LUBRIZOL 2063

LUBRIZOL 2063

LUBRIZOL 2063

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

.<br />

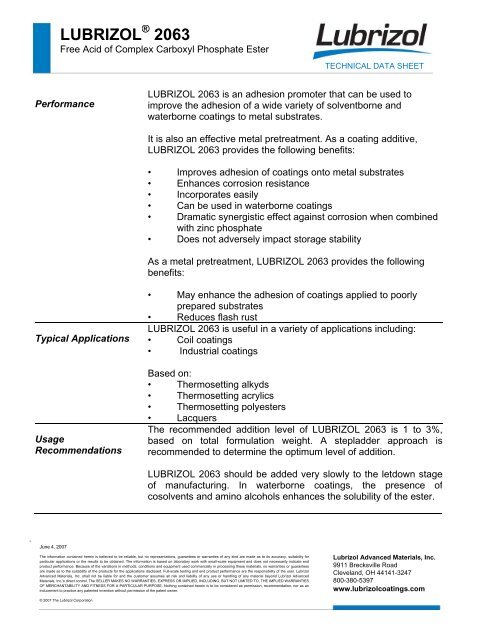

<strong>LUBRIZOL</strong> ® <strong>2063</strong><br />

Free Acid of Complex Carboxyl Phosphate Ester<br />

Performance<br />

Typical Applications<br />

Usage<br />

Recommendations<br />

June 4, 2007<br />

The information contained herein is believed to be reliable, but no representations, guarantees or warranties of any kind are made as to its accuracy, suitability for<br />

particular applications or the results to be obtained. The information is based on laboratory work with small-scale equipment and does not necessarily indicate end<br />

product performance. Because of the variations in methods, conditions and equipment used commercially in processing these materials, no warranties or guarantees<br />

are made as to the suitability of the products for the applications disclosed. Full-scale testing and end product performance are the responsibility of the user. Lubrizol<br />

Advanced Materials, Inc. shall not be liable for and the customer assumes all risk and liability of any use or handling of any material beyond Lubrizol Advanced<br />

Materials, Inc.'s direct control. The SELLER MAKES NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES<br />

OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Nothing contained herein is to be considered as permission, recommendation, nor as an<br />

inducement to practice any patented invention without permission of the patent owner.<br />

© 2007 The Lubrizol Corporation<br />

TECHNICAL DATA SHEET<br />

<strong>LUBRIZOL</strong> <strong>2063</strong> is an adhesion promoter that can be used to<br />

improve the adhesion of a wide variety of solventborne and<br />

waterborne coatings to metal substrates.<br />

It is also an effective metal pretreatment. As a coating additive,<br />

<strong>LUBRIZOL</strong> <strong>2063</strong> provides the following benefits:<br />

• Improves adhesion of coatings onto metal substrates<br />

• Enhances corrosion resistance<br />

• Incorporates easily<br />

• Can be used in waterborne coatings<br />

• Dramatic synergistic effect against corrosion when combined<br />

with zinc phosphate<br />

• Does not adversely impact storage stability<br />

As a metal pretreatment, <strong>LUBRIZOL</strong> <strong>2063</strong> provides the following<br />

benefits:<br />

• May enhance the adhesion of coatings applied to poorly<br />

prepared substrates<br />

• Reduces flash rust<br />

<strong>LUBRIZOL</strong> <strong>2063</strong> is useful in a variety of applications including:<br />

• Coil coatings<br />

• Industrial coatings<br />

Based on:<br />

• Thermosetting alkyds<br />

• Thermosetting acrylics<br />

• Thermosetting polyesters<br />

• Lacquers<br />

The recommended addition level of <strong>LUBRIZOL</strong> <strong>2063</strong> is 1 to 3%,<br />

based on total formulation weight. A stepladder approach is<br />

recommended to determine the optimum level of addition.<br />

<strong>LUBRIZOL</strong> <strong>2063</strong> should be added very slowly to the letdown stage<br />

of manufacturing. In waterborne coatings, the presence of<br />

cosolvents and amino alcohols enhances the solubility of the ester.<br />

Lubrizol Advanced Materials, Inc.<br />

9911 Brecksville Road<br />

Cleveland, OH 44141-3247<br />

800-380-5397<br />

www.lubrizolcoatings.com

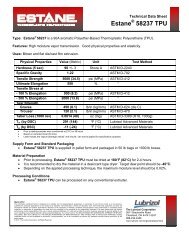

Physical<br />

Characteristics<br />

Packaging<br />

Regulatory Status<br />

<strong>LUBRIZOL</strong> ® <strong>2063</strong><br />

Page 2<br />

Appearance Clear Liquid<br />

Chemical Type Free Acid of Complex<br />

Carboxyl Phosphate Ester<br />

Density (g/cc) @ 25°C (77°F) 1.06 - 1.12<br />

Density (lb/gal) @ 15.6°C (60°F) 8.83 - 9.33<br />

NVM (% wt) 54 - 58<br />

Water (% wt) 1.5 max<br />

Flash Point °C (°F) 58 (136)<br />

Viscosity* (cP) 3700 max<br />

Acid Number** (mg KOH/g) 50<br />

Solvent Butyl Cellosolve<br />

*Measured on a Brookfield RVF Viscometer, #3 spindle, 2 rpm @25°C<br />

**Determined using Bromophenol Blue as indicator<br />

<strong>LUBRIZOL</strong> <strong>2063</strong> is available in 200 liter (55 gallon) drums and 20<br />

liter (5 gallon) pails.<br />

Store in original, unopened containers.<br />

Shelf life: 2 years. After this, the product should be tested prior to<br />

use.<br />

<strong>LUBRIZOL</strong> <strong>2063</strong> is FDA approved for use in a food contact coating<br />

applied to aluminum, as indicated by 21 CFR Section 175.260 –<br />

Partial phosphoric acid esters of polyester resins. To operate under<br />

this section, the coating must be cured at temperatures exceeding<br />

450°F (232°C). This allows <strong>LUBRIZOL</strong> <strong>2063</strong> to completely cure and<br />

properly bond to the aluminum.<br />

As indicated above, <strong>LUBRIZOL</strong> <strong>2063</strong> also finds use as an adhesion<br />

promoter in baked systems based on alkyds (including those<br />

modified with urea, melamine and vinyl functionalities), acrylics and<br />

lacquers. Baked systems containing <strong>LUBRIZOL</strong> <strong>2063</strong> are especially<br />

effective on aluminum and galvanized steel.<br />

Due to its resinous nature, <strong>LUBRIZOL</strong> <strong>2063</strong> can also be added to<br />

paint formulations replacing 3 to 10% of the base resins described<br />

above. Not only does <strong>LUBRIZOL</strong> <strong>2063</strong> not have any adverse effects<br />

on the paint’s storage stability, it also maintains its performance after<br />

long-term storage.<br />

Complete, up-to-date worldwide regulatory information is available<br />

on the Material Safety Data Sheet.