<br />

required a complete redesign of the suspension and braking systems and a significant<br />

change to the chassis. These changes resulted in a 61 inch wheel base,<br />

track widths of 44 inches in the front and 43 inches in the rear, a more rearward<br />

weight distribution of 45/55 front/rear, a center of gravity height of 11 inches, and<br />

a final weight of 399 lbs.<br />

United States<br />

uS air Force academy<br />

uSaFa Formula <strong>SaE</strong><br />

braKE : 4 wheel disk<br />

bScd : 95 mm bore / 72 mm stroke / single cylinder /<br />

510.4 cc<br />

cooling : Series cooling system with side mounted Al<br />

core radiators<br />

drivE : TRE geared torque-biasing<br />

ElEctronicS : PE 3 ECU, Traqmate System<br />

EnginE : KTM 525<br />

Fr/rr tracK : 1117mm/1092,44in/43in<br />

FramE : Triangulated Space Frame Chassis<br />

FuEl SyStEm : single port fuel injected<br />

FuEl typE : 93 Octane<br />

matErial : 4340 stell tube frame, carbon fiber body<br />

panels<br />

mpd : 34 @ 6600 rpm<br />

mpt : 35 @ 4400 rpm<br />

olwH : 2543.8/100.2<br />

SuSpEnSion : Unequal length, Non-parallel A-Arm<br />

System<br />

tirE : 19.5x7-10 R25B Hoosier<br />

uniQuE : Wireless ECU communication, Traqmate data<br />

logging system<br />

wEigHt : 549<br />

wHEElbaSE : 1549.4/61<br />

19columbia university<br />

Knickerbocker motorsports<br />

Equipped with powerful features and redesigned to improve performance in<br />

static and dynamic events, the KMR-13 is the sixth FSAE car constructed by<br />

Knickerbocker Motorsports.Reliability, efficiency,and preciseness are the bases<br />

to improve upon.The design and manufacturing of the KMR-13 surpasses the<br />

past iterations of KM cars due to substantial increase in manpower, manufacturing<br />

time, and funding.We achieved goals of closely-packaging dynamic systems<br />

and use of lighter,cutting-edge materials in static systems to carry out our<br />

design goals.Our car’s performance is greater than the sum of its parts and our<br />

attention to detail and knowledge has enabled us to take advantage of many<br />

synergies in the overall design leading the KMR-13 vehicle to be KM’s most<br />

successful design yet.We would like to thank our sponsors:Columbia Engineering<br />

Alumni Association,CU Department of Mechanical Engineering,Carleton<br />

laboratory,CU Facilities,Activities Board at Columbia,CU Powerhouse, Alcoa<br />

Inc.,Zoltek, Momentive,SOMS Technologies,Green Earth Technologies,Atlassian,<br />

QBC Bearings,Fedhill, PTC,Aurora Bearing,DENSO,lincoln Electric,Timken,Morel<br />

Industries,Hot Seat Chassis,and Aircraft Spruce.<br />

United States<br />

braKE : Tilton 77 Series Components, Brembo 34mm<br />

Calipers, 220mm Floating Rotors<br />

bScd : 67mm bore/ 42.5mm stroke/ 4 cylinder/ 599 cc<br />

cooling : Single Pass Side-Mounted Radiator with ECU<br />

controlled electric fan<br />

drivE : 520 Chain Driven, Quaife ATB, 52:11 gear ratio<br />

ElEctronicS : MegaSquirt 3, Custom lED Dash, Race<br />

Technology Dl1 Data logger<br />

EnginE : Honda CBR 600 F4i, custom intake and 4-1<br />

exhaust system<br />

Fr/rr tracK : 1219 mm front, 1168 mm rear<br />

FramE : 4130 Steel Space Frame<br />

FuEl SyStEm : Electronic Fuel Injection, Sequential<br />

FuEl typE : 93 Octane Gasoline<br />

matErial :<br />

mpd : 9500 RPM<br />

mpt : 8000 RPM<br />

olwH : 3150 mm long, 1470 mm wide, 1380 mm high<br />

SuSpEnSion : Double unequal A-arm, push rod actuated<br />

spring/damper. Adj. ARB<br />

tirE : Hoosier 20.5x7.0-13 R25A<br />

uniQuE : Active Aero Dynamic Kit<br />

wEigHt : 600 lbs<br />

wHEElbaSE : 1549.4 mm<br />

page 20 Information published as supplied by teams on or before April 10, <strong>2013</strong>

20<br />

Being a second year team, we are a group of highly motivated individuals ready<br />

to improve our team and design. Our <strong>2013</strong> prototype will include a full chromoly<br />

space frame with chromoly a-arms connected to aluminum uprights and hubs.<br />

The suspension geometry is designed and setup for autocross. The braking<br />

system for our car will be a floating rotor set-up using Wilwood PS1’s brake<br />

calipers. The drivetrain is designed for a Torsen T1 differential with a casing made<br />

of aluminum to seal it, driven by a 38T sprocket to give us the best combination<br />

to ensure maximum performance. Our powertrain includes a Yamaha YZF 450cc<br />

single cylinder engine coupled with a custom all aluminum intake manifold and<br />

stainless exhaust. Our design for the ergonomics was to create a simple yet<br />

complete driver interface. Including optimal driver position and switch placement.<br />

live data fed to the driver via a touch screen display located behind the wheel.<br />

The aero package will include a full carbon fiber body, side pods and rear diffuser.<br />

Please check out our website at sae.fiu.edu<br />

United States<br />

Florida international university<br />

panther motorsports<br />

braKE : Outboard disk brake<br />

bScd : 95mm bore/ 63.4mm stroke/ 1 cylinder /449 cc<br />

cooling : Coolant swirl tank with overflow. Temperature<br />

controlled fan<br />

drivE : Chain driven with Torsen lSD<br />

ElEctronicS : Touch-screen, traction control, thermal<br />

sensing fan cut-off<br />

EnginE : 2005 Yamaha YFZ 450<br />

Fr/rr tracK : 48 in/44 in<br />

FramE : Tubular Space Frame<br />

FuEl SyStEm : Megasquirt fuel management with<br />

student build electronic fuel injection<br />

FuEl typE : 93 octane<br />

matErial : 4130 Chromoly Steel<br />

mpd : 8000 rpm<br />

mpt : 7500 rpm<br />

olwH : length 3022 mm/119 in. Width 1397 mm/55 in.<br />

Height 1039 mm/40.9 in.<br />

SuSpEnSion : Double wishbone. Pushrod style.<br />

tirE : lCO Compound 6/18-10<br />

uniQuE :<br />

wEigHt : 570 lb<br />

wHEElbaSE : 1600 mm/63 in<br />

Information published as supplied by teams on or before April 10, <strong>2013</strong><br />

Innovation Intelligence ®<br />

We optimize<br />

everything.<br />

...and we’ll soon be starting our<br />

third decade of doing so. In the early<br />

1990s Altair brought technology from cutting<br />

edge biomedical research to structural<br />

engineers with the first release of OptiStruct.<br />

Later, our leadership was continued<br />

through multi-disciplinary optimization<br />

in HyperStudy. In the 2000s we initiated<br />

Optimization Centers, helping to nurture<br />

a culture of optimization in the product<br />

development teams of some the world’s<br />

most technically advanced companies.<br />

Now in this decade, through SolidThinking<br />

Inspire, Altair has delivered topology<br />

optimization to the designer’s desktop.<br />

Learn how Altair can help<br />

you optimize your products<br />

by visiting altair.com/optimize<br />

Follow Altair on:<br />

page 21

21dalhousie university<br />

dalhousie Formula <strong>SaE</strong> racing<br />

Dalhousie Formula SAE is competing in Michigan for the fourth year.<br />

This year’s design was focussed on improving each system from 2012, rather<br />

than redesigning any major components. The goals were to reduce the weight<br />

of every component, and to improve the reliability of systems which had been<br />

problematic in the past.<br />

One key improvement this year is the implementation of electro-mechanical<br />

paddle shifting, allowing our drivers to keep both hands on the steering wheel at<br />

all times.<br />

Dalhousie Formula SAE would like to thank all of our sponsors who make it possible<br />

to do what we do.<br />

Canada<br />

braKE : Floating steel rotors, 4 piston calipers<br />

bScd : 67 mm bore, 42.5 mm stroke, 4 cylinders, 599<br />

cc<br />

cooling : Side-mounted ducted radiator with fan<br />

drivE : RWD, 520 chain, Drexler lSD<br />

ElEctronicS : MoTeC M400 ECU, Custom tachometer/display<br />

EnginE : Honda CBR 600 RR<br />

Fr/rr tracK : 1200/1155 mm<br />

FramE : 4130 chromoly space frame<br />

FuEl SyStEm : Electric fuel injection<br />

FuEl typE : 93 Octane<br />

matErial : Steel frame, aluminum components, composite<br />

body panels<br />

mpd : 11000 rpm<br />

mpt : 8000 rpm<br />

olwH : 2679 x 1430 x 1067<br />

SuSpEnSion : Double unequal length A-arms, pushrod<br />

activated<br />

tirE : Hoosier 20 x 7 - 13 R25B<br />

uniQuE : Touchscreen display, Nova Scotia tartan<br />

headrest<br />

wEigHt : 280 kg with driver<br />

wHEElbaSE : 1545 mm<br />

of central Florida<br />

23university<br />

Knights racing<br />

<strong>2013</strong> is to be a culmination of many years of knowledge-gain, success, failure,<br />

and program building for UCF. 2012-<strong>2013</strong> was a large shift in knowledge and<br />

experience for the Knights Racing team, as many founding members graduated<br />

this past year. Utilizing years of development, UCF plans to continue the progress<br />

of previous years and build the best, most well rounded car, the school has seen.<br />

The KR13 features a tubular space frame chassis, updated to larger diameter tubing<br />

for a decrease in mass with no change in torsional rigidity. It is the 3rd UCF car<br />

to run a Suzuki GSx-R 600, featuring a new side intake and exhaust designed to<br />

increase torque and drivability, as well as tunability. The suspension was designed<br />

using carbon fiber double wishbones, with pushrods in the rear and pullrods in the<br />

front. Decreasing compliance and increasing adjustment repeatability were main design<br />

goals. The KR13 features an adjustable pedal box and custom carbon fiber seat<br />

to increase driver comfort and fit a wider range of drivers, in addition to a pneumatic<br />

shifting system simplify the driving experience. Other systems were designed to be<br />

lighter, more reliable, and more easily serviceable.<br />

United States<br />

braKE : Floating Outboard, Wilwood calipers<br />

bScd : 67mm bore / 42.5mm stroke / 4 cyclinder / 599<br />

cc<br />

cooling : Single, side mounted custom radiator; coolant<br />

swirlpot<br />

drivE : Chain Drive, Torsen Differential<br />

ElEctronicS : Haltech ECU; Race Technology Dl1 DAQ<br />

EnginE : Suzuki GSx-R 600<br />

Fr/rr tracK : 1220mm/1180<br />

FramE : Tubular Space Frame, ft. oversized tubing<br />

FuEl SyStEm : Fiberglass fuel tank w/ single stage pump<br />

FuEl typE : 93<br />

matErial : 4130<br />

mpd : 11500<br />

mpt : 8000<br />

olwH : l/W/H - 2640mm/1455mm/1091mm<br />

SuSpEnSion : FR & RR - Unequal length carbon wishbone,<br />

push-rod activated<br />

tirE : Hoosier 20 x 7.5 - 13<br />

uniQuE : Pneumatic paddle shifters, adjustable pedal box<br />

wEigHt : 600 lb<br />

wHEElbaSE : 1550mm<br />

page 22 Information published as supplied by teams on or before April 10, <strong>2013</strong>

of pittsburgh - pittsburgh<br />

25university<br />

panther racing<br />

Panther Racing’s <strong>2013</strong> entry is a steel tube space frame chassis with a 4-cylinder<br />

engine. This combination was selected due to the low cost and ease of manufacture<br />

of the chassis as well as the high power output of the 4-cylinder powertrain.<br />

The suspension was designed from the ground up starting with a switch to Hoosier<br />

tires. A host of electronics upgrades along with an improvement in engine<br />

performance will ensure the PR-002 remains competitive. New to the team is aerodynamics<br />

development in the form of an undertray aimed at reducing lift and drag.<br />

SHIFT YOUR<br />

INTO ÜBERDRIVE.<br />

Information published as supplied by teams on or before April 10, <strong>2013</strong><br />

United States<br />

braKE : Upright Tilton MCs, AP Racing CP4226 Calipers<br />

bScd : 67 mm bore/ 42.5 mm stroke/ 4 cylinder(s) / 599<br />

cc<br />

cooling : Single side mounted radiator, Spal pull fan<br />

drivE : Chain, Drexler differential<br />

ElEctronicS : MoTeC M400, PDM32, SDl3<br />

EnginE : Honda CBR600RR<br />

Fr/rr tracK : 1286 mm / 1177 mm<br />

FramE : Steel Tube Spaceframe<br />

FuEl SyStEm : Walbro external pump, Goodridge hose/<br />

fittings<br />

FuEl typE : 93<br />

matErial : 4130 Chromoly Spaceframe<br />

mpd : 10,500 rpm<br />

mpt : 8,500 rpm<br />

olwH : 2683 mm, 1465 mm, 1030 mm<br />

SuSpEnSion : Double unequal length A-arm, pushrod<br />

actuated Penske damper<br />

tirE : Hoosier 20.5x7-13 R23B/ Hoosier 20x7.5-13<br />

R25B<br />

uniQuE :<br />

wEigHt : 600<br />

wHEElbaSE : 1625 mm<br />

FEV is a playground for creative engineers. We help<br />

our customers innovate new concepts from emobility<br />

to greener engines to wind power generation. We’re<br />

constantly pursuing new ideas – redefining “possible”<br />

every day. If you dream of creating the future, join us<br />

and shift your career into Überdrive.<br />

Engineering Innovation<br />

FEV.com/uberdrive<br />

page 23

27<br />

york college of pennsylvania<br />

YC Racing is a seventh year team from York College of Pennsylvania. The team is<br />

composed of 16 mechanical engineering students and an electrical engineer. All<br />

of the students are seniors and build the car from scratch every year. The<br />

team has several goals to improve the car. These include reducing unsprung<br />

weight, increasing engine power, improve ergonomics, and have a more durable<br />

drivetrain. The total goal weight of the car is 493 lbs, 37 pounds less than<br />

last year. Our car makes use of a Yamaha R6 motor with a Taylor Race Quaife<br />

Differential. We have 81 hp at the sprocket with 32 ft-lbs of torque at 11500<br />

rpms. The suspension makes use of pull rods in the front and push rods in the<br />

rear for better packaging of the differential. YC Racing is different from other<br />

teams because we are all seniors and we do this as our capstone project. This<br />

means that we design, build, and test our own car in one year instead of being a<br />

club for four years.<br />

braKE : Front outboard, rear inboard Wilwood Calipers<br />

and Aluminum Rotors<br />

bScd : 65.5mm / 44.5mm / 4 / 599.8cc<br />

cooling : Water cooled<br />

drivE : Chain and sprocket<br />

ElEctronicS : Edge Performance ECU<br />

EnginE : 2005 Yamaha R6 w/ Wiseco pistons (13.4:1 CR)<br />

Fr/rr tracK : 1219mm Front, 1194mm Rear<br />

FramE : 4130 Alloy steel tube<br />

FuEl SyStEm : Fuel Injected<br />

FuEl typE : 93<br />

matErial :<br />

mpd : 12000 rpm<br />

mpt : 11500 rpm<br />

olwH : 2857.5 mm long, 1371.6 mm wide, 1212mm<br />

high<br />

SuSpEnSion : Pull Rod Front, Push Rod rear with<br />

Penske shocks<br />

tirE : 20.5x6-13 R25B Hoosier<br />

uniQuE : Hand Shifting and Clutch on wheel<br />

wEigHt : 643<br />

wHEElbaSE : 1575mm<br />

29<br />

yc racing purdue university<br />

United States United States<br />

purdue university - w lafayette<br />

The <strong>2013</strong> entry from Purdue University, West lafayette was designed with a focus<br />

on quick completion in order to start testing and driver training sooner. Therefore,<br />

many designs were kept the same, but were refined to ensure reliability. A major<br />

performance enhancement was the addition of an aero package that incorporates<br />

a front and rear wing, under tray, and sculpted bodywork. The vehicle’s electronics<br />

were also developed. A custom power distribution module was implemented which<br />

consolidated mechanical relays, terminal blocks, and other components into a solid<br />

state, reprogrammable unit. To improve drivability, modifications to the engine package<br />

were made and an electro-pneumatic clutch and shifter were added.<br />

The success of the Purdue FSAE team is not only due to the hard work and dedication<br />

of its members but also of the entire community that supports the team. A<br />

huge thank you goes out to Purdue University, our sponsors, our alumni, and the<br />

FSAE volunteers that make the events a success. A special thanks to our family<br />

and friends for their understanding, patience, and support this year.<br />

braKE : Four Wheel Disk<br />

bScd : 67 mm/ 42.5 mm/ 4 cyl/ 599 cc<br />

cooling : Water to Air<br />

drivE : Chain Drive<br />

ElEctronicS : M400 ECU, Custom PDM<br />

EnginE : Honda F4i<br />

Fr/rr tracK : 1226 mm/1218mm<br />

FramE : 4130 Space Frame<br />

FuEl SyStEm : Fuel Injection with Electronic Fuel Pressure<br />

Regulation<br />

FuEl typE : 93 Octane<br />

matErial :<br />

mpd : 11,000<br />

mpt : 7,000<br />

olwH : 3058 mm, 1423 mm, 1047 mm<br />

SuSpEnSion : SlA<br />

tirE : 20.5 x 7.0-13 R25B<br />

uniQuE :<br />

wEigHt : 268 kg<br />

wHEElbaSE : 1613 mm<br />

page 24 Information published as supplied by teams on or before April 10, <strong>2013</strong>

du Quebec-chicoutimi<br />

30universite<br />

F<strong>SaE</strong> uQac<br />

For <strong>2013</strong>, FSAE UQAC team have a goal to save as much weight as possible from<br />

the previous design. With our carbon fiber suspension design we were able to<br />

save a lot. The body is improved with a new design in carbon fiber (no structural).<br />

The wheels diameter also change, this parameter allow the entire vehicle to<br />

become significantly smaller and lighter. We also improved our drivetrain with 2<br />

axles thats increases our torque ratio from 4 to 6. Our motor is a Yamaha 80FI<br />

(500c) tune with AEM EMS-4 electronic controller.<br />

Information published as supplied by teams on or before April 10, <strong>2013</strong><br />

Canada<br />

braKE : Wilwood master<br />

bScd : 500 cc<br />

cooling : Custom design cooling package<br />

drivE : CVT<br />

ElEctronicS : AEM, EMS-4<br />

EnginE : Yamaha Genesis 80Fi<br />

Fr/rr tracK : 1193mm / 1155mm<br />

FramE : Tubular space frame<br />

FuEl SyStEm : EFI<br />

FuEl typE : Octane 93<br />

matErial : AISI 1020<br />

mpd : 65 hp at 9000 RPM<br />

mpt : 8000 RPM<br />

olwH : 2200mm<br />

SuSpEnSion : Double unequal A-Arm, Push rod actuated<br />

tirE : 10 inch wheels<br />

uniQuE : Carbon fiber suspension design<br />

wEigHt : 275 kg<br />

wHEElbaSE : 1550 mm<br />

page 25

31<br />

university of toledo<br />

rocket motorsports<br />

This year’s car, UTR-19, was built around simplicity and reliability while also<br />

taking on some new design features. Utilizing tyre consortium data as a starting<br />

point, UTR-19 features a rigid tubular chassis, CBR600 F4i, and Penske shocks<br />

backed up with extensive durability testing. Serviceability and weight reduction<br />

were also considered with every component designed. With a large amount of<br />

time dedicated to testing and refining we hope to have an all around reliable and<br />

fine tuned car for competition.<br />

braKE : Wilwood PS-1 calipers with floating rotors<br />

bScd : 67mm bore / 42.5 mm stroke / 4 cylinder /<br />

599cc<br />

cooling : left side mounted, single crossflow heat<br />

exchanger<br />

drivE : Chain<br />

ElEctronicS : Haltech Platinum Sport 1000, Race<br />

Technology Dl-1<br />