EMP - EIA - Sentula Mining

EMP - EIA - Sentula Mining

EMP - EIA - Sentula Mining

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

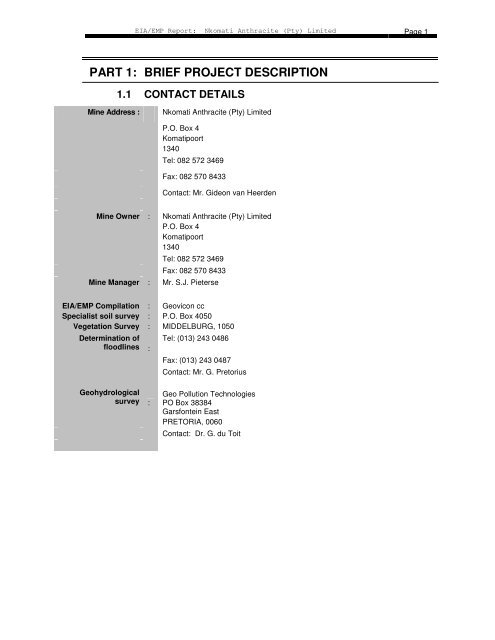

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

PART 1: BRIEF PROJECT DESCRIPTION<br />

1.1 CONTACT DETAILS<br />

Mine Address : Nkomati Anthracite (Pty) Limited<br />

P.O. Box 4<br />

Komatipoort<br />

1340<br />

Tel: 082 572 3469<br />

Fax: 082 570 8433<br />

Contact: Mr. Gideon van Heerden<br />

Mine Owner : Nkomati Anthracite (Pty) Limited<br />

P.O. Box 4<br />

Komatipoort<br />

1340<br />

Tel: 082 572 3469<br />

Fax: 082 570 8433<br />

Mine Manager : Mr. S.J. Pieterse<br />

<strong>EIA</strong>/<strong>EMP</strong> Compilation<br />

Specialist soil survey<br />

Vegetation Survey<br />

Determination of<br />

floodlines<br />

Geohydrological<br />

survey<br />

:<br />

:<br />

:<br />

:<br />

:<br />

Geovicon cc<br />

P.O. Box 4050<br />

MIDDELBURG, 1050<br />

Tel: (013) 243 0486<br />

Fax: (013) 243 0487<br />

Contact: Mr. G. Pretorius<br />

Geo Pollution Technologies<br />

PO Box 38384<br />

Garsfontein East<br />

PRETORIA, 0060<br />

Contact: Dr. G. du Toit<br />

Page 1

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

1.2 NAME AND ADDRESS OF THE MINERAL RIGHTS<br />

HOLDER<br />

Mineral Holder : Kangwane Mineral Exploration (Pty) Ltd (lessee) and Nkomati<br />

Anthracite (Pty) Ltd (sub-lessee) by virtue of mineral lease with<br />

protocol No 531.<br />

Address : P.O. Box 4<br />

Komatipoort<br />

1340<br />

Tel: 082 572 3469<br />

Fax: 082 570 8433<br />

Contact: Mr. Gideon van Heerden<br />

1.3 NAME AND ADDRESS OF THE MINING RIGHT<br />

APPLICANT<br />

<strong>Mining</strong> Authorisation<br />

Holder<br />

:<br />

Address : P.O. Box 4<br />

Komatipoort<br />

1340<br />

Nkomati Anthracite (Pty) Limited<br />

1.4 NAME AND ADDRESS OF THE LAND OWNERS<br />

Table 1 indicates the surface owners and coal right holders on and surrounding the proposed<br />

Nkomati Anthracite extension project.<br />

Table 1: Schedule of properties listing minerals rights holders and surface ownership on and<br />

surrounding the proposed Nkomati Anthracite Mine extension project area.<br />

FARM NAME AND<br />

NUMBER<br />

Grobler 479 JU<br />

Guillaume 480 JU<br />

Wildebeest 494 JU<br />

Rusplek 495 JU<br />

Sweet Home 496 JU<br />

Bonnie Vale 497 JU<br />

Excelsior 498 JU<br />

Murray 502 JU<br />

Fig Tree 503 JU<br />

Beginsel 504 JU<br />

Portion of Un-surveyed<br />

State Land<br />

SURFACE OWNER<br />

South African<br />

Development Trust<br />

(State)<br />

MINERAL TITLE<br />

HOLDER<br />

South African<br />

Development Trust<br />

(State)<br />

Page 2

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

1.5 REGIONAL SETTING<br />

Refer to Figure 1 for the regional setting of Nkomati Anthracite Mine.<br />

1.5.1 Magisterial District<br />

Kamhlushwa, Mpumalanga<br />

District Municipality: Ehlanzeni District Municipality<br />

Local Municipality: Nkomazi Local Municipality<br />

1.5.2 Direction and Distance to Nearest Towns<br />

Komatipoort - 50 km south<br />

Mozambique border - 10 km west<br />

Tonga - 6.5 km north<br />

1.5.3 Surface Infrastructure<br />

Roads:<br />

Tarred road access exists to within 3 km of the existing opencast workings. From Nelspruit<br />

Nkomati Anthracite Mine can be accessed either via Komatipoort and the Swaziland border<br />

tarred road, a distance of approximately 170 km or via Malelane and the Jeppes Reef Road<br />

through Tonga, a distance of approximately 150 km. Several minor farm roads exist on the<br />

proposed mining area.<br />

Railway lines:<br />

The Komatipoort/Swaziland rail link traverses the eastern portion of the mineral lease area,<br />

some 8 km from the existing mining operations.<br />

Towns:<br />

The towns of Mangweni, Kwa Mandulu, Masibekela and Madadeni and its related<br />

infrastructure are situated on the proposed mining area. The infrastructure includes schools,<br />

police station, clinics, churches etc.<br />

Powerlines:<br />

Powerlines servicing the above mentioned towns and the existing mining operations exist on<br />

the mining area.<br />

1.5.4 Presence of Servitudes<br />

• Eskom powerline servitude.<br />

• The R571 provincial road servitude.<br />

• Secondary gravel road servitudes.<br />

Page 3

Figure 1: Regional setting.<br />

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

Page 4

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

1.5.5 Land Tenure and Use of Immediate Adjacent Land<br />

The Matsamo Tribal Authority owns the immediately adjacent land. Land on the eastern side<br />

of the Komati River is used for extensive sugarcane farming. Land on the western side is<br />

used for low level grazing.<br />

1.5.6 Name of River Catchments<br />

Nkomati Anthracite Mine falls within the Komati River Catchment Area<br />

1.6 DESCRIPTION OF THE PROJECT<br />

1.6.1 Mineral Deposit<br />

Anthracite and anthracite coal.<br />

Inland<br />

1.6.2 Mine Products<br />

Duff 0.0 tons<br />

Peas 6,506 tons per month – Steel industries – X-strata<br />

Nuts 9, 006 tons per month – Steel industries – X-strata<br />

Export<br />

Duff 12, 008 tons per month - Glencore<br />

Peas 2,500 tons per month – Glencore<br />

Nuts 0.0<br />

1.6.3 Estimated Reserves<br />

Tons in situ<br />

Proven 6 300 000<br />

Indicated<br />

North Block 39 871 945<br />

Southern Block 10 927 840<br />

Total 57 099 785<br />

Page 5

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

1.6.4 <strong>Mining</strong> Method<br />

<strong>Mining</strong> method: Opencast: Lateral rollover technique<br />

Underground: Bord and Pillar<br />

<strong>Mining</strong> at Nkomati Anthracite Mine currently uses a “roll-over” opencast mining method typical<br />

of small-scale opencast operations in the province. The proposed mining entails both<br />

opencast and underground methods. The opencast reserves will be mined by conventional<br />

truck and shovel mining methods using the lateral rollover technique. The underground<br />

operations will utilise mechanised mining in conjunction with the bord and pillar mining<br />

method.<br />

Bord and pillar mining will be conducted by use of continuous miners.<br />

The primary mining height will be 2.5 meters. The pillar widths will be 7,5 meters and pillar<br />

centres 14 meters. This will give a FOS (primary) of 2.5 - 2.9.<br />

Bottom coaling will be conducted on retreat. Bottom coaling will extract the lower 3.5 meters.<br />

This will reduce the FOS to between 1.6 and 1.4.<br />

<strong>Mining</strong> will be conducted down dip.<br />

Support requirements.<br />

The coal seam at Nkomati Anthracite Mine has a varied roof and this becomes more<br />

complicated when the select cut and bottom coaling is added to the possible mining<br />

scenarios.<br />

The coal left in the roof should not be less than 0,5 meters.<br />

Bolting system:<br />

• 20 mm diameter bolts installed in a 25.6 mm diameter hole.<br />

• 1x 23 mm diameter x 500mm fast resin (red or purple) and 1 x 23 mm diameter x 500<br />

mm slow resin (yellow).<br />

• Bolt length of 1.5 meter.<br />

If the roof consists of 0,5 m coal overlain by 0,2 m mudstone, the bolt will be anchored in the<br />

shales higher up (0,8 m encapsulated in the shales)<br />

If the mudstone roof is exposed, the 1,5 meter bolt is more than sufficient to support the week<br />

0,2 m mud roof.<br />

If massive shales are exposed in the roof the 4 x 1.5 m bolts in a row with a row spacing of<br />

1.5 m will effectively reinforce the 1.5 m beam in the immediate roof.<br />

In terms of the suspension mechanism of support, the 4 x 1,5 m bolts in a row with a row<br />

spacing of 1.5 m.<br />

1.6.5 Planned Production Rate<br />

The planned production rate for Nkomati Anthracite Mine is in the order of 30 000 tons per<br />

month.<br />

Page 6

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

1.6.6 Planned duration of the Nkomati Anthracite Mine<br />

extension project<br />

Based on the quantity of coal within the Nkomati Anthracite Mine project area and the<br />

production rate, the life of mine is estimated to be twenty years.<br />

1.6.7 Surface infrastructure<br />

The following infrastructure is available on the existing mine:<br />

All haul roads are in place<br />

Access road is in place<br />

Electrical supply – Escom<br />

Topsoil and overburden stockpiling areas at plant area<br />

Water management facilities<br />

Telephone lines<br />

Workshop<br />

Washing plant<br />

Mine office<br />

Substation<br />

Roads, railways and powerlines<br />

All roads are gravel roads. All roads on the mining area are indicated on the surface layout<br />

plan.<br />

The existing power supply grid will be utilised for the electricity supply.<br />

No railway lines exist on the property.<br />

Solid Waste Management<br />

Industrial waste arising from the mine (classified as hazardous waste) will be collected in a<br />

different waste collection system and disposed of by a contractor in a registered hazardous<br />

waste site. Old oil and grease will be stored in 44-gallon drums and returned to suppliers for<br />

recycling.<br />

Domestic waste disposal:<br />

Chemical toilets are supplied for the current opencast and plant employees.<br />

A septic tank has been installed for the office complex. This septic tank has a 10 000 litre<br />

capacity. The septic tank has a maximum recommended daily use of 12 persons.<br />

Water Pollution Management Facilities<br />

No sewage treatment plant exists on Nkomati Anthracite Mine site.<br />

Nkomati Anthracite Mine will operate on the strategy of maximising the utilisation of “dirty<br />

water” in the mining area and on a policy of zero discharge of contaminated water. In order to<br />

achieve this, surface water drainage measures will be implemented. Water drainage is<br />

undertaken by diverting clean runoff water around the mining operations and all other<br />

Page 7

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

contaminated areas. Dirty water from contaminated areas will be collected via drains and<br />

diverted to a return water dam. This water will be utilised for dust suppression.<br />

No polluted water treatment plant exists at Nkomati Anthracite Mine.<br />

Water made in the opencast and underground mining area will be pumped to a return water<br />

dam. The return water dam has a surface area of 11 000 m 2 and an average depth of 2,0<br />

meters with a 0,5-meter freeboard. Thus the system has a maximum capacity of 23 827 m 3 .<br />

Slurry from the plant is gravitated to three slurry dams. These slurry dams are used in<br />

series. Full dams are laid dry to allow for cleaning and sale of the slurry.<br />

All water from the slurry dams is captured in a return water dam and recycled to the plant.<br />

The slurry and return water dams are not lined.<br />

The following water use activities in terms of Section 21 of the National Water Act of 1998<br />

have been identified:<br />

• 21(a): Taking water from a water resource – abstraction of borehole water.<br />

• 21(f): Discharging water containing waste through a French drain – usage septic<br />

tank.<br />

• 21(g): Disposing of waste in a manner that may detrimentally impact on a water<br />

resource – disposal of coal discard on a discard dump and disposal of mine affected<br />

water in a return water dam and slurry dams.<br />

• 21(j): Removing and disposal of water found underground to necessitate for<br />

efficient continuation of mining activities – pumping and disposing of seepage water<br />

from opencast and underground workings.<br />

Applications for the identified Water Use Licenses activities will be made and submitted to the<br />

Mpumalanga Regional offices of the Department of Water Affairs and Forestry.<br />

Potable Water Plant<br />

Water for office and general use is obtained from a borehole next to the offices. The borehole<br />

is 24 meters deep and apparently yields water with a poor taste (typical of water from Dwyka<br />

Tillite formations). Water for drinking purposes is carted to the mining area.<br />

Process water supply<br />

Process water is obtained from the old worked out mining pits. The mining pits are indicated<br />

on the surface layout plan.<br />

Mineral Processing Plant<br />

The existing coal beneficiation plant and its related structures will be used.<br />

Mineral processing is conducted in the coal washing plant.<br />

This plant consists of two stages:<br />

A crushing plant.<br />

A coal preparation plant.<br />

The crushing plant consists of a double roll crusher and a double deck-vibrating screen. No<br />

water is used in this stage of the washing plant.<br />

Page 8

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

The preparation plant is a dense medium plant consisting of a cyclone and a two-stage spiral<br />

plant. Magnetite is used to obtain the required density.<br />

Coal flow through the plant:<br />

ROM coal is brought from the opencast mining pit using articulated dump trucks.<br />

ROM coal is tipped on a tip that feeds the double roll crusher.<br />

The coal is crushed to approximately 120-mm nominal top size.<br />

The crushed coal is fed from the crusher via a conveyor belt to the double deck-vibrating<br />

screen. The vibrating screen separates the coal into the following fractions:<br />

120 x 60 mm<br />

60 x 30 mm<br />

30 x 0 mm<br />

(Note: 120 x 60 mm indicates the size fraction between 120 mm and 60 mm.)<br />

The 120 x 60 mm (large nuts) and 60 x 30 mm (medium nuts) is fed by conveyor belts to<br />

product stockpiles.<br />

The 30 x 0 mm coal is fed to the preparation plant via a vibrating feeder. A feed preparation<br />

screen separates the –3,0 mm from the +3,0 x 30 mm fractions.<br />

The –3,0 mm is fed to the two-stage spiral plant. The spiral plant separates the economical<br />

fraction (duff) from the tailings. Both the duff and the tailings are dewatered using DEMAG<br />

dewatering screens. The duff is fed to the duff stockpile via a duff conveyor belt whilst the<br />

tailings report to the discard conveyor.<br />

The +3,0 x 30 mm coal; is fed to a D.S.M cyclone. The discard material is separated from the<br />

product material by flotation in a dense medium. Magnetite is used to regulate the density.<br />

The discard material is fed to the discard conveyor, whilst the product is fed to a double decksizing<br />

screen. The double-deck sizing screen separates the coal into the following fractions:<br />

+30 mm (Small nuts)<br />

+10 x 30 mm (Peas)<br />

+3,0 x 10 mm (Duff)<br />

Each fraction is fed to its respective stockpiling area.<br />

Water consumption in the plant is at a rate of 0,8 m 3 per ton of coal washed. Approximately<br />

80% of this water is recovered from the slurry (tailings) and returned to the plant as process<br />

water.<br />

Slurry from the plant consists of approximately 40% solids. This water to solid ratio is<br />

necessary to transport the solids to the slurry dams.<br />

Areas of water use:<br />

Cyclone and spiral plants<br />

Areas of noise generation:<br />

Double roll crusher,<br />

Vibrating screens,<br />

Cyclone plant.<br />

Page 9

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

Areas of dust generation:<br />

The ROM coal is in a moist state and thus does not produce dust at the feed or crusher stage<br />

(dry stages). Limited dust is produced within the wet stages. Thus the processing plant does<br />

not produce excessive dust.<br />

The mineral processing plant layout is indicated in Figure 2.<br />

Page 10

Large<br />

nuts<br />

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

Spiral<br />

plant<br />

Tip<br />

Double<br />

roll crusher<br />

Vibrating<br />

screen<br />

Duff<br />

Fine tailings<br />

To slurry dam<br />

Meduim<br />

nuts<br />

vibrating feeder<br />

DMS<br />

Cyclone<br />

course tailings<br />

Small<br />

nuts<br />

Peas<br />

Figure 2: Schematic diagram of Mineral processing plant – Nkomati Anthracite Mine.<br />

Page 11

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

Plant residue disposal.<br />

Course tailings:<br />

Course tailings are fed to a tailing bin and loaded by articulated trucks. The tailings are<br />

stockpiled on the tailings stockpile. The rate of tailings generation is approximately 9 000<br />

tons per month (based on a 30 000 ton ROM rate). Due to the high quality of the ROM coal<br />

and the market quality demand for anthracitic coal the tailings are rewashed at a lower<br />

density and sold on the local market. Washing of the tailings gives an 85% yield suitable for<br />

the local markets. After washing the discard material is reduced to approximately 1 350 tons<br />

per month. This material will be disposed of on a discard dump. The design of the discard<br />

dump will be submitted to the Department of Minerals and Energy on completion.<br />

The position of the discard dump is indicated on the surface layout plan.<br />

Slurry:<br />

Slurry is pumped to the slurry dams at a ratio of 40% solids and 60% water. The solids are<br />

settled out of the slurry and the water captured in a return water dam.<br />

The rate of slurry production is approximately 7% of the ROM feed. This equates to<br />

approximately 2 100 tons per month (30 000 t ROM). Dried slurry is removed from the slurry<br />

dams and sold to the local brickworks. The average slurry sales per month are between 2<br />

000 – 3 000 tons per month. This gives rise to a total use of all slurry produced by the mine.<br />

Workshops and Buildings<br />

No new workshops will be constructed for the purpose of the proposed Nkomati Anthracite<br />

Mine extension project.<br />

Transport<br />

Employees use their own transport to and from the mine.<br />

Articulated trucks transport the ROM from the workings to the plant. Contractors are used to<br />

transport the product from the stockpile areas to the siding.<br />

Coal handling<br />

Washed coal is transported to the rail siding by contracted coal trucks.<br />

Water Balance Diagrams<br />

A water balance for Nkomati Anthracite Mine is indicated in Figure 3.<br />

Disturbance of Water Courses<br />

No disturbance of watercourses will result from the proposed Nkomati Anthracite Mine<br />

extension project. No mining will be undertaken within one hundred meters or within a 1:50<br />

year flood line; hence no watercourses will be undermined.<br />

Page 12

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

Storm Water<br />

Storm water measures will be necessary for the proposed extension project. Nkomati<br />

Anthracite Mine practices a policy of clean and dirty water separation where dirty water is<br />

contained and stored in the return water dam for re-use on the haul roads and material<br />

stockpiles.<br />

Page 13

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

Figure 3: Water Balance diagram.<br />

Page 14

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

PART 2: ENVIRONMENTAL IMPACT ASSESSMENT<br />

REPORT<br />

2.1 DESCRIPTION OF THE ENVIRONMENT LIKELY TO BE<br />

AFFECTED BY THE PROPOSED MINING<br />

General:<br />

2.1.1 Geology<br />

Nkomati Anthracite Mine falls within the Lebombo Coalfield.<br />

The Lebombo coalfield stretches from a point some 35 km south of Komatipoort up to the<br />

Swaziland border and consists of a fairly narrow north/south elongated development of coalbearing<br />

Vryheid Formation sediments, which have been warped by the Lebombo Monocline<br />

and are overlain by the Upper Ecca and Cave Sandstone formation sediments. The<br />

Drakensberg formation Volcanics caps the entire succession. This volcanic formation forms<br />

the prominent topographic feature that constitutes the border between Kangwane and<br />

Mozambique. Nkomati Anthracite mine is situated in the middle of this coalfield in the area<br />

commonly known as the Komatipoort sector.<br />

Lebombo coalfield – Komatipoort sector<br />

Exploration boreholes drilled in the southern portion of the Komatipoort sector indicate the<br />

following succession:<br />

The upper 34 meters consists of fine-grained sandstone – Cave Sandstone Stage.<br />

The cave sandstone Stage is underlain by a 21 Meter package of Red Beds Stage that<br />

consists of red mudstone that goes over to a bluish mudstone in the lower third of the<br />

succession.<br />

The Molteno Stage underlies the Red Beds Stage. This stage consists of a 47 meter thick<br />

succession of white medium to course grained sandstone with subordinate shale and<br />

mudstone layers.<br />

A 98-meter thick zone of the Upper Ecca Stage consisting of carbonaceous shale, sandstone<br />

and coal layers.<br />

Three relatively thick layers of carbonaceous shale occur at the top middle and bottom of the<br />

zone with the lower layers each containing a thin layer of coal and the upper containing a<br />

cluster of coal seams near the top. Seamlets of coal also occur within the sandstone layers.<br />

As seen above, numerous coal horizons are developed within the micaceous sediments of<br />

the Vryheid Formation. However, only three of these seam units appear to be laterally<br />

persistent and therefore of economic significance.<br />

Regionally the coal horizons thicken from south to north, whilst thinning from west to east. On<br />

the western margin, depositation and contemporaneous erosion occurred. The shape of the<br />

pre-Karoo floor also influences the depositation of the coal seams. This depositional<br />

influence is due to mainly gully (or trough) infilling giving rise to areas devoid of coal.<br />

The break-up of the Gondwanaland during the Jurassic period has left the greatest in print on<br />

both the structure and rank of the coal horizon in the Lebombo Coalfield. The vast outpouring<br />

of basaltic and ryolitic lavas that preceded the continental break-up gave rise to the regional<br />

anthracitization of the coal horizons.<br />

Page 15

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

North-south tensional faults occurred sub-parallel to the main rift valley due to movement of<br />

the “new” continents. These tension faults were intruded and filled with dolerite intrusions.<br />

Vertical displacements exceeding 50 meters are also associated with these dolerite<br />

intrusions.<br />

Late stage east-west trending faults occurred post-continental break-up.<br />

Regionally the strata dip eastwards at angles that vary from 5-12 o . A pronounced steepening<br />

of the dip to + 20 0 takes place further to the east as the Lebombo monocline, which formed as<br />

a response to the isostatic re-adjustment in the newly formed continental margin.<br />

These structural features from the natural demarcation of the reserve blocks within the<br />

Nkomati Mineral lease area.<br />

Local geology:<br />

The Komati Anthracite Mine mineral lease area is situated in the north-eastern portion of the<br />

former KaNgwane National State (Now Mpumalanga) within the central portion of the<br />

Komatipoort sector of the Lebombo coalfield. The reserve is situated approximately 50 km<br />

from Komatipoort and 10km west of the Mozambique border.<br />

155 boreholes were sited and drilled on the mining lease area to determine the potential coal<br />

reserves on the mining lease area. Representative borehole logs of the geological boreholes<br />

are indicated in Figure 4, whilst north-south and east-west cross-sections are indicated in<br />

Figure 5.<br />

Review of the borehole cores indicates that the upper 4-5 meters consists of a thick reddish<br />

alluvium. The thickness of the soil layer varies from hole to hole and is mostly controlled by<br />

the presence of up thrown or downthrown blocks and the proximity to the Komati River.<br />

The upper coal horizon (C3) occurs with in a coarse sandstone package that has an average<br />

thickness of 20 meters.<br />

A medium to fine grained sandstone layer with an average of 11 meters separates the upper<br />

and middle seam horizons. The middle seal horizon (C2) consists of two coal seams with an<br />

average seam width of 1,5 and 2,0 meters respectively. These seams are separated by a<br />

sandstone parting with a average width of 1,0 meters.<br />

A medium grained sandstone layer with an average width of 8,0 meters separates the middle<br />

and lower horizons. The lower coal horizon (C1) consists of an upper coal marker seam<br />

(average thickness 0,5 meters) and a 6,5 meter (average basal seam. The marker seam is<br />

separated from the basal seam by a 2,7 meter thick layer of carbonaceous sandy shale.<br />

The basal seam of the lower coal horizon rests conformably on a course to medium grained<br />

sandstone layer with and average thickness of 20 meters. Occasional coal stringers occur<br />

within this sandstone layer.<br />

A second carbonaceous layer occurs below the sandstone layer, which is again underlain by<br />

a course grained sandstone layer. These layers have average widths of 4,5 meters.<br />

The Ecca formation lies unconformaly on a dwyka tillite layer. This has an average of 2<br />

meters.<br />

The dwyka tillite layer rests unconformaly on a paleio-erosional granite floor.<br />

Page 16

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

Figure 4: Representative borehole log.<br />

Page 17

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

Figure 5: Geological cross-section.<br />

Page 18

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

Coal seams (see profile):<br />

The three major coal horizons intersected during drilling are:<br />

1. The C1 (lower), which varies in width from less than one metre up to a maximum of<br />

8,25 metres. This unit is distinctly zoned into three roughly equal leaves, namely CIAI,<br />

CIBI and CICI, the basal unit (CIAI) of which contains the highest quality coal with the<br />

best washability characteristics.<br />

2. The C2 (middle) can be sub-divided into a lower unit (C2B) and an upper unit (C2A)<br />

separated by up to three metres of sandstone and shale. The C2A seam exhibits the<br />

better quality characteristics. Both units vary from a stringer, centimetres in width, up<br />

to a maximum of 2,50 metres.<br />

3. C3 (upper) where fully developed also consists of an upper unit (C3A) and a lower<br />

unit (C3B), The lower unit is more persistently developed reaching a maximum<br />

thickness of 2 metres. This lower unit also exhibits the better washability<br />

characteristics when compared to the upper.<br />

Presence of dykes, sills and faults:<br />

All known dolerite structures and faults that occur on the mining area are indicated on Figure<br />

6. A score of north-south trending en-echelon dolerite dykes transept the mining area. These<br />

dolerite dykes represent lava infilling of a sub-parallel fault system. The dykes are not regular<br />

tabular bodies; down dip as well as along strike these dykes pinch and swell at random.<br />

The depth of weathering in the dolerite dykes is extensive. Where mining has occurred at<br />

depths in excess of 40 meters the dolerite still appears as khaki coloured stack of cubic<br />

blocks. Near vertical shearing is also present in the dolerite.<br />

The shearing and the dolerite occupied fault zones appear to have a high degree of porosity<br />

and thus a high permeability.<br />

North-south trending fault zone occur throughout the mining area, which is represented by a<br />

score of dolerite dykes. These dykes, as mentioned earlier represent doleritic lava infilling.<br />

Due to the weathering of the dykes, these faults have a high permeability.<br />

A second set of faults also occurs on the mining area. These faults have a general east-west<br />

strike. The east-west trending faults are not dolerite filled.<br />

2.1.2 Climate<br />

2.1.2.1 Regional Climate<br />

Nkomati Anthracite Mine falls within the summer rainfall region of South Africa, in which more<br />

than 80% of the annual rainfall occurs from October to March. 85% of the rainfall falls during<br />

summer thunderstorms. Such thunderstorms generally occur every 3-4 days in the summer.<br />

They occur as conventional thunderstorms and are usually accompanied by lightning, strong<br />

winds and sometimes hail. The thunderstorms are usually scattered and of short duration<br />

and intensity. The rainfall events are highly localised and can vary markedly over short<br />

distances. The gross annual “A” pan evaporation for the region, measured at Barberton, is 1<br />

635 mm. During the months of from September to March the mean evaporation is 157 mm<br />

per month. This equated to 67% of the total mean annual evaporation. Evaporation is the<br />

lowest between the months of May to July when an average mean monthly evaporation of 90<br />

mm occurs.<br />

Page 19

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

Figure 6: Presence of dykes and faults on Nkomati Anthracite mining area.<br />

Page 20

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

Temperatures in this climate zone are generally moderate to high, although low minima can<br />

be experienced during the winter months due to clear night skies. Temperatures can vary<br />

between 39°C (maximum) to 4°C (minimum) in summer and 36°C (maximum) to -2°C<br />

(minimum) in winter.<br />

Fog can occur throughout the year although the highest tendency occurs during November to<br />

December.<br />

The annual prevailing wind direction, during the day, summer and winter months, is northeasterly.<br />

Climatic data were obtained from the South African Weather Bureau recording stations in the<br />

vicinity of the site.<br />

2.1.2.2 Mean Annual Rainfall<br />

Average monthly rainfall and the number of days experiencing rainfall are presented in Table<br />

2. The average rainfall per year is 768 mm, with the wetter months occurring from November<br />

to February.<br />

Table 2: Average rainfall records for Nkomati Anthracite Mine recorded at Barberton weather<br />

station.<br />

MONTH MM NO. OF DAYS > 10 MM<br />

January 104 3.4<br />

February 105 3.5<br />

March 77 2.3<br />

April 64 2.2<br />

May 22 0.6<br />

June 9 0.3<br />

July 8 0.1<br />

August 15 0.4<br />

September 31 0.8<br />

October 77 2.6<br />

November 122 4.1<br />

December 134 4.1<br />

Total 768 24.4<br />

From the table above it can be seen that 60.5% of the MAP occur during November to<br />

February. The maximum monthly rainfall recorded also occurs within this period. The mean<br />

annual rainfall is approximately 65% of the maximum monthly precipitation recorded for the<br />

twelve months of the year.<br />

On average 24.4 days of the year receive more than 10 mm of precipitation.<br />

2.1.2.3 Maximum Rainfall Intensities<br />

Maximum rainfall intensities have been calculated for selected intervals on a monthly basis<br />

and are presented in Table 3<br />

Page 21

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

Table 3: Maximum recorded precipitation for selected intervals.<br />

MONTH 15 MIN 30 MIN 45 MIN 60 MIN 24 HOURS<br />

January 37.0 53.0 55.0 59.0 88.4<br />

February 30.5 40.0 48.0 52.0 62.9<br />

March 33 52.0 57.3 57.3 75.6<br />

April 30.0 54.0 61.0 65.1 72.7<br />

May 12.0 19.7 21.2 21.5 36.6<br />

June 16.0 20.5 23.0 25.5 45.8<br />

July 6.0 7.6 7.7 7.9 21.4<br />

August 13.0 15.2 15.4 15.5 19.3<br />

September 13.3 14.6 14.9 15.6 41.6<br />

October 19.0 28.5 29.5 29.5 50.6<br />

November 24.0 41.0 42.2 43.0 65.6<br />

December 22.2 27.5 37.0 44.5 65.1<br />

The highest maximum rainfall intensities were recorded during January of the 15 min, 30 min<br />

and 24-hour periods, whilst the highest intensities for the 45 and 60-minute periods were<br />

recorded during April.<br />

The expected maximum rainfall intensities for selected duration and return periods are<br />

indicated in Table 4.<br />

Table 4: Maximum rainfall intensities for Nkomati Anthracite Mine calculated over 22 years.<br />

1:50 YEARS 1:100 YEARS<br />

MONTH 60 MIN 24 HRS 60 MIN 24HRS<br />

January 65 110.4 69.8 125.1<br />

February 56.5 89.2 63.5 99.6<br />

March 51.0 122.0 57.7 139.9<br />

April 31.2 66.5 35.5 75.8<br />

May 22.6 45.4 25.8 52.0<br />

June 17.7 51.5 20.5 60.1<br />

July 12.0 18.3 13.8 21.0<br />

August 18.1 28.5 21.1 32.9<br />

September 26.1 40.0 30.1 46.1<br />

October 38.3 61.1 43.4 67.7<br />

November 62.8 88.6 70.8 99.1<br />

December 49.1 80.3 54.4 89.3<br />

The maximum expected precipitation from a 1:50 year 60 minute storm event is 65 mm and is<br />

likely to occur during January.<br />

The maximum expected precipitation from a 1:50 year 24-hour storm event is 122 mm and is<br />

likely to occur during March.<br />

The maximum expected precipitation from a 1:100 year 60 minute storm event is 69.8 mm<br />

and is likely to occur during January.<br />

The maximum expected precipitation from a 1:100 year 24-hour storm event is 139.9 mm and<br />

is likely to occur during March.<br />

2.1.2.4 Mean Monthly Maximum and Minimum Temperatures<br />

The area has a temperature climate with warm summers and moderate to cold winters.<br />

Page 22

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

Table 5: The mean maximum and minimum temperatures.<br />

MONTH DAILY MAX. °C DAILY MIN. °C HIGHEST. °C LOWEST. °C<br />

January 28.9 18.3 38.6 11.4<br />

February 28.8 18.1 37.7 10.2<br />

March 28.1 16.7 37.0 7.0<br />

April 26.5 14.1 36.6 4.3<br />

May 24.9 9.5 33.8 1.1<br />

June 22.5 5.9 30.5 -1.5<br />

July 23.1 6.0 30.6 -0.6<br />

August 24.9 8.2 34.3 -2.7<br />

September 26.9 11.5 38.4 2.8<br />

October 27.3 14.6 39.2 4.3<br />

November 27.1 16.3 38.0 6.6<br />

December 28.4 17.7 38.0 8.8<br />

2.1.2.5 Wind Direction and Speed<br />

The nearest wind recording station for which data is available is situated at Nelspruit.<br />

Records have been kept for the period 1959 to 1988 regarding direction, frequency and<br />

velocity for each of the eight main directions. This is indicated in Table 6.<br />

Table 6: Average wind speed and direction.<br />

MONTH<br />

Page 23<br />

N NE E SE S SW W NW<br />

N V N V N V N V N V N V N V N V<br />

Jan 17 2.6 160 3.6 66 3.7 84 4.3 5 3.7 26 3.8 23 3.0 38 3.6<br />

Feb 16 2.4 142 3.4 76 3.6 92 4.1 7 2.9 34 3.5 27 2.7 33 3.1<br />

Mar 18 2.7 123 3.4 60 3.5 93 3.9 4 3.2 27 3.6 30 2.7 42 3.0<br />

Apr 15 2.4 112 3.3 45 3.0 69 3.9 4 2.9 31 3.7 39 2.8 51 3.3<br />

May 17 2.7 96 3.3 45 3.4 68 4.0 3 2.8 37 3.8 63 3.2 93 3.4<br />

Jun 16 2.7 86 3.2 43 3.0 60 3.8 6 3.4 60 4.2 51 3.2 102 3.2<br />

Jul 17 3.0 102 3.5 45 3.1 70 4.2 5 3.2 49 3.6 47 3.0 81 3.3<br />

Aug 18 3.3 146 3.7 75 3.9 70 4.3 5 4.0 39 4.0 47 3.1 78 3.3<br />

Sept 25 3.3 226 3.9 79 3.8 70 4.5 3 4.6 37 3.8 37 2.9 50 3.2<br />

Oct 25 3.6 207 4.0 76 4.1 84 4.5 6 3.7 22 3.4 19 3.6 28 3.2<br />

Nov 18 2.9 191 3.7 78 3.9 89 4.0 9 3.5 29 3.9 17 3.5 25 3.5<br />

Dec 16 2.7 172 3.6 81 3.7 86 4.3 10 3.0 29 3.8 20 2.9 28 3.5<br />

Avg 18 2.9 147 3.6 64 3.6 78 4.1 6 3.4 35 3.8 35 3.1 54 3.3<br />

Wind directions are predominantely southeasterly during the summer months and<br />

northwesterly during the winter months. The greatest mean wind velocity occurs during the<br />

period August to October.<br />

2.1.2.6 Mean Monthly Evaporation<br />

The gross annual “A” pan evaporation recorded at Piet Retief is 1 635 mm. It is evident that<br />

there is a monthly moisture deficit throughout the year; this results in an average annual<br />

deficit of 870 mm. Furthermore it is also observed that the maximum potential water loss<br />

occurs during August, September and October.

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

Table 7: Mean monthly evaporation for the region.<br />

MONTH EVAPORATION (MM) RAINFALL (MM) DEFICIENCY<br />

January 182 104 78<br />

February 156 105 51<br />

March 151 77 74<br />

April 117 64 53<br />

May 97 22 75<br />

June 82 9 73<br />

July 92 8 84<br />

August 119 15 104<br />

September 150 31 121<br />

October 162 77 85<br />

November 169 122 47<br />

December 181 134 47<br />

TOTAL 1 635 768<br />

During the seven summer months from September to March the mean monthly evaporation<br />

totals 1 100 mm, representing 67% of the mean annual evaporation.<br />

2.1.2.7 Extreme weather conditions<br />

Hail: Occurs 4 to 7 times per year<br />

Drought: ± every 6 years<br />

Frost: Can occur from end of April to September<br />

Wind: Winds with a velocity > 8m/s occur on average for 18 days per year.<br />

2.1.3 Topography<br />

The local topography can be seen in Figure 7.<br />

The Nkomati Anthracite Mine falls on the 2531 DB (Tonga) and 2531 DD (Fig Tree) topocadastral<br />

sheets.<br />

The Lebombo Mountain range to the east and the Mananga Mountains to the south dominate<br />

the regional topography within the vicinity of the mine.<br />

The mine falls within the area occupied by the plains of the Lebombo mountains range. This<br />

area consists of a gently undulating surface with a general westerly to north-westerly slope.<br />

The Komati River meanders through the area, and forms an important topgraphical feature.<br />

Topographical highs occur to the south east of the mining area. These topographical highs<br />

form part of the Lebombo Mountain range, with KU-Hluhlu peak obtaining an elevation of<br />

1810 mamsl. The surface elevation over the proposed mining areas ranges from 240 to 250<br />

mamsl. The apparent dip is towards the northeast.<br />

Page 24

Figure 7: Local topography.<br />

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

Page 25

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

2.1.4 Soil<br />

2.1.4.1 Introduction<br />

The complete soil report is attached as Appendix 1.<br />

The assessment of the present (pre-mining) soil environment is an integral part of the<br />

compilation of an Environmental Management Programme Report (<strong>EMP</strong>R) for the<br />

development of mining activities.<br />

In order to comply with legislation and <strong>EMP</strong>R requirements, Geovicon cc soils division was<br />

commissioned by Nkomati Anthracite Mine to conduct a soil survey over the new reserve<br />

area. The farms surveyed are: Wildebeest 494 JU, Rusplek 495 JU, Sweet Home 496 JU<br />

and Bonnie Vale 497 JU.<br />

2.1.4.2 Survey area<br />

Nkomati Anthracite Mine is an existing operational mine, situated about 50 kilometres south of<br />

Komatipoort within the Mpumalanga province.<br />

The topography of the area is characterised by the Lebombo Mountain range to the east and<br />

the Mananga Mountains to the south. The mine falls within the area occupied by the plains of<br />

the Lebombo Mountain range. This area consists of a gently undulating surface with a<br />

general westerly to northwesterly slope. The Komati River meanders through the area and<br />

forms an important topographical feature. Topographical highs occur to the south east of the<br />

mining area. These topographical highs form part of the Lebombo Mountain range, with Ku-<br />

Hluhlu peak obtaining an elevation of 1810 mamsl.<br />

The surface elevation over the proposed mining areas ranges from 240 to 250 mamsl. The<br />

apparent dip is towards the northeast.<br />

The pre-mining land capability over the proposed mining area is arable land (sugar cane) to<br />

east of the Komati River and grazing or wilderness land on the western side.<br />

The current land use over the areas under consideration is arable land and grazing land.<br />

2.1.4.3 Procedure<br />

A desktop study and terrain analysis was conducted on available 1:50 000 topocadastral<br />

maps and mining layout plans to preliminarily delineate soil units. This terrain analysis was<br />

followed up by field observations and auger test holes. A 120mm diameter bucket auger was<br />

used during the drilling of the test holes.<br />

All test holes were drilled to a maximum depth of 2.0 meters. Where hard rock was<br />

encountered, the test hole depth was drilled to refusal. 27 auger test holes were drilled over<br />

the property based on the terrain analysis study.<br />

Vertical profiles of the test holes were described and samples of the different horizons<br />

selected for chemical analysis.<br />

The identification and classification of soil forms was carried out in terms of the A Taxonomic<br />

System for South Africa (Soil classification work group, 1991). Agri Enviro Lab in Bethal did<br />

the chemical analyses of the soil samples.<br />

Page 26

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

2.1.4.4 Results:<br />

Soils<br />

A total of 27 augured holes were drilled in the survey area. Soils identified during the survey<br />

are summarised in Table 8 and the distribution thereof illustrated in Figure 8.<br />

Table 8: Soil forms identified in the Nkomati Anthracite Mine study area.<br />

SOIL FORM A-HORIZON B1-HORIZON B2-HORIZON<br />

Shortlands Orthic Red Structured B<br />

Bainsvlei Orthic Red apedal B Soft plinthic B<br />

Rensburg Vertic G-Horizon<br />

Dundee Orthic Stratified Alluvium<br />

Katspruit Orthic G-Horizon<br />

Hutton Orthic Red apedal Unspecified.<br />

Soils of the Shortlands soil form consist of reddish brown, apedal topsoil with a depth of 30<br />

cm and a reddish dark brown structured sub surface soil with a depth of 50 cm.<br />

Soils of the Bainsvlei soil form consist of light greyish brown, apedal topsoil with a vertical<br />

depth of 30 cm on top of a reddish brown apedal sub surface layer with a depth of 40 cm.<br />

The underlying layer is soft plinthite with iron and manganese concretions.<br />

The Rensburg soil form consists of a strongly structured topsoil layer with high clay content<br />

with a capacity to swell and shrink markedly in response to moisture changes. The depth of<br />

the A-horizon is approximately 50 cm. This overlies a dark greyish-brown non-calcareous<br />

sandy-loam G Horizon with a depth of 60 cm.<br />

The Dundee soil form is unconsolidated and contains stratification’s caused by alluvial or<br />

colluvial deposition. Unlike soil horizons that have developed by pedogenetic processes,<br />

stratified alluvium owes its distinguishing features to a depositional process and is thus not a<br />

sequence of so-called genetic horizons.<br />

Soils of the Katspruit soil form consist of a very dark-greyish unstructured sandy-loam Orthic<br />

A Horizon with a vertical thickness of 25 cm. The Orthic A Horizon overlies a dark greyishbrown<br />

non-calcareous sandy-loam G Horizon. The G horizon has a vertical thickness of 30<br />

cm.<br />

Soils of the Hutton form consist of a non-structural dark reddish-brown fine sandy-loam Orthic<br />

A-horizon. This horizon has an average vertical thickness of 15 cm. The Orthic A-horizon<br />

overlies a Red Apedal B horizon. This horizon is a dark red eutrophic (highly leached), luvic,<br />

slightly structured (in wet state) sandy-clay loam horizon with a minimum vertical thickness of<br />

100 cm.<br />

Page 27

Figure 8: Soil types.<br />

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

Page 28

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

Chemical analyses<br />

Soils from representative holes were sampled and sent to the laboratory for analyses. The<br />

results of analyses of soil samples taken are summarised in Table 9.<br />

Table 9: Chemical properties of the different soil forms on the study area.<br />

Soil form Horizon<br />

PH P K CA MG NA<br />

KCI ppm ppm ppm ppm ppm<br />

Rensburg Vertic A 7.2 7 220 4936 2135 555<br />

G-Horizon 7.3 3 236 4670 2080 614<br />

Bainsvlei Orthic A 6.0 38 521 1314 542 15<br />

Red Apedal B 5.1 3 199 686 624 15<br />

Dundee Orthic A 5.6 24 259 1136 541 21<br />

Stratified alluvium 5.8 4 37 1522 457 10<br />

Soil Potential<br />

The soil potential of the different soil forms within the study area is presented in Table 10.<br />

Table 10: Soil potential of the soil forms occurring on the study area.<br />

SOIL FORM SOIL POTENTIAL<br />

CROP PRODUCTION<br />

DRYLAND IRRIGATION<br />

GRAZING<br />

Shortlands Moderate Moderate Moderate<br />

Bainsvlei Moderate-High Moderate Moderate<br />

Rensburg Low None to Very Low Moderate<br />

Dundee Low Moderate Moderate<br />

Katspruit None None Moderate<br />

Hutton High High High<br />

Of all the soil forms that occur on the study area only the Hutton, Bainsvlei and Shortlands<br />

soil forms are suitable for dryland and irrigated crop production.<br />

All soils encountered in the survey area have a moderate to high grazing potential. The soils<br />

are however sensitive to overgrazing.<br />

Page 29

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

Soil Erodibility<br />

The erodibility of the soils occurring in the study area is presented in Table 11.<br />

Table 11: Erodibility of the soils occurring in the study area.<br />

SOIL FORM EROSION SUSCEPTIBILITY INDEX<br />

WATER EROSION WIND EROSION<br />

Shortlands Moderate Moderate<br />

Bainsvlei Moderate - Low Moderate - Low<br />

Rensburg Moderate Low<br />

Dundee Moderate - Low Moderate - Low<br />

Katspruit Moderate Low<br />

Hutton Very low Moderate to High<br />

2.1.5 Pre-mining land capability<br />

Crops generally grown in the area are sugarcane and citrus fruits. These crops grow well<br />

within the area due to the absence of frost and the relatively warm winters. The limiting factor<br />

is water supply. Farms situated along the banks of the Komati River have surface extraction<br />

quotas and rights from the river. The land has an arable land capability. The land capability<br />

of the area is indicated in Figure 9.<br />

2.1.6 Land use<br />

Pre-mining land use is arable land (sugarcane), housing and town infrastructure and grazing.<br />

The areas occupied by riverbanks have a pre-mining wilderness land use.<br />

Land use on a part of the property can be characterised as mining due to previous and<br />

present mining practises.<br />

Page 30

Figure 9: Land capability.<br />

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

Page 31

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

2.1.7 Natural vegetation/plant life<br />

According to the “Vegetation of South Africa, Lesotho and Swaziland” (1998) Nkomati<br />

Anthracite Mine is situated in the Savannah Biome of South Africa. The savannah biome is<br />

the largest biome in South Africa occupying 46% of its area. Characteristically it exists of a<br />

grassy ground layer and a distinct upper layer of woody plants. Where the upper layer exists<br />

near the ground the vegetation is referred to as shrubveld. The intermediate stages as well<br />

as where it is as dense as woodland, are known as Bushveld.<br />

The environmental factors demarcating the biome are complex. Altitude ranges from sea<br />

level to 2 000 meters above sea level. Rainfall varies from 235 to 1 000 mm per year and<br />

frost may occur from 0 to 120 days per year. Almost every major soil type occurs within the<br />

biome and geological types also vary a lot. A major factor delimiting the biome is the lack of<br />

sufficient rainfall that prevents the upper layer from dominating. Fires and grazing coupled<br />

with the low rainfall keep the grass layer dominant. Summer rainfall is essential for the grass<br />

dominance, which, with its fine material, fuels annual fires. Almost all species are adapted to<br />

survive fires. Approximately 10 % of plants, both in the grass and tree layer, are killed by fire.<br />

Even with severe burning most species can resprout from the stem bases.<br />

The height of the shrub-tree layer varies from 1 t0 20 meters, except for the Bushveld where it<br />

varies from 3 t0 7 meters. The shrub-tree element may dominate in overgrazed areas.<br />

Savannah vegetation types are mainly used for grazing purposes. In some types crops and<br />

sub-tropical fruit are cultivated.<br />

Regional vegetation<br />

According to the “Vegetation of South Africa, Lesotho and Swaziland” (1998) Nkomati<br />

Anthracite Mine is situated in the Mixed Lowveld Bushveld veld type of the Savannah Biome<br />

of South Africa. This vegetation type can be described as variously dense bush on the<br />

uplands, open tree savannah in the bottomlands and dense riverine woodland on riverbanks.<br />

General species in the area are listed below in Table 12.<br />

Table 12: Vegetation distribution within the Nkomati Anthracite Mine extension area.<br />

COMMON NAME: LATIN NAME:<br />

TREE LAYER - UPLANDS<br />

Red bushwillow Combretum apiculatum<br />

Largefruit bushwillow Combretum Zeyheri<br />

Silver clusterleaf Terminalia sericea<br />

Black monkey orab\nge Strychnos madagascariensis<br />

Maroela Sclerocarya birrea<br />

False maroela Lannea stuhlmannii<br />

Weeping wattle Peltophoram africanum<br />

Tree layer – bottomlands<br />

Knobthorn Acacia nigrescens<br />

Scented thorn Acacia nilotica<br />

Common falsethorn Albizia harveyi<br />

Magic guarri Euclea divinorum<br />

SHRUB LAYER<br />

Page 32

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

Hairy corkwood Commiphora africana<br />

Wild grape Cissus cornifolia<br />

Sickle bush Dichrostachys cinerea<br />

Flaky thorn Acacia exuvialis<br />

Zebrawood Dalbergia melanxylon<br />

Round leaf teak Pterocarpus rotundifolia<br />

GRASS LAYER<br />

Herringbone grass Pogonarthria sqarrosa<br />

Blueseed grass Tricholaena monachane<br />

Culyleaf lovegrass Eragrostis rigidior<br />

Natal red top Melinus repens<br />

Black-footed signal grass Brachiaria nigropedata<br />

Guinea grass Panicum maximum<br />

Finger grass Digitara eriantha<br />

Spear grass Heteropogon contottus<br />

OTHER GRASSES<br />

Kalahari sand quick Schmidtia pappophoroides<br />

Spreading bristle grass Aristida congesta<br />

Bushvels signalgrass Urochloa mosambicensis<br />

Nine-awned grass Enneapogon cenchroides<br />

This type of bushveld is confined to a frost-free area, with frequent fires and general grazing<br />

by cattle and game. The economic uses of this veld type are cattle and game farming,<br />

ecotourism and the cultivation of subtropical fruit, vegetables and sugarcane.<br />

2.1.8 Animal life<br />

Commonly Occurring Species<br />

Man has literally decimated the mammalian population. Of the antelope, only steenbok and<br />

duiker remain within the broader area and might visit the cultivated areas sporadically.<br />

The bird population in the area has a narrow range comprising mainly of terrestrial birds and<br />

waterfowl. Bird habitats occur along the fringes of the Komati River and properties to the<br />

west of the river. No major habitats for birds occur on the eastern side of the Komati River<br />

within the vicinity of the mining area although it is possible that some bird species inhabit the<br />

un-rehabilitated areas. During a site visit the following birds were identified in the vicinity of<br />

the mining area (Table 13).<br />

Page 33

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

Table 13: Birds identified in the area of Nkomati Anthracite Mine.<br />

SCIENTIFIC NAME COMMON NAME<br />

TERRESTRIAL/WATER<br />

HABITAT<br />

Streptopelia snegalenis Laughing dove Terrestrial habitat<br />

Oena capensis Namaqua dove Terrestrial habitat<br />

Streptopelia capensis Cape turtle dove Terrestrial habitat<br />

Columba guinea Rock pigeon Terrestrial habitat<br />

Numida meleagris Helmeted guineafowl Terrestrial habitat<br />

Vanellus armatus Blacksmith plover Water habitat<br />

Passer domesticus House sparrow Terrestrial habitat<br />

Bostychia hagedash Hadeda ibis Terrestrial habitat<br />

Francolinus swainsonii Swainson’s Francolin Terrestrial habitat<br />

Estrilda astrild Common waxbill Water/terrestrial habitat<br />

Ploceus velatus Masked weaver Water/terrestrial habitat<br />

Elanus caeruleus Blackshouldered kite Terrestrial habitat<br />

Ardea cinerea Grey heron Water habitat<br />

The list is sparse since no attempt was made to identify the “little brown bird” component –<br />

larks, pipits, warblers and cisticolas nor the swallow and swifts.<br />

Endangered or rare species<br />

None of the birds are endangered nor are their habitats within the area to be disturbed.<br />

According to the department of Environmental Affairs and Tourism no endangered species<br />

occur within the area.<br />

2.1.9 Surface water<br />

2.1.9.1 Surface Water Quantity<br />

Nkomati Anthracite Mine falls within the Komati River catchment. This catchment area covers<br />

11 209 km 2 extending from the Transvaal Plateau west of Carolina to the Lebombo Mountain<br />

range at Komatipoort in the east. The total average mean annual runoff of the Komati River is<br />

1420 million m 3 . The Komati River catchment is divided into three sub-catchments (excludes<br />

Mozambique). These sub-catchments are namely the upstream, Swaziland and the<br />

downstream catchment. The Nkomati Anthracite Mine falls within the downstream catchment<br />

of the Komati River. This catchment area extends from the Swaziland border to 4 km inside<br />

Mozambique in the east. This catchment consists of 15% (1 672 km 2 ) of the total Komati<br />

River catchment area. Table 14 indicates the MAR of the respective sub-catchments of the<br />

Komati River catchments. Figure 10 shows the respective sub-catchments of the Komati<br />

River.<br />

Page 34

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

Table 14: MAR of Komati River Sub-catchments.<br />

PROPERTY UNIT<br />

KOMATI<br />

U/S Swazi<br />

SUB-CATCHMENT<br />

LOMATI<br />

D/S U/S Swazi D/S<br />

TOTAL<br />

Catchment Area km 2 6049 1995 1672 228 566 699 11209<br />

% of area<br />

MAR:<br />

% 54 18 15 2 5 6 100<br />

Natural X 10 6 m 3 703 360 44 77 149 87 1420<br />

Afforested X 10 6 m 3 640 336 44 64 127 66 1277<br />

% Contribution % 50 26 4 5 10 5 100<br />

Livestock, game and crop production are the most important farming practices within the<br />

lower Komati sub-catchment. No afforestation occurs within this sub-catchment. Developed<br />

irrigation by far exceeds the water use of any other water users within the sub-catchment.<br />

Catchment boundaries.<br />

The general drainage pattern of the area in which the mine is situated flows towards the<br />

north. The Komati River forms the main drainage channel. Four tributaries drain across the<br />

mineral rights area towards the Komati River; namely:<br />

Nhlenga River<br />

Mgobode River<br />

Mdzabi River<br />

Mbiteni River<br />

The Mdzabi River and the Mditeni River converge shortly before flowing into the mining area.<br />

The boundaries of these catchments are indicated on Figure 11 and tabulated in Table 15.<br />

Table 15. Catchments that occur on the mineral lease area of Nkomati Anthracite Mine.<br />

CATCHMENT AREA (KM 2 ) MAR (M 3 .A -1 ) X1000<br />

Nhlenga River (A) 113 5 198<br />

Mgobode River (B) 75 3 450<br />

Mdzabi River ( C) 71 3 266<br />

Mditeni River (D) 67 3 082<br />

Mambane River (E) 21 966<br />

Subcatchment of Komati River (F) 86 3 956<br />

Mean annual runoff.<br />

The mean annual runoff for each of the catchments is indicated in Table 15.<br />

The size of the southern mining surface rights area is approximately 95 ha. This area is<br />

situated within the Nhlenga River catchment which has a MAR of 5 198 000 m 3 a -1 . The<br />

contribution to the MAR of the Nhlenga River catchment generated y the southern mining<br />

surface rights area is 43 700 m 3 a -1 which equates to 0,84%. The actual disturbed area<br />

(area disturbed by mining) has a size of approximately 44 ha. A MAR of 20 300 m 3 a -1 will be<br />

generated from this area, which constitutes 0,39% of the MAR from the Nhlenga river<br />

catchment.<br />

Page 35

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

The northern mining area occupies a surface area of approximately 12 ha and is situated<br />

within the Komati River sub-catchment (F) which has a MAR of 3 956 000 m 3 a -1 . The<br />

disturbed area will generate a MAR of 5 520 m 3 a -1 which constitutes 0,14% of the subcatchment.<br />

Page 36

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

Figure 10: Sub catchments of Komati River.<br />

Page 37

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

Figure 11: Local catchments.<br />

Page 38

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

Normal dry weather flow.<br />

The Nhlenga, Mgobode, Mdzabi, Mbiteni and Mambane rivers are seasonal rivers and thus<br />

have no dry weather flow.<br />

The Komati River is a perennial river. Monthly flow volumes have been recorded by the<br />

Department of Water Affairs & Forestry during the period 1939 – 1997 at the Tonga. This<br />

data was used to determine the mean monthly flow of the Komati River downstream of the<br />

mining area and is indicated in Table 16.<br />

Table 16. Mean monthly flow volumes of the Komati River downstream of Nkomati<br />

Anthracite Mine.<br />

PRECIPITATION MEASURED FLOW VOLUME (10 6 M 3 )<br />

MONTH MMP (MM) MEAN MIN MAX<br />

January 104 103.47 5.29 440.73<br />

February 105 122.07 3.66 401.51<br />

March 77 105.68 1.08 380.87<br />

April 64 66.79 0.88 315.72<br />

May 22 42.68 0.06 331.94<br />

June 9 32.64 0.05 143.24<br />

July 8 30.48 0.00 222.83<br />

August 15 26.82 0.00 198.65<br />

September 33 30.69 0.00 542.57<br />

October 77 33.87 0.18 175.13<br />

November 122 64.68 0.58 388.48<br />

December 134 89.41 3.50 440.73<br />

Shaded area indicates dry weather flow.<br />

150<br />

100<br />

50<br />

0<br />

January<br />

February<br />

March<br />

April<br />

May<br />

June<br />

July<br />

August<br />

September<br />

October<br />

November<br />

December<br />

Figure 12: Comparison between mean monthly flow of the Komati River and MMP.<br />

MMP<br />

Mean Monthly Flow<br />

MMP in mm<br />

MMF in mil. cub. m.<br />

Page 39

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

From table 16 and Figure 12 it can be seen that the Komati River flows throughout the year.<br />

The driest period of the year occurs between May to September whilst the low flow conditions<br />

occur during May to October.<br />

Flood peaks and volumes.<br />

Data was obtained from DWAF on the peak flows of the Komati River. 660 recorded cases<br />

were obtained and statistically analysed to obtain the 1:20 1:50 and 1:100 year flood peaks as<br />

indicated in Table 17.<br />

Table 17: Flood peaks for the Komati River.<br />

RECURRENCE INTERVALS YEARS FLOW (CUMEC)<br />

1:20 180<br />

1:50 300<br />

1:100 420<br />

Flood Lines of the Komati River.<br />

Due to the close location of present and previous mining activities at Nkomati Anthracite Mine<br />

the 1:100 year flood lines of the Komati River need to be determined over the property.<br />

Four sections were surveyed over the Komati River at 1-meter height intervals. The sections<br />

extended for at least 150 meters either side of the Komati River.<br />

The 1:100 year flood event flow velocity, stream width and elevation through each section<br />

were calculated and are presented in Table 18 and graphically indicated on the survey<br />

sections (Figure 13).<br />

Table 18: 1:100 year flood event data for the portion of the Komati River that Flows<br />

through the Nkomati Anthracite Mine.<br />

Page 40<br />

SECTION FLOW VLOCITY (M.S -1 ) WIDTH OF STREAM (M) ELEVATION OF WATER LEVEL<br />

(MAMSL)<br />

A 1,49 74,5 236,2<br />

B 1,37 82,25 235,8<br />

C 1,25 82,75 234,9<br />

D 1,31 83,55 233,4<br />

River diversions.<br />

No river diversions will occur on the mine property.

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

Figure 13: Cross-section over Komati River: Floodline determination.<br />

Page 41

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

2.1.9.2 Surface water quality.<br />

Surface water quality of the Komati River.<br />

Surface water quality is currently monitored on a monthly basis at three localities (Table 19) in<br />

the Komati River. The latest results from the samples obtained are indicated in Table 20.<br />

Table 19. Monitoring localities in the Komati River.<br />

SAMPLE NUMBER LOCALITY<br />

NK 1 Komati River upstream of Nkomati Anthracite Mine<br />

NK 2 Komati River at bridge near Nkomati Anthracite Mine.<br />

NK 3 Komati River downstream of Nkomati Anthracite Mine.<br />

Table 20. Water analysis of the Komati River in the vicinity of Nkomati Anthracite Mine.<br />

SAMPLE NO: NK 1 NK 2 NK 3<br />

pH: 7.0 7.1 7.1 mS/m<br />

Electrical conductivity: 40.4 39.2 40.8 mg/l<br />

Total dissolved solids: 216 213 219 mg/l<br />

Nitrate: [N] 0.1 0.1 0.1 mg/l<br />

Total alkalinity: [CaCO3] 104 102 110 mg/l<br />

Chloride: [Cl] 25 18 17 mg/l<br />

Sulphate: [SO4] 8.3 9.1 8.5 mg/l<br />

Fluoride [F] 0.09 0.01 0.09 mg/l<br />

Calcium: [Ca] 12.1 12.7 12.4 mg/l<br />

Magnesium: [Mg] 14.2 14.6 14.7 mg/l<br />

Sodium: [Na] 40.9 40.2 41.1 mg/l<br />

Potassium: [K] 1.4 1.7 1.9 mg/l<br />

Iron: [Fe] 0.13 0.11 0.09 mg/l<br />

Manganese: [Mn] 0.01 0.01 0.01 mg/l<br />

Total Hardness: [CaCO3] 89 92 91 mg/l<br />

From the above it is evident that Nkomati Anthracite Mine does not adversely affect the water<br />

quality of the Komati River.<br />

2.1.9.3 Drainage density of area to be disturbed.<br />

The drainage area to be disturbed (including previously disturbed areas) was determined to<br />

be 0.6 km/km 2 .<br />

2.1.9.4 Surface water use.<br />

Surface water use in close proximity of the mine is for aquatic life, stock watering and<br />

irrigation. The local inhabitants residing on the mining area use the water for domestic<br />

purposes. Ground water is also used for domestic consumption.<br />

Page 42

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

2.1.9.5 Water Authority.<br />

Department of Water Affairs and Forestry.<br />

2.1.9.6 Wetlands.<br />

The area of land adjacent to a stream or river that is at least periodically, influenced by<br />

fluctuations of water level is the riparian zone. This zone is primarily defined by the<br />

geomorphology of the river valley, the nature of the valley substratum and the hydrological<br />

regime of the river, but is manifest in a distinct zone of vegetation that forms the riparian<br />

wetland.<br />

Thus a riparian wetland can be defined as:<br />

“ Riparian wetlands are open ended (exoreic) systems which occur adjacent to river and<br />

stream channels where plant species distribution and growth is determined by, at least<br />

intermittent, soil (root zone) saturation or inundation as a consequence of fluctuations in flow.”<br />

From the above definition and the biological survey conducted on the property it is obvious<br />

that the fringe Forrest along he banks of the Komati River constitutes a riparian wetland. The<br />

biological survey indicated a forest width of between 10 – 15 meters wide. This width is<br />

supported by the hydrological survey of the river and the1: 100-year flood line determination.<br />

Three major features separate riparian ecosystems from other wetland ecosystem types:<br />

They have a linear form as a consequence of their proximity to rivers and they form a<br />

boundary between the terrestrial and aquatic ecosystems<br />

Energy and materials from the surrounding landscape converge and pass through<br />

riparian ecosystems in greater amounts per unit area than with any other system.<br />

Riparian ecosystems are connected hydrologically to both upstream and downstream<br />

ecosystems, at least intermittently.<br />

The narrow spatial dimension of the riparian wetland on the property and the open endedness<br />

makes it extremely sensitive to landscape change.<br />

2.1.10 Groundwater<br />

Since mining activities can potentially impact on the groundwater, a description of the current<br />

groundwater conditions is required. The purpose of this section is, therefore to describe the<br />

current prevailing groundwater conditions. This will serve as a reference baseline for<br />

quantifying potential mining impacts on the existing groundwater regime. Geo Pollution<br />

Technologies (Pty.) Ltd. (GPT) was appointed to conduct a geohydrological study of the<br />

proposed Nkomati Anthracite Mine extension project area of the Nkomati Anthracite Mine.<br />

The report is attached as Appendix 2.<br />

Local Geohydrology<br />

At least four aquifer types may be inferred from knowledge of the geology of the area:<br />

• A shallow aquifer formed in the weathered zone, perched on the fresh bedrock.<br />

• A deeper aquifer formed by fracturing of the Karoo sediments.<br />

• Aquifers associated with the contact zones of the intrusives.<br />

• Aquifers formed within the more permeable coal seams and sandstone layers.<br />

Page 43

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

Shallow perched aquifer<br />

The near surface weathered zone varies across the area. It can be expected that this<br />

weathered zone will be shallower on higher lying areas and areas with steeper slopes<br />

and deeper in lower lying areas.<br />

From exploration boreholes drilled in the area the average thickness of the weathered<br />

zone can be estimated at 7m below ground level. This unit is comprised of<br />

transported colluvium and in-situ weathered sediments. Groundwater flow patterns<br />

usually follow the topography, often coming very close to surface in topographic lows,<br />

sometimes even forming natural springs as found in the surrounding area.<br />

Experience of Karoo geohydrology indicates that recharge to the perched<br />

groundwater aquifer is relatively high, up to 3% of the Mean Annual Precipitation<br />

(MAP).<br />

Aquifers associated with coal seams<br />

There are two coal seams present in the area name the No3 and No2 Lower Seam.<br />

The position of the bottom of the coal seams below ground level varies between 35<br />

and 80 meters below surface for seam 3 and between 40 and 105 meters below<br />

surface for the no2 lower seam. This forms a layered sequence within the hard rock<br />

sedimentary units. The margins of coal seams or plastic partings within coal seams<br />

are often associated with groundwater. The coal itself tends to act as an aquitard<br />

allowing the flow of groundwater at the margins.<br />

Fractured Karoo rock aquifers<br />

Dolerite intrusions in the form of dykes and sills are common in the Karoo<br />

Supergroup. These intrusions can serve both as aquifers and aquifuges. Thick,<br />

unbroken dykes inhibit the flow of water, while the baked and cracked contact zones<br />

can be highly conductive. These conductive zones effectively interconnect the strata<br />

of the Ecca sediments both vertically and horizontally into a single, but highly<br />

heterogeneous and an-isotropic unit on the scale of mining. These structures thus<br />

tend to dominate the flow of groundwater. Unfortunately, their location and properties<br />

are rather unpredictable. Their influence on the flow of groundwater is thus<br />

incorporated by using higher than usual flow parameters for the sedimentary rocks of<br />

the aquifer.<br />

Typical primary permeability of the sandstone is 1 x 10 -3 m/d, increasing up to 1 x 10 -2<br />

m/s in the cleaner, coarser-grained sandstones. However, for the Karoo rocks, the<br />

secondary permeability is generally believed to have greater significance in the<br />

hydrological character of these rocks 1 . Typical effective conductivity values for Karoo<br />

fractured aquifers are between 1 x 10 -2 m/d and 1 x 10 2 m/d. A rule-of-thumb is that<br />

the vertical permeability is generally in the order of 10% of the horizontal permeability.<br />

Unsaturated zone<br />

Although a detailed characterization of the unsaturated zone is beyond the scope of<br />

this study, a brief description thereof is supplied.<br />

Page 44

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

Based on measurements taken during the hydrocensus, it was determined that the<br />

unsaturated zone varies between 2 and 20 meters thick. The reason for the great<br />

variations in water levels can be ascribed to large topographical differences between<br />

high and low lying areas.<br />

The unsaturated zone is represented graphically in Figure 14.<br />

2.1.10.1 Depth of groundwater table<br />

The borehole parameters of the hydrocensus boreholes are summarized in Table 21.<br />

Borehole X Y<br />

SWL<br />

(mbgl)<br />

SWL<br />

(mamsl)<br />

Elev<br />

(mamsl)<br />

BH1 31.8632 -25.7259 4.99 266.01 271<br />

BH3 31.79107 -25.9095 17 267 284<br />

BH5 31.7983 -25.7729 5.6 244.4 250<br />

BH6 31.7983 -25.7729 5.5 244.5 250<br />

BH7 31.81108 -25.7509 2.41 246.59 249<br />

Table 21: Borehole information.<br />

From the data it is evident that the groundwater depth varies across the site, mainly due<br />

to topography and heterogeneity of the secondary structures in the bedrock. This<br />

heterogeneity of the fractured rock aquifer on such a small scale can be ascribed to the<br />

presence of structures such as dykes, fractures, fissures, joints and faults creating<br />

secondary pathways for flow. Groundwater levels varying between 2m and 20m below<br />

ground level were measured during this survey. At the site itself, groundwater levels are<br />

between 5 and 10 metres below ground level.<br />

There is a good correlation between static water level and topography as illustrated in<br />

Figure 15. Using these values it is possible to extrapolate the average depth to the<br />

groundwater level using Bayes Extrapolation technique.<br />

A map of the static groundwater level of the area (Figure 16) was constructed using<br />

these extrapolated groundwater levels. These calculated groundwater levels were also<br />

used to calculate the thickness of the unsaturated zone (= depth from the surface to the<br />

groundwater level) by subtracting groundwater levels from the topography. Contours of<br />

the unsaturated zone thickness are depicted in Figure 14.<br />

Page 45

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

Figure 14: Unsaturated zone.<br />

Page 46

Static Water Level (mamsl)<br />

<strong>EIA</strong>/<strong>EMP</strong> Report: Nkomati Anthracite (Pty) Limited<br />

275<br />

270<br />

265<br />

260<br />

255<br />

250<br />

245<br />

240<br />

245 250 255 260 265 270 275 280 285 290<br />

Elevation (mamsl)<br />