Correlation of regenerated fibres morphology and surface ... - Lenzing

Correlation of regenerated fibres morphology and surface ... - Lenzing

Correlation of regenerated fibres morphology and surface ... - Lenzing

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Lenzing</strong>er Berichte, 82 (2003) 83-95<br />

morphological characteristics, the increased<br />

degree <strong>of</strong> crystallinity, high degree <strong>of</strong><br />

polymerisation <strong>and</strong> molecular orientation <strong>and</strong><br />

the smallest void system.<br />

Fibre<br />

Sorption<br />

velocity ∗<br />

(g 2 /s)<br />

Contact<br />

angle<br />

( o )<br />

p<br />

γ s<br />

(mJ/m 2 )<br />

d<br />

γ s<br />

(mJ/m 2 )<br />

Raw viscose 0.089 80.66 25.54 8.24<br />

STDEV 1.6E-03 1.16 0.28 0.25<br />

Mer. viscose 0.175 69.26 39.95 5.46<br />

STDEV 5.0E-04 0.89 3.16 3.13<br />

Raw modal 0.052 82.38 25.01 7.99<br />

STDEV 1.0E-04 2.36 3.40 3.13<br />

Merc. modal 0.150 72.92 35.43 5.26<br />

STDEV 1E-04 1.69 3.11 2.93<br />

Raw lyocell 0.063 81.06 25.36 8.03<br />

STDEV 9.5E-05 2.87 3.34 3.11<br />

Merc. lyocell 0.157 71.52 36.69 5.41<br />

STDEV 1.0E-04 1.29 3.16 2.96<br />

Table 4. Sorption velocities, contact angles, polar <strong>and</strong><br />

disperse components <strong>of</strong> the SFE <strong>of</strong> the raw <strong>and</strong> washed<br />

slack-mercerised viscose, modal <strong>and</strong> lyocell <strong>fibres</strong>.<br />

∗ -calculated in the linear part <strong>of</strong> the slope<br />

Due to the inner <strong>surface</strong>, diameter, <strong>and</strong> volume<br />

<strong>of</strong> the mercerised lyocell fibre’s voids, they are<br />

able to adsorb more water then CMD <strong>fibres</strong>,<br />

beside the fact that they have the most<br />

crystalline structure [11]. In comparison to raw<br />

<strong>fibres</strong>, the mercerised lyocell <strong>fibres</strong> have a 5<br />

times higher sorption velocity <strong>and</strong> after water<br />

absorption their weight increases by 133 %.<br />

Comparing all three types <strong>of</strong> <strong>fibres</strong>,<br />

mercerisation caused an increase <strong>of</strong> absorption<br />

speed <strong>and</strong> amount <strong>and</strong> reduced the time needed<br />

to complete fibre wetting. The adsorption speed<br />

is almost identical; this correlates with the fact,<br />

that mercerisation reduces the differences in<br />

crystallinity index <strong>and</strong> crystalline orientation.<br />

The amount <strong>of</strong> adsorbed water correlates with<br />

the voids systems volume.<br />

Contact angles<br />

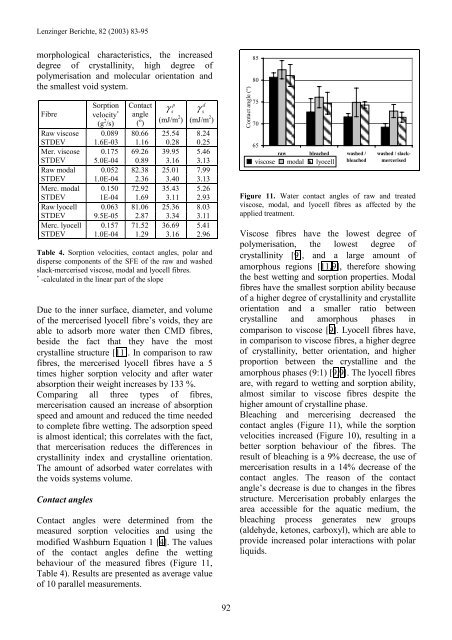

Contact angles were determined from the<br />

measured sorption velocities <strong>and</strong> using the<br />

modified Washburn Equation 1 [4]. The values<br />

<strong>of</strong> the contact angles define the wetting<br />

behaviour <strong>of</strong> the measured <strong>fibres</strong> (Figure 11,<br />

Table 4). Results are presented as average value<br />

<strong>of</strong> 10 parallel measurements.<br />

92<br />

Contact angle (°)<br />

85<br />

80<br />

75<br />

70<br />

65<br />

raw bleached washed /<br />

bleached<br />

viscose modal lyocell<br />

washed / slackmercerised<br />

Figure 11. Water contact angles <strong>of</strong> raw <strong>and</strong> treated<br />

viscose, modal, <strong>and</strong> lyocell <strong>fibres</strong> as affected by the<br />

applied treatment.<br />

Viscose <strong>fibres</strong> have the lowest degree <strong>of</strong><br />

polymerisation, the lowest degree <strong>of</strong><br />

crystallinity [9], <strong>and</strong> a large amount <strong>of</strong><br />

amorphous regions [11,9], therefore showing<br />

the best wetting <strong>and</strong> sorption properties. Modal<br />

<strong>fibres</strong> have the smallest sorption ability because<br />

<strong>of</strong> a higher degree <strong>of</strong> crystallinity <strong>and</strong> crystallite<br />

orientation <strong>and</strong> a smaller ratio between<br />

crystalline <strong>and</strong> amorphous phases in<br />

comparison to viscose [9]. Lyocell <strong>fibres</strong> have,<br />

in comparison to viscose <strong>fibres</strong>, a higher degree<br />

<strong>of</strong> crystallinity, better orientation, <strong>and</strong> higher<br />

proportion between the crystalline <strong>and</strong> the<br />

amorphous phases (9:1) [9,9]. The lyocell <strong>fibres</strong><br />

are, with regard to wetting <strong>and</strong> sorption ability,<br />

almost similar to viscose <strong>fibres</strong> despite the<br />

higher amount <strong>of</strong> crystalline phase.<br />

Bleaching <strong>and</strong> mercerising decreased the<br />

contact angles (Figure 11), while the sorption<br />

velocities increased (Figure 10), resulting in a<br />

better sorption behaviour <strong>of</strong> the <strong>fibres</strong>. The<br />

result <strong>of</strong> bleaching is a 9% decrease, the use <strong>of</strong><br />

mercerisation results in a 14% decrease <strong>of</strong> the<br />

contact angles. The reason <strong>of</strong> the contact<br />

angle’s decrease is due to changes in the <strong>fibres</strong><br />

structure. Mercerisation probably enlarges the<br />

area accessible for the aquatic medium, the<br />

bleaching process generates new groups<br />

(aldehyde, ketones, carboxyl), which are able to<br />

provide increased polar interactions with polar<br />

liquids.