Acid Tar Remediation Projects - MUEG

Acid Tar Remediation Projects - MUEG

Acid Tar Remediation Projects - MUEG

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

REMEDIATION OF CONTAMINATED SITES<br />

(<strong>Tar</strong>, <strong>Acid</strong> <strong>Tar</strong> and Oil Sludge Lagoons)<br />

18.07.2012 1

Environmental Rehabilitation<br />

<strong>MUEG</strong> – Environmental Rehabilitation<br />

18.07.2012 2

-<br />

-<br />

-<br />

-<br />

-<br />

The remediation of contaminated sites is a special part of the <strong>MUEG</strong><br />

business and includes the following activities:<br />

<strong>Remediation</strong> of landfill sites:<br />

Municipal waste<br />

Industrial waste<br />

Refinery waste<br />

<strong>Remediation</strong> of contaminated industrial areas<br />

<strong>Remediation</strong> of contaminated military areas<br />

<strong>Remediation</strong> of<br />

Water body restoration<br />

<strong>Remediation</strong> <strong>Projects</strong><br />

contaminated refinery areas<br />

<strong>Remediation</strong> <strong>Projects</strong><br />

18.07.2012 3

Refinery Waste <strong>Remediation</strong><br />

<strong>MUEG</strong> has developed and applied treatment processes to solve and<br />

prevent problems of refinery waste (acid tar, tar and oil sludge).<br />

<strong>MUEG</strong> has tested various methods to treat refinery waste material after<br />

excavation. The common goal was and is not only the sustainable<br />

remediation of the site but the environmentally friendly handling and<br />

utilisation of the refinery waste as well.<br />

Production of substitute fuel,<br />

Treatment plant Beuna<br />

Treatment and Utilisation<br />

Period Amount (to)<br />

u.a. Oil sludge (Bayernoil Raffinerie, TOTAL) 2008 77,200<br />

u.a. Oil sludge (TESECO, Bayernoil, TOTAL) 2009 73,300<br />

u.a. Oil sludge (OMV, Baufeld-Mineralölraffinerie, TOTAL) 2010 74,200<br />

Total 224,700<br />

18.07.2012 4

Refinery Waste <strong>Remediation</strong><br />

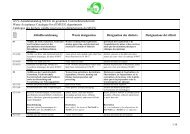

List of References – <strong>Acid</strong> <strong>Tar</strong> <strong>Remediation</strong> <strong>Projects</strong> Status: 06/2012<br />

<strong>Projects</strong> Country Period of time Treated wastes Quantities (tons)<br />

<strong>Remediation</strong> of former petrol station P301 (ADDINOL) Germany 1996 - 1997 <strong>Acid</strong> tar, Fuller's Earth 35,000<br />

<strong>Remediation</strong> project: Monticelli Pavese Italy 1997 - 1998 <strong>Acid</strong> tar 6,700<br />

<strong>Remediation</strong> of former industrial area "Landfill Site<br />

Leonhardt" (ADDINOL)<br />

Germany 1999 - 2002 <strong>Acid</strong> tar, Fuller's Earth 117,400<br />

<strong>Remediation</strong> tar Lagoon "Factory Lauta" Germany 2000 <strong>Tar</strong> resin 1,500<br />

<strong>Remediation</strong> of contaminated site "Cerro al Lambro" Italy 2002 - 2003 <strong>Acid</strong> tar 2,000<br />

Risk prevention at paraffin factory "Webau" Germany 2002 - 2003 <strong>Acid</strong> tar, <strong>Tar</strong>, Contaminated soil 28,000<br />

<strong>Remediation</strong> of Upper <strong>Acid</strong> <strong>Tar</strong> Lagoon, Mittelbach Germany 2003 <strong>Acid</strong> tar 1,300<br />

<strong>Remediation</strong> of <strong>Acid</strong> <strong>Tar</strong> Lagoon 2, Neukirchen Germany 2003 - 2005 <strong>Acid</strong> tar, <strong>Acid</strong> tar residues, Contaminated soil 78,000<br />

<strong>Remediation</strong> of former tar processing plant in Rositz Germany 2003 <strong>Tar</strong> residues 1,300<br />

<strong>Remediation</strong> of former industrial area "Landfill Site<br />

Leonhardt" (ADDINOL), west embankment<br />

Germany 2004 - 2005 <strong>Acid</strong> tar contaminated soil 20,000<br />

<strong>Remediation</strong> of Lower <strong>Acid</strong> <strong>Tar</strong> Lagoon, Mittelbach Germany 2005 - 2008 <strong>Acid</strong> tar 62,000<br />

<strong>Remediation</strong> of <strong>Acid</strong> <strong>Tar</strong> Lagoon in Pesnica Dvor Slovenia 2007 - 2008 <strong>Acid</strong> tar, <strong>Acid</strong> tar contaminated soil 31,250<br />

<strong>Remediation</strong> of <strong>Acid</strong> <strong>Tar</strong> Lagoon 3, Neukirchen Germany 2009 - 2011 <strong>Acid</strong> tar 35,000<br />

<strong>Acid</strong> <strong>Tar</strong> Lagoon, Incukalns Latvia 2010 - ongoing <strong>Acid</strong> tar 30,200<br />

Total: 449,650<br />

18.07.2012 5

Sampling / Site Investigation<br />

Main targets: sampling at different locations at different depths to obtain<br />

representative material of contaminated sites like tar, acid tar and oil sludge lagoons<br />

Two methods are possible depending on circumstances and available equipment:<br />

1. Use of a pontoon and drilling equipment<br />

2. Use<br />

Sampling and Investigation of Contaminated Sites/ Deposits<br />

of an excavator<br />

<strong>Acid</strong> tar sampling with excavator<br />

Romania, <strong>Acid</strong> <strong>Tar</strong> Lagoon (2006)<br />

Sampling with pontoon and drilling<br />

Equipment, <strong>Acid</strong> tar lagoon (2010)<br />

Sampling with excavator,<br />

<strong>Acid</strong> tar lagoon, Scandinavia (2008)<br />

18.07.2012 6

Mixing unit for material tests,<br />

“Eirich Mixer”<br />

Test for incineration<br />

Tests for incineration in power plants<br />

<strong>MUEG</strong> laboratory<br />

Test material: -<br />

Additives: -<br />

liquid, muddy (viscous) or solid<br />

acid tar<br />

possible: tar, oil sludge etc.<br />

for conditioning of the material<br />

to a secondary fuel<br />

→ conditioning in a closed mixing unit<br />

→ production of substitute fuel<br />

(under laboratory conditions)<br />

Necessary for determination of the<br />

best recipes!<br />

18.07.2012 7

Mobile treatment plant of <strong>MUEG</strong>, <strong>MUEG</strong> - acid tar project, Slovenia<br />

•<br />

•<br />

•<br />

•<br />

•<br />

<strong>Remediation</strong> Process<br />

Main facility parts (Example: acid tar remediation project)<br />

Tower crane/ Excavator<br />

Pre-treatment area (pre-treatment with additives)<br />

Treatment plant with reaction drum<br />

Exhaust gas cleaning system<br />

Storage area for additives and fuel products<br />

18.07.2012 8

Recovery with tower crane by <strong>MUEG</strong><br />

Excavation technologies<br />

Recovery with excavator by <strong>MUEG</strong> Recovery with slurry pump<br />

<strong>Remediation</strong> Process<br />

Recovery of tar, acid tar or oil sludge<br />

material depending on the consistency:<br />

- with tower crane<br />

- with excavator technology<br />

- with slurry pump<br />

The recovery technology largely determines<br />

the success of the treatment process!<br />

18.07.2012 9

Excavation/ separation of harmful substances<br />

(drums, tyres etc.), acid tar project in Germany<br />

Handling of Harmful Substances<br />

Harmful Substances<br />

Harmful substances<br />

- demolition waste (brick, metal, concrete, wood,<br />

and plaster board etc.)<br />

- household and commercial waste, like<br />

drums (plastic, metal) with hazardous waste,<br />

wood residues, glass, metals, plastic etc.<br />

- old car bodies<br />

- munitions and explosives<br />

-etc.<br />

Handling<br />

- excavation of waste material<br />

- separation of waste material<br />

- cleaning of the harmful substances<br />

- separate storage in containers<br />

- transport for recovery / disposal<br />

- environmentally friendly recycling<br />

18.07.2012 10

Thermal / Energetic<br />

Utilisation<br />

Delivery of substitute fuels to the power station<br />

Delivery control system – Bunker equipment – Feed system to coal boilers (2 x 900 MW)<br />

Since 2002 <strong>MUEG</strong> has operated a truck unloading station<br />

at Schwarze Pumpe to supply annual quantities of up to<br />

420,000 tons of its own substitute fuels, derived from acid<br />

tar and other waste, to the brown coal boilers of the<br />

power station for thermal utilisation.<br />

The substitute fuel can also be burnt in cement kilns if<br />

they have the appropriate technological conditions (such<br />

as Latvian acid tar remediation project).<br />

18.07.2012 11

Recovery<br />

(emission reduced)<br />

Also possible for:<br />

<strong>Tar</strong>, Oil Sludge<br />

<strong>Acid</strong> <strong>Tar</strong><br />

Lagoon<br />

<strong>Remediation</strong> Concept<br />

Elimination of acid tar from lagoons – Qualified concepts<br />

Treatment of substitute fuel<br />

Mobile treatment plant with gas<br />

cleaning system<br />

(neutralization / solidification)<br />

Transport by<br />

truck or railway<br />

Contaminated soil, harmful substances etc.<br />

Treatment on-site and/or disposal on landfill<br />

- separation, if necessary on-site treatment<br />

(such as thermal desorption, microbiological treatment)<br />

Energetic utilisation<br />

(power plant- or cement kiln)<br />

- comprehensive experiences<br />

- qualified and existing approvals<br />

„B.A.T.“<br />

Best Available Technology<br />

(State of the Art)<br />

18.07.2012 12

<strong>Remediation</strong> Process<br />

<strong>Remediation</strong> of oil sludge lagoons – possible options<br />

Liquid waste (pumpable):<br />

oil, water, sludge with low content<br />

of solids<br />

Oil sludge<br />

lagoon<br />

temporary<br />

storage<br />

Solid waste (not pumpable):<br />

Oily sludge/oily sediments<br />

harmful<br />

substances<br />

Harmful<br />

substances<br />

Sieving<br />

Unit<br />

liquid phase<br />

solid phases<br />

Recycling of separated waste<br />

Separator (De-/Tricanter)<br />

Thermal treatment<br />

- Thermal desorption unit (direkt TDU)<br />

- Incineration/ co-burning etc.<br />

18.07.2012 13<br />

Output<br />

material<br />

- oil<br />

- water<br />

- sediments<br />

Output<br />

material<br />

- such as<br />

cleaned<br />

material

Contaminated<br />

Soil<br />

<strong>Remediation</strong> Process<br />

Cleaning of contaminated soil – possible options<br />

The technology of the treatment plant and the utilisation as well as the<br />

disposal routes of contaminated soil essentially depend on the type and<br />

concentration of pollutants!<br />

transport<br />

temporary<br />

storage<br />

transport<br />

transport<br />

transport<br />

Hazardous waste<br />

landfill<br />

Soil treatment<br />

with thermal desorption unit<br />

Output<br />

material<br />

(cleaned<br />

soil)<br />

Output<br />

Material<br />

(cleaned<br />

soil)<br />

Microbiological<br />

treatment of soil<br />

18.07.2012 14

<strong>MUEG</strong> Headquarters<br />

Contact<br />

<strong>MUEG</strong> – Mitteldeutsche Umwelt-<br />

und Entsorgung GmbH<br />

Geiseltalstraße 1<br />

D-06242 Braunsbedra<br />

Telefon: + 49 34633 / 41 – 0<br />

Fax: + 49 34633 / 41 – 261<br />

E-Mail: info@mail.mueg.de<br />

Internet: www.mueg.de<br />

Thank you for your interest in our <strong>Remediation</strong><br />

Service!<br />

18.07.2012 15